The topic of this article is the VAZ-2110 engine (8 valves) injector in the fuel injection system. The main task is to find all its advantages and disadvantages and compare it with a carburetor engine. But to do this, you will need to delve a little deeper into history, look at how this engine was developed, how good it is in operation and repair. And the story will begin in the late 70s of the last century, when VAZ engineers started thinking about designing front-wheel drive cars. And then we will look at the injection system, its differences from the carburetor, its advantages and disadvantages.

Engine history

And now the story about where the VAZ-2110 engine (8 valves) injector comes from. And it was put in place at the end of the 70s. During these years, designers begin to understand that the classics produced for many years have a high cost. In addition, the Fiat 124 was the best car in Europe in 1964. Almost two decades have passed, the model range needs to be updated. And the experiments began. First of all, we modernized the gas distribution drive and started using a belt. But it did not take root on the VAZ-2105 engine (production years: 1980-1988), although it reduced the noise level.

The reason is simple: the pistons need scrapings that prevent them from hitting the valves if they break. But when repairing engines, pistons with 1.3 liter engines were installed, as a rule, of suitable size, but without recesses. But in the early 80s the eighth generation was released. Newer, comparable to European counterparts. And most importantly, the cars have front-wheel drive, a motor with a belt drive to a timing mechanism. And this was the same engine that, with a lot of modifications, is installed on modern cars. On models 2109 and 2110, these power units were adapted for the first time to an injection system.

How to get rid of the smell of gasoline

To understand where the smell of gasoline may be coming from in your car, you should study the car's fuel supply diagram. Let's look at the example of a car of the tenth family:

Osipov Mikhail, VAZ 2112, Toyota Camry, driving experience 11 years.

Hi all! My name is Mikhail, now I’ll tell you a story about how I managed to exchange my two-wheeler for a 2010 Camry. It all started with the fact that I began to be wildly irritated by the breakdowns of the two-wheeler, it seemed like nothing serious was broken, but damn it, there were so many little things that really started to irritate me. This is where the idea arose that it was time to change the car to a foreign car. The choice fell on the melting Camry of the tenth years.

Yes, I had matured morally, but financially I just couldn’t handle it. I’ll say right away that I am against loans and taking a car, especially not a new one, on credit is unreasonable. My salary is 24k a month, so collecting 600-700 thousand is almost impossible for me. I started looking for different ways to make money on the Internet. You can’t imagine how many scams there are, what I haven’t tried: sports betting, network marketing, and even the Vulcan casino, where I successfully lost about 10 thousand ((The only direction in which it seemed to me that I could make money was currency trading on the stock exchange, they call it Forex. But when I started delving into it, I realized that it was very difficult for me. I continued to dig further and came across binary options. The essence is the same as in Forex, but it’s much easier to understand. I started reading forums, studying trading strategies. I tried it on a demo account, then opened a real account. To be honest, I didn’t manage to start earning money right away, until I understood all the mechanics of options, I lost about 3,000 rubles, but as it turned out, it was a precious experience. Now I earn 5-7 thousand rubles a day. I managed to get the car buy after half a year, but in my opinion this is a good result, and it’s not about the car, my life has changed, I naturally quit my job, I have more free time for myself and my family. You’ll laugh, but I work directly on the phone)) If If you want to change your life like me, then here’s what I advise you to do right now: 1. Register 2. Practice on a Demo account (it’s free). 3. As soon as you get something on the Demo account, top up your REAL ACCOUNT and go to REAL MONEY!

I also advise you to download the application to your phone, it’s much more convenient to work from your phone.

Reason #1: Filler pipe (2108-1101080). This is the hose that connects the filler neck and the gas tank. It cracks due to age, the problem is solved by replacing it. Reasons: gasoline leaks when the tank is full and when refueling.

Gasoline vapor recovery system (Separator), on VAZ 2110, 2111, 2112 it is mounted under the left rear fender. We check/blow out the hoses and, if necessary, change/clean them with a spoke and a compressor. By the way, these are not the only pipes that can leak; carefully check the entire fuel line for leaks.

- We remove the separator ventilation hose from the side member (in the arch of the removed wheel).

- We heat the end of the hose in hot water or crush it with pliers.

- We put the purchased valve with a cap on this hose.

- We take our device behind the separator and secure it with clamps.

Reason No. 3: Attaching the fuel pump. The fuel pump is secured using a pressure ring, and an O-ring is installed to prevent gasoline vapors from entering the passenger compartment.

We check the condition of this gasket, the terminal block seal on the fuel pump and whether the clamping ring nuts are tightened sufficiently (removal instructions).

It is not uncommon for fuel tank studs to break and have to be rebuilt. A temporary solution in this case is to seal the gas tank flap with tape.

Our readers recommend!

In order to get rid of constant fines from cameras, many of our readers successfully use Special Nano Film for license plates. A legal and 100% reliable way to protect yourself from fines. Having familiarized ourselves and carefully studied this method, we decided to offer it to you.

Our readers recommend!

In order to get rid of constant fines from cameras, many of our readers successfully use Special Nano Film for license plates. A legal and 100% reliable way to protect yourself from fines. Having familiarized ourselves and carefully studied this method, we decided to offer it to you.

Keywords:

- gas tank

- bad smells

- car fuel system

Main engine components

No significant differences may be detected upon a cursory examination. Both carburetor and injection systems do not affect the basic design of the engine. But it's worth taking a closer look at the little things. For example, take a look at the VAZ-2110 injector thermostat (8 valves). What immediately catches your eye is that it can be taken apart! Exactly! Engineers in Europe sit and think about how to reduce the life of a car, while ours at the same time carry out real improvements that are for the benefit of the consumer. It is clear that it is not the housing that breaks in the thermostat, but the insides - the temperature-sensitive element or valve. Therefore, why produce millions of cases? It will be much more profitable to make one for the car, and if the thermostat breaks down, change only the insides.

But these are not all the advantages of domestic engines. Please note that in the USA and Europe all cars are the same, sometimes there is no point in repairing it, it’s easier to throw it away and buy a new one. The reason is partly in the engine. For example, AvtoVAZ is almost the only plant that continues to install internal combustion engine blocks made of cast iron on its products! In all developed countries, aluminum alloys have long been used for this purpose! The service life of the engines suffers, but most importantly, there is no way to repair it, since it cannot be bored or relined. And this is much cheaper than buying a new engine or car. Maybe a wealthy burgher can afford this, but in our country a car is still a luxury for many people.

What is an injector?

Now let’s see what the injector circuit looks like on a VAZ-2110 car, let’s look at the main components and operating principle. But first you need to answer the questions of what an injector is and what it is needed for. Everyone knows that until the end of the 90s carburetors were installed. In them, with the help of air flows, mixture formation took place, and then supply to the intake manifold of the fuel system. Moreover, such a cunning device can mix gasoline with air in an ideal proportion - 14 to 1. But there is a game of vacuum and atmospheric pressure.

Important nuances

When replacing the gas tank and the studs on it, we must not forget about several important points:

- Fire safety. Work on the gas tank, as well as on any part of the vehicle’s fuel system, should only be carried out in a well-ventilated area or in the open air. There should be no sources of open fire or flammable materials nearby. And, of course, there should always be a fire extinguisher at hand;

During any work on the VAZ 2110 fuel system, a fire extinguisher must be nearby

When screwing new studs into a VAZ 2110 tank, it is recommended to treat them with THREADLOCKER sealant

Replacing the tank is not a very complicated procedure. Even a novice car enthusiast can do it. To successfully complete this operation, he will need not so much repair skills as physical strength: removing a large tank with remaining gasoline from under the car is quite difficult. And if the car owner cannot boast of a strong physique, then at this stage he cannot do without an assistant.

Injector features

But the VAZ-2110 engine (8 valves) injector is much simpler than the carburetor version. But this is from the point of view of an electrician. The fact is that the system consists of many electronic devices that are responsible for the operation of the entire engine. Instead of a carburetor, a ramp is installed on the intake manifold. Essentially, this is a piece of pipe that contains the air-fuel mixture. It is pumped from the tank using an electric pump under low pressure. By default, the ramp is completely sealed; it is separated from the intake manifold channels by electromagnetic valves - injectors. But here’s the peculiarity: a constant pressure is maintained in the ramp, which is regulated by a sensor, and the quality of the mixture and the amount of gasoline supplied depend directly on how open the throttle valve is.

Purpose and place of fuel hoses in VAZ cars

The fuel system of any car consists of a relatively small number of components - a tank, filters, a pump, a carburetor (in classic carburetor engines) or a fuel rail with injectors (in injection engines), etc. All these components are connected by a network of pipelines through which fuel circulates. In this case, pipelines consist of two parts - metal tubes and rubber hoses.

The combined design of pipelines is used for a reason. The fact is that individual parts of the car and components of the fuel system, although they are fixed in strictly defined places, still do not have an absolutely rigid fixation. While the car is moving, parts, especially those located on the engine (carburetor or ramp with injectors), move relative to each other, so they cannot be rigidly connected with metal tubes. Elastic rubber hoses come to the rescue, ensuring uninterrupted fuel supply regardless of the position of the fuel system components.

If we talk about fuel hoses in general, they perform several main functions:

- Communication of vehicle fuel system components;

- Compensation for longitudinal and transverse displacements of fuel system components during vehicle operation;

- Compensates for movement of fuel system components when performing various adjustments, maintenance or repairs.

Thus, they play an important role in the operation of the vehicle. This fully applies to all cars of the Volzhsky Automobile Plant, the hoses of which will be discussed in more detail.

Diagram of the injection system

So, now in more detail about the power supply systems of the VAZ-2110 injection engine. First on the list is the fuel pump. It is mounted directly in the tank, together with the filter, and the engine rotor is driven only when the ignition is turned on (provided that the pressure in the ramp is below the minimum level). Next, the fuel flows through the tubes into the ramp. This is where the mixture is formed. The air first passes through a filter for purification. The filter housing is connected to the throttle assembly by a flexible pipe.

Recommendations

Every car enthusiast can do a lot to extend the life cycle of all elements of the unit in question. To ensure that your car's power system works flawlessly, use the following recommendations:

- Refuel only at approved gas stations.

- Replace fuel and air filters in a timely manner.

- Use cleaning additives with caution.

- Try not to drive on a half-empty gas tank, especially in winter.

Source

Sensor system

The VAZ-2110 engine (8 valves) is no less interesting. The injector, a control system device, to be more precise, includes many sensors. All control occurs using sensors. So, between the filter and the throttle there is a mass air flow sensor. A position sensor is mounted on the damper itself. In the ramp - pressure. In addition, between the second and third cylinders on the surface of the internal combustion engine block there is a knock sensor. And on the generator drive pulley - engine speed. The vehicle's speed is measured from the gearbox. All data that comes from reading devices is sent to the electronic control unit.

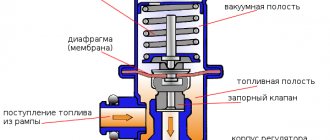

Fuel pressure adjustment

How is pressure maintained in the fuel system of the VAZ-2110? On cars with VAZ-2111 and VAZ-2112 engines, a pressure regulator is installed directly on the fuel rail. With its help, a certain pressure value is maintained inside. Moreover, it allows you to maintain both air pressure in the intake pipe and fuel inside the ramp.

The design of the regulator is not very complicated. Inside it are a valve, a diaphragm and a return spring. When the engine is running, the regulator allows you to maintain pressure in the range of 284-325 kPa. On the one hand, the diaphragm of the device is affected by fuel, and on the other, by low pressure in the intake pipe. As soon as the pressure in the intake manifold decreases, the valve begins to open. In this case, excess fuel is passed into the drain line to the tank. The pressure in the ramp is significantly reduced.

As soon as the pressure in the intake manifold increases (this happens when the damper opens), the valve on the regulator begins to open at a significantly higher pressure of the fuel mixture. At the same time, the fuel pressure inside the ramp increases significantly.

But on VAZ-2114 and VAZ-21124 engines, the pressure regulator is placed inside the module, next to the fuel pump. This is a kind of check valve in the fuel system of the VAZ-2110, which operates at a certain pressure (about 400 kPa). If the pressure exceeds the norm, the drain line opens and excess fuel is returned back to the tank.

Source

Electronic control unit

This is, so to speak, the very heart of the system. On the VAZ-2110, the injector circuit comes down to precisely this device. A small case with many pins, and inside is the most interesting thing - a microcontroller. It is he who regulates the entire operation of the engine. The internal memory contains a so-called fuel map. Using it, the controller determines how much air and gasoline must be supplied to the ramp so that the engine operates in normal mode and detonation does not occur. But the most important thing is how long it is necessary to apply an impulse to the fuel injectors so that they open and inject the mixture into the combustion chamber.

Fuel filter BAZ 2110

The main task of a car fuel filter is to clean the supplied fuel from dirt, dust, condensate and fuel resins. To ensure smooth operation of the engine and reduce the likelihood of its failure, it is recommended to change the VAZ 2110 fuel filter every 15-20 thousand. km run. However, the specific timing of replacement is determined by the quality of the fuel used, the conditions of use of the car, as well as its total mileage.

The formation of dust and dirt entering the fuel filter is explained by the interaction of gasoline with metal and air in the process of various chemical compounds. If you do not replace it in a timely manner, then this element will gradually become clogged with harmful impurities and dirt, resulting in an increased load on the engine and lower reducing its power. Also, various chemical impurities, dirt and dust will begin to enter the engine, which will inevitably lead to problems with its operation, and in the future, failure.

Which is better: carburetor or injector?

And now a little about which VAZ-2110 engine will be more reliable: an injector or a carburetor? But you need to look at this issue from different angles. For example, beginners will like the injector. Constant speed, there is no need to shut off the air supply in cold weather, and starting off is much easier. But there is another advantage - the car is more responsive at high speeds. Even at a speed of 120 km/h, when you press the gas pedal, the car quickly picks up speed. With carburetor engines this happens much more slowly. Therefore, overtaking in a car with an injector is safer. But when starting from a traffic light, the carburetor will easily “break” the injector. And the reason is higher torque at the bottom. And the cost of maintenance, of course, is higher for injection “tens”, since sometimes it is not easy to make an accurate diagnosis in the event of a breakdown.

VAZ 2110 injector engine, diagram and principles of operation of the “tens” injection engine

The VAZ 2110 is an injector engine that is distinguished by its efficiency, increased power and stability of operation when compared with the VAZ 2110 carburetor engines. The widespread use of injection engines at AvtoVAZ began in the 2000s. Today we will tell you in detail how the “ten” injection engine works. It is worth recalling that the “ten” injection engines were installed with different volumes and number of valves. Today on the secondary market you can find injection VAZ 2110 with 8 and 16-valve power units with a displacement of both 1.5 and 1.6 liters.

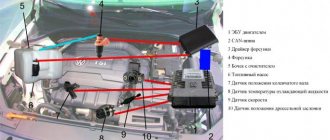

VAZ 2110 engine injector, operation diagram

Power units with an injector differ from carburetor versions in the principle of supplying fuel to the combustion chamber of a gasoline engine. If a carburetor engine needs to “suck” fuel from the carburetor chambers, then in the injection version fuel is injected under pressure through nozzles. This is much more economical, since the solenoid valves of the injectors allow only the required amount of fuel to pass through and not a drop more. This is closely monitored by electronics, which gives commands using information from various sensors; after analyzing all the data, the necessary impulse is sent to the injector and it supplies fuel to the engine. Moreover, the entire process occurs almost instantly. Below is a detailed diagram of the operation of the VAZ 2110 engine injector.

- 1 – ignition relay

- 2 – battery

- 3 – ignition switch

- 4 – neutralizer

- 5 – oxygen concentration sensor

- 6 – nozzle

- 7 – fuel rail

- 8 – fuel pressure regulator

- 9 – idle speed regulator

- 10 – air filter

- 11 – diagnostic block

- 12 – mass air flow sensor

- 13 – tachometer

- 14 – throttle position sensor

- 15 – indicator lamp “CHECK ENGINE”

- 16 – throttle assembly

- 17 – immobilizer control unit

- 18 – ignition module

- 19 – coolant temperature sensor

- 20 – controller

- 21 – spark plug

- 22 – knock sensor

- 23 – fuel filter

- 24 – fan switch relay

- 25 – electric fan of the cooling system

- 26 – relay for turning on the electric fuel pump

- 27 – fuel tank

- 28 – electric fuel pump with fuel level indicator sensor

- 29 – gasoline vapor separator

- 30 – gravity valve

- 31 – safety valve

- 32 – speed sensor

- 33 – crankshaft position sensor

- 34 – two-way valve

The most important element of the power system of the “ten” injection engine is the electric fuel pump, which is located in the tank; it is this that constantly provides the necessary pressure in the ramp with injectors through which fuel is supplied to the intake manifolds. The fuel pump in the VAZ 2110 injector is quite noisy. It is enough to insert the ignition key and turn it, and you will hear the characteristic “buzzing” of the electric fuel pump inside the car. If you do not hear a buzzing sound before starting the engine, but the engine still does not start, then the fuel pump is faulty. And therefore, it will not be possible to start an injection engine from the “pusher”, because there is still no pressure in the ramp and injectors, which means that fuel will not be supplied.

Repair and maintenance of injection engines requires special diagnostic equipment. The VAZ 2110 was equipped mainly with injection engines with a displacement of 1.5 and 1.6 liters, both 8 and 16 valve versions. Below are brief characteristics of these motors in the table below.

Engine model

| Working volume | Number of valves | Power hp(kW) | Torque Nm | |

| VAZ 2111 | 1499 cm3 | 8 | 76 (56) | 115.7 |

| VAZ 2112 | 1499 cm3 | 16 | 93.5 (69) | 128 |

| VAZ 21114 | 1596 cm3 | 8 | 82 (60) | 125 |

| VAZ 21124 | 1596 cm3 | 16 | 89 (65.5) | 131 |

The most powerful engine of all that was installed on the “ten” is the injection 16-valve VAZ-2112 with a volume of 1.5 liters. However, this power unit has one drawback: if the timing belt breaks, the pistons meet the valves, which leads to serious and expensive repairs of the power unit. And high-quality repair and maintenance of VAZ-2110 injection engines requires special diagnostic equipment. Often, a malfunction of just one sensor leads to unstable operation of the entire engine.

Replacing the Fuel Pump Mesh for VAZ 2107 Injector AUTOTEXNIKA.RU

Replacing the fuel pump VAZ injector

Cases when a VAZ 2107 injector fuel pump needs to be replaced are not that frequent, and its service life depends not only on the properties of the gas pump itself, but also on the condition of the gas tank. The reason why I had to change it was because a small speck got into it because the filter came off.

Electric fuel pump device

The design of an injection fuel pump is conventional and can be divided into two parts:

The most important thing is its structure itself. The fuel pump in the VAZ 2107 is a replacement. The fuel pump fuse (injector) is also clogged. Testing and replacement of the VAZ injector fuel pump, replacement of the VAZ 2110 fuel pump. The electric fuel pump itself is hermetically sealed to protect against the ingress of fuel. The fuel enters the pump through the filter and the intake hole and is supplied to the power system through the outlet hole (sealed from the electric motor).

Where is the fuel pump on the VAZ 2107 injector?

On carburetor engines, the fuel pump is installed on the right side of the block and is visually accessible. On the injector, it is located in the gas tank and only the output tubes coming from it are visible, and replacement is somewhat more complicated.

Symptoms for replacement

Signs of a malfunction of the VAZ 2107 injector fuel pump appear both when starting the engine and during operation:

- “heavy”, long engine start;

- jerking when moving;

- uneven operation at idle;

- The fuel pump doesn't pump.

Diagnostics

The primary conclusion whether the fuel pump is working or not can be assessed by ear when the ignition is turned on. If you don’t hear a quiet buzzing noise from behind, then you need to check the voltage supply to the gas tank block and then draw a conclusion about its malfunction.

This has never happened in a gas tank before.

Computer diagnostics. Replacement of electric fuel pump. Cleaning (washing) of injectors (injectors) on VAZ 2107 Engine.

Strange crap found. Replacing the fuel pump VAZ 2107

Add to the group in VK Donat to pay for the Internet: WEBMONEY- R394885703159 YANDEX.

You can check the serviceability of the fuel pump using the MTL-2 pressure gauge; this is the most correct way. You can somewhat roughly estimate the pressure using air pressure gauges to check tire pressure. On the bottom side of the fuel pump there is a neat former VAZ 2107 from 2004. Color 2107 injector. To do this, screw a rubber hose to the sensor and connect it to the fuel system.

The pressure of the VAZ 2107 injector fuel pump when the ignition is on should be 4.0 atmospheres, and when the ignition is running 2.8-3.2. Replacing the fuel pump mesh on the injector with your own. In reality, the pump pressure is different and was slightly less, but this may be an error in the pressure gauge.

The carburetor pump is checked by setting the camshaft position by cranking the engine so as to ensure free movement of the pump foot. The hose is unscrewed from the carburetor or filter and the presence of fuel supply is determined by pressing the foot.

To replace the fuel pump on an injection vase you will need:

- key to 10;

- 2 keys for 17;

- key to 7;

- crosshead screwdriver;

- a simple screwdriver.

I recommend removing the gas tank mount for ease of repair work. Replacement of fuel pump VAZ 2110, 2112, replacement, etc. To remove the fuel pump you need:

- disconnect the pressure relief pipes in the gas tank;

- Unscrew the main pipelines using 2 17mm wrenches;

- remove the gasket from the gas tank neck;

- unscrew the tank mount;

- move the tank to the side;

- remove the power and fuel level block;

- unscrew the fuel pump flange;

- remove the fuel pump filter;

- remove the tube from the pump after heating it;

- We take out the old pump and install a new one.

When installing the filter, do not hesitate to give it a good tap, otherwise it may fall off like mine. The fuel pump mesh on the VAZ injector is replaced if the old one is dirty or torn. Replacing the VAZ 2110 fuel pump mesh: description of the work. Its replacement is carried out in the same way. Usually it is sold complete with a fuel pump; if not, you will have to buy it, the price is 25 rubles.

Reassemble in reverse order. We heat the hose again in boiling water; if the mounting location of the old electric fuel pump does not allow the part to be properly secured, then we cut it off.

Important

When choosing, pay attention to performance and maximum pressure. Replacing a VAZ 2110 fuel pump: work procedure. I had a Bosch 0 580 454 456 and replaced it with a close analogue of FR 453-453 from WEBER

I had Bosch 0 580 454 456 and replaced it with a close analogue of FR 453-453 from WEBER.

- OEM part number 21083-1139009-01;

- Installation of VAZ 2108 - 2115;

- Pressure - 580 kPa;

- Productivity - 60 l/min;

- Voltage - 13.5 V.

Consumption per 100 km at a speed of 120 is about 8 liters. Very pleased.

Replacing the fuel pump VAZ 2107 injector video:

principle of operation, device, how it differs from a carburetor

Every car enthusiast knows that a car can have either an injection engine or a carburetor. But not everyone knows what each of them is. Therefore, you should understand this issue as best as possible. First, let's note that the function is the same. A combustible mixture is formed and supplied to the engine. There is only a big difference between their work. Let's consider which one.

The principle of operation of an injection type engine

To be specific, a carburetor is a device that creates a mixture of air and fuel, and it is also able to regulate the flow of the resulting mixture. The principle of operation is to suck it into the motor. This is possible due to the fact that the intake manifold and the atmosphere have different pressures.

An injection engine involves the operation of electronics. In this system, the quality of the mixture is controlled without human intervention. It is injected in doses using nozzles. After injection, the mixture is sent to the engine for combustion. Currently, cars are equipped with an electronic rather than a mechanical system. Next, let's look at how one differs from the other.

Comparison of injector and carburetor

Let's look at the principle of operation of a carburetor. This device is capable of forming a mixture that consists of air and fuel. The mixture is rich in flammable and flammable substances. It is needed so that the motor can carry out the required work. No matter how many revolutions the propulsion system makes, it absorbs the same amount of mixture by volume.

In terms of costs, the carburetor consumes a lot of fuel. At the same time, the air becomes heavily polluted.

Now let's look at the operating principle of the injector system. The whole device works in such a way that a lean mixture of air and fuel is sent to the engine, which must be accurately dosed. In modern cars this occurs under the influence of the control unit. Since fuel is dosed in grams (portions), its consumption is significantly low. In addition, the toxicity of exhaust gases is practically zero when leaving the exhaust pipe. It turns out that the internal combustion engine practically does not pollute the air.

The injector can increase engine power by up to ten percent, and the valve block is designed in such a way that engine performance improves. The principle of operation that allows the internal combustion device is that the injector forms a mixture of air and fuel, and what is important for it is fuel that is of different quality, otherwise it is impossible to drive the car.

Also, I would also like to note that, unlike a carburetor, which freezes in winter and overheats in summer, the injector is not affected by the temperature of the external environment.

If we talk about how reliable a carburetor is, its operating principle is very simple. The device is made in such a way that after fuel combustion, heavily polluted air comes out through the exhaust pipe. But it does not require regular maintenance and repair work during operation. It is only important, in order not to damage the device, to use a fuel filter and only a high-quality brand.

Diagnostics of injection engines - how to come to the aid of your car?

Primary diagnostics of injection engines consists of monitoring the condition of all control sensors of the unit. To do this, a thorough inspection is carried out, during which it is necessary to ensure the integrity of the insulation and the reliability of the connection of the plug connectors.

Diagnostics and repair of injection engines - briefly about the device itself

But first, let's look at what an injection engine is. How is it different from a carburetor? The main difference is the air-fuel mixture supply system. In previous engines, the fuel mixture was sucked directly through the carburetor, where the components were dosed, and then the gasoline was mixed with air. At the same time, due to imperfect design, the engine lost up to 10% of power.

In a fuel injection (or injection) engine, fuel enters the combustion chamber by forced injection at high pressure through injectors. Dosing and control of the amount of incoming fuel is carried out by electronics. As a result, the level of harmful emissions into the environment is reduced, and engine power is significantly increased, its performance characteristics are improved, and fuel consumption is reduced.

Advantages of injection systems:

- precise dosage of fuel supply;

- by optimizing the composition of the air-fuel mixture, the level of toxicity of exhaust gases becomes significantly lower;

- the dynamic characteristics of the car are improved, the injection system adjusts the fuel supply depending on the load;

- the use of an injection system leads to an increase in engine power by more than 7%.

Disadvantages include expensive repairs to the injection engine power supply system, fairly high requirements for fuel quality, and the availability of special equipment for repairs and diagnostics.

Diagnostics of injection engines - how to detect a breakdown yourself?

What malfunctions most often plague injection systems? The most significant malfunction can be considered a breakdown of the sensor that controls the position of the crankshaft. In this case, engine repair is most often required, since the alarm failure is caused by serious problems with the power unit.

Preliminary diagnostics of an injection engine with your own hands is quite possible, but to accurately determine the cause of the malfunction you will need special equipment, which is only available at service stations. If the fuel pump fails along the way, the only thing that can be done is to replace the faulty unit. If it is not in stock, then you will have to rely only on a tow truck.

The simplest failure is considered to be the failure of the phase sensor. The injection system is designed in such a way that in the event of such a malfunction, it begins to supply twice as much fuel. It is unlikely that you will be able to determine the cause of excessive fuel consumption on your own; this will require special instruments for diagnosing injection engines.

Do-it-yourself injection engine diagnostics - a few more observations

What else can lead to a sudden increase in engine power consumption? Experts recommend paying attention to the mass air flow sensor. This malfunction can be identified by dark exhaust, decreased throttle response, the appearance of unpleasant jerks and unstable engine operation in idle mode. Naturally, you can drive such a car, but only to the nearest service station, where injection engines are diagnosed and repaired.

It happens that the engine starts to stall. Experienced drivers know that the reason may not only be a malfunction in the fuel supply, but most often this occurs due to breakdowns of electrical equipment (faulty ignition coil, spark plugs, etc.). Even a novice car enthusiast can determine this. But if you need to repair injection engines, the malfunctions of which have already been described in this article, then it is best to contact professional service centers.

An injection engine is a rather complex mechanism, the operation of which must be well tuned in order to get maximum performance from it. The article discusses in detail the operating principle of an injection engine.

Before we start talking about this miracle of technology, let's dispel some myths. An injection engine works on the same principle as a diesel engine, with the exception of the ignition system, however, this does not give it much more power than a carburetor engine. The increase will be a maximum of 10%.

The center of the entire system is the ECU (electronic control unit). It goes by many names, "brains", "computer" and so on. Essentially, yes, it’s a computer that contains a huge number of tables on mixture composition, fuel injection time, and so on. For example, if the engine speed is 1500, the throttle is open 10 degrees, and the air flow is 23 kg, then one amount of fuel will enter the cylinder. If the input parameters change, then the result will be different. If any problems arise with the control unit, for example, the firmware crashes, then everything goes to waste, the engine either starts to work haphazardly or stops altogether.

Replacing the fuel tank

Before replacing the tank, it is recommended to protect yourself from possible troubles and remove the wire in the negative terminal of the battery. The work will be completed as quickly and correctly as possible only with the participation of an assistant.

It is recommended to remove the pump immediately after shutting it off to avoid damaging the sensor and fuel lines.

After removing the old gas tank, you will need to perform the following operations to install a new one:

Install a new fuel level sensor gasket and lower the sensor together with it into its place in the tank.

Then lift the tank, first from the rear, then from the front, install it on new clamps, screwing them to the body with new bolts.

Next, connect the fuel hoses, separator and air pipes.

After that, go into the cabin and connect the fuel level sensor and pump to the connectors.

Close the hatch, screw it on and put the seat cushion in place.

After installation, you must make sure that all fuel lines and sensor wires are connected

After replacing the tank, you need to make sure it is working: start the engine, see if there are any problems with the fuel supply or leaks due to poor connections.

Today, you can repair and replace the gas tank on a “ten” at any service station. However, this procedure is not considered difficult to perform independently. Therefore, it is more advisable to remove, repair or change the gas tank yourself.

Injection engine sensors

All elements can be divided into actuators and sensors. First, we'll look at sensors.

Mass air flow sensor (MAF)

This element is installed in front of the air filter, right at the inlet. Its operation is based on the principle of difference in readings. So, electricity passes through two platinum filaments. Their resistance changes depending on the temperature. One of the threads is reliably hidden from the air flow, which makes its resistance unchanged. The second one is cooled by the flow, and based on the difference in values, according to the same tables mentioned above, the ECU calculates the amount of air.

Engine absolute pressure and temperature sensor (DBP)

It is used either as an alternative or in conjunction with the above for higher reading accuracy. In short, it has two chambers, one of which is sealed and has an absolute vacuum inside. The second chamber is connected to the intake manifold, where a vacuum is created during the intake stroke. Between these cameras there is a diaphragm, as well as piezoelectric elements. They generate tension when the diaphragm moves. The signal then goes to the ECU.

Actuators

The actuators got their name because they make adjustments to the operation of the engine. That is, the control unit receives a signal from the sensor, analyzes it, and then sends the signal to the actuator.

Fuel pump

Let's start with the power system. It is installed in the tank and supplies fuel to the fuel rail at a pressure of 3.2 - 3.5 MPa. This ensures high-quality fuel spray into the cylinders. As soon as the engine speed increases, the appetite also increases, which means more fuel must be supplied to the ramp to maintain pressure. The pump begins to rotate faster at the command of the control unit. Most modern cars, starting around 2013, are equipped with a fuel module, which includes a pump and a built-in filter. This significantly affects the cost of filter replacement, because the entire module must be replaced. Some manufacturers write in the instructions that the module is installed for the entire service life of the car, but you should not believe that any filter can last more than 2 seasons.

Nozzle

After the fuel has passed the entire circuit of the wire, it enters the nozzle, which meters its supply into the cylinder. The injector is a very small diameter solenoid valve that sprays gasoline into the combustion chamber. The ECU modifies the amount of fuel supplied by time intervals while the injector is open. As a rule, this is tenths of a second.

Throttle valve

We have all once seen a carburetor and looked into it from above. So it had dampers that blocked the air. The principle is the same here. Perhaps there is nothing more to tell.

Idle air control (IAC)

This is also an electromagnetic valve, the rod of which closes the air duct that bypasses the throttle valve. Depending on the voltage that the control unit supplies to it, it opens this very channel.

Ignition module

Knock sensor VAZ 2110 12.2113 15, GAZ 406dv. (StartVolt)

Both RRP prices (recommended retail price) or the one indicated below are available for ordering.

7 Car model: 3102;3110;31105;3111;3302;2217;2705;3221;3221;2752;2110;2111;2112;2113;2114;2115;3102;2109;21099;2108;2123;21214;21213 Details

| Internal code | 30401 |

| vendor code | VS-KS 0110 |

| Brand | STARTVOLT |

| Type | Knock sensors |

| car brand | Lada(VAZ) |

Description Knock sensor VAZ 2110 12.2113 15, GAZ 406dv. (StartVolt)

7 Model: 3102; 3110; 31105; 3111; 3302; 2217; 2705; 3221; 3221; 2752; 2110; 2111; 2112; 2113; 2114; 2115; 3102; 2109; 21099; 2108; 2123; 21214; 21213

Characteristics Knock sensor VAZ 2110 12.2113 15, GAZ 406dv. (StartVolt)

| Express delivery | from 300 ₽ * | from 1 day * | Buy with delivery |

Your review will be published after being moderated

| Brand/Article | Description | Availability | Term | Price |

| BOSCH 0261231046 | Knock sensor | 17 | 4 days | RUB 1,226 |

| 4 | 3 days | RUB 1,305 | ||

| 27 | 4 days | RUB 1,305 | ||

| 1 | 4 days | RUB 1,178 | ||

| 18 | 3 days | RUB 1,226 | ||

| 3 | 2 days | RUB 1,226 | ||

| 2 | 7 days | RUB 1,178 | ||

| 3 | 2 days | RUB 1,276 | ||

| Bosch 0261231046 | 5 | 5 days | RUB 1,226 | |

| PEKAR 183855000 | KNOCK SENSOR | 3 | 2 days | 327 rub. |

| KRAFT kt104848 | Knock sensor VAZ 2110-2112, 2113-2115, 2170-2172, 1117-1119, 2190-2192, GAZ | 4 | 2 days | 299 rub. |

| 1 | 2 days | 336 rub. | ||

| KRAFT KT104848 | Knock sensor VAZ-2110-12,2113-15 (KRAFT) analogue 18.3855 | 4 | 20 days | 588 rub. |

| 4 | 1 day | 288 rub. | ||

| STARTVOLT vsks0110 | Knock sensor for cars VAZ 2110, 2115, GAZ 406 (VS-KS 0110) | 2 | 3 days | 263 rub. |

| 5 | 2 days | 259 rub. | ||

| 200 | 3 days | 244 rub. | ||

| STARTVOLT VSKS0110 | Knock sensor VAZ-2110-12,2113-15, GAZ 406dv. (STARTVOLT) | 1 | 4 days | 251 rub. |

| 56 | 20 days | 497 rub. | ||

| 3 | 3 days | 251 rub. | ||

| 2 | In stock | 251 rub. | ||

| 1 | In stock | 251 rub. | ||

| 1 | In stock | 251 rub. | ||

| 2 | 4 days | 251 rub. | ||

| 23 | 20 days | 497 rub. | ||

| 1 | 5 days | 251 rub. | ||

| 1 | 4 days | 251 rub. | ||

| 1 | In stock | 251 rub. | ||

| 2 | In stock | 251 rub. | ||

| 1 | 5 days | 251 rub. | ||

| 1 | 31 days | 226 rub. | ||

| 3 | In stock | 251 rub. | ||

| 55 | 1 day | 251 rub. | ||

| 1 | 4 days | 251 rub. | ||

| 1 | 31 days | 226 rub. | ||

| 23 | 30 days | 251 rub. |

Show all analogues

7 Model: 3102; 3110; 31105; 3111; 3302; 2217; 2705; 3221; 3221; 2752; 2110; 2111; 2112; 2113; 2114; 2115; 3102; 2109; 21099; 2108; 2123; 21214; 21213

Thank you for your attention to the project. Together we will make dvizhkom.rf better. After correcting the inaccuracies, we will send you an email telling you about the changes.

Unfortunately, now you can order more if you call us at 8-800-775-7556

The quantity to order an item must be a multiple of

We have sent you a password to the specified email address. You can change your password or other registration data in your personal account settings

Hereby, in accordance with Federal Law No. 152-FZ “On Personal Data” dated July 27, 2006, you confirm your consent to the processing of personal data by RAT LLC: collection, systematization, accumulation, storage, clarification (updating, changing), use, transfer solely for the purpose of fulfilling your order and informing about it, as well as promotions and campaigns of RAT LLC, including blocking, depersonalization, destruction. We, RAT LLC, guarantee the confidentiality of the information we receive. The processing of personal data is carried out for the purpose of effective execution of orders, contracts and other obligations accepted by RAT LLC as binding on you.

This consent applies to the following personal data: last name, first name and patronymic, email address, postal address for delivery of orders, contact phone number, payment details.

The principle of operation of an injection engine

So, after we have figured out the main components of an injection engine, let's see how it works. After the starter cranks the crankshaft, the DPKV tells the control unit which cylinder is in which position. In turn, the phase sensor reported the clock cycles. The control unit took this information into account and opened the injector in the cylinder in which the intake stroke begins. But he opened it for a reason, but for a strictly defined period of time, which, according to the tables, corresponds to the readings of the mass air flow sensor or DBP. This is how the working mixture was formed.

Video: how a gasoline injection internal combustion engine works

After the intake stroke has ended here, compression begins, at which time intake occurs in the other cylinder. Here the piston reaches top dead center, as indicated by the DPKV and DF, respectively, it is time to apply voltage to the ignition module, to the desired cylinder. To do this, the control unit contains two transistors, which take over two cylinders each.

Then, when the explosion occurs, the ECU looks at the readings of the knock sensor and adjusts the ignition timing for the next cylinder along the stroke. But that is not all. After this, when the gases reach the oxygen sensor, the control unit adjusts the composition of the mixture, namely, the opening time of the injector, which allows for the most efficient use of fuel and its combustion. If the ECU detects a lack of oxygen, but the throttle valve remains open, the idle air control valve opens slightly.

Engine warm-up and engine temperature sensor

This point is worth considering separately; let’s just say this is a small clarification. So, the engine warm-up mode is in no way connected with the readings of some sensors, that is, nothing depends on them. In particular, these are mass air flow sensor and air pressure sensor, as well as a knock sensor. The block, as already mentioned, contains certain tables, there are a lot of them, millions. So, during the warm-up mode, the ECU works strictly according to these tables and nothing else. This means that if the air to fuel ratio is written into it as 14.1:1, then it will be so. This figure is the generally accepted standard for operating temperature. So, until the engine temperature reaches the one specified in the firmware of the control unit, the warm-up mode will not turn off. Afterwards the ECU starts working based on the sensors.

Replacing the fuel pump with “Pekar” — Lada 2107, 1.6 l., 1997 on DRIVE2

The old pump was tired... the car did not develop full power... it took a long time to accelerate and all the issues related to the faulty fuel pump. I got tired of this whole thing, I climbed onto the World Wide Web, and, after reading about gas pumps, I decided to settle on “Pekar”, it has a double plunger.

1) Using a spanner or a regular open-end wrench for thirteen, unscrew the two nuts securing the fuel pump to the cylinder block and remove it from the studs. 2) Following the fuel pump, remove the sealing gasket, it must be intact and at least 0.3 mm thick, if necessary, replace it with a new one.3) Next, remove the heat-insulating spacer and after it another sealing gasket. If necessary, replace the second gasket if it is damaged.

Now that the fuel pump is removed from the car, replace it with a new one or make some other repairs. Before installing a new pump, it is necessary to check the minimum protrusion of the pusher, this is especially true if the car has already driven more than 90 thousand. km. The operation of the diaphragm unit will depend on the amount of protrusion of the pusher, namely, it becomes possible to reduce the fuel supply by the fuel pump and, as a result, a diaphragm rupture may occur.

The amount of protrusion of the pusher should be 0.8-1.3 mm. Adjustment of the protrusion is carried out by adding shims between the heat-insulating spacer and the cylinder block, the shims are either added or replaced with a new thinner one. Before measuring the amount of protrusion of the pusher, it is also necessary to take into account that the amount of protrusion will be influenced by the gasket between the spacer and the fuel pump body, therefore, in order to carry out a more accurate measurement, install both gaskets between the cylinder block and the spacer. As an opening of the old pump showed, the diaphragm was torn, That's why the car was struggling.

Which is better, an injection or carburetor engine?

This issue is quite controversial; each point of view has many opponents and supporters, both among ordinary drivers and among specialists who fully understand the principle of operation of an injection engine. So, the carburetor engine is distinguished by simplicity and transparency of operation. That is, if the mechanic adjusted the idle speed, then it remained that way.

As for the injection engine, it all comes down to timely maintenance, as well as the quality of the parts used.

>