Without a working lubrication system, no car will last long. Its most important element is the oil pump, which provides full pressure in the system. However, it also does not last forever, and in case of failure it must be replaced. You can solve the problem even without contacting the service, but you will have to spend a lot of time. Today we’ll talk about why the oil pump fails on a Priora and how to change it if it fails.

How to replace the oil pump on a Lada Priora

Over time, every motorist is faced with the fact that a light on the instrument panel lights up for insufficient oil pressure. This signal tells us that the pressure in the engine lubrication system has decreased. The most common cause of this is a broken oil pump. That is why the problem cannot be ignored, and the oil pump of the Priora VAZ 2170 must be replaced as soon as possible. The majority of new cars are equipped with oil pressure lights on the instrument panel. Loss of oil pressure is a serious problem as it is necessary to supply oil to engine parts to prevent wear.

Lada Priora Hatchback 2009, 98 l. With. - spare parts

Cars for sale

Lada Priora, 2016

Lada Priora, 2016

Lada Priora, 2012

Lada Priora, 2007

Comments 32

Mannol is “tested”, God forbid you pour such oil into the engine, Mannol is produced in Germany? Then I'm a millionaire. The proven Shell is better.

Tell me, how did you find out that the problem was in the distributors? I bought a car with a mileage of 100 tons, with a converted ShPG at 124, and at first I didn’t notice the problem with oil pressure, my light doesn’t come on at idle, but with small drawdowns, it blinks actively, the mechanical pressure gauge shows 0.4-0.5 b when hot, this is very not enough (I’m wondering where to start, how could I have driven 40 thousand with such pressure, the hydraulics are silent. I’ll say right away, changing the oil, filter, sensor did not lead to anything. So I’m thinking maybe this is just my case? Because the old owner mentioned that there were “evil” shafts... And it is not known what was stuck in when the drain was returned.

That's exactly how it was discovered - at random. First the sensor, then I tried different oils (with a filter of course), then the oil pump, and then we got to the camshafts.

As I understand it, there was a problem with the distributors? Is everything right? I've encountered the same problem and am looking for a solution with minimal cost...

That's right, in the camshafts. I’ve only gotten around to them so far, but I haven’t changed them.

Sorry, I didn’t know all the intricacies of your business! It’s just that the reason for this “illness” was the pressure sensor and I changed it. Good luck in solving the problem!

Based on your symptoms, it sounds like the oil pressure sensor needs to be replaced! Let them inspect it at the service station - if it’s all covered in oil, then it’s 100%!

I understand that you sincerely want to help, but the fact is that this problem was solved more than three years ago and replacing the oil pressure sensor did not help, the problem was the wear of the camshafts. And then go to the service station to unscrew the sensor, when this can be done just in the yard. In any case, thanks for participating

Source

Engine oil pressure. What should it be? Let's analyze the 16-valve engine from the VAZ 2112

Nowadays, fewer and fewer cars are equipped with an engine oil pressure sensor, if you look at budget foreign cars - I don’t even remember which ones have it. However, now there are enough cars of previous generations on the market, but they had such a sensor. For example, on some VAZ, UAZ, VOLGA, etc. Many people ask the question - what oil pressure should be in the engine, that is, what is the normal value and what is not? It is not always possible to find information specifically about your model, so this article will be useful to everyone...

Why do you need oil at all?

I often hear that oil is the lifeblood of the engine. This is not entirely true, of course, the comparison is very rough, but still, the engine will not function without oil (or it will, but not for a very long time).

Modern motor oils lubricate and protect all rubbing parts, and these are pistons (with their rings), shafts, bearings, etc. Let's just say that good oil extends the life of the engine by many thousands of kilometers.

BUT oil must flow through the system, just like blood itself through human vessels, if the oil is simply poured in a pan and does not go to the rubbing parts - IT IS USELESS!

What builds up oil pressure in the system?

Everything is simple here - there is a special oil pump that takes oil from the engine sump and pumps it through the system. It is usually installed in the engine sump and driven by special gears that the engine turns during operation.

Oil through many channels begins to be supplied to the right places under pressure, as I already wrote, this is the crankshaft and its bearings, the camshaft and its “bed”, pistons, and much more.

It is the pump that is responsible for the pressure; if the pump stops, the pressure indicator will drop to zero. THIS CANNOT BE ALLOWED! Because the engine will not be lubricated at all, which will lead to instant breakdown, especially at high speeds.

BUT often the oil pump does not stop, but simply begins to pump worse, this indicates its wear, which is why you need to know the oil pressure in the engine! To respond in time to the nearest oil pump failure.

Alarm indication

Of course, now in almost all cars there is an emergency indication for a complete lack of pressure, this is known to us all - a “burning oil can”. If it does not go out for some time after starting, for example 10 - 20 seconds is one thing, it is almost always the fault of the oil filter. But if the lamp is constantly on, then this is already an alarm bell. Perhaps the oil pressure sensor has simply failed, or perhaps the oil pump has failed.

In any case, the emergency indication is very important, and I do not advise you to joke with it; nevertheless, this is fraught with a major overhaul of the engine.

Remember this rule, if the lamp comes on, then turn off the car and preferably immediately to a service station, either a tow truck, or in tow.

How to check oil pressure?

The actual check is carried out using a special device - a pressure gauge. It is also worth noting that you need to warm up the engine to operating temperature, usually 90 degrees Celsius.

If you measure with a cold engine, especially in winter, the pressure can jump to high values, from 0.5 BAR or even higher, but measuring with a cold engine is WRONG!

In order to check the pressure, you need to find the emergency sensor, which is responsible for the indication on the dashboard. It is worth noting that it is not always located nearby and it is convenient to unscrew it. We unscrew it, and in its place we attach the test output connected to the pressure gauge.

The check can then be divided into two options:

- AT “idle” it is usually from 900 to 1200 rpm.

- Then at “higher” speeds, usually 4000 - 5000 engine speeds.

It is also worth noting that if you unscrew the emergency sensor, the “oil can” will light up on your instrument panel, this is normal.

Now a short video showing how measurements are taken.

What value should it be?

To begin with, it is worth noting that pressure is measured in bars (BAR), because we are measuring liquid. It’s unlikely that anyone will tell you the exact values now, because the structures of the engines are different, but there is a certain normal interval.

AT idle speed it is 2 BAR (or 0.2 MPa), for most cars

At 4000 - 5000 rpm - this is 4.5 - 6.5 BAR (0.45 - 0.65 MPa), also for most brands

If we take our VAZ 2112 16 valve version, then the pressure at idle is slightly higher, about 1.5 - 2.5 BAR. But at 4000 - 5000 rpm 0.4 - 0.6 BAR.

Actually, I’ll end here, I think the information was useful, read our AUTOBLOG.

Malfunctions and replacement of the oil pump Lada Priora

Over time, every motorist is faced with the fact that a light on the instrument panel lights up for insufficient oil pressure. This signal tells us that the pressure in the engine lubrication system has decreased. The most common cause of this is a broken oil pump. That is why the problem cannot be ignored, and the oil pump of the Priora VAZ 2170 must be replaced as soon as possible.

The majority of new cars are equipped with oil pressure lights on the instrument panel. Loss of oil pressure is a serious problem as it is necessary to supply oil to engine parts to prevent wear.

Malfunctions in the operation of the pressure reducing valve

The structure of the pressure reducing valve is quite simple, which ensures its reliability and reduces the likelihood of breakdown. However, sometimes this still happens. Most often this is due to wear and tear of the mechanism, so do not forget to regularly diagnose all components of the car, as well as promptly replace outdated parts.

There are two main types of mechanism failure.

- The valve creates insufficient pressure. Usually the cause of this problem lies in the spring. With prolonged use, it becomes less elastic and stretches. As a result, the valve remains slightly open all the time. Due to this, the pressure decreases, and the oil does not reach some engine components. Sometimes it happens that unprofessional craftsmen install a spring with insufficient elasticity during repairs. This has the same effect.

- Excessive pressure builds up in the valve. As a rule, the cause of this breakdown is the entry of debris into the mechanism or the use of old viscous oil.

How to determine that the pressure relief valve is broken?

It is impossible to determine at first glance that the valve is broken. It is necessary to carefully inspect other elements of the system and exclude the possibility of damage to other parts of the oil pump. In order to understand that there are malfunctions in it, you should look at the dashboard. Most car models have a sensor located there that indicates problems in the system. It is a warning light with a pictogram that lights up at high speeds.

If this happens, you should stop the car immediately, as further movement may lead to permanent engine damage. Turn it off and get out of the car. Next, you will need to take the following steps.

- Wear protective gloves. At the moment, the engine compartment of the car is hot, so you can easily get burned.

- There is no point in checking the oil level if you have just stopped. It will take time before it drains into the crankcase. At this time, you need to inspect the engine: look for fresh oil leaks or damage to the crankcase.

- If the problem is a broken crankcase, you will need to seal it. This can be done using available materials: an ordinary rag, a piece of rubber and even tape.

- Inspect the oil filter. Damage to its gasket can also cause a breakdown.

- If the above items are in order, you should check the oil level. This is done with a special probe with o and “maximum”. Ideally, the oil level should be between them. If there is a lack of lubricant, simply add it.

All further actions are carried out on the valve removed from the pumping system. Examine it carefully. Often the cause of breakdown is clogging of the mechanism. This usually happens to drivers who are too lazy to change the oil. Dirt accumulates on the surface of the valve or spring, which prevents normal operation. If you have recently carried out a major overhaul of your car, then there is a risk that the valve was not properly washed and there are particles of chips and other debris left in it.

There is an unusual way to check the functionality of this element. Take a small piece of cotton (or other breathable) fabric and place it on the fitting that is parallel to the lid. Now you need to take a sharp breath through the material. If you feel strong resistance, it means that the valve is working as it should: it blocks the air flow and passes it through a special hole. A working mechanism should not be easily blown through.

Table: diagnosis of low pressure in the oil pump, causes and remedy

| Guide to diagnosing hypotension | ||

| Malfunction | Cause | Remedy |

|

|

|

| Low oil pressure throughout the entire engine speed range | There is too little oil in the engine. The oil intake screen is dirty, the oil intake tube is broken | Add oil to the engine. Remove the oil sump, clean the mesh, if necessary, replace the tube. |

| Worn oil pump | Remove, check, replace if necessary | |

| Engine bearing wear | Repair the engine |

Signs of a faulty oil pump

There are several typical symptoms of a faulty oil pump. These include:

- Reduced engine oil pressure. This will be indicated by the oil can light on the dashboard.

- Increasing engine oil pressure. Engine oil is squeezed out of various seals and joints in the system. For example, oil seals, gaskets, oil filter connection points. In more rare cases, due to excess pressure in the oil system, the car refuses to start at all. This happens because the hydraulic compensators stop performing their functions, and accordingly, the valves function poorly.

- Increased oil consumption. Occurs due to leakage or waste.

It is necessary to understand that some of them may indicate failure of other elements of the oil system. Therefore, it is advisable to carry out the check in a comprehensive manner.

Screwing in the drain plug

Next, screw the drain plug into the pan. There is an O-ring installed on the plug. You need to make sure it is in place. Sometimes it falls. Without it, the plug will leak oil. It is advisable to lubricate the threads of the plug with a thin layer of sealant. During operation, the tray heats up. And oil that gets on the threads forms carbon deposits. It burns so badly that it is very difficult to unscrew the plug at the next oil change. The sealant will prevent the formation of carbon deposits on the threads. And the stopper is secured by an O-ring. It contracts under pressure when twisted. And prevents the cork from unwinding. In addition, it creates a tight connection.

Should you contact a specialist or make a replacement yourself?

Naturally, it is best to turn to professionals! If you have not encountered this breakdown before, then intervention on your own can cause even more serious consequences, as a result of which you will lose a lot of time and additional funds.

The Priora VAZ 2170 oil pump is not an expensive part, but its removal and installation is not a simple task. It is also necessary to carry out diagnostics, because Along with the pump, you often have to change the filter and, of course, the engine oil itself.

Causes of oil pump failure

The reason why the oil pump has failed can be determined by diagnostics. There are at least 8 main oil pump faults. These include:

- Clogged oil pickup strainer. It is located at the inlet of the pump, and its function is to coarsely filter the engine oil. Like the system’s oil filter, it gradually becomes clogged with small debris and slag (often such slag is formed as a result of flushing the engine with various means).

- Malfunction of the oil pump pressure reducing valve. Usually the piston and spring included in its design fail.

- Wear of the inner surface of the pump housing, the so-called “mirror”. Occurs for natural reasons during engine operation.

- Wear of the working surfaces (blades, splines, axles) of the oil pump gears. It happens both over time of long operation and due to rare changes of (very thick) oil.

- Using dirty or unsuitable engine oil. The presence of debris in the oil can be for various reasons - careless installation of a pump or filter, use of low-quality lubricating fluid.

- Careless pump assembly. In particular, various debris was allowed to get into the oil or the pump was not assembled correctly.

- Drop in oil level in the engine crankcase. Under such conditions, the pump operates at excessive capacity, which causes it to overheat and may fail prematurely.

- Dirty oil filter. When the filter is very clogged, the pump has to make significant efforts to pump the oil. This leads to its wear and partial or complete failure.

The most common failures of the pressure reducing valve

As operating experience shows, a malfunction of the pressure reducing valve can manifest itself in the following:

1. Inability to maintain normal blood pressure. As a rule, this is caused by mechanical failures of the unit. The weakest element of the system is the spring.

During operation, it can stretch and open the valve even with a slight increase in pressure. As a result, oil does not reach many engine components, they wear out and fail.

The reasons for a spring malfunction are its wear due to long-term operation, installation of the wrong spring during a major overhaul (defective or excessively soft), and installation errors.

2. Problems with opening the valve when peak pressure is reached. During operation, the valve lumen may become clogged. As a result, the RKMN jams and does not open even at high pressure.

The result is the destruction of many important engine components and the need for major repairs. The main cause of the malfunction is untimely oil change.

It's easy to explain. Dirt particles are deposited on the surface and constantly increase the size of the growth. Poor flushing quality leads to the accumulation of various debris and chips in the channels.

Troubleshooting

Direct connection of the pump to the crankshaft avoids damage associated with its drive. This, however, does not exclude the possibility of other malfunctions.

Pump malfunctions and their symptoms

The main malfunctions of the VAZ 2110–12 oil pump include:

- clogging of the oil receiver mesh;

- damage to the device body;

- wear of gear seats in the housing and cover;

- wear of the drive or driven gear;

- damage to the pressure reducing valve;

- deformation or damage to the valve spring.

A constantly burning warning light in the form of an oil can indicates a drop in pressure in the lubrication system to a critical level

Features of valve operation

In general, having delved into the principle of operation of this mechanism, you can find that it is quite simple. So, the main element that reacts to what is happening in the oil line is a special thrust bolt. This bolt, under the influence of the external environment, presses on the spring, which already presses or releases the valve in relation to the cross-section of the passage. If the oil pressure in the system begins to increase and, at the same time, exceeds the permissible maximum pressure level, then the oil will overcome the resistance of the regulator (simply springs) and squeeze it into the seat. In this way, the pressure indicator will stabilize, the spring will return to its normal position, and the car engine will be able to continue to function normally. Technically, the valve structure is as follows:

- A relatively small body, inside of which a special system of channels is machined. Oil moves through them.

- The spring, rod and body of the regulator lower and increase oil pressure.

It should definitely be said about how simple the design of this valve is - all functions are performed by elementary actions. Due to the elementary nature of the components, a high level of reliability is ensured.

It should also be noted that the pressure regulator can technically be designed in two versions. The first involves placing the housing inside the pump, without separating the two devices. The second option is that the valve has its own separate body and is located somewhere along the oil line. Considering the conditions under which the valve has to operate, it is not surprising that breakdowns also occur from time to time.

This point should also be given attention

How to determine if an oil pump is faulty

There are two types of pump testing - without dismantling it and with dismantling it. Without removing the pump, you can verify its malfunction only when it is already in a “dying” state, so it is better to remove it to perform detailed diagnostics.

How to check the oil pump without removing it

Before directly testing the pump, it makes sense to check the oil pressure in the system using a pressure gauge. This way you can make sure that the oil pressure light is working correctly and did not light up in vain. To do this, a pressure gauge is screwed in instead of the emergency lamp pressure sensor.

Please note that the pressure value often drops precisely “when it’s hot,” that is, when the engine is warm. Therefore, the test must be carried out on a warm engine and at idle speed. The minimum and maximum pressure values will differ for different machines. For example, for a VAZ “classic” (VAZ 2101-2107) the minimum emergency pressure value is 0.35...0.45 kgf/cm². It is under such conditions that the emergency lamp on the instrument panel is activated. The normal pressure value is 3.5…4.5 kgf/cm² at a rotation speed of 5600 rpm.

On the same “classic” you can check the oil pump without removing it from its seat. To do this, you need to dismantle the distributor and remove the pump drive gear. Next, evaluate her condition. If there are numerous scuffs on its surface on the blades or on the gear axis, then the pump must be dismantled. It is also worth paying attention to the gear splines. If they are knocked down, it means the pump is jammed. This is usually due to debris and/or sludge in the oil.

Another check without dismantling the pump is to check the play of its rod. This is done in the same way, with the distributor removed and the gear removed. You need to take a long screwdriver and simply move the rod with it. If there is play, it means the pump has failed. On a normal working pump, the gap between the surfaces of the rod and the housing should be 0.1 mm, respectively, and there is practically no play.

Oil receiver mesh

For further inspection it is necessary to dismantle and disassemble the pump. This is also done in order to subsequently flush out any accumulated debris. First you need to unscrew the oil receiver. In this case, it is necessary to check the condition of the sealing ring present at the joint. If it has hardened significantly, it is advisable to change it. Pay special attention to the oil receiver mesh, since most often it is the reason that the pump does not pump oil well. Accordingly, if it is clogged, it needs to be cleaned, or even the entire oil receiver complete with mesh must be changed.

Checking the pressure relief valve

The next item to check is the pressure relief valve. The task of this element is to relieve excess pressure in the system. The main components are a piston and a spring. When the extreme pressure value is reached, the spring is activated and the oil is poured back into the system through the piston, thereby equalizing the pressure. Most often, the malfunction of the oil pump pressure reducing valve is due to the failure of the spring. It either loses its rigidity or bursts.

Other VAZ cars

Let's look at how to check the oil level on VAZ series cars using the example of the VAZ 2112 and Lada Priora 16 valves.

Level measurements on these vehicles are carried out only on a warm engine. The probes here have a special appearance - a corrugated area with marks along the edges without letters.

Therefore, if the engine is cold, you will have to start it and warm it up until the fan turns on.

Then turn off the engine, wait 3-5 minutes until the oil drains into the crankcase and take measurements, see the algorithm above.

Since the dipstick itself between the marks has a corrugated shape, this causes a problem for many drivers.

Everything is simple here - the working fluid must be in the grooved zone, then the level is considered normal. But where this place should be, opinions differ.

Experienced drivers recommend proceeding from the operating conditions of the vehicle.

If the VAZ 2112 and Lada Priora are operated under normal conditions on flat terrain, then it is considered normal if the oil level is in the middle in the corrugated zone.

If cars are driven on moderately rough terrain, then the normal level may be 2/3 from the bottom mark in the corrugated zone, and if in mountainous terrain, then 3/4.

Also, many experienced car owners rely on the number of engine revolutions.

POPULAR WITH READERS: How to make an antifreeze with your own hands

If during driving the number of crankshaft revolutions does not exceed 3000 rpm, then the oil level can be kept in the middle, if more than 4000 - at 3/4 of the lower mark. Filling 1 liter means raising the level from the lower to the upper marks.

Lada Priora Hatchback 2009, 98 l. With. - spare parts

Cars for sale

Lada Priora, 2016

Lada Priora, 2016

Lada Priora, 2012

Lada Priora, 2007

Comments 32

Mannol is “tested”, God forbid you pour such oil into the engine, Mannol is produced in Germany? Then I'm a millionaire. The proven Shell is better.

Tell me, how did you find out that the problem was in the distributors? I bought a car with a mileage of 100 tons, with a converted ShPG at 124, and at first I didn’t notice the problem with oil pressure, my light doesn’t come on at idle, but with small drawdowns, it blinks actively, the mechanical pressure gauge shows 0.4-0.5 b when hot, this is very not enough (I’m wondering where to start, how could I have driven 40 thousand with such pressure, the hydraulics are silent. I’ll say right away, changing the oil, filter, sensor did not lead to anything. So I’m thinking maybe this is just my case? Because the old owner mentioned that there were “evil” shafts... And it is not known what was stuck in when the drain was returned.

That's exactly how it was discovered - at random. First the sensor, then I tried different oils (with a filter of course), then the oil pump, and then we got to the camshafts.

As I understand it, there was a problem with the distributors? Is everything right? I've encountered the same problem and am looking for a solution with minimal cost...

That's right, in the camshafts. I’ve only gotten around to them so far, but I haven’t changed them.

Sorry, I didn’t know all the intricacies of your business! It’s just that the reason for this “illness” was the pressure sensor and I changed it. Good luck in solving the problem!

Based on your symptoms, it sounds like the oil pressure sensor needs to be replaced! Let them inspect it at the service station - if it’s all covered in oil, then it’s 100%!

I understand that you sincerely want to help, but the fact is that this problem was solved more than three years ago and replacing the oil pressure sensor did not help, the problem was the wear of the camshafts. And then go to the service station to unscrew the sensor, when this can be done just in the yard. In any case, thanks for participating

Replacing the oil pump on a Priora 16 valve

Over time, every motorist is faced with the fact that a light on the instrument panel lights up for insufficient oil pressure. This signal tells us that the pressure in the engine lubrication system has decreased. The most common cause of this is a broken oil pump. That is why the problem cannot be ignored, and the oil pump of the Priora VAZ 2170 must be replaced as soon as possible.

The majority of new cars are equipped with oil pressure lights on the instrument panel. Loss of oil pressure is a serious problem as it is necessary to supply oil to engine parts to prevent wear.

Why does the breakdown occur?

Most often it all starts with a late oil change. For this reason, hard deposits appear in the engine, which over time fall off the walls and, when entering the pump, destroy it. And it doesn’t matter what kind of filter you have, because any filter is after the pump.

All this leads to a decrease in oil pressure, which subsequently leads to wear of other parts. And then the likelihood that replacing one pump can be done is very small. Therefore, it is very important to monitor the oil level and change the oil pump on time!

As follows from the purpose, improper operation of the oil pump leads to the fact that the oil does not circulate sufficiently throughout all engine systems. If the pump is not replaced in a timely manner, this leads to the so-called “oil starvation”. The consequences of this phenomenon are different and can be very dangerous. So, insufficient oil leads to:

• Excessive wear of units and components; • Penetration of mechanical wear products into the oil; • Reduced oil pressure in the system; • Overheating of parts; • Ingress of solid particles into various units and their jamming.

What kind of oil to pour into the engine

There are no difficulties with choosing the oil and filter elements used.

This engine is not so critical to the quality of consumables, so the car owner can purchase inexpensive semi-synthetic Russian oil, which is recommended by this automaker. If we talk about what kind of oil to pour into Priora, then most car owners purchase Lukoil lubricant, which in terms of its viscosity should correspond to the climatic region where the car is operated.

You will also need to purchase an oil filter for this job. It is best to buy it original in the appropriate stores, since its cost today is not too high.

Signs of a faulty oil pump. Symptoms, causes and main problems

Oil pump malfunctions can significantly harm a car's engine because they disrupt the normal circulation of engine oil through the system. The causes of the breakdown may be poor-quality oil used, its low level in the crankcase, failure of the pressure relief valve, contamination of the oil filter, clogged oil receiver mesh and several others. You can check the condition of the oil pump either with or without dismantling it.

- Signs of breakdown

- Causes of malfunction

- Verification methods

Signs of a faulty oil pump

There are several typical symptoms of a faulty oil pump. These include:

- Reduced engine oil pressure. This will be indicated by the oil can light on the dashboard.

- Increasing engine oil pressure. Engine oil is squeezed out of various seals and joints in the system. For example, oil seals, gaskets, oil filter connection points. In more rare cases, due to excess pressure in the oil system, the car refuses to start at all. This happens because the hydraulic compensators stop performing their functions, and accordingly, the valves function poorly.

- Increased oil consumption. Occurs due to leakage or waste.

It is necessary to understand that some of them may indicate failure of other elements of the oil system. Therefore, it is advisable to carry out the check in a comprehensive manner.

Causes of oil pump failure

The reason why the oil pump has failed can be determined by diagnostics. There are at least 8 main oil pump faults. These include:

- Clogged oil pickup strainer. It is located at the inlet of the pump, and its function is to coarsely filter the engine oil. Like the system’s oil filter, it gradually becomes clogged with small debris and slag (often such slag is formed as a result of flushing the engine with various means).

- Malfunction of the oil pump pressure reducing valve. Usually the piston and spring included in its design fail.

- Wear of the inner surface of the pump housing, the so-called “mirror”. Occurs for natural reasons during engine operation.

- Wear of the working surfaces (blades, splines, axles) of the oil pump gears. It happens both over time of long operation and due to rare changes of (very thick) oil.

- Using dirty or unsuitable engine oil. The presence of debris in the oil can be for various reasons - careless installation of a pump or filter, use of low-quality lubricating fluid.

- Careless pump assembly. In particular, various debris was allowed to get into the oil or the pump was not assembled correctly.

- Drop in oil level in the engine crankcase. Under such conditions, the pump operates at excessive capacity, which causes it to overheat and may fail prematurely.

- Dirty oil filter. When the filter is very clogged, the pump has to make significant efforts to pump the oil. This leads to its wear and partial or complete failure.

Regardless of the reason that caused the partial failure of the oil pump, it is necessary to carry out a detailed check of it and, if necessary, make repairs or complete replacement.

How to determine if an oil pump is faulty

There are two types of pump testing - without dismantling it and with dismantling it. Without removing the pump, you can verify its malfunction only when it is already in a “dying” state, so it is better to remove it to perform detailed diagnostics.

How to check the oil pump without removing it

Before directly testing the pump, it makes sense to check the oil pressure in the system using a pressure gauge. This way you can make sure that the oil pressure light is working correctly and did not light up in vain. To do this, a pressure gauge is screwed in instead of the emergency lamp pressure sensor.

Please note that the pressure value often drops precisely “when it’s hot,” that is, when the engine is warm. Therefore, the test must be carried out on a warm engine and at idle speed. The minimum and maximum pressure values will differ for different machines. For example, for a VAZ “classic” (VAZ 2101-2107) the minimum emergency pressure value is 0.35...0.45 kgf/cm². It is under such conditions that the emergency lamp on the instrument panel is activated. The normal pressure value is 3.5…4.5 kgf/cm² at a rotation speed of 5600 rpm.

Causes of poor engine pressure

There may be several reasons for this. The most common are:

- The oil level in the engine is lower than it should be, and therefore it does not completely enter the system.

This is how the oil in the editorial car was drained. Through the O-ring of the oil dipstick.

The oil pickup is cracked. Through such a crack, air enters the system, and viscous oil cannot reach components and sensors. The oil pump does not work well due to worn parts. There is oil loss in the lubrication system.

Inoperative oil filter.

The oil is diluted. A replacement is required, we have already written in more detail about the choice of oil for the 16-valve VAZ-2112 engine.

The light may also come on when the oil pressure sensor is broken or a wire has simply come off it. In this case, you need to play it safe and double-check everything.

Low engine oil level

Checking the oil level

Oil cannot be sucked into the oil pump. In this case, there will be air at the outlet. In the VAZ-2112 engine, the oil receiver is located in the lowest part of the crankcase so that it is always immersed in oil.

If you do not regularly add oil and do not control its level, this can negatively affect the operation of the engine. The oil will also lose its properties. It will not be able to wash the rubbing parts, and will also fall on them in the form of sediment. A particularly thick mixture will clog the oil receiver mesh, preventing it from sucking in full oil.

The solution in this situation is to constantly monitor the oil level and add it. It is also necessary to carry out a complete oil change in accordance with the regulations. It is not recommended to drive more than 15,000 kilometers on one oil. The oil change on the VAZ-2112 should be done every 10,000 - 15,000 km.

Oil pickup cracked (clogged)

Cleaning a clogged oil receiver

An oil receiver is located between the pump and the oil. When it cracks, a vacuum occurs in the tube and oil cannot enter the system. The cause of such a breakdown may be engine vibration, which results in the formation of a crack. It can increase during operation, taking less and less oil. This could also be caused by a manufacturing defect. This will require a complete replacement of the part.

We recommend: Possible malfunctions and their independent elimination on Eberspacher autonomous heaters

Oil pump failure

Oil leak from oil pump

In this option, the pump will pump less oil into the system than it may need. As a result, the pressure in the system will not be sufficient. This will be especially noticeable when starting the engine.

Losses in the lubrication system

To distribute the oil evenly between all components that require lubrication, one pump will not be enough. This will require coordinated work of other parts. Among these we can note:

- Oil nozzles.

- Crankshaft bearings.

- Gaps at the oil filter mounting location.

- Broken bushing on the balance shaft.

Oil dilution

Since liquid oil passes through all the cracks that are in the system, the pump cannot create sufficient pressure in it. Such unsuitability of the oil may occur due to the fact that it loses its performance properties. Its additives stop working, and it can additionally be diluted with gasoline.

Oil filter failure

In the context in the literal sense of the word. Look how much dirt it filtered out. Here is the answer to the question about his role!

The filter has valves and an element that cleans the oil. When the latter becomes clogged with dirt during operation, it can no longer pass oil through itself. Then the bypass valve helps him. It is normally in the closed position. When the filter becomes clogged, oil begins to flow through the valve. But if the valve hangs in the closed position, then there is nowhere for the oil to come from in the system. In this case, the engine begins to starve of oil. The way out of this situation is to timely change the oil and filter.

Should you contact a specialist or make a replacement yourself?

Naturally, it is best to turn to professionals! If you have not encountered this breakdown before, then intervention on your own can cause even more serious consequences, as a result of which you will lose a lot of time and additional funds.

The Priora VAZ 2170 oil pump is not an expensive part, but its removal and installation is not a simple task. It is also necessary to carry out diagnostics, because Along with the pump, you often have to change the filter and, of course, the engine oil itself.

DIY replacement

And so, if you have enough skills and free time, you can replace the Priora oil pump yourself, while saving money. To do this you will need a tool such as:

• Set of wrenches; • Set of heads; • Tools necessary for measuring gaps; • flat screwdriver.

If all the necessary parts and tools are prepared, you can begin replacing the oil pump:

1. First of all, disconnect the cable from the negative terminal of the battery; 2. Then drain the engine oil; 3. Then you need to remove the timing belt from the timing drive; 4. Disconnect the connector from the crankshaft position sensor; 5. Using screwdrivers, remove the pulley from it and remove the key from the groove; 6. After which you need to remove the oil sump; 7. Then, using a key of eight, turn the bolts of the oil receiver and remove it; 8. Remove 6 bolts from the oil pump to the cylinder block, use a screwdriver to move it, and remove the oil pump from the VAZ 2170 Priora; 9. Clean the cylinder block and pump housing from the old gasket; 10. Before replacing, fill the cavity of the oil pump with lubricant for better suction of oil from the crankcase during startup; 11. Install the oil pump and all the removed parts on the Lada Priora VAZ 2170 car, also in the reverse order; 12. And upon completion, adjust the tension of the timing belt and generator drive, after which you can fill the engine with oil.

Tip: after replacing the pump, it is recommended to change the oil filter!

About filters and oils

I immediately recommend pouring oil no lower than Motul 5W40, which will provide all rubbing surfaces of the engine with an oil film. Oil and air filter from Bosch.

What is the approximate cost of the above spare parts?

- The bottom of the motor will cost 24,000 rubles.

- Cylinder head 16500 rub.

- Mounted 20,000 rub.

- Oil and filter 5000 rub.

In total, excluding work, spare parts cost 65,500 rubles, or $1,100. Such repairs for a domestic car are too high, since the assembled unit 21126 will cost 75,000 rubles, but in our case you will have an engine with a higher compression ratio, higher compression, good pick-up from below, reduced fuel consumption, power of approximately 120 hp and a resource of 350,000 km minimum. If the belt breaks, the valves will no longer meet the valves; it will be enough to set the marks and install a new belt. Since there will be a long intake manifold and an exhaust manifold without a catalyst, the engine will “breathe” more freely, which means fuel consumption will decrease and power will increase.

An important factor is proper running-in and timely maintenance, which will contribute to the stable operation of the engine throughout its entire service life. I strongly recommend the following activities:

- every 7-8 thousand km. change oil and all filters;

- With each oil change, remove the oil receiver and clean it;

- clean the throttle valve every 20,000 km;

- pour G11 antifreeze into the cooling system and change it every 3 years;

- pour gasoline with octane number A-95;

- change the timing belt every 50,000 km.

If you want to increase engine power by installing wide-phase camshafts, a direct-flow exhaust system, a throttle valve with a diameter of 52-56 mm, boring the cylinder head channels, and get 150 hp at the output, then the engine life will be reduced to the factory mark of 200,000 km. For stable operation of the engine, you should not install “shafts” with a very wide phase, otherwise the engine will operate unstably and “spit” gasoline into the exhaust pipe.

practical guide

1. Remove the crankshaft timing belt and its key.

2. Remove the crankshaft position sensor.

4. Using a 10 mm socket wrench, unscrew the six bolts securing the oil pump to the cylinder block.

5. Remove the oil pump from the engine.

6. Remove the remnants of the sealing gasket from the mating surface of the cylinder block.

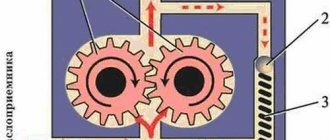

1. Using a 5 mm hex wrench, unscrew the six bolts holding the pump housing and cover together.

2. Separate the pump housing and the cover.

3. Remove the drive gear from the cover

4. Remove the driven gear from the housing

Recommendation

The pressure reducing (safety) valve plug is tightened with a large torque. When unscrewing it, you may accidentally damage the pump cover. Also, the turnkey edges on the cork itself are damaged. Therefore, do not disassemble the valve unless necessary. The valve can be washed without disassembling it.

5. We wash the pump parts with diesel fuel or kerosene, wipe them dry and lubricate the gears with clean engine oil.

1. Inspect the oil pump parts. They should not show signs of heavy wear, metal accumulation, cracks or other damage.

2. Using a caliper, measure the diameter of the mounting hole of the driven gear in the pump body and the thickness of the partition between the driven and driving gears.

The diameter of the driven gear seat in the pump housing should not exceed 75.1 mm. The minimum thickness of the dividing wall between the drive and driven gears is 3.4 mm.

3. Using a micrometer, measure the thickness of the driven and driving gears. If the driven gear is thinner than 7.35 mm, and the driving gear is thinner than 7.41 mm, replace the gears.

Conclusion

You can replace the oil pump on a Priora with your own hands, but this process requires special skills and experience. Therefore, it is better to contact specialists who will perform diagnostics and also, before replacing a worn part, flush the engine, thereby clearing it of solid particles that can harm other parts.

As we have seen, a malfunctioning oil pump is a serious failure. Replacing it in a timely manner can save you from unnecessary problems and protect your engine from additional wear, thereby extending the “life” of your car. Don't forget to change your engine oil on time and look at the dashboard.

Source