In a car, the oil pump serves to create pressure inside the oil line. Pressure lubrication is vital to the proper operation of certain engine parts. In such engines that use a dry sump, the pump is also used to pump oil from the crankcase to the oil tank. There is one important part in this whole system, without which the pump will not be able to function normally - the oil pressure reducing valve.

It is necessary to ensure that the pressure leaving the pump is maintained at the same level throughout the entire period of engine operation. The oil pump can be driven from a camshaft pulley or a crankshaft pulley - this depends on the specific design of the machine.

Oil pump structure: 1- intake gears; 2- valve; 3-lock spring.

Features of valve operation

In general, having delved into the principle of operation of this mechanism, you can find that it is quite simple. So, the main element that reacts to what is happening in the oil line is a special thrust bolt. This bolt, under the influence of the external environment, presses on the spring, which already presses or releases the valve in relation to the cross-section of the passage.

If the oil pressure in the system begins to increase and, at the same time, exceeds the permissible maximum pressure level, then the oil will overcome the resistance of the regulator (simply springs) and squeeze it into the seat. In this way, the pressure indicator will stabilize, the spring will return to its normal position, and the car engine will be able to continue to function normally. Technically, the valve structure is as follows:

- A relatively small body, inside of which a special system of channels is machined. Oil moves through them.

- The spring, rod and body of the regulator lower and increase oil pressure.

https://www.youtube.com/watch?v=DT2aupjaztg

It should definitely be said about how simple the design of this valve is - all functions are performed by elementary actions. Due to the elementary nature of the components, a high level of reliability is ensured.

It should also be noted that the pressure regulator can technically be designed in two versions. The first involves placing the housing inside the pump, without separating the two devices. The second option is that the valve has its own separate body and is located somewhere along the oil line. Considering the conditions under which the valve has to operate, it is not surprising that breakdowns also occur periodically. This point should also be given attention.

The oil pump pressure reducing valve, as an element of any hydraulic system, is responsible for normalizing the pressure created by the oil pump. That's all its function. It would seem like such a small thing, but it affects the operation of all engine systems. Let's take a quick look at the lubrication system to understand the purpose of the valve in the operation of the system.

The lubrication system of any modern automobile engine is a combined type. This means that only some of the parts are lubricated by natural drainage or the drip method. The main part of the rubbing surfaces are lubricated under pressure. The lubricant must form an anti-friction film and reduce the coefficient of friction of parts.

The cyclic principle of operation of the entire engine lubrication system involves constant circulation of oil from the crankcase through the filter. The oil pump ensures the movement of lubricant along the circuit. After this, the oil goes under pressure to the main and connecting rod journals of the crankshaft, and under pressure it passes through the oil line to the camshaft journals.

Video tutorial on how to remove a coked pressure relief valve

Through a channel inside the connecting rod, lubricant is cyclically supplied to the piston pin. All other parts are lubricated by flowing or splashing oil, which is converted into an oil film by the rotating engine parts. After this, the oil flows into the crankcase, where it is again sucked into the oil pump through the oil intake.

High-speed and sports engines have a dry sump lubrication system. Such a system does not depend on the amount of oil in the crankcase, because it is located in a separate oil tank, where it is immediately pumped after the lubrication cycle. The dry lubrication system does not depend on the position and level of the oil mass in the crankcase.

Stable oil pressure and temperature are the main factors for optimal engine performance

A prerequisite for normal engine operation is the constant maintenance of stable oil pressure and temperature. If overheated, the lubricant may lose viscosity and lose the basic physical characteristics necessary for the formation of an oil film, which is why many engines use a lubricant cooling system with an oil cooler and a temperature sensor. The oil radiator can be either liquid-cooled or air-cooled.

Maintaining a minimum pressure in the system is important to fully supply the entire line with oil, regardless of the degree of distance from the oil pump. Also for supplying lubricant through narrow and long channels of the cylinder block, cylinder head, crankshaft and camshaft and connecting rods. The pressure is controlled by a sensor that is installed in the lubrication system and transmits the pressure level to the dashboard, and also transmits pressure data to the engine control unit. If the critical pressure is insufficient, the control unit turns off the engine to avoid oil starvation.

Instructions for verification

So:

- First, check the serviceability of the electrical circuit going from the sensor to the instrument panel

. Throw the wire going from the sensor to the engine to ground, the light will go out if the circuit is working properly. - The second reason could be the oil filter. Such a breakdown is determined by unscrewing the oil pressure sensor. It should be moistened with oil; a dry sensor means that the filter is clogged or its valve is stuck.

- When it does not work, open the pan and check the oil receiver itself and the condition of its rubber sealing ring.

- After these checks, one reason remains - a breakdown of the unit itself.

For your information:

- The engine of the VAZ 2110 model is equipped with a combined lubrication system. On machines of this model there is a gear oil pump, which is located at the front end of the cylinder block.

- Special gears with trochoidal internal gearing reduce mechanical losses during rotation.

- The oil pump itself is equipped with a fully in-line, non-separable filter. With bypass and anti-drainage valves. This device ensures good oil circulation and lubrication through all components of the internal combustion engine (ICE).

- It works by rotating the crankshaft. The connection method to the crankshaft is direct, which is typical for all VAZ cars with front-wheel drive.

- On all-wheel drive and classic models, the system is supplemented with special transmission parts: a timing chain, an intermediate shaft, and a set of gears that transmit torque from the crankshaft.

- The service life of this pump is from 120 thousand km, it works properly when the engine has already undergone a major overhaul. However, during operation, breakdowns are not excluded.

If replacement is still required, it is better for you to choose the VAZ 2110 oil pump from among reliable manufacturers.

Operating procedure

So:

- Disconnect the negative cable from the battery terminal.

- Drain the oil from the engine (through the drain plug in the oil pan).

- We take out the camshaft drive belt.

- Now remove the oil sump.

- On engines with a fuel injection system, disconnect the block with wiring from the sensor that counts crankshaft revolutions.

- Using two screwdrivers, remove the pulley from the crankshaft.

Equipment classification

The oil pump and pressure maintenance valve have a certain classification according to their design. The pumps are:

- Adjustable;

- Unregulated.

In the adjustable version, constant pressure is maintained by changing the position of one of the pump parts. But the device of the unregulated version could not do without the use of a pressure reducing valve. Each of the options discussed above is divided according to the structure of the mechanism into gear and rotary.

In turn, oil pressure regulators are of hydraulic and pneumatic types, regardless of the type, both of them are designed to maintain pressure at a given level. Based on the power source, valves are of the following types:

- Reduction, controlled by a pneumatic drive;

- Electrically driven;

- Autonomous, not requiring a power source.

Now it’s time to consider the purpose and operating principle of the pressure reducing valve.

As already mentioned, the oil valve is necessary to maintain the pressure at a certain level. After the engine has started, the task of the pressure reducing valve is to stabilize the pressure and maintain the level throughout the entire period of engine operation.

During operation, the regulator controls the speed of oil movement: increases or decreases it, depending on what is required at that particular moment. This is accomplished by fully opening the valve and lowering it, whereby the pressure decreases, or by partially opening it, where it begins to increase. Each of these actions is performed at the moment when it is needed; thanks to its device, the regulator determines this independently.

How to choose a quality oil filter

The most difficult and serious issue in using an oil filter is its choice.

Among the most popular filter models, we can mention the Swiss Finwhale LF101 filters, used on VAZ, GAZ, KIA and Hyndai, Renault and Chevrolet cars, suitable for all the most popular cars in Russia. Recommended service life is 15 thousand km.

Among the products of European manufacturers, one can note the good quality of MAHLE OC 235 from the Austrian MAHL GRUPPE. The filter element material is designed to work with synthetics and semi-synthetics. The price, like the first one, does not exceed 220 rubles.

Among domestic products, we note the products of Samara manufacturers, designed for VAZ cars:

- oil filter 2112-VAZ Salut priced at 150 rubles, interesting for its high level of production;

- oil filter basalt BM 1208, in which the anti-drainage and bypass valves are located in parallel, the cost of the model is no more than 140 rubles.

For Japanese cars, we can recommend reliable and high-quality filters - products from German manufacturers MANN W914/2 and Japanese NITTO 4TP-121.

The main question in choosing an oil filter is not to buy a fake. The more popular the product, the more often and more actively it is counterfeited. It is difficult to identify a fake, but if you have knowledge about the characteristics of individual brands of oil filters or the specifics of companies' production, it is a very real thing. The quality of printing on the oil filter housing, the presence of micro burrs, and poor quality packaging give out counterfeit products.

Very often, information about the manufacturer contains contradictory information, or completely illiterate spelling of words, or incorrect information about filter models. One interesting way to identify counterfeits is to determine the weight of a new device. According to experts, a fake is always lighter than the original part, and the difference can reach 15-20%.

In most engines, the oil filter is located quite inconveniently from a maintenance point of view, and you have to work from the inspection hole when changing the device. To be more sure, it is better to clarify the question of where the oil filter is located in the car’s operating manual.

Often the filter housing gets stuck to the mounting flange, and it takes a lot of effort to unscrew the round housing. To unscrew, you can use a homemade or branded oil filter wrench.

Replacing the device is quite simple. The manual usually advises filling the new filter ¾ full with engine oil and screwing it onto the mounting flange by hand, without using wrenches or tools. The twisting force is quite easy to check visually. From the moment the oil filter housing gasket touches the flange, screw it another 4/5 turns. When installing the device, pay attention to the quality and condition of the gasket itself; the tightness of the housing depends on this.

Common valve failures

The sealing washer must be replaced with a new one after each disassembly of the mechanism.

So, there are a number of the most common oil pressure valve failures. They also manifest themselves in different ways, so let’s devote a little time to this moment. The first common problem is the inability of the regulator to maintain the parameters required by the engine. This happens due to failure of the mechanical parts of the device.

As a rule, this happens due to the breakdown of a weak element of the device - the pressing spring. If the spring has not been replaced over many thousands of kilometers traveled, then over time it becomes stretched and no longer holds the valve. As a result, the opening of the passage in the housing may occur when it is not necessary. This will lead to a lack of lubrication in places where it is urgently needed.

Scouring on the surface of the plunger is one of the possible causes of malfunction.

The second common problem is improper installation of the pressure regulator or lack of maintenance. Here the problem is expressed by the valve not opening when the pressure exceeds the permissible level. This happens due to clogging of the flow area or wedging of its individual elements. The result is a lack of normal lubrication, which will lead to failure of individual engine components and assemblies.

As a rule, the valve becomes clogged due to the fact that the engine oil is not changed in a timely manner. Solving such a problem is quite difficult; more often it comes to completely replacing the valve, since it is quite difficult to find individual small components. It is not difficult to prevent the problem - wash the engine before each oil change and replace the latter according to the manufacturer's regulations.

Useful tips

Finally, here are some useful tips that may help you avoid problems with the oil pump pressure reducing valve or make it possible to identify its malfunction in time:

- Fill the engine only with high-quality motor oil of the appropriate type and viscosity grade. Lubrication requirements can be found in the vehicle manufacturer's recommendations.

- Never mix different brands of oils, even if they are of the same class.

- Change the oil and oil filter in a timely manner. The regulations for this procedure are also indicated in the car owner's manual.

- Do not allow dirt, moisture, or process fluids to enter the lubrication system.

- Monitor oil pressure. When the corresponding warning light on the device turns on, do not hesitate to go for diagnostics.

- Pay attention to the operating temperature of the engine. Overheating can cause coolant to enter the lubrication system.

- If you decide to replace or adjust the oil pump pressure relief valve without the necessary skills and tools, it is better to use the services of specialists.

Pressure reducing valve device

Often the pressure reducing valve is installed in the bypass channel of the oil pump.

The pressure reducing valve in a modern engine looks like an infusorian slipper compared to other complex devices. The oil pump valve is extremely simple. In VAZ 2110, 2109, 2112 engines, in the ZMZ 406 engine it is a ball on which a spring is constantly acting. The force of the spring pressure on the valve can be adjusted by a stop screw in the oil pump housing. The relief valve in some engines has a separate housing, but in most cases it is built into the oil pump bypass passage.

The valve is located between the suction chamber and the compression chamber. As soon as the pressure exceeds the norm, the oil puts more pressure on the valve than usual, it opens and releases the lubricant back to the pump inlet or into the crankcase. The pressure is adjusted using a stop screw located in the oil pump housing.

Removal

- First of all, disconnect the “-“ (minus) wire from the battery, as with any other repair.

- Drain the oil (through the plug on the oil pan) from the engine

- We take out the camshaft drive belt

Attention: After removing the timing belt (timing belt), do not turn the crankshaft or camshaft, otherwise the pistons will bend the valves, and you will have more repair work and the PRICE will increase.

- We take out the crankshaft toothed pulley, then its key, using two flat-head screwdrivers.

- Now remove the oil pan

- Unscrew the oil intake fastener

Unscrew the oil intake fasteners and remove it

- Using a 10mm socket with an extension and a ratchet, unscrew the six bolts securing the oil pump to the cylinder block.

Unscrew the mounting bolts using a ratchet socket

- Remove the unit from the engine.

Note: There is a gasket between the oil pump and the cylinder block.

- Be sure to wash the new oil pump with gasoline to wash off the preservation lubricant.

- We fill it with oil before installation so that it does not rotate dry when starting.

- It is also important to rotate the drive gear to install the pump on the crankshaft: so that the protrusions on the gear coincide with the groove on the crankshaft

- Lubricate the lip of the oil seal before putting the pump back

- Carefully tuck the seal lip onto the shaft journal using a wooden stick.

- When tightening bolts, be careful and careful not to strip the threads.

- Install the remaining parts in reverse order.

Disassembly

- We clamp the pump body in a vice, placing soft pads on the jaws and, using a 8-mm hexagon, unscrew the bypass valve plug.

Unscrew the valve plug

- We remove the piston and spring of the bypass valve.

- We check the seat of the bypass valve - the presence of burrs and scratches is unacceptable

- Using a 5mm hexagon, unscrew the six bolts securing the pump housing to its cover.

Unscrew the bolts securing the housing to the cover

- We take out the pump housing.

- We take out its drive gear from the cover.

- Behind it, we remove the driven gear.

- We wash all pump parts with gasoline, diesel fuel or kerosene, wipe the gears dry, and lubricate them with clean oil before installing them back.

- We carefully inspect the body for cracks, chips, and severe burrs, and if found, replace it.

Note: We check that the driven gear seat located in the pump housing does not exceed 75.10 millimeters in diameter. And the permissible minimum thickness of the partition between the driven and driving gears was no less than 3.4 millimeters. The permissible axial play at the drive gear should not exceed 0.12 millimeters, and at the driven gear - 0.15 millimeters

Permissible seat diameter and permissible partition thickness

- The same goes for pump gears; scuffing, chips, and cracks are not acceptable.

- We check the condition of the pressure reducing valve spring; if it is broken, cracked, or very short (compressed and does not match the dimensions), we replace it.

Conclusion

The injection pump pressure reducing valve is one of several valves in diesel fuel systems, which is responsible for the normal operation of the entire power unit. If it fails, the car owner is immediately faced with several problems that will make operating the vehicle very difficult.

Despite their rather simple design, such valves do not very rarely fail. Often the problem can be diagnosed by the car owner himself, but we recommend seeking qualified help from a diesel systems specialist. If the problems are related specifically to the pressure reducing valve, then you will not need to allocate a significant budget to purchase and install the spare part.

Repair and malfunction of pressure reducing valve

With such a simple device, it is quite obvious that the valve can have only two malfunctions - it either does not open at elevated pressure, or is not tightly locked, which leads to a decrease in pressure in the lubrication system. Both options are dangerous. In the first case, valve malfunctions are fraught with crushed oil seals, gaskets and seals, and torn hoses. All this leads to oil leakage and, for obvious reasons, to failure of the crank mechanism at a minimum.

To avoid this trouble, you should look at the oil pressure scale from time to time. High pressure is good, but when it gets too good, you need to disassemble the pressure relief valve and make sure it is working. Replacing the spring or cleaning the valve seat will help eliminate the problem.

A clogged valve can cause a lack of optimal pressure in the oil pump.

The second extreme is when the pressure relief valve does not maintain the minimum pressure. This situation also does not lead to anything good. As a rule, this is due to a clogged valve. Debris or slag gets into the valve seating plane and prevents it from blocking the drain channel. The valve is jammed, as a result the pressure in the system drops, and how this ends is known.

Monitoring instrument readings is important. LED lighting of instrument panels is great, but it wouldn’t hurt to buy and install an additional pressure gauge for the lubrication system, preferably a mechanical one, as part of tuning the device. It is more expensive and more complicated, but it more objectively reflects the condition of the lubrication system in the engine.

Replacing the oil pump on a VAZ-2112 16 valves photo, video

If a red indicator lights up on your instrument panel, signaling a lack of oil pressure in the system, then do not rush to run to the store and buy a new oil pump.

The video discusses the most basic reasons why oil pressure may drop in a VAZ engine:

Replacing the oil pump

There is nothing difficult about replacing an oil pump. We drive the car into the pit, prepare the tools and get to work.

- Disconnect the battery.

Removing the battery terminal for repair - Drain the oil into the prepared container (stopper on the tray).

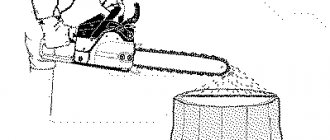

The plug is unscrewed with a key - We jack up the car, place it on a good stand (a stump will do just fine) and remove the right wheel.

- Remove the timing belt.

Timing belt without casing. - Remove the crankshaft pulley and key (you will need an assistant to clamp the flywheel with a screwdriver).

- Remove the crankcase cover.

Removing the pallet - We remove the oil intake itself.

- We clean the oil receiver grid (with solvent or kerosene).

- And directly remove the oil pump itself (6 bolts on the cylinder block).

The location of the 6 bolts that secure the oil pump is marked with arrows

Reassemble the oil pump in reverse order.

The pan and oil pump gaskets must be replaced with new ones. Also, the new oil pump should be washed out of preservative grease and filled with oil (to prevent it from running dry during the first start after repair).

Why is an oil pump needed?

Pump appearance

The oil pump in the engine is designed to build up pressure in the oil system, for the necessary lubricating effect of all rubbing parts of the internal combustion engine. If the pressure in the system is insufficient, the lubrication effect will be ineffective, which in turn will lead to the engine being unsuitable for operation. In this case, the low oil pressure warning light on the instrument panel should light up. Therefore, you should not delay repairing the oil pump.

You are left with two options. Take the car to a service station and lose a lot of time and money, or change the oil pump yourself.

Pump diagnostics

Oil pump removed for diagnostics. Symptoms: oil leak.

First, you need to make sure that the oil pressure sensor itself is working properly - check whether the sensor itself is dry or oily.

Secondly, you need to check whether power is supplied to it correctly or whether a wire is broken somewhere. And only after these procedures, if the light does not go out, will you have to change the oil pump.

Why might it break prematurely?

An oil leak from the oil pump can lead to expensive engine repairs.

Replacement of the oil pump can also be caused by poor quality oil, which will lead to rapid clogging of the oil receiver grid and subsequent lack of oil pressure in the system. It is not uncommon for an oil pump to become wet and oil to leak from underneath it. In these cases, you can get by by replacing the gasket and cleaning the oil receiver mesh.

In general, the oil pump does not bring much trouble to VAZ-2112 owners. It is designed for 120 thousand kilometers. When purchasing a new pump and spare parts for its repair, choose original spare parts. The official manufacturer of oil pumps for the VAZ-2112 is the Tolyatti Plant (TZA).