The engine has a lot of important components and mechanisms. One of them is the flywheel. It is this unit that transmits the generated torque to the box through the clutch. Also, thanks to the flywheel, the engine rotates when the starter is activated (when trying to start). In addition, the unit is designed to dampen vibrations and vibrations, and smoothly transfer forces to the box. In today's article we will pay attention to this type of mechanism, such as a damper flywheel. Volkswagen has been installing such elements for a long time. Statistics show that more than half of modern foreign cars with manual transmission are equipped with this type of flywheel.

Characteristic

So what is this element? The damper flywheel (dual-mass) is a mechanical disk-shaped unit. On one side it is attached to the transmission, on the other - to the engine crankshaft. Additionally, it has a ring with teeth, thanks to which it can rotate when the starter gear is engaged. The main task of the element is to transmit and smooth out torsional vibrations that come from the engine.

It is worth noting that the damper flywheel has some differences from conventional ones. Thus, previously, simple flywheels made of disc-shaped cast metal were installed on cars. These elements could not equalize the moment and smooth out vibrations. All impacts went directly to the gearbox and clutch. Let’s look at how exactly the damper flywheel is designed on the T5 and other cars below.

What is a flywheel and why is it needed?

When considering the specific functions of the flywheel, the following characteristics stand out:

- Reducing oscillatory movements when rotating the crankshaft. In this case, the flywheel can be considered as one of the engine parts.

- Transfer of torque from the engine to the gearbox. In addition, it is the primary clutch disc.

- Responsible for transmitting torque from the starter to the crankshaft.

In other words, the flywheel is necessary to perform three important functions: starting the engine from the starter, transmitting torque to the gearbox and ensuring smooth operation of the crankshaft.

The principle of operation itself is quite simple to explain: for clarity, imagine an ordinary toy top. If the top begins to spin by hand, then the flywheel begins to spin from the rotational movements of the crankshaft. The top will spin until the applied energy runs out. The drive disk is able to transfer the received energy back, thereby forcing the crankshaft to work. As a result, we have a closed system that ensures the operation of the flywheel.

Design

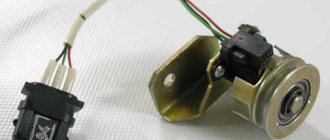

The main difference from single-mass flywheels is the presence of two disks. They are combined into one device. Each disk is attached to its own source - the box and the engine. In this case, the elements are able to rotate freely from each other. The discs are connected to each other by a bearing.

But how is torque transmitted from the motor to the box through such a flywheel, since the disks rotate freely relative to each other? For this purpose, the design includes springs and flanges. They can be of different shapes - in the form of a gear, an asterisk, or a polygon. These elements are closed with a sealing cap. Also note that the flanges and springs under this cover are filled with a special lubricant.

In total, the design of the damper flywheel includes:

- Primary disk.

- Secondary disk.

- Arc spring.

- Bearing.

- Sealing cap.

- Flange.

Purpose of DMF

If you look at the curve of the change in torque on the shaft, taken with high time resolution, it will be a purely oscillatory process. It is impossible to strictly transfer this to the transmission, especially if it is a powerful modern engine with a high compression ratio, high torque at low speeds and a minimum number of cylinders. The entire car will vibrate, and the transmission will quickly fall apart.

Typically, a massive flywheel is used to dampen vibrations, and a torsional vibration damper is installed in the clutch disc. If the transmission is automatic, then the torque converter additionally operates, but to save fuel it closes, starting from a certain speed.

This is interesting: After how many km do you change the engine oil and what will happen if you don’t do this?

All these devices work better the more fuel spent on their maintenance. A heavy flywheel is difficult to spin, as is a powerful damper, and the extinguished energy is partially spent on reducing the service life of parts.

As an alternative, but more advanced and effective solution, a dual-mass flywheel was proposed, denoted by the English abbreviation DMF (Dual Mass Flywheel).

It turned out that the energy in torque pauses can be replenished from that accumulated not only in the rotating masses, but also in the spring-damping mechanism, which is located between the two halves of the flywheel.

This makes it possible to reduce the total weight of the product while simultaneously improving its characteristics. This is especially noticeable on fundamentally harder-running diesel engines, with which it all began, and then downsizing products appeared in the form of small-cylinder turbo engines with a significant level of filling, which worked no less harshly on gasoline.

Features of work

Every year engineers create more and more powerful and efficient engines. Not so long ago, a one and a half liter engine developed no more than 80 horsepower. Now engines with this displacement produce 110 or more. More power is good, but as torque increases, acoustic and vibration comfort deteriorates. Various vibrations were constantly transmitted to the body.

For this purpose, a damper flywheel was created. It transmits torque evenly, without shocks. The flywheel itself works very simply. As we said earlier, one part of it is connected to the gearbox, the other to the engine. So, when the first part of the flywheel is deflected to the maximum angle, the moment is transferred to the second disk. And all vibrations and shocks are smoothed out thanks to damper springs. Note that the same springs are on the clutch element. However, they already smooth out the loads that are placed specifically on the disk.

How to check a dual mass flywheel

After dismantling the gearbox and clutch, it is easy to determine the presence of play in the flywheel mechanism. In the original state there should not be any, everything is clamped with new springs, although even without disassembling the car you can indirectly assess the condition of the flywheel by sharp acceleration from low speeds, when operating conditions are the worst.

The engine has maximum pulsation due to insufficient rotation speed, and the torque reaches its peak level. A faulty flywheel will make a knocking noise.

About faults and resource

Repair of the damper flywheel may be required after a mileage of 200 thousand kilometers. This is precisely the resource that this mechanism often has. How to check the damper flywheel? Malfunctions can be judged by the following signs:

- Grinding noise when stopping and starting the engine (as if the starter is still working).

- Clicking noises when accelerating dynamically.

- Characteristic vibrations. This happens especially often at idle. As they grow, the vibrations gradually pass.

What defects may the owner of a car with a damper flywheel encounter? Among the problems, the first thing worth noting is the leakage of lubricant that is located under the sealing cover. Malfunctions can also be judged by various creases, scratches and cracks on the surface of the element. All this can be seen visually by removing the box and clutch assembly. If there is no external damage, but vibrations and sounds remain, we can assume that there are defects inside (or the damper and spring element is broken).

A more accurate diagnosis will be at a specialized stand, where a technician will check the element for vibrations.

Recommended inspection times

Structure of a dual-mass flywheel

All car owners whose cars are equipped with DMF are recommended to periodically diagnose the unit in services. The period is determined independently, depending on the availability of time (about 1-2 times a year).

If during operation of the vehicle clearly noticeable rattling or strong vibrations are detected, especially when the engine is idling, a visit to the service station cannot be postponed. This is definitely a faulty node that has two DMF disks.

It is important to understand that operating a car with a faulty DMF threatens to completely destroy the flywheel.

About repairs

Our owners rarely replace the damper flywheel with a new one. Most often they resort to a cheaper solution - repairs. The fact is that the cost of a new flywheel is about 1 thousand dollars. And the repair price is no more than 500. But the problem is complicated by the fact that few craftsmen competently restore dual-mass flywheels. We also note that repairing the part will not be possible if there are cracks or dents on the body. In this case, the only way out is to replace it with a new one.

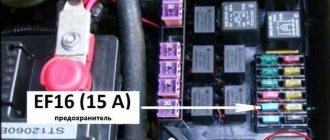

The process of restoring an old one involves dismantling the element and replacing its internals. During the repair the following is carried out:

- Replacement of all damaged elements.

- Installing new bolts.

- Balancing the flywheel (is a mandatory step).

- Lubricant replacement.

Experts do not recommend saving on details. If you install cheap springs, such a flywheel will soon require repeated repairs. As for the resource of the restored flywheel, it is about 200 thousand kilometers. But this is only possible if high-quality parts were used and the repair itself was carried out according to technology.

Pros of a flywheel

Is it worth buying a car with a similar mechanism? To answer this question, you need to consider all the pros and cons of the device. So among the advantages it is worth noting:

- Smoother gear shifting.

- Increased service life of internal combustion engine and transmission parts (since they are not subject to increased vibration load).

- Reduced inertial moment when switching speeds.

- Saving space in the clutch housing. This is an important point for cars with a small displacement.

Minuses

But there is also another side to the coin. First of all, it is worth noting the price of the mechanism itself. Such an element is very expensive, which certainly affects the cost of the car itself. It is also necessary to note the resource, which is lower than that of single-mass elements. When repairing, you should pay a large amount of money so that the part will again serve its 150-200 thousand kilometers.

But even with such shortcomings, the damper flywheel is increasingly used not only on passenger cars, but also on commercial vehicles. It is technologically more advanced, but at the same time, expensive to repair. You should only buy a car with such a flywheel if there are no obvious signs of wear. Otherwise, you will have to immediately pay about $500, or even more, for repairs. If we talk about new cars with a guarantee, buying cars with a similar flywheel is completely justified here.

A little about the 2-mass flywheel

Nowadays, almost 80 percent of all new cars are equipped with a 2-mass flywheel. This unit is mostly used in cars with diesel engines, however, they are not uncommon in gasoline units.

A 2-mass flywheel may be designated DMF. Installed in tandem with a gearbox, single or double clutch. It is not uncommon in CVT systems.

How does a dual mass flywheel work?

It will be useful to know that DMF has been used since the mid-80s. last century, but they became popular 10 years later. However, at first, 2-mass balancers practically did not fail.

Subsequently the situation changed. 2-mass flywheels began to fail more and more often. The designers were able to identify the specific cause of this problem. It turns out that the engines of older cars had low power, which was the reason for the longevity of DMF.

Over time, engines have become much more efficient, and permissible ECO emission standards have been tightened around the world.

Modern 2-mass flywheels can withstand at most 150-200 thousand kilometers in such conditions. Any replacement of the transmission mechanism forces the repairman to also work with the DMF. These are additional financial costs.

When replacing the clutch, it turns out that the flywheel is so leaky that there is no objective possibility of holding out for the same amount of time as the new mechanism. They cannot work in tandem, so the owner has to decide to install a new 2-mass flywheel.

In monetary terms, replacing a DMF costs a Russian 20-50 thousand rubles. The final cost depends on the specific car model. Such monetary expenses occur in retaliation for the comfort and aggressive driving style, because in many cases it is the driver who is involved in the early operation of the element.

How to save a resource?

To extend the life of the damper flywheel, you should know some rules:

- Do not significantly load the car. This applies to those who prefer to drive with a trailer. In this case, a colossal load is placed on the flywheel, and its service life is significantly reduced.

- Avoid towing other cars (for the same reason).

- Do not keep the clutch pedal depressed when stopping at a traffic light. It is better to immediately move the gearshift lever to the neutral position.

- Do not release the clutch pedal when changing gears.

- Avoid sudden starts from a standstill and aggressive driving.

- Do not drive at low speeds. This is especially harmful for diesel cars. Such engines produce significant vibrations, as a result of which the load on the flywheel increases. In this case, the springs of the damper system wear out.

This is the only way to maximize the life of this element in the car.

Let's sum it up

So, we found out what a damper flywheel is and what its features are. As you can see, this mechanism has a more complex structure than its single-disk counterparts. At the same time, the work of the damper flywheel is aimed at increasing comfort and reducing various vibrations. In conclusion, it is worth noting that the cost of maintaining a car with a manual transmission and such a flywheel will be no cheaper than a car with an automatic transmission. After all, the service life of a torque converter automatic transmission can be more than 250 thousand kilometers. And the damper flywheel on a manual transmission lasts one and a half times less. Therefore, you should not assume that a manual car will be cheaper to maintain and maintain. This is only true in the case of single-mass flywheels, which more and more automakers are now abandoning.