Using two 17mm wrenches, unscrew the nuts of the two bolts securing the bracket on the right side member of the body.

The lower bolt can be removed immediately, and the upper bolt can be removed along with the bracket.

We take out the cotter pin and use two 19mm wrenches to unscrew the upper nut from the axis of the pendulum arm.

We remove the axle with the lever from the bracket.

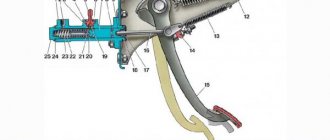

The bracket contains two plastic bushings (sliding bearings). At both ends of the axle there are two flats on which lock washers are installed. Rubber seals are placed on the bracket shoulders and the outer part of the bushings, which are held in place by lock washers. The plastic bushings should fit tightly in the bracket, and the lever axis should not have radial play in the bushings. When the bushings are worn out, replace them with new ones. When assembling, add Litol-24 or Fiol lubricant to the pendulum arm bracket. After tightening the upper nut, we check the turning torque of the lever axis in the bracket. The lever should rotate when a load is applied to its free end within the range of 1–2 kgf. Install the pendulum arm bracket in the reverse order of removal.

PENDULUM, WHAT'S INSIDE, WHICH PENDULUM IS BETTER, TIPS. replacing the pendulum of a VAZ 2106 Steering rods VAZ, Diagnostics, advice. REPLACING THE PENDULUM OF A VAZ CLASSIC. Replacing the pendulum on a classic

How to adjust the steering gear

Adjustment of the steering gear may be necessary if the steering wheel becomes very difficult to turn or a slight sticking is clearly felt when turning the steering wheel. Adjustment is carried out using a 19-mm open-end wrench and a flat-head screwdriver. In addition, for precise adjustments you will definitely need the help of a partner.

- The car is installed on smooth asphalt. The steering wheels are installed straight.

- The hood is opened, the steering gear is cleaned of dirt with a piece of rags. There is an adjusting screw with a lock nut on the crankcase cover of the gearbox. This screw is covered with a plastic cap, which will need to be pryed off with a screwdriver and removed.

Adjusting the steering column play

The need for adjustment arises after repair of the unit or when large play appears when turning the steering wheel. If the mechanism has a large free play, the wheels lag somewhat behind the movement of the steering wheel. To make the adjustment you will need:

- flat screwdriver;

- 19 mm wrench.

We align the steering wheel in the center, and then perform the following actions:

- Using a 19 mm wrench, unscrew the nut located on top of the steering gearbox.

Video: adjusting the steering column play on a “classic”

Replacing silent blocks on the lower arm of a VAZ-2107

Now the replacement process itself. Let's start with the lower arm of the VAZ-2107:

- For ease of work, we place the car in a viewing hole and immobilize it using a handbrake and wheel chocks installed under the rear wheels;

- We do not remove the wheel on the side where the replacement is being made, but it will have to be jacked up;

- We install wooden stands under the ball joint of the lower arm. After this we lower the jack. The height of the stands should be such that the wheel hangs out. Thus, we unload the lower lever;

- We unscrew the nuts securing the lever to the axle, having previously treated them with WD-40;

- You can press out silent blocks on this lever without any tools. Let's look at how to remove the front hinge (which is located closer to the front of the car). Before starting the process, you should generously treat the silent block with WD-40, making sure that the product gets inside between the axle and the inner race of the element.

- We take a pry bar, which will be used as a power lever, and rest it on the rear bolt securing the axle to the body (which is closer to the rear hinge). Using a pry bar, we move the lower arm back, while the silent block will rest against the car body. Using a pry bar to create force, we strike the side surface of the lever with a hammer. Since the hinge rests on the body, and the lever moves towards the rear of the car, the force created, including impact, leads to the silent block being pushed out of its seat. We do this until the hinge comes out of the socket as much as possible. Then we remove it by prying it with the same pry bar or a reinforced screwdriver.

- Before planting the new element, generously lubricate the seat and the silent block itself with soapy water;

- After removing the old rubber element, the seat will lower slightly relative to the axis, so before doing this you should lift it, centering the position of the hole;

- For pressing, you will need a piece of pipe whose walls will rest against the side of the holder (it will act as an extension). We put the silent block on the axle, having first moved the lever back as much as possible with a pry bar. We put a piece of pipe on the hinge and hit the attachment with a hammer until the side rests against the body of the lever.

In this simple way we press out and press in the front silent block. The rear hinge changes in a similar way, but there are several nuances.

First, you need to put on a washer and screw on the fastening nut from the side of the front hinge, having previously lubricated the threads and the axle itself with nigrol (the next time you replace it, it will be easier to unscrew the nut, and the possibility of the silent block sticking will be eliminated), so that during the process of pressing out the rear element, the lever rests against it.

Secondly, good access will be hampered by the steering end, which must be removed.

To do this, we use either a ball joint remover, or we remove it from the seat by creating tension with a pry bar and striking the socket body with a hammer.

How to identify a faulty pendulum

The easiest way to determine if the lever is faulty is to listen for knocking noises while driving on rough roads. You shouldn’t deliberately drive into a hole or run over a bump, so you can pull over to the side of the road and experiment

But this is not the only way to determine the malfunction of such an important part as the pendulum

The second way to determine whether the VAZ 2107 pendulum arm is faulty is the presence of large play in the steering wheel. This can be determined quite simply by turning the steering wheel in one direction and the other. But the most common case of pendulum failure is the presence of load when turning the steering wheel. But these factors do not always indicate that the pendulum lever is the culprit. Malfunctions with such symptoms may include loosening of the bolts or overtightening of the adjusting nut. Therefore, before you start replacing the device, you should definitely make sure that it is broken. This can be done after dismantling it. The first sign of a part malfunction is the presence of defects on its component elements, so to determine the failure you will need to disassemble the mechanism.

Location of the pendulum on the VAZ 2107

This product is located on a VAZ 2107 car from below the engine compartment. You can see the pendulum when you open the hood and look at the bottom of the car on the passenger side. It is most convenient to dismantle or examine the device from below from an inspection hole or on an overpass.

A bipod extends from the pendulum, which controls the rotation of the front wheels of the VAZ 2107. The photo below shows a view of the pendulum arm on the VAZ 2107.

Removal and repair of the pendulum

To carry out the work, you will need to stock up on a standard set of tools and a steering rod puller, and then begin the work process:

After removing the product, it is replaced or repaired. Installation of a new pendulum arm is carried out in the reverse order of removal. It is advisable to replace the pendulum arm only if it cannot be repaired. In frequent cases, the product can be repaired, which many motorists do on their own.

Repair of the mechanism is carried out using the following procedures:

The product is assembled in the reverse order of removal, but initially all parts should be lubricated with Litol-24

This completes the replacement of such an important device on the VAZ 2107. After assembly, you should check the steering wheel play

Currently, pendulum arms with rolling bearings are also sold on the market. There are different reviews about the reliability of this option. Everyone is inclined to believe that the pendulum on bearings facilitates the rotation of the steering wheel and lasts several times longer than the factory one, but it is not repairable. In the end, the choice is yours.

Source

↑ Assembly and installation of the pendulum lever

The bracket contains two plastic bushings (sliding bearings). At both ends of the axle there are two flats on which lock washers are installed. Rubber seals are placed on the bracket shoulders and the outer part of the bushings, which are held in place by lock washers.

The plastic bushings should fit tightly in the bracket, and the lever axis should not have radial play in the bushings. When the bushings are worn out, replace them with new ones.

When assembling, add Litol-24 or Fiol lubricant to the pendulum arm bracket.

After tightening the upper nut, we check the turning torque of the lever axis in the bracket. The lever should rotate when a load is applied to its free end within the range of 1–2 kgf.

Install the pendulum arm bracket in the reverse order of removal.

Replacing the swing arm

If repair is not possible, you can install a new swingarm and secure it. The procedure is the reverse of removing the pendulum from the car body.

Replacing the pendulum on a VAZ 2107 is a fairly simple process. You can make it yourself.

The first signal that needs to be taken into account and the pendulum replaced is a bent bipod of the pendulum arm. It is possible to carry out repairs to replace the pendulum without an overpass. Initially, it is necessary to dismantle the main filter housing so that it does not interfere. Next, you need to unscrew the castle nuts of the tie rods, as well as the ball pin nut. After this, it is necessary to press out the ball pins of both steering rods. To do this, a long steel rod is used, which is struck with a hammer.

Where is the swing arm located?

It is located under the bottom of the car, you can see it by opening the hood of the car and looking at the very bottom of the engine compartment, and the easiest way to look at it is from the bottom of the car, to do this, climb under the car and find the lever there that comes from the pendulum itself, and for clarity, this lever is indicated by an arrow.

Pendulum VAZ 2107: replacement, repair

Rear-wheel drive vehicles have a pendulum arm. In VAZ 2104 and VAZ 2107 cars, this is an important part of the steering linkage. It functions as a support on the right side and guarantees the desired steering angle ratio.

Functions and purpose

The steering gearbox is installed on the driver's side, and the steering pendulum mechanism is connected to the bipod on the passenger's side. They are connected to each other by a steering rod and serve as support points. The driver controls them by acting on the steering rod. The pendulum body is made of cast iron or aluminum and has the shape of a cylinder with holes for attaching it to the spar or to the frame. In the center, an axle is inserted through a hole, which is threaded through the body and makes the handle more movable, and also serves as a support for the steering rod. The other end of the bipod moves like a pendulum and therefore has this name.

Types of pendulums for VAZ 2104–2107

In the manufacture of pendulum levers, bushings are used, and the bearings on which the lever axis rests. They are designed to provide longer service life for moving parts. Manufacturers believe that bushings are more durable because, unlike fragile bearings, they are not subject to influences other than abrasion. However, both materials are subject to wear. If the elements are worn out, the driver will feel more tension in the steering wheel than usual, and it becomes difficult to control the car due to increased play. When hitting a hole or bump, extraneous knocks begin to be heard from the side of the pendulum, and the steering wheel travel increases. And if the mechanism itself is damaged, the bolts are loosened, or the adjusting nut is overtightened, then the wheel will rotate more tightly.

The designers tried to make the pendulum airtight and isolated the internal cavity of the body with two rubber rings, but usually after traveling 45–90 thousand km it has to be completely changed. When a car drives onto country roads, all the dirt is pulled inside.

Rolling bearings solve this problem; they are little subject to wear from contamination and do not require additional lubrication. But, unfortunately, not all manufacturers supply high-quality products to the market.

Selection of pendulum lever.

When choosing bushings or bearings, you need to rely, first of all, on the quality characteristics of the product. So, bushings can be made of polyurethane and will last longer. The pendulum handle on bearings moves more easily and freely, therefore it does not put stress on the steering wheel and is considered by many drivers to be more durable, but in fact, it all depends on the quality. If you buy a good product, you will not have to repair or replace it often.

Replacement of the pendulum lever of VAZ 2107, VAZ 2104.

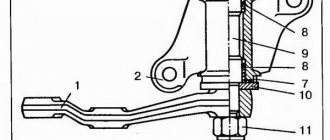

Pendulum design for VAZ 2104 - VAZ 2107 1 - bipod; 2 — bracket body; 3 — washer; 4 — adjusting nut; 5 - cotter pin; 6 — upper washer; 7 - seal; 8 — bushing; 9 – axis; 10 — lower washer; 11 - lock nut.

Many owners of VAZ 2104 - VAZ2107 cars buy, make repairs and change the pendulum themselves.

To do this you need:

- prepare tools, use the repair kit for the VAZ 2107 – VAZ 2104 pendulum;

- remove the front right wheel;

- unscrew the nuts securing the bracket on the right side member;

- the most time-consuming part is pressing out the ball pins of both steering rods. It is better to use special ones for these purposes. puller for tie rod ends. But you can also go a cheaper way: to do this, you can take a steel rod and rest it on the ball pin, the nut is not completely unscrewed, and start hitting it with sharp blows of a hammer.

This must be done carefully so as not to strip the threads or flatten the castle nut, so it is better to screw on another nut.

- remove by unscrewing two nuts, while on the other side you need to put on an adjustable wrench that will keep the bolt from turning;

- unscrew the top nut;

- remove the axle from the bracket. During assembly, add lubricant to the pendulum arm bracket.

- The bushings should fit tightly in the bracket, and the axle should have no radial play. When the bushings are worn out, replace them with new ones.

- check the turning torque of the axle - by tightening or loosening the nut, observe while turning the bipod. When turning, the bipod should “walk” easily and without effort. The lighter this force, the less it will be transmitted to the steering wheel.

Designs on bearings cope better with this task.

- check the play on both sides;

- tighten the top nut;

- install the bracket in place.

Repairing the pendulum on a VAZ 2104 - VAZ2107 car is not difficult and will not take much time, but to be sure of the result, it is better to contact a professional.

korchim.ru

VAZ 2106 bearings in the pendulum

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

I also installed “left” bearings on the bearings at first. Soon it crashed and I ended up putting it back on bushings.

so you need to take the right ones, I got myself a light steering wheel on bearings from a kit, the one that is sold in Elex Lada, I almost dashed off 40 thousand and everything is fine

. that a normally lubricated, bushed lever is not much tighter.

My bushings were flying every 15k, I replaced them with bearing ones and forgot about them.

lucky.

My bushings were flying every 15k, I replaced them with bearing ones and forgot about them.

lucky.

The original factory one on the bushing fell apart at 5 points. I replaced it with a bearing one (Moscow, there is no nut on top, it is tightened from below with a hexagon. I have already driven 26 thousand. Everything is OK. There are no backlashes and the steering wheel is light.

the quality of levers on bearings cannot be high, since they are not placed on a conveyor, and, accordingly, their production is artisanal. IMHO, and most likely the design in this form does not allow the use of the bearing under such loads, otherwise the Italians would have installed such a unit..

the quality of levers on bearings cannot be high, since they are not placed on a conveyor, and, accordingly, their production is artisanal. IMHO, and most likely the design in this form does not allow the use of the bearing under such loads, otherwise the Italians would have installed such a unit..

Excuse me, but I haven’t heard a more idiotic answer. First of all, the kit? Light steering? ? the latest development of the company ?Actual? approved by the Scientific and Technical Center (STC) of AvtoVAZ, as well as a number of independent examinations. ?Light steering? is a fundamentally new development based on the VAZ-2105 worm steering mechanism and is intended for installation on “classic” ones. VAZ models: 2104, 2105, 2106, 2107, Niva., the kit uses a pendulum on bearings, and it was not made in a garage; secondly, the Italians made a classic 30 years ago, it doesn’t even have a heated rear window, that doesn’t mean that heating is not needed, following your logic, then if the classics were made 100 years ago when the steam engine was in fashion, then the introduction of an internal combustion engine is also not necessary

it’s just that in 30 years new developments appear that are not profitable for the plant to install because this is a significant increase in price, especially since the classics were taken out of production, remember the beards in cars there are still mounting holes there for receivers that do not exist in life (currently in museums) and the last ones before You need to try something to write yourself and then give advice. For example, I installed a pendulum from the above-listed device and I’m happy as an elephant