There is not so much perfect in this world, and maybe not at all, so when something, at first glance, very thoughtful and perfect fails, you should not be surprised, you should accept it as inevitable.

LPG equipment is also susceptible to breakdowns and malfunctions. Today we will talk about malfunctions of the 4th generation HBO ; we will try to suggest the cause of the breakdown (inoperability) based on the characteristic symptoms.

First, a few words about what causes fourth-generation gas equipment to malfunction.

- Most often, gas equipment fails due to the fault of the motorists themselves. There is no desire to delve into the essence of the HBO device and perform the slightest maintenance thereof.

- Wear of parts also occurs due to poor quality gas, pollution, as well as violation of operating rules and errors made when installing gas equipment on a car.

Significant loss of engine power:

- Gas injectors do not work properly or are out of adjustment.

- The gas reducer cannot create the optimal pressure for proper operation. Poor heating of the gas reducer.

- Faulty lambda probe.

- Problem with filters (clogged gas filter, clogged fine gas filter).

- Gas lines are clogged.

Types and device

At the heart of gas and gear temperature sensors is a thermistor. The thermistor has a negative characteristic with the designation NTC, i.e. when heated, its resistance decreases.

In 4th generation HBO systems, elements with a nominal value of 1.7 to 10 kilo-ohms are used. But the most common are 2.2 and 4.7 kOhm.

The gearbox temperature sensor has a brass body, differing only in the connector, length and size of the thread.

Gas sensors can be of plastic or metal construction. The location may include:

Dips during sudden gas changes

- Gas injectors are not calibrated correctly.

- The gas filter is clogged.

- The gas pressure in the reducer is insufficient.

- Problem with gas lines.

If, when switching to the engine, it starts to “go bad”, most likely the problem is in a faulty gas system , in this case, switch back to gasoline and continue driving it until the reasons for the interruptions in the operation of the internal combustion engine are established. Repairing gas equipment with your own hands is highly undesirable unless you are well versed in gas equipment and have all the necessary equipment to carry out repair work. In all other cases, we recommend contacting specialists or the service station that installed this gas equipment.

Thank you for your attention, see you again at HBOshnik. Bye!

Causes of malfunctions of car gas equipment

If during the operation of the car unexpectedly deviations from the norm are discovered in any of the indicators, it is necessary to immediately inspect the car. The absence of external signs of breakdown will be the reason for diagnostics using special equipment. Problems occur for the following reasons:

- wear of consumables: filters, seals;

- physical damage to mechanisms and equipment components;

- improper operation of the vehicle;

- refueling with low-quality fuel;

- installation errors (poor quality installation of equipment).

Complete diagnostics can be done on your own if you have some experience or at gas equipment maintenance centers. Using special tools and devices, a specialist will identify the specific reason for the malfunction of the gas equipment.

Important! Some problems cannot be solved on your own if you do not have professional skills and knowledge in this area.

SergeyKoLeo › Blog › Main malfunctions of gas equipment... (1-4 generations)

Main malfunctions of HBO

For the first and second generation of HBO

1. The reason for the lack of supply of the gas mixture to the power plant may be a failure of the electromagnetic gas valve installed on the carburetor. The speed valve is stuck in the closed position. The pipeline is clogged. The filter elements are clogged. The speed valve does not operate. The flow valve does not open completely.

2. The car’s power plant is turned off, gas continues to flow into the system due to: the switch is faulty, the gearbox has failed, the gas solenoid valve on the carburetor is not sealed.

3. The existing difficulties in starting the power unit of the car arise due to a malfunction of the gearbox. The gearbox has not been adjusted correctly. The fuel mixture of gasoline and gas is supplied simultaneously.

4. The reason for the increased consumption of the gas mixture when the gearbox freezes is due to the lack of complete tightness of the gearbox diaphragm. The cooling system is full of air mass. The coolant level is low.

5. The presence of a gas smell in the car interior occurs due to: lack of tightness in the exhaust gas exhaust system. The solenoid valve on the carburetor is not sealing. Leakage occurs from the gear housing or from various connections in the gas line.

6. When the power plant is operating in idle mode, there may be no development of engine speed due to a malfunction of the gearbox itself, the ignition system or a clogged air filter.

7. High consumption of the fuel gas mixture occurs due to: poor heating of the gearbox by coolant. Gearbox malfunction. The presence of a reduced level of compression on the engine cylinders. The gearbox is out of alignment. The ignition system has a malfunction. Air filter clogged.

Typical causes of malfunctions for the third generation of gas equipment.

1. The car’s power plant does not gain full power due to a software misalignment. The lambda probe, stepper gas supply regulator, and gearbox have malfunctions. The gas lines and gas filter are clogged.

2. Opening the throttle valve can lead to “failure” due to: an incorrectly selected mixer. There was a violation of the regulations of the entire system. There is a malfunction of the sensor that records the throttle position.

3. Reaching the recommended temperature does not allow the engine to switch to working with gas mixture fuel due to: lack of tachometer readings based on the engine speed. The gearbox temperature sensor is faulty.

4. The appearance of various levels of “popping” that occurs on the intake manifold when the throttle valve is open occurs due to existing violations in the timing valve thermal clearance adjustments. The gas distribution mechanism and ignition system have a malfunction. There is no tightness in the intake tract, which causes air to be sucked in. Incorrect operation of the stepper regulator gas supply or incorrect adjustment of the system leads to a lean fuel mixture.

5. An increase in gas fuel consumption occurs due to: violation of the lambda control system adjustments. There is a malfunction of the lambda probe and the stepper gas mixture supply regulator. The compression level in the engine cylinders is reduced. A violation of gear adjustments has occurred. The ignition system has a malfunction. The air filter is clogged.

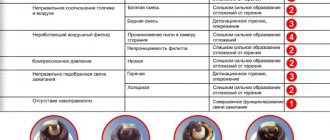

The fourth generation of HBO is characterized by such malfunctions

1. There is no stable operation of the power unit at idle. Due to violation of adjustments on the timing valves, thermal clearances. There is a malfunction in the gas distribution mechanism of the unit. The level of motor compression is reduced. Malfunction of the lambda probe. The gas injection system was adjusted incorrectly. There is a malfunction in the ignition system. The normal operation of gas injectors is not ensured.

2. There is no development of full motor power due to clogging of the fine filter, gas line and gas filter. There is a malfunction of the lambda probe and gas injectors. The gas injection system is not adjusted correctly. The level of reducer gas pressure is reduced.

3. Having reached the recommended temperature, the power plant cannot switch to power supply with a gas mixture. The battery is discharged, the charge level is below nine volts. The gearbox does not heat up. The causes of this malfunction may be the gas pressure sensor, reducer temperature and gas temperature. There is no signal about the number of revolutions of the power unit.

4. The reasons for increased gas consumption are: when the injector and calibration fittings are selected incorrectly. Reducer pressure level is increased. The gas injection system is out of adjustment. Malfunction of the lambda probe, gas injectors, gearbox and ignition system. There is no heating of the gearbox coolant. The compression level in the engine cylinders is reduced. There are irregularities in the gearbox adjustment. The air filter is clogged.

5. A sharp opening of the throttle valve leads to failure due to: violations in the adjustment of thermal clearances on the timing valves. Detection of a malfunction in the gas distribution mechanism of a vehicle's power unit. Reducing the level of motor compression. Detected malfunction of the ignition system and gas injectors. Clogged fine gas filter, gas lines and gas filter. The presence of low gas pressure in the reducer. The injector and calibration fittings are not selected correctly.

6. The spontaneous return of gas injection to the gasoline mixture may be due to such a reason as a low temperature level of the gas mixture, which appears due to insufficient power of the gearbox. The battery has been discharged. The charge level indicator is less than nine volts. There is a malfunction of the gas pressure sensor, temperature sensor and reducer. There is no signal for power plant speed.

Source

Electrical part

When driving on gasoline fuel, you may not notice the appearance of gaps in spark formation. A more powerful spark is required to ignite the gas fuel-air mixture. Therefore, the car’s ignition system must be in full working order.

First of all, you should pay attention to:

- candles

- high voltage wires

- spark plug tips

- coils or ignition module

Sometimes the problem is solved by reducing the spark gap to 0.7-0.9 mm. But if there are breakdowns to ground, it is necessary to replace the spark plugs.

You can initially check all elements of the system for breakdown visually. To do this, you need to dismantle all the spark plugs and inspect them along with the tips and armor wires. There should be no traces of a spark passing through the insulation (usually white), as well as breaks, cracks and fractures.

Signs of spark leakage on the spark plug and tip

It is possible to more accurately check the ignition system for breakdown only with the help of a special tester. We talked about this here.

It is important to know! If a problem is found in the high-voltage wires and spark plugs, the entire set must be replaced. Otherwise, the problem will return after some time.

In addition, you need to check all equipment terminals. The presence of bare and oxidized wires, connectors, and twists must be eliminated (the latter is generally not acceptable). The integrity of the wiring must not be compromised.

Often, jerking when driving on gas is caused by loss of contact/s on the LPG solenoid valve or injectors.

Failures can occur due to a wire that has partially fallen off due to vibration or a malfunction of the gearbox temperature sensor.

There may also be a bad ground from the battery to the body and equipment, as well as the gas installation control unit (ECU).

HBO maintenance

Maintenance and operation of a vehicle with a STAG control system

MAINTENANCE OF THE GASOLINE/GAS SWITCH

1. Description of the Petrol/Gas switch.

The only element that serves to connect the driver with the STAG control unit is the Petrol/Gas switch.

A) Gas level sensor – Four green LEDs display the gas level in the cylinder. The reserve level is signaled by a glowing red LED, located in a row with green LEDs that indicate the filling level of the cylinders - LED GoFAST, LED-300, in the case of LED-300/401 V, as well as LED-401; the red reserve LED is located under the switch state change button.

B) Signal LED

Operating status for: STAG-200, STAG-4, STAG-300:

- off (gasoline operating mode) – informs that the engine is running on gasoline;

- LED blinks slowly (once per second – AUTO mode) – the engine starts on petrol; the control unit waits for the engine temperature;

- flashes normally (2 times per second, no sound signals - AUTO mode) - waiting for revolutions; after reaching the set parameters, the system will automatically switch to LPG power supply;

- the LED flashes quickly (4 times per second, with simultaneous emission of sound signals - emergency mode) - the system has encountered a situation that does not allow the engine to operate on gas; for example, lack of gas in the cylinder, LPG installation error; the engine is powered by gasoline;

- lights up (gas operating mode) – the engine is running on gas.

Operating status for: STAG-4 Q-BOX, STAG 400 DPI, STAG 200 GoFast:

- off (gasoline operating mode) – informs that the engine is running on gasoline;

- the LED flashes slowly (once per second - AUTO mode) - the engine starts on gasoline, and after reaching certain parameters the system automatically switches to gas power;

- flashes normally (2 times per second, no sound signals - AUTO mode) - the system switches the engine to gas power. This state can last up to 10 seconds, depending on the current engine operating parameters;

- the LED flashes quickly (4 times per second, with simultaneous emission of sound signals - emergency mode) - the system has encountered a situation that does not allow the engine to operate on gas; for example, lack of gas in the cylinder, LPG installation error; the engine is powered by gasoline;

- lights up (gas operating mode) – the engine runs on gases;

- shines red - gas reserve determination (only for LED-300/401B, as well as LED-4O1).

C) B/G button, AC logo button, GAS button

– selection of the operating mode of the LPG/CNG installation.

Programming the type of fuel.

Control unit in GASOLINE mode:

- turn on the ignition;

- turn on the ignition without starting the engine;

- press the button on the switch until the signaling LED goes out;

- turn off the ignition.

Attention: The engine will only be powered by gasoline.

Control unit in AUTO mode:

- turn on the ignition;

- turn on the ignition without starting the engine;

- press the button on the switch until the signaling LED starts flashing;

- turn off the ignition.

Attention: each subsequent engine ignition will occur in AUTO mode.

H. Information sound signals generated by the switch:

- two short beeps and one long beep (after turning on the ignition) – lack of required technical inspection of the installation;

- three long beeps repeated every minute – the car is ignited in emergency mode (only for STAG-200, STAG-300, STAG-4 Q-BOX).

Signs of complete gas consumption:

– sound – three beeps (short or long, depending on the switch); – blinking green SIGNAL DIODE:

- next to the B/G button (for LED-300),

- next to the GAS button (for LED GoFast);

– blinking white diode under the button – “AC” logo (for LED-300/401B and LED-401).

Note: The gas level indicator displays the current gas level in the cylinder after switching the engine operating mode to gas; Due to the high inertia of the gas in the cylinder, as well as due to the technical capabilities of the measuring system, the diodes indicating a full cylinder may go out disproportionately in relation to the actual state of the gas, and the reserve indication should be considered as indicative.

Emergency engine start on gas

(only for STAG-200, STAG-4, STAG-Z00, STAG-4 Q-BOX, 200 GoFast)

Procedure for STAG-200, STAG-4, STAG-ZOO:

- press the B/O button with the ignition on;

- While holding down the I/O button, start the engine.

Procedure for STAG-4 Q-BOX, 200 GoFast:

- turn on the ignition;

- press the button on the switch and hold for about 3 seconds;

- after the sound signal, release the button;

- start the engine.

NOTE! An emergency start is possible only when the air temperature is positive and the gas equipment is properly installed. After an emergency start, you should wait until the engine temperature reaches the optimal level! Otherwise, the gearbox may freeze and damage the engine!

6. Automatic calibration of gas level indicator

(only for STAG-200, STAG-4, STAG-300, STAG-4 Q-BOX, 200 GoFast)

Calibration procedure for STAG-200, STAG-4, STAG-300:

- turn on the ignition;

- press and hold the switch button;

- turn off the ignition;

- release the switch button (at this moment the calibration procedure begins, the beginning of which is signaled by a series of triple short blinks of the signaling diode);

- fill a full cylinder of EPO/SMO gas;

- turn on the ignition.

Calibration procedure for STAG-4 Q-BOX, STAG 200 GoFast:

- turn on the ignition;

- press and hold the switch button;

- turn off the ignition within 3 seconds after pressing the button;

- release the button after turning the switch into programming mode (the start of programming is signaled by a repeated smooth increase in the level of the indicator from the minimum to the maximum value);

- fill a full LPG/CNG gas cylinder;

- turn on the ignition.

Indication of calibration status after completion of the procedure:

smooth increase and then drop of the pointer on the LED indicator, from reserve to maximum and back (twice) - calibration is successfully completed;

changing the level indicator on the LED indicator from reserve to maximum (five times) - the calibration could not be completed successfully.

ATTENTION. Calibration should be carried out while filling the gas into an empty cylinder. Upon completion of refueling, turn on the ignition switch, which is equivalent to completing the calibration procedure.

Description of gas equipment with control unit: STAG-200, STAG-4, STAG-300, STAG QBOX, STAG 400DPI

Automotive gas equipment is designed to supply a car engine with gas fuel and is an additional fuel system. Gas is supplied to the engine compartment of the car from a cylinder through shut-off valves through a high-pressure pipeline. In the engine compartment, gas flows through a pipeline through a gas solenoid valve (can be combined with a gas reducer) into the gas reducer. Gas reducer is a device that reduces gas pressure to 2 bar. When using propane-butane as fuel in a gas reducer, not only a decrease in pressure occurs, but also a transition from the liquid phase to the vapor phase, which is accompanied by a strong decrease in temperature. Therefore, during these processes, additional heating of the gearbox is required, which is provided by the engine coolant. From the reducer, gas flows to the gas injectors through a vapor phase purification filter. The gas injector nozzles are connected to the gas supply fittings to the engine cylinders, located similarly to gasoline injectors. After switching the car to gas, the gas injectors begin to inject gas fuel instead of gasoline injectors. Gas injection is controlled by the STAG electronic gas injection control unit.