Sometimes owners of cars equipped with gas equipment are faced with a problem when the engine does not switch to gas when the 4th generation of gas equipment is installed, and continues to run on gasoline. In today's article, we will try to understand the reasons why the LPG does not switch to gas, or immediately stalls after switching.

Possible cause of the problem

In order to understand why failures may occur when turning on the HBO, it is necessary to recall how the installation works.

Unlike the second generation for carburetor and injection cars, where switching is performed forcibly by an equipment button or semi-automatically (based on engine speed), in the fourth generation, the transition from gasoline to gas is controlled by an electronic unit (ECU) in automatic mode.

The controller reads readings from the sensors; if the parameters match those programmed into it during setup, the gasoline injectors are turned off and the gas injectors are turned on.

Thus, if the LPG does not switch from gasoline to gas or switches late, the unit’s power button begins to beep and blink and the car stalls, the main causes of the failure may be:

- insufficient coolant level in the car system;

- air plug in the housing of the GBU evaporator reducer;

- malfunction, defect or incorrect installation of the evaporator temperature sensor;

- MAP sensor malfunction or incorrect installation;

- The installation fuse has blown/oxidized.

In addition, the cause of the defect may be:

- incorrect installation of the gearbox or wear of its membrane;

- contamination of the supply line, as well as filter elements (pressure loss); breakdown/defect of “gas brains”;

- Damage or clogging of LPG injectors;

- wear of electric valves and their coils;

- incorrect equipment settings.

Symptoms and costs

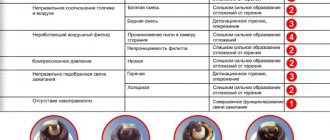

During the operation of a car with HBO, 18 characteristic malfunctions most often occur.

Some of them are malfunctions in the operation of the gas installation itself, and the other part are typical problems that should be expected from a car powered by gas for a long time. 1. Loss of coolant.

Signs: The coolant level in the reservoir drops below normal. Topping up doesn't help. The situation repeats itself again and again. Puddles (drops) may appear under the car.

Reason: when installing HBO, you have to cut into the cooling system. Coolant is used to warm up the gearbox. Leaks most often appear in “tie-in” areas. The gearbox itself may leak. It is possible for both coolant to enter the intake manifold and gas to enter the cooling system.

Repair cost: 1000-6000 rubles.

2. Engine overheating.

Signs: the temperature gauge needle enters the red zone, the antifreeze is boiling.

Reason: during installation, the circulation of liquid in the system was disrupted, the system became airy.

Repair cost: up to 1000 rubles. It is necessary to remove air from the system, and in some cases replace pipes and clamps.

3. The car jerks when running on gas.

Signs: when running on gas, power increases unevenly, the car jerks, the engine has difficulty maintaining idle speed. At the same time, the engine works perfectly on gasoline.

Reason: It might just be running out of gas. In the case of mechanical gas equipment (I and II generations), the gearbox is probably malfunctioning, or there are leaks in the intake system. In addition, the stepper motor for controlling gas dosing could fail. Injectors (if multipoint injection is available) can also be the culprit.

Repair cost: it all depends on the cause of the problem. A set of LPG injectors including replacement will cost 4,000-9,000 rubles.

4. The gas reserve indicator does not work.

Symptoms: regardless of the amount of gas filled, the indicator shows a value different from the actual one.

Reason: The gas level sensor works on a principle similar to the float in the toilet tank. A stuck float is the most common cause of incorrect readings. Perhaps the reason lies in an electrical fault: no contact, short circuit, etc. and so on.

Cost of repair: most often you can get away with tapping the gas cylinder. If the float comes to life, consider yourself lucky. If not, you will have to prepare from 800 to 2000 rubles.

5. The heating does not work.

Symptoms: Regardless of the position of the set temperature control knob, cold or barely warm air blows from the vents.

Cause: The cooling system became airy during installation. It is possible that the cause of the anomaly is the incorrect installation of the LPG reducer.

Repair cost: removing air from the system will cost no more than 1000 rubles. To change the location of the gearbox you will have to spend up to 3,000 rubles.

6. The gas cylinder cannot be filled completely.

Signs: The gun fires too early.

Reason: Sometimes the gun itself is to blame. However, much more often the cause lies in a faulty filling device valve. It can be replaced or removed and cleaned. Before going to the service center, you should try to fill up with gas at another station, just in case.

Repair cost: a new valve costs from 600 to 1000 rubles. The cost of replacement work is about 500 rubles. But most often you can get away with cleaning the valve - from 500 to 1000 rubles.

7. Power loss.

Signs: in this case we are talking about a situation in which the dynamic performance of the car worsens from month to month, although initially everything was in order. On gasoline the engine runs properly.

Reason: HBO filters may be the culprit, but not only. In old-type mechanical systems (I and II generations), the reason may lie in wear of the gearbox, and in the presence of a multipoint injection system, in malfunctions in the operation of the LPG control electronics or faulty injectors.

Repair cost: replacing the filter will cost 500-1000 rubles. In other cases, costs depend on the specific case.

8. Smell of gas.

Signs: You can smell gas in or near the car.

Reason: The gas has a pungent odor, so even a small amount is immediately noticeable. The cause may be either small leaks or a leaky exhaust system. In old-type systems, due to loss of tightness of the intake duct, gas can enter the air intake system for the passenger compartment.

Cost of repairs: everything is assessed individually in each specific case. The repair begins with a classic check of the tightness of the connections, which will cost approximately 500 rubles. In some situations, the cost of elimination can reach up to 3,000 rubles.

9. The engine does not develop speed.

Signs: The engine runs perfectly at low speeds, but is reluctant to increase speed.

Reason: the reasons can be different, ranging from the prosaic clogging of the gas filter and a faulty gearbox (or its too low performance), and ending with problems with the software.

Repair cost: to replace the filter you will need from 500 to 1000 rubles. To replace the gearbox you will have to pay 10 times more. Diagnostics and tuning are assessed individually, depending on the type of installation and engine.

10. The engine suddenly stalls.

Signs: the engine stalls at the most unexpected moment: at an intersection, when releasing the gas, when braking, etc.

Cause: In older type systems, the cause lies in incorrect adjustment or improper modification of the intake system. Sometimes it turns out that the gearbox is installed incorrectly. In systems with multipoint injection, such problems are not observed, and if something similar happens, then the cause must be sought in the electronic control system.

Cost of repair: repair involves painstaking diagnosis and precise adjustment. Costs will range from 800 to 2000 rubles.

11. The Check Engine light comes on.

Symptoms: The check engine light stays on all the time or only comes on under certain repeating conditions and goes off after a few days.

Reason: for some reason, the composition of the mixture does not correspond to the parameters provided by the car manufacturer. You can drive the car, but ignoring the problem risks burning out the valve seats or damaging the catalyst.

Cost of repair: for diagnostics you will have to pay from 800 to 2000 rubles. Further costs depend on the scope of work.

12. The engine “shoots”.

Symptoms: applies to vehicles with mechanical type LPG for distributed injection. When starting or accelerating from low speeds, the mixture explodes in the intake manifold.

Reason: failure of the ignition system, incorrect adjustment of the mixture composition, installation errors, very large volume of the intake manifold.

Repair cost: replacement of high-voltage wires and spark plugs, and sometimes filters, will be required. For everything you will have to pay about 5,000 rubles. Additional costs will be required for re-adjustment and repair of damage caused by the explosion. The final cost may exceed 15,000 rubles.

13. Worn fuel pump.

Signs: a characteristic hum is heard in the rear of the car. When driving on gasoline, sometimes there is not enough power, the engine runs intermittently and is difficult to start.

Reason: In some cars with LPG, the fuel pump wears out faster than usual. Much depends on the type of equipment and how it is installed.

Repair cost: depends on the model and type of pump. The cost of a new pump is from 2500 to 8000 rubles.

14. Worn valve seats.

Signs: The engine loses power or runs rough. The valve clearance cannot be adjusted correctly.

Reason: wear of valve seats is accelerated not by the gas itself, but by a lean mixture - the result of incorrect adjustment of the gas equipment. It is worth noting that the composition of the mixture must be correct not only in steady-state conditions, but also in transient conditions, for example, during acceleration.

Repair cost: the repair is very serious and consists of dismantling the head and regenerating it. The cost of restoration ranges from 13,000 to 25,000 rubles.

15. Wear of the ignition system.

Signs: an engine with an old type LPG does not work correctly - it “shoots” and stalls. For HBO with multipoint injection, this problem is not typical, or at least has less acute symptoms.

Reason: Creating a spark in a mixture of propane, butane and air requires a higher voltage than in a mixture of air and gasoline. For this reason, the ignition system is more stressed and wears out faster.

Repair cost: for a new spark plug you will have to pay from 150 to 1000 rubles. The cost of new high-voltage wires is from 2,000 to 20,000 rubles. A regular old-style ignition coil will cost about 1,000 rubles, and a cassette – 10,000 rubles.

16. Body corrosion.

Signs: corrosion occurs wherever the LPG installer intervened: near the remote filling device, under the screws securing the LPG wiring to the body, under the screws holding the gearbox, and also in the trunk - in the area where the gas tank is attached.

Reason: installation requires drilling holes in the body necessary for fastening the LPG elements. The holes are protected by simple methods - usually treated with aerosols, which do not always perform their role well.

Cost of repair: sometimes it is enough to clean the damaged areas of rust and re-treat them. In extreme cases, it is necessary to move the attachment points to other places.

17. Exhaust system corrosion.

Signs: the engine is noisy, you smell gas, and the exhaust system resonates when changing speed.

Reason: The combustion of liquefied gas produces more water vapor than the combustion of gasoline. As a result, the exhaust system corrodes faster and mainly on the inside. The exhaust system may "ring" and resonate, although upon inspection it appears to be in good working order and sealed.

Repair cost: in the case of popular cars, replacement will be cheaper: from 5,000 to 10,000 rubles.

18. Damage to the intake manifold.

Signs: the engine runs unevenly, stalls, and does not idle.

Reason: after installing the HBO, depressurization of the manifold may occur at the places where the injectors are installed. In cars with LPG for distributed injection, the gas destroys the manifold and other elements of the intake system, for example, the flow meter.

Cost of repair: It is very rarely possible to restore the manifold or other elements of the intake system. Repair consists of replacing damaged elements with serviceable ones (new or used). It is necessary to prepare for expenses in the amount of 3,000 to 20,000 rubles.

What to do if HBO does not switch to gas

In most cases, it is possible to detect and repair a breakdown with your own hands.

Airlock

So, the first thing you need to do is bring the level of antifreeze/antifreeze in the expansion tank to normal. Then, by pressing on the radiator pipes and simultaneously releasing gas, try to “drive” the air plug out of the evaporator reducer. If this method does not help, and you are also sure that there is air, then you need to remove the output hose from the gearbox and drain a small part of the liquid (by starting the internal combustion engine for a couple of seconds), after first replacing it with a clean container.

You can detect the presence of a plug in the following way: heat the car engine to operating temperature, compare the heating intensity of the pipes and the evaporator itself.

Next, check the correct installation of the gas equipment (we wrote about this here), also inspect the mechanical damage to the installation, and the presence of kinks in tubes/hoses.

Temperature sensor

If the work done does not give a positive result, you need to make sure that the wires going to the gearbox temperature sensor are intact, and also make sure that its connectors are free of traces of oxidation. Wiring twists are not allowed here, only soldering or secure terminals.

If there is no visible damage to the evaporator temperature indicator, its diagnosis is required. You can find a defect, knowing the parameters (resistance) of a particular sensor, using a multimeter. And if you have a cable for adjusting/diagnostics of gas equipment, as well as software, it will be possible to identify the fault much faster.

The reason that the HBO does not switch to gas (4th generation) is usually a breakdown of the sensor or adjustment of its operating parameters. If adjusting the values does not produce results, it will need to be replaced or repaired.

As an option, to start the gas installation, you can try to short-circuit the sensor wires and then get to the place where it is purchased/repaired.

Problems with the 2nd generation of HBO

In a situation where the 2nd generation of LPG on an injector or carburetor does not switch to gas, there are usually three reasons:

- airing of the gearbox or low fluid level;

- malfunction of the fuel type switch button;

- failure of the gas solenoid valve coil.

You can find all other causes and methods for eliminating them by following the links in the article. If you still have questions, ask them in the form below, we will definitely give a detailed answer.

Main malfunctions of HBO buttons and solutions

When installing and operating gas equipment, malfunctions in the operation of the fuel switch buttons are sometimes detected. What problems occur most often on 2nd, 3rd and 4th generation HBO buttons and how to solve them?

Problem: the LPG button is flashing and the gas level is not working correctly - the lowest LED is always on.

Solution:

- Check the serviceability of the sensor on the multivalve when the cylinder is filled;

- Check for broken wiring in the sensor itself. Remove the sensor, measure the resistance with a multimeter, and scroll through the readings with a magnet. Acceptable final resistance is either 0-30 Ohm or 0-90 Ohm;

- Look into the controller settings and make sure you have selected the correct sensor type;

- Perform calibration. Remove the sensor and use a magnet to expose the empty cylinder. In the controller settings, set it so that the reserve lights up, then use a magnet to turn the arrow on the sensor by about 25% and make settings in the program so that the corresponding LED lights up.

Problem: the LPG button beeps when switching from gasoline to gas.

Solution:

- Check to see if there is a break in the injector wiring;

- Replace main filters and gearbox filters;

- Check the amount of gas - there may not be enough pressure in the cylinder.

Problem: the car does not switch to gas, there is no light when the button is pressed.

Solution:

- Check if the unit is powered by a battery;

- Check for nitrous on the gas system fuse block;

- There may also be nitrous or a break at the connection point of the system start wire;

- If everything is fine, but when you press the button the diodes do not light up and the system does not work, inspect the LPG control unit - it may burn out.

After reading the review of HBO buttons, you now know about their advantages and main problems during operation, which will help you choose the most suitable option.

Spontaneous switching from gas to gasoline and back, reasons:

- First of all, I would recommend starting small - checking and, if necessary, replacing the filter, namely the coarse filter, which is located in the gearbox. If the filter is clogged, the gas supply will be difficult; as a result, the engine will automatically switch to gasoline and continue working on it.

- The problem may lie in the wires of the gearbox temperature sensor. To do this, check the wires for oxidation. Due to oxidation, resistance occurs that interferes with the correct operation of the sensor. As a result, temperature readings can very often vary between 30° and 80°. The LPG begins to change the injection time based on the temperature of the gearbox, and as a result, jerks begin while driving when running on gas.

- Gas quality. Strange as it may seem, it is precisely because of the quality of gas that spontaneous switching from gas to gasoline and vice versa very often occurs. The fact is that most gas installations operate on a propane-butane mixture, which, depending on the time of year, can be “summer” or “winter”. In the so-called “summer” one, butane predominates, in the winter one – propane, since this gas evaporates well even at low temperatures. As for butane, it is heavier and the process of its evaporation begins already at 0° and even +5°. However, due to the fact that butane is cheaper, gas stations are trying to save money and add more butane to the propane-butane mixture. At sub-zero temperatures, such a mixture evaporates poorly, the pressure in the cylinder decreases or even reaches zero, as a result, the liquid fraction of the gas does not enter the reducer. The engine “understands” this phenomenon in its own way, believing that the gas has run out and switches to gasoline.

A solution to this problem can be installing an adapter on the filling fitting and pumping air or nitrogen into the cylinder

4-5 atmospheres. With this modification, you can easily “overwinter” if you don’t let the tank empty completely.

- The gas-gasoline switch is faulty. Often the cause of a malfunction, when spontaneous switching from gas to gasoline and back occurs, may lie in the switch itself. In this case, it is necessary to check the switch and replace it if it is faulty.

- Provided option. If the engine itself switches from gas to gasoline at certain speeds, this may be provided by the settings of one or another LPG kit. There is an option that is provided in some gas installations, when the engine reaches a certain speed, the ECU gives the command to switch to gasoline to achieve greater engine efficiency and develop greater speed, for example, during acceleration or during overtaking.

- Poor gearbox heating. If there is an arbitrary switch from gas to gasoline, the reason may be poor heating of the gearbox with coolant. In this case, it is necessary to check the antifreeze level, as well as the correct connection of the gearbox heating lines; there may be creases or kinks in the hoses. In addition, you should check the vacuum line for air leaks or frozen hoses.

Check the gas reducer itself. Start the engine and let it idle, wait until the transition from gasoline to gas occurs. Then turn off the engine and disconnect the vacuum hose from the gearbox, take a soap solution and soap the outlet for the vacuum hose on the gearbox. The appearance of bubbles on a switched off engine will indicate a gearbox malfunction or the need to install a gearbox repair kit, as described here and here.

Filters

Clogged coarse filter or liquid phase filter. If the car owner has not undergone maintenance for a year or more than 10,000 km. path, then the liquid phase filter is most likely clogged and requires replacement.

You may be interested in an article on how to replace filters with your own hands on 4th generation LPG.

Solution: Replace the coarse and fine filters.

What other problems can there be on a car with HBO?

If the fuse on the main plus of the LPG system has burned out or oxidized, the fuel switch button will not work. Replacing the fuse will resolve the issue.

Malfunctions in the operation of the engine where landi renzo equipment is installed may not necessarily be associated with gas equipment. It is necessary to analyze at what point a situation arises when the internal combustion engine does not switch to gas.

When the speed is floating, the internal combustion engine does not operate smoothly; you need to look for the root cause in the following:

- You need to check the ignition, unscrew it and see what condition the spark plugs are in.

- Be sure to check the compression of the internal combustion engine on the bench.

- Contact a mechanic and have the valves balanced.

- Pay attention to the performance of the lambda probe.

- Adjust gas injection, check injectors.

- There may be malfunctions in the timing of the motor.

Sometimes drivers notice that a gas engine loses its power characteristics. The following breakdowns must be excluded:

- gas injectors do not cope with their task and are poorly adjusted;

- the reducer does not create the necessary pressure due to poor heating;

- the fault is a non-working lambda probe;

- gas filters are clogged;

- blockages in gas lines.

HBO is installed to save fuel. If excessive gas consumption occurs, you need to look for the cause of possible problems:

- broken gearbox, low pressure;

- clogged air filter;

- problems with the ignition system;

- The gearbox does not want to warm up.

- the operation of the gas injectors or injection system is disrupted;

- compression in the internal combustion engine is below normal;

- calibration fittings for injectors are selected incorrectly;

- factory defect of the lambda probe.

If there are failures during re-gassing, you need to re-calibrate the injectors, change the filter, see what pressure is in the reducer and check the integrity of the gas lines.

Additional Information

Regarding HBO-4, such systems use more advanced switches. Such switches have only 2 operating positions: turn on the gas and turn off the gas. Many switches for 4th generation gas equipment have an indication of the remaining fuel in the cylinder .

When you turn on the gas on modern gas equipment, an automatic system will be activated, which controls not only the warm-up temperature of the gearbox, but also the crankshaft speed of the Daewoo Nexia.

Unfortunately, in HBO-2, like in HBO-4, there is no possibility of starting a cold engine on gasoline. But this option is available in HBO-4+ and HBO-5. To start a cold engine on gas, you need special injectors that are not susceptible to icing .

Many Daewoo Nexia drivers note that the operation of HBO-2 is highly dependent on the street temperature. There are known cases when, in frosts of -10 C, gas-cylinder equipment refused to start. Of course, a lot depends on the components used, as well as the settings of the gas equipment. But if you compare the operation of GBO-2 and GBO-4, then with the fourth generation of gas equipment there are usually much fewer problems .

The number of problems with gas equipment can be reduced to a very minimum if you do not forget about the need to undergo routine inspections and repairs of gas equipment . It is necessary to regularly change fuel filters and gaskets . The gas reducer requires periodic cleaning, as do the gas injectors.

High-quality gas equipment maintenance will ultimately pay off in fuel savings. At the same time, the safety and comfort of movement will increase.

Useful tips

When the engine starts to run poorly when switched to LPG, or the gas equipment does not turn on, there is no need to tempt fate and bring the car to a state where it will no longer start at all. It is better to drive on gasoline until the problem is fixed.

The internal combustion engine will not switch to gas automatically if at least one of the sensors (temperature, pressure) is faulty or the gearbox is not heated. If there is no impulse from the tachometer, automatic switching to gas is not possible.

It is highly undesirable to repair gas equipment yourself. To do this, you need to understand the system and have the appropriate diagnostic equipment. First of all, you need to contact the specialists who installed the gas equipment to fix the problem.

When gas-cylinder equipment turns off at the most inopportune moment, it is often the fault of the drivers themselves, who do not want to understand the operation of the system and do not perform regular preventive inspections at the service station.

Breakdowns can occur in cars running on methane or propane-butane. Not all LPG manufacturers take into account that the car will not always be filled with fuel that meets European quality standards. Installing the system in a certified center will minimize the likelihood of problems with gas equipment and engine operation in general.

Types of sensors

Gas equipment of any generation is a complex system of several components, one of which is sensors. These hardware design elements are divided into two types:

Gas equipment began to be organized in a similar way from the second generation, but only in the fourth generation did the use of sensors become widespread. Of course, all manufacturers have differences in LPG sensors, but in general terms the principles of their design and operation are the same.