As you know, cheaper gas fuel allows you to significantly save money during the operation of various vehicles. To do this, it is enough to install HBO on your car.

In the case of gasoline engines, gas equipment has been used since the days of carburetor engines. Further development of gas injection systems made it possible to install similar solutions on injection engines, both on engines with distributed injection and on engines with direct injection.

As for diesel engines, just a few years ago it was not possible to convert diesel engines to gas, or such work would have been very difficult. However, today the situation has changed radically. Next, we will talk about how to convert a diesel engine to gas, what gas-diesel is, as well as what pros and cons this solution has.

How does HBO work?

Diesel fuel burns under pressure, but gas does not. The process will proceed as follows:

- The supply of diesel, which is responsible for ignition, is reduced.

- The gas injection process takes place.

Gas injectors will work simultaneously with diesel ones. Their ratio depends on the engine speed. Most often it is 50/50 for propane. If methane, the gas share increases to 70 percent and higher. If you're driving on the highway, gas usage will be highest.

Is it profitable?

If a gasoline engine runs entirely on gas, the cost of fuel costs is exactly halved.

Under favorable conditions, the payback of diesel gas equipment will occur in 70-100 thousand kilometers. And only after this mileage will you start saving. That is why gas is installed on a diesel engine only in rare cases, and only on domestic trucks. Such a system is practically never found on passenger cars.

Requirements for gaseous fuels

- ensuring good mixture formation;

- high caloric content of the combustible mixture;

- absence of corrosion and corrosive wear;

- minimal formation of deposits in the intake and exhaust tracts;

- maintaining quality during storage and transportation;

- low cost of production and transportation.

Benefits of using gaseous fuels

The octane number of gas fuel is higher than that of gasoline (the average octane number is 105), therefore the knock resistance of liquefied gas is greater than that of even the highest quality gasoline.

This allows for greater fuel efficiency in an engine with a higher compression ratio. At the same time, the combustion rate of gas is slightly lower than that of gasoline. As a result, the load on the cylinder walls, piston group and crankshaft is reduced, which allows the engine to run smoothly and quietly.

The gas mixes easily with air and fills the cylinders more evenly with a homogeneous mixture, so the engine runs smoother and quieter. The gas mixture burns completely, so no carbon deposits form on the pistons, valves and spark plugs.

Gas fuel does not wash away the oil film from the cylinder walls, and also does not mix with the oil in the crankcase, thus not worsening the lubricating properties of the oil. As a result, cylinders and pistons wear less, and the frequency of engine oil changes increases.

Compared to gasoline, liquefied gas has the following advantages:

- one and a half to two times less cost;

- higher detonation resistance (octane number 105);

- a gas engine runs smoother, and its service life increases by about one and a half times;

- the frequency of engine oil changes increases by one and a half to two times, since its aging period decreases;

- the service life of spark plugs increases by 40%;

- the gas contains practically no sulfur, which causes corrosion of metals and their wear;

- the toxicity of exhaust gases is reduced (CO by half, CH by 50...100%, NOx by 20...30%);

- unlike gasoline, the gas mixture is more homogeneous in composition;

- Resinous deposits do not accumulate on parts and devices of the power supply system, since petroleum gas dissolves them;

- Carbon formation on engine parts is significantly reduced.

Compressed natural gas compared to liquefied petroleum gas has the following advantages:

- greater safety, since it is lighter than air and evaporates in case of leaks;

- cheaper;

- large natural reserves;

- exhaust gases are more environmentally friendly.

Flaws:

- lower combustion rate compared to gasoline, as a result of which engine power is reduced by approximately 7...12% (up to 20%);

- difficulty starting the engine at low temperatures;

- an increase in the vehicle's metal consumption by 25...30 kg with liquefied gas and by 700...800 kg with compressed gas;

- the use of additional expensive equipment leads to an increase in the cost of the car by 20..27%;

- increased gas consumption compared to gasoline;

- the need for periodic inspection of gas storage cylinders at testing stations;

- the labor intensity of engine maintenance and repair increases by 3...5% (these costs are offset by savings from increasing the overhaul life of engines);

- the travel range at one gas station does not exceed 200...250 km;

- increased safety requirements when using gas cylinder installations.

Liquefied gas is commonly used in passenger car engine power systems. Converting a car to run on liquefied gas is easier and cheaper than converting it to run on compressed gas. In addition, liquefied gas is in a cylinder under relatively low pressure (approximately 1.6 MPa), and the high degree of rarefaction of compressed gas requires increasing this figure by 12-15 times.

HBO equipment

It has few differences when compared with gas equipment for gasoline engines. But on diesel engines it becomes possible to control the supply of diesel fuel using a special device.

For cars with different fuel supply systems, electronic activators or software units that control the system are suitable.

They allow you to shut off or open the gas system if necessary. Their advantages:

- Security system monitoring.

- Possibility of opening the gas supply if it runs out.

- The ability to force the car to use diesel by pressing just one button.

What cars is it used on?

To the question of whether it is possible to convert regular diesel to gas, the answer will be in the affirmative. Such an alteration is indeed possible. But it is also important to consider for which car such an upgrade is planned.

In theory, any engine that runs on diesel fuel can be adapted for gas equipment. Moreover, the standard type of fuel system used does not play a key role.

Conventional atmospheric diesel internal combustion engines and turbocharged engines can be converted to gas diesel.

The costs of re-equipping a passenger car are naturally lower compared to modernizing a truck or special equipment. But if the machine travels short distances, then the payback period for the equipment can be several years. Therefore, conversions in which diesel also runs on gas mainly concern commercial vehicles.

Economic effect

The most important thing here is monetary interest. The higher the oil price, the better gas fuel systems will develop. Developers are constantly developing systems, providing more and more diesel engines. The most important thing is the availability of appropriate gas stations.

Advantages of gas

Replacing fuel with gas provides the following advantages:

- Save time and money.

- Since the gas will burn better, all the characteristics and power of the car will increase.

- The engine will run quieter.

You might be interested >> Installing LPG on UAZ Patriot

Flaws

But there are some disadvantages:

- Installing LPG on a diesel engine is not a cheap pleasure.

- Problem with gas stations. Not all places have the option to purchase methane.

- You will only benefit from diesel fuel gas if you travel long distances in your car. That is, when more than 50 thousand kilometers are covered in a year.

As you can see, all the shortcomings relate only to the price of materials. There is nothing that reduces the technical aspects of the vehicle.

Advantages and disadvantages

The main advantage of methane or propane on diesel is reduced fuel costs. Savings can range from 10% to 25%. Maximum efficiency is felt when driving at medium speeds on country roads.

Truck with installed composite gas cylinders

Among the disadvantages are the long payback period for urban use or low mileage, the cost of re-equipment, as well as the presence of additional components that may fail.

Installation of gas equipment on diesel

Installing LPG on a diesel engine is not easy. There are 2 ways.

There is only one way - to convert a diesel engine for LPG

This method is easier. But he will radically switch the car to gas fuel. You won't be able to go back to diesel. The ignition temperature of fuel is about 300 degrees, while that of gas is 700 degrees. Therefore, you will have to redo the power and ignition systems. To do this you will need to make the following changes:

- Install spark plugs instead of injectors.

- Install gas injectors into the intake manifold.

- Remove unnecessary metal from the combustion chamber and install iron gaskets.

Method two - gas diesel

Regular gas cylinders may not be suitable for diesel. This is because, unlike a gasoline engine, a diesel engine runs without sparks. In such cases, gas diesel engines that inject fuel are suitable. Such engines operate simultaneously on two fuel options:

- Diesel, which is used to ignite the mixture.

- Gas used for transportation.

To control the processes, special sensors and a block for controlling gas equipment are used. They will allow you to make adjustments and monitor the situation. The control unit sends signals to the injectors and the engine. This ensures the supply of diesel fuel.

The best gas for diesel is methane. It can be mixed with fuel in a ratio of 4 to 1.

If you decide to use propane, you will need twice as much diesel fuel.

When comparing the benefits of methane and propane, the former is cheaper in price, but it is more difficult to find since most gas stations only sell propane.

A pump is used to supply fuel.

Advantages of gas equipment on diesel cars:

- You can drive using both fuel options.

- Less harm to the environment.

- Oil and engine life are increased.

- No risk of detonation.

You might be interested >> 2nd generation LPG for carburetor

Disadvantages of gas equipment on a diesel engine:

- Difficulty in setting up and regulating.

- You need a lot of space in your car to install a gas cylinder.

- It is necessary to frequently change the filter and drain the condensate.

- High price of equipment.

Installing LPG in a car with a diesel engine is much more expensive than with a gasoline engine. HBO is rarely installed on a diesel engine for passenger cars due to the high price of components. And for trucks and large equipment, such engines are a good option to save money.

Types of fuel used

Conversion of a classic diesel engine to gas is possible only for a specific type of alternative fuel. You cannot use methane and propane-butane at the same time.

In terms of cost, switching from diesel fuel to methane will be more expensive than converting from diesel to propane-butane. But this way the best economic effect is achieved.

Methane will allow better fuel economy, although propane will cost less to install.

Switching to propane allows you to use gas for no more than 30-50% of the total volume of fuel burned. And the share of methane can be up to 80%. The following characteristics are taken into account:

- engine speed;

- period of the year;

- load on the fuel system;

- road terrain;

- pressure and temperature indicators of gas;

- presence or absence of a turbine.

Considering all this and the principle of operation when diesel turns to gas, we can conclude that methane plants will be more preferable.

What is needed to install gas equipment on diesel?

- Control block. The main one in this system. It consists of controllers and controls the operation of the kit.

- Fuel pump. One of the most important components. Necessary for fuel supply. If you use gas, you will have to convert it.

- Reducer-evaporator. In cylinders, propane is in liquid form. An evaporator reducer is needed to turn it into gas. Methane is already in gas form, but a reducer is still needed to maintain pressure.

- Gas injectors. Necessary to pass gas into the combustion chamber.

- Fuel switch. It is needed so that the driver can manually change the fuel at will.

- Temperature, synchronization, gas sensors and others. Needed for the engine. Used to create a mixture.

- Gas cylinder. Quite large in size. This is where the gas is located.

- Highway. This is the tube through which gas flows from the cylinder to the engine.

- Refueling devices. Required for gas refilling.

- Multivalve. It is necessary that the gas can enter and exit the cylinder.

- Protective equipment. Needed to protect the cylinder from overfilling and to relieve excess pressure.

- Filter. Responsible for purifying gas from impurities and debris.

As you can see, LPG on a diesel engine has many advantages. It is indispensable for trucks and large equipment.

Payment for HBO 10%

Increasing state subsidies for natural gas motor fuel.

New information has appeared (news statement dated June 16, 2020) that 60% of the costs of switching vehicles to LPG are now paid by the government.

Energy Minister Alexander Novak explained that compressed natural gas (methane) is an environmentally friendly and economical type of fuel. Therefore, the government’s task is to support the gas engine industry.

From 2022 to 2024, the government will actively finance this area. In total, the state plans to invest 50 billion rubles. To re-equip one car, it takes from 80 to 150 thousand rubles. Alexander Novak predicts that new increased subsidies will make this procedure more affordable. Doubling the size of subsidies will make the transition to CNG feasible for 10-12 thousand cars already in 2022.

Government subsidies for converting vehicles to gas now cover 60% of costs instead of 30%. This applies to both individuals and legal entities. These subsidies significantly reduce the cost of converting a car to LPG. Now is the best time for this!

Gas for diesel engine

So, the active development of gas injection systems has led to the emergence of the fifth generation of gas injection systems. This scheme makes it possible to implement liquid phased distributed injection. The solution is suitable for installation on any fuel-injected cars, easily integrates and is compatible with OBD and EOBD on-board diagnostic systems.

In the case of a diesel engine, this scheme is also taken as a basis, allowing a modern turbodiesel to operate on liquefied gas. As a result, such an engine is often called a gas diesel engine due to the installed gas equipment.

It is important to understand that the installation and configuration process itself is very different from a similar procedure on gasoline engines. In other words, installing LPG on a diesel engine is a more complex task that requires significant modifications

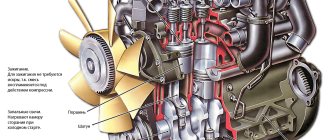

The principle of operation of a diesel engine on gas: features

The main difference between a diesel internal combustion engine and a gasoline one is the principle of ignition of the fuel in the cylinders. In gasoline units, a spark is used to ignite the mixture of air and fuel, which is created at the spark plugs.

In a diesel engine, air is first strongly compressed, which heats up from such compression. After this, at the last moment, the nozzle injects diesel fuel into the combustion chamber, then the heated and compressed fuel-air mixture ignites on its own.

Now let's move on to HBO. Methane or propane is used as gas fuel. However, if gas is supplied to the cylinders instead of diesel fuel, ignition will not occur. The fact is that to independently ignite the gas-air mixture, higher temperatures are needed compared to diesel fuel.

Taking into account this feature, it is necessary to first inject a small amount of diesel fuel into a diesel engine, and only then supply gas. Simply put, diesel fuel is ignited by compression, then igniting gas fuel.

Naturally, with this operating scheme, only partial replacement of diesel fuel with gas is possible, but in percentage terms we can talk about indicators of about 25-30% diesel fuel to 70-75% liquefied gas. It is quite obvious that this solution can provide significant savings on expensive diesel fuel.

Let us add that although the mandatory injection of diesel fuel does not allow you to completely switch to gas, this feature makes it possible to maintain the functionality of diesel injectors

In practice, this is important, especially considering the high cost of any elements of the fuel equipment of a diesel engine

We also note that an alternative to the solution described above is a complete conversion of diesel to gas. In this case, it is necessary to completely dismantle the fuel system of the diesel engine, install an external ignition system, modify the cylinder head, etc. As a result, the diesel engine will be able to run on methane, but the complexity of such modifications and the high cost of work do not allow this method to gain widespread popularity.

If we talk about the first scheme, the partial gas injection system takes into account the engine speed, the pressure of the air pumped by the turbocharger, the volume of injected diesel fuel, the position of the gas pedal, the load on the engine, the coolant temperature and a number of other important parameters.

Simply put, thanks to close interaction with standard internal combustion engine control systems, gas equipment “selects” and dynamically adjusts the required amount of gas supplied. This allows you to find and maintain the optimal balance between the amount of diesel fuel and gas for normal and stable operation of the engine in all modes.

Where should it be installed

As already noted, installing gas equipment on a diesel engine is highly complex. Therefore, this is a job for specialists who understand the intricacies of the issue. The installer must be licensed, and the list of works includes setting up and testing gas equipment. The installer will complete the necessary documents for registration and will subsequently perform periodic maintenance and inspections.

It may seem that installing a gas diesel engine differs little from the usual one. But we note that some work in garage conditions is impossible to perform efficiently. It's about setup, first and foremost. This cannot be done without a special stand.

The benefits of our gas-diesel technology

- Replacement of diesel fuel 60-70% in a mixed operating cycle.

- Possibility of conversion of any diesel engines, including COMMON RAIL EURO-4.

- Possibility to use both types of fuel: diesel and gas.

Gas diesel: scientific and educational film about technology

Gas to diesel: operating principle

*% replacement is in the range of 45-80%

| Total |

| Savings per 100 km, rub. |

| Savings per year, rub. |

| Savings over the life of the vehicle, rub. |

Replacement coefficient when using gas equipment on diesel engines

The electronic unit in the diesel gas equipment controls the fuel supply and controls the process of diesel substitution, which reaches 80% (peak substitution).

The replacement coefficient is calculated dynamically depending on engine operating parameters: speed, load, fuel pressure, turbine boost pressure; and is adjusted according to numerous factors: engine detonation, engine and incoming air temperature and other factors.

The software package allows you to achieve accurate calibration of engine operation in gas-diesel mode.

Retrofitting methods

There are 2 main ways to install gas equipment on a diesel engine.

- Complete refurbishment of the internal combustion engine. This allows you to completely abandon diesel fuel. But drastic changes have to be made. Here you need to change the compression ratio, install an ignition system, etc. In total, this will cost at least 200 thousand rubles. At the same time, the engine’s power and torque ratings will drop.

- Application of the Dual Fuel system. This is a dual-fuel system in which diesel fuel and gas are used in certain proportions. Modernization costs up to 100 thousand rubles.

It is the second method that is most widespread.

The principle of operation of a gas turbo engine

A turbocharged engine has a pump in its design, which significantly increases the air supply. The goal is to increase the pressure in the cylinders to improve the dynamic characteristics of the engine. This is its fundamental difference from the usual one.

The turbo engine is installed from the factory on some modern foreign cars: Subaru, BMW, Skoda, Mercedes Benz. Manufacturers thereby strive to increase the power of the car without increasing engine speed.

Installing gas equipment for a turbocharged gasoline engine does not fundamentally change its operation pattern. When it comes to HBO 4 for a turbo engine, the ECU intercepts the signals and transmits them to the normal process in a form adapted for operation on gas. Therefore, the engine works on the same principle as a gasoline engine.

If you select a gas propane turbo 250 hp, 5th generation, direct injection of gas fuel occurs in liquid form and again changes nothing in the principle of operation of the internal combustion engine. A computer program adapts the system to the alternative fuel.

Technically, installing gas equipment on a turbocharged car is simple. The performance characteristics of the car do not deteriorate; the same principle of operation is maintained. The type of fuel changes, and this is its peculiarity.