According to the existing regulatory requirements of the manufacturer, replacing the alternator belt, that is, on the generator set drive in the Lada Granta model, should be performed after every 30 thousand kilometers. It is recommended to check the condition of this element at 14-16 thousand periodic mileage.

Replacing the alternator belt is carried out following the basic principles of operation. The Lada Granta car is installed on a flat area without a slope. The generator drive does not have a tensioner, so the process is slightly more complicated; in some cases, replacement occurs without a tensioner. The instructions prohibit the reuse of the belt drive, since this component is endowed with the property of one-time stretching, which appears when the attachment is completed and placed under load at the factory (tension).

Re-use is resorted to only in emergency conditions, when, in the event of a breakdown, the belt is put back in order to get to the service center. In other situations, it is better to stock up on a new set in advance.

How to replace the Grant alternator belt

The replacement process is not simple and depends on the equipment of the car: whether there is a tensioner, air conditioning. In the latter case, you cannot do without a lift and dismantling the engine mount due to the air conditioning compressor clutch pulley.

For a Granta with air conditioning, for installation you will need to hang the wheel and remove one engine mount.

How to change a belt on a Grant 8 and 16 valve without air conditioning and tensioner

What you will need for work :

- a knife, if you just need to cut off an old part;

- crank or ratchet with head 13;

- long strong wire;

- flat screwdriver;

- partner – you can replace it yourself, but it’s easier with an assistant.

Step 1. Dismantling

The car is on a flat surface, neutral is engaged without the handbrake. The battery is disconnected .

If the old belt is not needed, we cut it in an accessible place and take it out.

If you need to save the old one, do everything up to step 3.

A replacement is needed with a length of 8223mm, six-wedge. Called 6RK 823. PHOTO: www.zr.ru

Step 2. Remove the generator mount

We approach the generator mount with head 13:

- we remove the lower bolt by 2-3 turns;

- Use it to completely unscrew the top bolt.

In this situation, we proceed to installation. PHOTO: www.zr.ru

Step 3. Raise the part

Scroll the generator up. The top mount becomes higher than the bracket to which it is screwed.

We press the part to the engine. We fix it with strong wire. For example, we hang it from the cylinder head bolt.

In this situation, we proceed to installation. PHOTO: www.zr.ru

At this stage, you can remove the old part if you did not cut it. We engage fifth gear and push the car back, squeezing the belt with a screwdriver from the generator drive pulley.

Step 4. Install a new one

We pull the new one onto the pulleys.

The installation takes place in the position of the generator when it is pressed against the engine. PHOTO: www.zr.ru

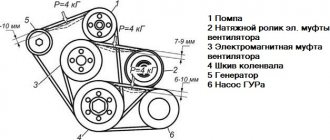

Engage fifth gear , push the car back, pressing the belt against pulley 1 in the picture. This is where a helper will come in handy.

As soon as we put it on, we work in reverse order:

- unplug the generator;

- press it into working position;

- return the upper mounting bolt and tighten the lower one.

Replacing the alternator belt on a Grant with air conditioning

It's more difficult here. Step by step :

- we drive the car onto a lift or overpass;

- remove the tensioner;

- take off the front right wheel;

- we support the internal combustion engine and dismantle the pillow;

- change the required part.

The whole problem is in points 5 (air conditioning compressor clutch) and 7 (right engine mount) - our belt passes through them (number 6). The rest: 1-drive of auxiliary devices, 2/3-tensioner, 4-generator. PHOTO: www.zr.ru

What you need

- new belt marked 6РК 995;

- spanners 8, 19;

- socket wrenches 8, 10;

- Torx keys T20, T27;

- ratchet with extension and heads E14, 17.

Step 1. Tensioner

The car is on a lift or overpass.

The front right wheel studs are loose.

Open the hood. Remove the terminals from the battery.

We find the tensioner, take out the spanners 19 and 8:

- 19 we put on the lead screw;

- 8 hold the locknut;

- we touch;

- Turn the lead screw clockwise to loosen the tension.

We remove the lock nut and loosen the tension. PHOTO taken from: www.zr.ru

Step 2. Get under the car

You need keys 8, 10 . Filming:

- central shield (numbers 1, 5, 7);

- right shield (number 2).

Step 3. Wheel

Remove the front right wheel. Using keys 8, Torx t20, t27, we dismantle the fender liner according to the diagram.

To work with the fender liner you need three different keys. Having removed it, we gain access to the engine support. PHOTO: www.zr.ru

Step 4: Engine Mount

Getting ready to remove the engine mount.

We securely support the engine under the crankcase - the support should take the weight of the internal combustion engine.

Using a wrench or ratchet with an E14 head, unscrew the screws securing the support to the engine .

Use head 17 to unscrew the screws securing the support to the body.

We remove the support. Make sure the weight of the engine is securely supported in the crankcase!!! PHOTO: www.zr.ru

Step 5. Dismantling and installation

We remove the belt from the pulleys and rollers and pull it out.

install the new one in the reverse order.

Do not mix up the screws that secure the mount to the engine. The top one (included in the triangular part) is shorter than the bottom one!

Confusion is dangerous for the further operation of the machine. PHOTO: www.zr.ru

The final tension can be adjusted by adjusting the tensioner.

DIY replacement instructions

A Lada Granta 8-valve car requires replacement of the alternator belt in the same way as a 16-valve car after identifying defects or according to the regulations. The procedure can be performed by a driver who does not have much experience in repair work. It is enough to have the necessary tools and basic knowledge of where the components that require replacement are located.

Tools and materials

Before replacing, you need to purchase a new alternator belt. In order not to make a mistake with your choice, you should look at the catalog number in the operating instructions. It should be 1118-1041020-07. The size should be 823 mm.

You should buy originals so as not to buy a fake or low-quality product. The packaging should be marked 6РК 823. You should not save money by buying a cheaper product. A low-quality belt will not last long, and the consumables will have to be changed earlier than required by regulations. High-quality belts are produced by Bosch and Gates.

You should also buy a tensioner pulley if you decide to change it too.

In addition to consumables, you need to prepare the following tools:

- a set of keys;

- TORX E-14 head;

- long screwdriver;

- jack;

- emphasis

Stages

The procedure for replacing the generator set belt on a Lada Granta with air conditioning is complicated by the fact that the belt passes through the support of the power unit. Therefore, before putting on a new strap, it will have to be dismantled.

Replacement consists of the following steps:

- First, using a “19” wrench, you need to loosen the lock nut of the strap tensioner lead screw. While unscrewing the locknut, hold the screw with the head at “8”.

- To loosen the belt tension, rotate the lead screw in the direction of movement clockwise. By following these steps, you can adjust the tension of the accessory drive belt.

- To replace the strap, you need to remove the right engine mount.

- Having moved under the car, you need to dismantle the right and middle protective shields of the engine compartment.

- Then unscrew the fastenings in the middle and front part of the right front wheel arch liner. Next, bend the fender liner behind the wheel brake disc.

- Using a jack, we hang the right front wheel and dismantle it. The fender liner fastenings can now be released.

- At the next stage, we place a stop under the oil pan of the power unit so that it holds the weight of the engine.

- Using a TORX E-14 head, unscrew the screws that secure the support to the cylinder block bracket of the power unit. Using the “17” socket, unscrew the two nuts and the support bolt that secures it to the body side member.

- We dismantle the engine mount with the cushion.

- Now, through the resulting opening, you can remove the strap from the pulleys of the auxiliary units and pull it out of the engine compartment.

- We install a new consumable in place of the worn-out product. In this case, its tension should be adjusted using the tensioner screw. The deflection of the belt in the gap between the air conditioner compressor and the power unit pulley with a force of 10 kilograms should be within 7-8 mm.

- We perform assembly in the reverse order of removal.

This completes the replacement. Now you know how to replace and tighten the generator set belt on a Lada Granta.

Instructions on how to assemble a tensioner on a grant

Any Grant has space for installing a tensioner. To assemble this you will need:

- generator bracket from Kalina;

- tension roller and its bracket;

- screw tensioner;

- new belt from Kalina;

- bushings and bolts.

Assembly diagram, full list of parts with article numbers, see below:

The tensioner is not installed from the factory in order to save money. SCHEME: Lada.online

in detail here:

Car with air conditioning: the differences are not only in the presence of a tensioner

Owners of cars with air conditioning will have to stock up on WD-40 or similar lubricant, a “10” key, and also a cylinder one, since the right front wheel will need to be removed.

We do not change the procedure, otherwise the lubricant will not have time to act.

- We wet the bolts securing the cushion and bracket.

- We support the front part of the car on the right with a jack.

- We remove the wheel.

- While lowering the car, unscrew the tension roller.

We work carefully because we only need a little engine lift.

Note that to work you will have to lower the car without the wheel.

An attempt to reduce the cost of cheap Grant configurations led to the absence of a tensioner on the alternator belt, which is why the latter can be over-tensioned and, as a result, fail.

Characteristics of the Lada Granta alternator belt

VAZ 2190 was launched on sale in 2011. The car is an economical version of the Lada Kalina with a larger trunk and a more modern generator mechanism. The mechanism for adjusting the alternator belt tensioner that is missing in the Lada Granta is its feature, unlike other models. The economy class model was designed to replace its own outdated predecessors, the creation of which had already been completed at AvtoVAZ.

Granta generally appealed to its own motivated audience. The low cost of the car helped her receive leniency towards complaints regarding the properties that accompany AvtoVAZ products. Just like no matter what kind of car produced by this concern, it has a number of shortcomings. alternator belt is also accompanied by measured problems . The supplier of belts for it is Gates. In relation to Grants, their recommended service life is equal to the warranty period of the car.

But, as the experience of the car’s owners has shown, closer to 5,000 km, a corresponding sound is heard, signaling that the alternator belt , unable to withstand a very strong tension. Despite the fact that the alternator belt is equipped with an automatic tensioner, in practice it is often overtightened, which leads to rapid rupture. A case without any problems is considered under warranty; the alternator belt is replaced, but with a significant time investment.

Those for whom it is not important to replace a consumable under warranty conditions create a replacement without the help of others. This is naturally faster, but you still need to spend time buying a belt and installing it.

General questions about working with the Grant generator

Let's consider general questions: everything except replacement.

Tension check

There are two approaches: visual assessment and physical.

Visual assessment of condition:

- the car is on a flat surface, the gear is in neutral, the handbrake is off, the hood is open;

- We don’t start the car - we put it in 5th gear;

- We opened the hood and found a generator: we push the car back, resting against the bumper;

- We inspect the required part along its entire length: are there any breaks or cracks? It needs to be changed.

Poor quality will lead to unexpected problems on the way.

Physical assessment :

- if you have a tool that measures pressure force: press the belt with a force of 10 kg*s - the deflection should be no more than 10 mm;

- there is no special tool: we try to turn it across - it should turn no more than 90 degrees.

How to tighten the alternator belt on a Grant

This section applies only to machines with a tensioner. No - change the part or see above how to install it.

Subsequence:

- we use ring wrenches 8, 19;

- Throw key 19 onto the lead screw;

- wrench 8 for locknut;

- we touch;

- Now you can turn the lead screw: clockwise to loosen, counterclockwise to tighten;

- got the desired result - tighten the locknut.

It is better to take ring wrenches, since a head with a ratchet or a wrench will not work.

When to change: technical regulations for replacing a VAZ 2190 belt

AvtoVAZ requires checking the condition of this part every 15,000 kilometers .

every 30,000 kilometers, regardless of condition.

How to remove a generator on a Grant

It needs to be removed for repairs, replacement of bearings or rollers.

The step-by-step process involves:

- remove the negative terminal from the battery;

- working with the generator: disconnect the wiring harness from it;

- remove the cover of the power wire nut, remove the nut and remove the wire from the bolt;

- unscrew and pull out the upper and lower fastening bolts - to work with the lower one, you may need to climb into a hole, throw off the tin protection of the internal combustion engine and dismantle it from below;

- move the part to the right mudguard, remove the belt, and remove it.

You can do without a hole . Example:

Possible breakdowns and their causes

In some cases, after carrying out technical work on the drive belt, a number of malfunctions may occur in the car. As a rule, most car owners panic and call a tow truck and send their car to the nearest service center for diagnostics.

Don't panic! In most cases, the car owner can easily fix all the faults on his own, without resorting to expensive diagnostics at car repair shops.

Typical faults and solutions:

Failure 1: The battery charge indicator on the dashboard flashes. Typically, this problem occurs when the drive belt is not tensioned. In this case, when it is running, the battery does not charge properly, due to which an error message is displayed on the dashboard.

Remedy: You need to adjust the belt tension. Then you need to disconnect the battery terminals for 30 seconds, and then return them to their place. After this procedure, start the engine. If everything is done correctly, the error will not be displayed.

Failure 2: generator pulley whistling. Typically occurs as a result of failure to clean during maintenance work.

Remedy:

- Clean the pulley by re-disassembling this unit, or apply a cleaning agent to the inner surface of the belt. Then you need to turn on the starter 2-3 times for short intervals of 10-15 seconds. Upon completion of this procedure, the malfunction should disappear.

- It is worth considering that if you leave this problem unattended, you will soon have to replace the belt. Contamination on the pulley serves as a sandblast, which destroys the inner surface of the drive belt, rendering it unusable.

Despite the rather complex design of the power plant, this car can boast of its driving performance and efficiency. It is precisely because of its driving characteristics and savings during operation that this car is widely in demand among citizens of the CIS.

Let's summarize

To work with the generator and to replace the belt you need:

- set of spanners, Torx t20 and 27, ratchet with heads or wrench, knife;

- if there is no tensioner, you can assemble and install it;

- if there is no air conditioner, replacement is easiest;

- is there air conditioning? To work, you need a pit or a lift with dismantling the engine support;

- They change consumables every 30 thousand mileage according to regulations.

More articles on repair Grants at the link.

Write comments and share your experience.

Solution

You can avoid regular contact with the described problem. There are several ways out for this.

- Generator replacement. Suitable for those who purchased a car with a ZiT generator. Since 2013, new Grants began to be equipped with a generator from Bosch.

- Replacing the bearing on the generator. This option, like the next two, threatens to void the warranty.

- Reduce belt tension by thinner fastening.

- Install the tensioner from Kalina.

Read:

Regarding the third point, some masters are not puzzled by finding a suitable option. They fix the standard fastening themselves, using a grinder and a sharpener to make it thinner. To implement the fourth option, contact a service station (also with loss of warranty) or perform all the manipulations yourself.

The alternator belt tensioner from Kalina installed in the Lada Granta will not relieve the car owner from worries. In the new design, the bracket requires close attention. Its service life is limited. It is subject to deformation during operation and cannot be restored, only completely replaced.

Reviews

| № | Positive |

| 1. | Victor: The factory RPM served me for 35,000 km, after which it was replaced by LYNXauto 13X1050LX. Both are good quality at an affordable price. |

| 2. | Ivan: after 30,000 km the RPM whistle appeared, tightened it a little, disappeared. It served for another two thousand, after which it broke off. I am satisfied with the quality of the original belts, there are no complaints. |

| 3. | Vladlen: I’ve heard negative reviews about RPM, I can’t confirm. Every 15,000 km I carry out diagnostics, moderate driving style, do not exceed 3500 rpm. |

| 4. | Ignat: at the first maintenance after purchase, the master tightened up the RPM a little, after which it served for more than 35,000 km. This is very good for the domestic auto industry. |

| 5. | Gennady: at the third maintenance, he did not change the “traditions”; he bought the original RPM, since there were no problems with the previous one, and served over 30,000 km. |

| 6. | Vasily: my recommendations to motorists, install the original RPM. Mine worked 33,000 km. I'm happy with the quality, no complaints. |

| 7. | Georgy: Every maintenance in a row I carry out RPM prevention, keep the engine compartment clean. There are no complaints about the quality of the belt, my recommendations are to buy the original one. |

| Negative | |

| 1. | Victor: My RPM has already flown 15,000 km. A whistle appeared and after 50 km it was torn into pieces, fortunately the speed was 90 km/h. |

| 2. | Gennady: despite the manufacturer’s specified service life of 30,000 km, my strap only lasted 20,000 km. I don’t recommend domestic ones; I think it’s better to pay extra for imported ones, but in good quality. |

| 3. | Vladimir: I join the negative reviews addressed to RPM, since domestic ones do not last more than 20,000 km. |

Related link:

How the heating system works on the Lada Grant. Stove heater diagram

Signs of wear on the RPM

Before you start replacing the RPM, conduct your own diagnostics and evaluate the actual condition of the parts and mechanisms. Perhaps the cause of the malfunction is in another unit adjacent to the generator.

- We open the hood, the engine must cool down so as not to damage the skin of the hand and fingers.

- We put the gear in neutral and turn the alternator belt. Rotation occurs quite easily, by hand, without special equipment.

- We inspect each area one by one.

Signs of wear on the RPM

The following will indicate the need to replace the RPM:

- fraying, side abrasions;

- peeling of rubber, thread fiber;

- other mechanical damage;

- teeth tears;

- the presence of oily traces and streaks on the surface of the belt.

If there are no comments on the RPM, we proceed to inspect the tensioner roller. Often the reason for the appearance of third-party noise is precisely this, worn-out roller bearings. We loosen the structure with our hands and check that it is working properly.

If the belt breaks on the way, it is allowed to travel on the battery's reserve energy, but not more than one hour. In practice, experts recommend no more than half an hour of free movement.