The topic of this article is the VAZ-2110 engine (8 valves) injector in the fuel injection system. The main task is to find all its advantages and disadvantages and compare it with a carburetor engine. But to do this, you will need to delve a little deeper into history, look at how this engine was developed, how good it is in operation and repair. And the story will begin in the late 70s of the last century, when VAZ engineers started thinking about designing front-wheel drive cars. And then we will look at the injection system, its differences from the carburetor, its advantages and disadvantages.

Engine history

And now the story about where the VAZ-2110 engine (8 valves) injector comes from. And it was put in place at the end of the 70s. During these years, designers begin to understand that the classics produced for many years have a high cost. In addition, the Fiat 124 was the best car in Europe in 1964. Almost two decades have passed, the model range needs to be updated. And the experiments began. First of all, we modernized the gas distribution drive and started using a belt. But it did not take root on the VAZ-2105 engine (production years: 1980-1988), although it reduced the noise level.

The reason is simple: the pistons need scrapings that prevent them from hitting the valves if they break. But when repairing engines, pistons with 1.3 liter engines were installed, as a rule, of suitable size, but without recesses. But in the early 80s the eighth generation was released. Newer, comparable to European counterparts. And most importantly, the cars have front-wheel drive, a motor with a belt drive to a timing mechanism. And this was the same engine that, with a lot of modifications, is installed on modern cars. On models 2109 and 2110, these power units were adapted for the first time to an injection system.

Specifications

| Index | VAZ-2110 | VAZ-21102 |

| Engine volume, cm³ | 1499 | 1499 |

| Power, l. With | 72 | 79 |

| Torque, Nm | 104 | 118 |

| Compression ratio | 9.9 | 9.8 |

| Cylinder block | cast iron | cast iron |

| Number of cylinders | 4 | 4 |

| The order of fuel injection into the cylinders | 1-3-4-2 | 1-3-4-2 |

| cylinder head | aluminum | aluminum |

| Cylinder diameter, mm | 71 | 71 |

| Piston stroke, mm | 82 | 82 |

| Number of valves per cylinder | 2 (SOHC) | 2 (SOHC) |

| Timing drive | belt | belt |

| Hydraulic compensators | No | No |

| Turbocharging | No | No |

| Valve timing regulator | No | No |

| Fuel supply system | carburetor | injector, distributed fuel injection |

| Fuel | gasoline AI-92 | gasoline AI-95 |

| Environmental standards | Euro 2 | Euro 2 |

| Resource, thousand km | 125 | 125 |

| Location | transverse | transverse |

Main engine components

No significant differences may be detected upon a cursory examination. Both carburetor and injection systems do not affect the basic design of the engine. But it's worth taking a closer look at the little things. For example, take a look at the VAZ-2110 injector thermostat (8 valves). What immediately catches your eye is that it can be taken apart! Exactly! Engineers in Europe sit and think about how to reduce the life of a car, while ours at the same time carry out real improvements that are for the benefit of the consumer. It is clear that it is not the housing that breaks in the thermostat, but the insides - the temperature-sensitive element or valve. Therefore, why produce millions of cases? It will be much more profitable to make one for the car, and if the thermostat breaks down, change only the insides.

But these are not all the advantages of domestic engines. Please note that in the USA and Europe all cars are the same, sometimes there is no point in repairing it, it’s easier to throw it away and buy a new one. The reason is partly in the engine. For example, AvtoVAZ is almost the only plant that continues to install internal combustion engine blocks made of cast iron on its products! In all developed countries, aluminum alloys have long been used for this purpose! The service life of the engines suffers, but most importantly, there is no way to repair it, since it cannot be bored or relined. And this is much cheaper than buying a new engine or car. Maybe a wealthy burgher can afford this, but in our country a car is still a luxury for many people.

Which engine is better, 1.6 16- or 8-valve?

16 classes the engines were installed in a limited series at AvtoVAZ or at the SuperAvto subsidiary. They were also installed by tuning fans themselves.

In terms of manufacturability, they are superior to 8-cl. engines. Accordingly, if there is an option to take a 16-cl. motor, it would be nice to go with this option. But everything has its own nuances.

Advantages of 16-valve engines over 8-valve engines

- The best cylinder blowing is more power.

- More stable engine operation - less noise.

- Greater efficiency means lower fuel consumption.

However, 16th grade. the engine (1.6 l) from Priora (21126) bends the valves when the belt breaks. For some reason this scares many people. You just need to monitor the condition of the car, belts, rollers, pump, then everything will be fine! On all modern cars the valves bend.

What is an injector?

Now let’s see what the injector circuit looks like on a VAZ-2110 car, let’s look at the main components and operating principle. But first you need to answer the questions of what an injector is and what it is needed for. Everyone knows that until the end of the 90s carburetors were installed. In them, with the help of air flows, mixture formation took place, and then supply to the intake manifold of the fuel system. Moreover, such a cunning device can mix gasoline with air in an ideal proportion - 14 to 1. But there is a game of vacuum and atmospheric pressure.

VAZ 21102, price

Engines of this format, multi-valve, began to be installed on middle-class cars only in the early 90s. In some ways, such engines certainly win, so it is not surprising that there are practically no live production models with eight-valve engines left abroad. And we still have it. Don't throw it away. Let's try to find advantages in this motor, and we have already found the first thing - price. Since cars of the tenth family are no longer produced, you can find 21102 on hand for an average of 80 thousand. This will be a car with average mileage without capital. The 16-valve version will cost 120-140 thousand. The difference is significant.

Injector features

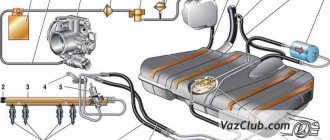

But the VAZ-2110 engine (8 valves) injector is much simpler than the carburetor version. But this is from the point of view of an electrician. The fact is that the system consists of many electronic devices that are responsible for the operation of the entire engine. Instead of a carburetor, a ramp is installed on the intake manifold. Essentially, this is a piece of pipe that contains the air-fuel mixture. It is pumped from the tank using an electric pump under low pressure. By default, the ramp is completely sealed; it is separated from the intake manifold channels by electromagnetic valves - injectors. But here’s the peculiarity: a constant pressure is maintained in the ramp, which is regulated by a sensor, and the quality of the mixture and the amount of gasoline supplied depend directly on how open the throttle valve is.

Characteristics of VAZ 21102

You shouldn’t expect miracles from a car plant that hasn’t been able to develop a coherent line of engines in its 40 years of existence, but thanks for what it has. The owners of the VAZ 21102 car initially considered themselves somewhat deprived of fate, because they received fewer valves than the owners of the same dozen, only with an index one more - 21103. The same engine, almost the same characteristics. But 21103 costs $300 more. Does it make sense to overpay, or to safely drive a VAZ 21102? We have listed the technical characteristics in the table, and we will explain everything that does not fit in the table in words.

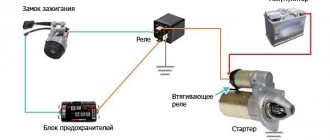

Diagram of the injection system

So, now in more detail about the power supply systems of the VAZ-2110 injection engine. First on the list is the fuel pump. It is mounted directly in the tank, together with the filter, and the engine rotor is driven only when the ignition is turned on (provided that the pressure in the ramp is below the minimum level). Next, the fuel flows through the tubes into the ramp. This is where the mixture is formed. The air first passes through a filter for purification. The filter housing is connected to the throttle assembly by a flexible pipe.

Add a comment Cancel reply

You must be logged in to post a comment.

The VAZ 2110 is an injector engine that is distinguished by its efficiency, increased power and stability of operation when compared with the VAZ 2110 carburetor engines. The widespread use of injection engines at AvtoVAZ began in the 2000s. Today we will tell you in detail how the “tens” injection engine works.

It is worth recalling that injection engines on the “ten” were installed with different volumes and number of valves. Today on the secondary market you can find injection VAZ 2110 with 8 and 16-valve power units with a displacement of both 1.5 and 1.6 liters.

Sensor system

The VAZ-2110 engine (8 valves) is no less interesting. The injector, a control system device, to be more precise, includes many sensors. All control occurs using sensors. So, between the filter and the throttle there is a mass air flow sensor. A position sensor is mounted on the damper itself. In the ramp - pressure. In addition, between the second and third cylinders on the surface of the internal combustion engine block there is a knock sensor. And on the generator drive pulley - engine speed. The vehicle's speed is measured from the gearbox. All data that comes from reading devices is sent to the electronic control unit.

Transmission and suspension

Lada 21102 has a built-in five-speed manual transmission (MT). This box is used on all versions of the 2110 line. It has good noise insulation, the lever stroke is comfortable, and the smoothness of switching is much better than that of Zhiguli and Samara.

The body (casing) of the box is made of aluminum alloy. Inside the casing there is a primary (drive) and secondary (driven) shaft. The shafts are combined with the differential and final drive. The five forward gears are equipped with synchronizers, which improve smooth shifting.

Gear ratios: 1st gear - 3.636, 2nd - 1.95, 3rd - 1.357, 4th - 0.941, 5th - 0.784. For reverse gear - 3.5. The final drive ratio is 3.7. The operating instructions state that you need to change the transmission oil every 75 thousand km.

Electronic control unit

This is, so to speak, the very heart of the system. On the VAZ-2110, the injector circuit comes down to precisely this device. A small case with many pins, and inside is the most interesting thing - a microcontroller. It is he who regulates the entire operation of the engine. The internal memory contains a so-called fuel map. Using it, the controller determines how much air and gasoline must be supplied to the ramp so that the engine operates in normal mode and detonation does not occur. But the most important thing is how long it is necessary to apply an impulse to the fuel injectors so that they open and inject the mixture into the combustion chamber.

Advantages

The VAZ 21102 engine injector became widespread, even though it was installed under the hood of only two car models. Manufacturers managed to achieve this due to the fact that it has quite a large number of positive qualities:

- The VAZ 21102 8 valve engine is different in that now you don’t have to worry too much about the condition of the timing belt, since if it breaks, no major problems will occur. The designers used a special piston design that prevents the valves from meeting the pistons.

- The engine design now lacks a carburetor. Many owners of the standard modification often encountered problems with clogged jets, which, thanks to the installation of an injector, disappeared forever. Now there is no need for constant cleaning and adjustment.

- The motor copes well with movement. There are no difficulties in using a car with such an engine under the hood in urban conditions. The motor works just fine, and its power is enough for a confident start.

- An enviable resource. The design of the engine is as simple as possible, so if you properly care for it, maintain it on time and operate it wisely, you can drive even more than 200 thousand kilometers without any problems.

- Ease of maintenance. Since no major mechanical changes were made to the design of the internal combustion engine, its maintenance is as simple as possible. You can change the oil and filter elements without much difficulty in a garage environment.

Which is better: carburetor or injector?

And now a little about which VAZ-2110 engine will be more reliable: an injector or a carburetor? But you need to look at this issue from different angles. For example, beginners will like the injector. Constant speed, there is no need to shut off the air supply in cold weather, and starting off is much easier. But there is another advantage - the car is more responsive at high speeds. Even at a speed of 120 km/h, when you press the gas pedal, the car quickly picks up speed. With carburetor engines this happens much more slowly. Therefore, overtaking in a car with an injector is safer. But when starting from a traffic light, the carburetor will easily “break” the injector. And the reason is higher torque at the bottom. And the cost of maintenance, of course, is higher for injection “tens”, since sometimes it is not easy to make an accurate diagnosis in the event of a breakdown.

Natural habitat VAZ 21102

Summarizing this small study, we can say with confidence that the 16V nameplate will cost significantly more than a standard one and a half liter eight-valve engine. If you look at consumables and maintenance, the picture is quite impressive. The capricious engine of the 103rd Lada will not always put up with low-quality fuel, while the 21102 will gladly gobble up what it is given at any gas station, unless, of course, it is an outright surrogate. The design of a dozen with 16 valves increases the cost:

- only high-quality leaded gasoline;

- expensive timing drive system;

- replacement and maintenance of an expensive catalyst;

- increased fuel consumption at lower levels.

Consequently, for small cities with an average level of service and inconsistent quality of gasoline, it is better to choose 21102. Here, the pursuit of maximum speed is unlikely to justify the significantly higher costs of maintenance and the starting cost of the car itself. Therefore, the number of valves is not the main thing here. The main thing is to choose the right engine for its future habitat, which is what we sincerely wish for everyone.

Source

DTZO: temperature indicator

The regulator screws directly into the cooling system pipe. Located between the filter housing and the power unit. The task of the coolant sensor is as follows:

- when starting a cold engine – informing the system about the supply of an enriched mixture;

- if it overheats, turn on the fan to cool the radiator.

If we talk about carburetor engines, then one of the listed functions was performed by the choke. The measuring element (DTZO) plays an important role for the stable operation of the power unit. It is characterized by the following problems:

- violation of contacts;

- high probability of failure if the fan starts when the engine is cold;

- difficulty starting a hot engine;

- increased fuel consumption if the indicator fails.