Good day. I would like to tell you, or more precisely explain, how, once and for all, to get rid of such an ailment of HBO on an injection engine as freezing (or as it is also called sticking) of revolutions. Very often I heard and read on the Internet such phrases as: “RPM hangs at 2000”, “RPM does not drop”, “RPM rises xx in neutral”, “high RPM when changing gear”

etc. I’ll start by explaining the reason for the high speed on an injection engine.

So, as you know, the principle of operation of an injection engine is as follows: the throttle valve regulates the air supply, and in principle never closes completely, the sensors calculate the amount of air, the computer calculates the required amount of fuel (gasoline) and sends a command to the injector about the injection duration. In the absence of load, when there is no need to maintain the speed, be it in neutral or the clutch is depressed, the computer goes into the fx mode (forced idling) when no signal is sent to the injector and fuel is not supplied to the system, or rather, it is supplied in small quantities, the speed decreases and Drivers have faces like cows in India! However, often in the 2nd generation gas equipment, so-called mixers are used to prepare the gas-air mixture, which operate from a vacuum behind the throttle; accordingly, even when the gas pedal is released and there is no load, no gas occurs, because fuel continues to flow into the manifold through the mixer in sufficient volume to maintain high speeds, as a result of which the speed does not drop, why? yes, because thanks to a general misconception, the gearbox is not configured correctly))) what is the misconception?

You need an idle screw! Yes Yes!

it is needed regardless of the engine capacity! This is what an incorrect recommendation for setting up the gearbox looks like: If the engine capacity is up to 2 liters, then screw the xx screw all the way, and adjust the gearbox using the sensitivity screw, i.e.

changing the elasticity of the membrane spring. To understand the absurdity of this recommendation, let's simplify the principle of operation of the gearbox as much as possible and, in the roughest approximation, accept the membrane as a valve (with a large cross-section) which, under load, opens allowing a larger amount of gas to flow, closes when there is no load, and the idle screw is an adjustable channel (with small cross-section) the cross-section of which is sufficient to supply gas only to maintain idle speed. During xx, the membrane must be completely closed and gas must flow through channel xx. And everything becomes clear and understandable and everyone can figure out how to properly configure the gearbox. Take your time, finish reading. Ideally, the elasticity of the diaphragm spring should be adjusted so that the diaphragm passes gas in proportion to the opening of the throttle valve, i.e. at each moment or at each angle of opening of the damper, a certain amount of gas was supplied to the mixer; this is impossible to achieve in practice, because the membrane is either open or closed. It immediately becomes clear that for each car the performance of the gearbox and the elasticity of the spring are strictly individual, and in our case not only is the power of the gearbox selected incorrectly, or rather not selected at all, it is also not configured correctly, hence the consumption and dullness of the engine and the problems associated with incorrect tuning . To dot the I’s, I’ll describe how to correctly configure the gearbox on a second-generation LPG.

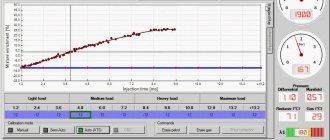

1. Screw xx is screwed in all the way, the dispenser is completely open, the sensitivity screw (the name, damn it, speaks for itself, with a weakened spring, the membrane will open from a small vacuum, the cross-section of which is tens or maybe hundreds of times larger than channel xx) unscrew 5 turns from a completely closed state. 2. Start the engine and warm it up to operating temperature. 3. Tighten the sensitivity screw until the engine stops completely 4. Unscrew the xx screw a couple of turns, try to start, if it stalls again, unscrew the xx screw again. As a result, we adjust the xx screw so that xx is stable when the screw is tightened as much as possible (i.e., if you tighten the screw further, the mixture becomes very lean and xx is disturbed, which is manifested by engine twitching). 5. Dispenser. We press the gas pedal to 2500-3000 rpm. in minutes and leave motionless. If, when trying to gain speed, the engine choke a few revolutions, tighten the dispenser and again try to set the speed with the pedal. We tighten the dispenser until the speed starts to drop; as soon as it starts, we unscrew it back by 0.5 - 1 turn. The ideal would be to check the lambda value through the OBD connector at 3000 rpm, which should be within 1, or by the exhaust oxygen sensor, the voltage of which should be within 0.4 - 0.8 volts.

We try to drive it, if the speed still freezes, then we try to tighten the dispenser by 0.5-1 turns, in most cases it helps. If it doesn’t help, then tighten the sensitivity screw another 0.5 - 2 turns, respectively unscrew the xx screw to maintain a stable xx and adjust the dispenser because its adjustment and the sensitivity screw adjustment are closely interconnected. I hope the information will be useful to everyone who is tormented with HBO and freezing speed! Stable idle speed everyone!)))

Any car - carburetor or injection, with a weak or powerful engine, constantly requires fuel consumption during operation. You can significantly save on fuel if you install gas equipment. Currently, there is a huge selection of LPG kits from different manufacturers for all types of engines. But only two of them - the first and second generations - are suitable for carburetor cars.

At the dawn of HBO

1st generation LPG was created for cars with carburetors that did not have sensors and control units. The adjustment and tuning of the gas equipment was carried out mechanically, the fuel consumption was through a simple dispenser. The scheme is simplified and reliable, but the big disadvantage is that the exhaust parameters did not reach European standards.

The 2nd generation HBO was equipped with a lambda probe. It was built into a carburetor or injector with a primitive electronic system. Fuel was supplied using a dispenser; sensors helped monitor the composition of the gas mixture. The first step was taken towards injection systems. HBO 2 has one injector that performs single gas injection into the intake manifold based on a signal from the gas computer.

What is included

The innovation of 2nd generation gas cylinder equipment is an electronic reducer-evaporator and an electronic fuel switch. The equipment for carburetor and injection cars differed.

2nd generation gas system for carburetor includes the following elements:

- cylinder with valve for refilling;

- multivalve;

- gas lines;

- coarse filter for gas purification;

- reducer-evaporator with electrical circuit;

- fuel switching panel with button and electrical wiring;

- mechanical type dispenser;

- gas and air mixer;

- gasoline electric valve to shut off the gasoline supply.

2nd generation LPG with injector has a slight difference from the carburetor version. There is no gasoline electric valve; emulators for the operation of injectors and a lambda probe have been added. When the car switches to gas, the devices perform emulation, “deceiving” the gasoline controller, telling it that the gasoline injectors are working.

The signal types may vary for each ECU. Yota emulators have the ability to customize the output signal.

In engines with a monoinjector, large-volume intake manifolds with air reserve receivers are installed; when operating on gas fuel, they are filled with a gas-air mixture, and there is a danger of its ignition. Therefore, when installing the second generation on the injector, it is necessary to provide protection against explosions (backfire pops).

For this purpose, an “anti-bang” is mounted on the injector. The plastic valve opens when the permissible pressure limits in the vehicle's intake manifold increase. When the indicators decrease, the anti-clap closes on its own. The anti-pop valve is most often placed on the air filter housing.

This problem was foreseen by well-known manufacturers of gas equipment Torelli, Lovato, Tomasetto, Atiker. Inexpensive but reliable HBO is produced by the Digitronic company.

Electronic gear adjustment procedure

An electronic gearbox, such as Tomasetto, provides for two main gas adjustments on carburetor cars:

- pressure in the second stage (it can be called sensitivity);

- the volume of gases passing through the channel at idle.

The engine must be started on gasoline fuel and warmed up to the nominal temperature level. The idle speed is set to one thousand per minute. The supply is turned off and gasoline is produced. The adjustments are in the following starting position:

- maximum eversion of the dispenser (the gas channel is open to the largest cross-sectional area; with a two-section chamber, each chamber is adjusted separately: for the first - the largest opening, for the second - the minimum);

- the screw that determines the idle speed is screwed to the extreme position and unscrewed five turns;

- the screw adjusting the sensitivity is installed in an intermediate position.

First you need to set the idle speed. To do this, the car starts on gas fuel, using a choke, the speed is set to two thousand per minute. Then the choke is gradually removed, and by rotating the screw that determines the idle speed, the speed is set to the maximum. These operations are repeated until the choke is completely removed and the engine operates stable in idle mode.

The maximum speed is set using the idle speed screw. The screw that determines the sensitivity is gradually tightened. When the speed is lost, they are added by the screw that regulates the idle speed. If this does not work, then the sensitivity adjustment is tightened a couple of turns and the procedure is repeated.

At the end of the adjustment, this screw will be screwed in almost all the way, and the engine speed when idling reaches its maximum value - about 1.2 thousand per minute. After this, this indicator is reduced - slightly below the nominal value, by tightening the idle speed screw, then, unscrewing it slightly, it is set to about a thousand revolutions per minute.

Next, you need to adjust the sensitivity of this unit: the adjustment of the same name is gradually turned away until it affects the engine speed when idling, and it is twisted approximately one turn in the opposite direction. If everything is done correctly, when you press the gas pedal sharply, the power plant should respond responsively.

You might be interested >> Filter for gas equipment 4th generation

The third step is to set up the dispenser. With the engine running, the revolutions are set to three and a half thousand per minute, and the screw of the mechanical gas dispenser is tightened until they begin to change. Then this adjustment must be turned back half to three-quarters of a turn.

For a two-section dispenser that provides for separate settings in sections, the above applies to the first of them, the second is placed at a third of the previously configured ones.

If the pressure in your reducer is adjusted in the first stage, then turn off the motor and close the gas flow pipe. Then, using the control hole, which is closed with a bolt, connect a pressure gauge to the cavity of the first stage, allowing you to measure pressure up to one and a half kgf/cm2.

The power plant starts up, and at idle the pressure level is set to about 0.4 kgf/cm2. Then the idle speed and sensitivity of the gearbox are adjusted again. You should take into account the increased gas hazard of these works, therefore, if you are not confident in the reliability of the connection, you need to contact a service center.

Attention! Work on adjusting the two-section dispenser poses an increased gas hazard. Be careful.

How HBO 2 works

Liquefied propane-butane passes through the multivalve along the flow line. As soon as the driver switches the button to gas fuel, the electric valve will open the way to the evaporator reducer. Gas fuel will be sent to the internal combustion engine through a dispenser and mixer.

The difference with the operating principle of LPG 1 is that the fuel selection button, which is equipped with electronics, starts the car on gas without additional actions on the part of the driver.

If the engine does not start for some time, the electronics will close the gas supply to the gearbox. LED indicators on the LPG fuel switching panel will signal this. In fact, the gas solenoid valve will be de-energized. To start the car the next time, switch gas fuel to gasoline, or turn off the ignition and turn it on again.

The fuel type switch remote control allows the car to switch to gas from petrol automatically by pressing a button when it reaches a certain number of revolutions. This rule applies when installing 2nd generation LPG on an injector.

In the second generation of gas equipment, the buttons responsible for switching from gasoline to gas differ for injection and carburetor systems. When operating a car on gas fuel, the switch button is used to control engine operation. The operation of equipment using a gas mixture is based on the supply of pulses created by the ignition system.

The period of time when the gas valve opens when starting the engine, or until the required speed is reached at which the switch to gas occurs, is set on the fuel switching panel.

At temperatures below 10 degrees Celsius, before the engine starts running on gas fuel, you should warm up the engine on gasoline in normal mode.

The switch to gas is carried out when the coolant temperature reaches about 40 degrees above zero. Italian LPG Lovato 2nd generation is adapted to the Russian climate, equipped with protection against humidity and mechanical damage.

Advantages and disadvantages of HBO 2

Despite some imperfections, 2nd generation gas equipment has its advantages:

- suitable for engines with fuel injection and for cars with carburetors;

- the design of second-generation gas equipment is simple and reliable;

- easy connection diagram and installation of gas equipment;

- it is easy to configure and regulate the system;

- An important advantage is that you can regularly start the engine on gas at an ambient temperature above 10 degrees Celsius.

The advantages of second-generation gas equipment include the low cost of repair kits.

- There is no feedback from the car engine, which leads to unstable operation in some modes (motor elements fail prematurely due to incorrect settings for the mixture quality or ignition timing).

- Increased gas consumption.

- There is a danger of a backfire of the gas mixture in the intake manifold.

- The emission of spent fuel in 2nd generation gas equipment does not comply with Euro-3 standards and higher.

- Slow response to pressing the accelerator pedal.

- The need to constantly adjust the valve clearance to prevent uneven engine operation under heavy loads.

When operating HBO 2, it should be borne in mind that water entering the air intake affects the number of revolutions.

On a note! The main modification of the power plant for gas equipment is to increase the compression ratio and integrate an octane corrector into the system.

You can’t do business with the 2nd generation of gas equipment today, since new versions of gas equipment have been released, which take into account many of the shortcomings.

Gas reducers Lovato

This material talks about the evolution of automobile gas reducers produced by the Lovato company, but most of the following is also true for other brands represented on the Russian market.

Purpose of the gas reducer

The first task of any automotive propane reducer, regardless of the generation of gas equipment, is to transfer gas from a liquid to a gaseous state and maintain a stable gas temperature during engine operation.

Equipment adjustment

You can try to adjust the operation of HBO Atiker, Lovato and Tomasetto yourself. To figure out how to set up a 2nd generation LPG on an injector, you should have relevant experience and know the operating principles of the car’s electrical equipment.

Subject to adjustment when operating a vehicle on LPG:

- the number of idle speeds at which the engine switches to gas;

- if necessary, adjustment of the gas mixture dispenser is required;

- when operating a car on propane-butane fuel, the air filter quickly becomes dirty, it must be replaced with a new one or blown out;

- the gas line is checked for leaks;

- the presence of gas in the cylinder is monitored;

- It is necessary to ensure that the gas tank is not empty to periodically start the engine on gasoline.

When installing gas equipment, it is sometimes necessary to increase or decrease the number of revolutions at which the injection engine switches to gas. To do this, turn the adjustment resistance on the HBO switch button, achieving the required parameters. In a carburetor car, the delay time for automatically turning off the gas is regulated in the same way.

Car owners, from their own experience and budget, clearly feel the systematic rise in fuel prices. Finding yourself in such a situation, the only way to save money is to use gas equipment. Particularly lucky car owners managed to deliver it before the cost increased. They equipped the cars with new systems and configured Lovato’s 2nd generation LPG with their own hands. Using the example of setting up equipment from this brand, we will tell you about all the advantages of this choice.

HBO adjustment 4th generation

The fourth generation operates using electronics, which detect engine heating, the number of revolutions, sends impulses to the gearbox, controls the movement of the injectors and the performance of the fuel supply system. Correct setting of gas equipment allows you to synchronize the functioning of the fuel system components and not interfere with the operation of the gasoline ECU (electronic control unit).

There are no universal tuning indicators, since the operation of the gas system is influenced by:

- gas quality;

- intensity of fuel consumption;

- filtration efficiency;

- carbon deposits on pipe walls.

It is important to set the correct HBO parameters. It is not possible to do this yourself without special knowledge and skills. Therefore, it is recommended to contact a professional specialized car service for tuning.

In the process of setting up the 4th generation HBO, the following actions are performed:

- The outgoing reduction pressure is adjusted because the standard level of 1 atmosphere is not suitable for every car. Therefore, adjustments are made on an individual basis. To increase engine power at high speed (from 150 km/h), it is necessary to increase the pressure by 0.1-0.3 atm.

- Parameterization of the fuel map is carried out together with calibration. Suitable parameters are determined based on the quality of the combustible mixture. Low-quality fuel has a negative impact on consumption.

- Nozzles of a certain diameter are selected for injectors. Poorly fitted parts may not function effectively.

- The float of the cylinder is adjusted to the optimal level of gas pressure. It is important to choose the right place to install the cylinder. As a rule, it is mounted instead of a spare wheel in the luggage compartment of a car.

In most cases, it is enough to correctly configure the main system nodes. Complete rules for adjusting HBO can consist of 50-page instructions.

Advantages

Correct adjustment of Lovato 2nd generation LPG in the injector and carburetor can be done with your own hands. In comparison with the new type of gas equipment (4th and 5th generations), the 2nd generation gas equipment gearbox has somewhat lost its relevance. However, this does not indicate that there is no point in using it. Not at all. The present systems have been preserved on almost all cars. And some experts advise using them. The “blame” for this is the outstanding qualities of 2nd generation HBO:

- availability and proven quality of the system. As a result, installation work can be carried out on your own;

- virtually complete absence of electronic components, which radically simplifies adjustment;

- the ability to repair individual components without leaving the garage. Having identified a malfunction, it is not necessary to rush to the service station. Having basic knowledge, you can do all the necessary work with your own hands;

- reasonable price for equipment. The purchase and installation of gas equipment of a higher class is much more expensive. The situation is completely different with 2nd generation gas equipment. Purchasing and further setting up gas equipment for a 2nd generation car really helps out in the current circumstances.

Results

Regulating gas equipment on your own takes half an hour. And replacing a gas filter with a 2nd generation Lovato gas filter is also not a source of difficulties. It is extremely important in this matter to maintain attention and concentration, avoid haste and strictly follow the practical guidance.

The release of more modern cars forces manufacturers of gas systems to develop, moving with the times. Although the number of obsolete vehicles is inevitably decreasing, in pursuit of savings on fuel and car maintenance costs, 2nd generation LPG does not lose popularity among car owners. Its installation and adjustment does not require special equipment. Therefore, it is possible to install gas equipment on a car yourself in the conditions of an average garage.

How is the work carried out?

How is it possible to adjust 2nd generation HBO with your own hands? In fact, the 2nd generation HBO differs slightly from its predecessor (1st generation HBO). The only difference is that an electromechanical system was introduced. Through its use, it is possible to coordinate the force of the gas flow.

Speaking about how to adjust the 2nd generation LPG, it is important to note that the creators managed to significantly reduce the load on the engine (gas burns much more slowly), increase the capabilities of the power unit (oil is stored on the surface of the cylinders), reduce the amount of carbon deposits and reduce the harm from exhaust emissions. By the way, it is the last moment described that allows the catalyst to last much longer. If necessary, when setting up the 2nd generation Lovato gas system with your own hands, the gas supply remains at a certain level.

Attention! The lambda probe emulator is a very useful product. It thoroughly helps with setup, but only if it is in good condition.

Unit technical characteristics

It is important to add that such a unit is ideal for automotive systems not only of the second, but also of the first generation. This is explained by the fact that the gearbox is distinguished by the presence of a dual control system, which will increase the productivity of the unit as a whole.

You may be interested >> Diagnostics of gas equipment of a car

Moreover, some devices of this brand may contain not one, but several stages of gas pressure reduction. In addition, there are models containing so-called auxiliary valves, designed to relieve the gas flow at the moment when the pressure in the device begins to increase.

In addition to all that has been said, there are also products on sale that are capable of functioning in those cars that are equipped with a powerful engine.

How is the gearbox controlled?

The 2nd generation Lovato gas reducer has its own characteristics. In general, gas is sensitive to many important points and changes in the operation of the system. It happens that gas equipment was installed, but then increased fuel consumption or other problems with the engine appeared. Let's say the car starts to start slowly or stalls regularly. In this case, it is better to adjust the gearbox.

What needs to be done for this? To familiarize yourself with the process features, you can view a diagram of the existing pins and control components.

Adjust the electric gearbox. You have regulators available - fluid pressure (2) and gas volume (2). The following algorithm of actions must be followed:

- switch to gasoline, turn on the car and warm up the engine to 95 degrees;

- set the speed to 900-1100 rpm and turn off the fuel supply (in this case, gasoline);

- set the initial positions of the adjusting screws: set the dispenser to the extreme mark, turn the XX regulator (2) all the way and then turn it exactly 5 turns, turn the 1 regulator all the way.

Put XX. Namely:

- Switch the control to gas and turn on the car. Using the choke, set the speed of the power unit to around 2 thousand;

- gradually return the choke to its place and unscrew the XX regulator (2). Do this until the maximum engine speed is achieved. What does it mean? Turn screw 2 until the speed stops increasing. When you reach the specified goal, stop;

- operate in the sequence described until the suction is fully recessed;

- turn the adjusting screw (2) evenly. It is necessary to reach such a state that the sum of revolutions becomes presumably the same as when running on gasoline. During adjustment, you must remember that after rotating the regulator, the reaction to changes is not observed instantly, but after some time. This means that you definitely need to take a break.

Adjust the sensitivity of the gearbox. Everything is simple here. Turn the adjusting screw (1) until the XX speed decreases (increases) (again, do not forget about the delays). After this, turn the regulator slightly back - 1.25 rpm. Next, try to apply pressure on the gas. It is perfect if the car immediately responds to your actions.

However, it is important not to forget one more thing. If the adjusting screw “1” was not tightened well enough, it is preferable to leave it untouched. Among other things, provided that the engine capacity is less than 3 liters, then it is also better not to touch the described screw.

Set up the dispenser. To this end:

- set the number of revolutions to 3500. Accordingly, it is preferable to involve an assistant in the process and ask him to press the gas (do not use the choke). No helpers found? It is necessary to secure the throttle cable using a screwdriver;

- Turn the adjusting screw until changes in speed appear. Turn the screw to the left and to the right to make sure that all actions were carried out correctly;

- turn the screw until the speed increases. As soon as the rotation stops producing results, you need to stop;

- From now on, turn the screw 0.75 rpm. from the limit.

- Call an assistant and ask him to press the gas. Do not forget to turn screw 2 by 1/4 turn at the same time. There should be a feeling of a slight decrease in speed;

- turn the sensitivity screw half a turn;

- re-adjust the dispenser.

Measure the level of carbon dioxide in the exhaust. The standard figure is around 0.35%. Are the numbers too high? Turn the XX screw on the gearbox and increase the air injection (for this, use a special screw on the carburetor). If reduced speed is observed, the opposite actions should be taken.

If possible, to correctly configure and adjust the 2nd generation HBO, use a lambda probe emulator. It allows you to see to what extent the work has been done accurately. At the same time, you can make any necessary adjustments along the way.

A simplified method used when repairing 2nd generation gas equipment with your own hands (Lovato brand) is the basics of adjustment (sensitivity bolt in combination with a greed bolt):

- The membrane sensitivity bolt is completely screwed in until it stops slightly.

- Next, unscrew the sensitivity bolt 5 turns from the twisted position.

- The greed bolt (main chamber) on the hose is screwed in, in turn, to a slight stop.

- After this, unscrew the greed bolt 3 turns from the twisted position.

The procedure for setting up the 4th generation HBO - how to do it yourself

After a car is equipped with gas equipment, proper adjustment of its operation is required. In addition, during operation of a gas-powered machine, or after its repair, diagnostics may be necessary, and then calibration/adjustment of the gas equipment.

Today we will figure out how to configure the 4th generation HBO on our own.

What you need to get started

Both fuel consumption and engine life will depend on how well the gas system is adjusted. To adjust it you need:

- laptop, tablet or smartphone;

- specialist. software;

- diagnostic cable or bluetooth scanner (OBD2 format);

- sufficient amount of fuel in the tanks - there should be 10-15 liters of gas/gasoline.

Software for this purpose can be downloaded freely on the websites of equipment manufacturers or on the websites of their offices. representatives. The software may have minor differences in the interface, but the essence is the same for all. You just need to purchase the cord or make it yourself.

Adjustment procedure

For the setup procedure to proceed correctly, it is very important that the car is in absolutely good working order. The fuel and ignition systems are required to be in perfect condition, and they must operate without failure.

The engine should be warmed up to operating temperature (this is approximately 80-95 C). Turn off all possible consumers (we are talking about lighting, radio, air conditioning), the power steering should be left alone. After this, connect the appropriate connectors of the diagnostic cable to the HBO ECU block, as well as to the PC. The usual location of the chip/connector is in a place under the hood near the gas electronic control unit.

Connector for diagnostics of the HBO controller 4

Auto-tuning procedure

After entering the software interface (take Stag software as an example), you will need to install basic data. To do this, in the “parameters” - “auto parameters” tab, set the required values:

This is how the car parameters are set

- Number of cylinders (everything is clear here).

- Number of cylinders per coil (it depends on what type of ignition system the car is equipped with). The correctness of the values that were set can be determined by comparing the readings located in the right column of the software. Should be max. coincidence of idle speed (idle) of the engine with the readings of the tachometer located on the dashboard of the car.

- If the engine speed is read from the camshaft sensor, you need to check the appropriate box, but here it is important to know how many pulses are issued per shaft revolution (often, this is 1 pulse).

- “Rpm signal” - we can leave it at 2.5 V.

- When floating the engine speed, you should check the “RPM signal filter” checkbox.

- Next, you should select the engine type standard/turbo.

- If you do not know what type of lambda probe it is, it will be better if you leave the software settings at the factory and skip this point. But as for gasoline injection, you need to know which one - pairwise or phased (usually phased).