Signs of a faulty fuel pump

The very fact of a malfunction or failure of the fuel pump is determined by a number of external signs. As a rule, this is the inability to start the car or interruptions in engine operation while driving. In addition, symptoms of a breakdown may include an uncharacteristic hum and loss of power during acceleration.

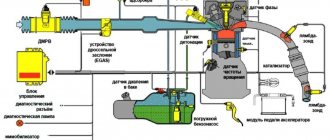

The fuel system of a modern car consists of the following elements:

fuel inlet pipe;

fuel outlet pipe;

The reason for stopping the fuel supply to the engine may be a malfunction of any of these components.

The fuel pump does not work: signs of failure

Regardless of the engine design, if the fuel pump fails, the symptoms of its failure for both types appear the same, and they manifest themselves as follows:

- If the spark plugs are working properly, the spark is good, the engine turns, but there is no flash in the cylinders.

- Individual flashes occur in the engine cylinders, but the engine does not start.

- The engine starts, but the speed fluctuates.

- The engine starts, the idle speed is normal, but when you try to increase it or start moving, the engine stalls.

- While driving, the car twitches, when you try to increase the speed, you feel failures in the engine, and the dynamics of the car decrease (does not pull).

It is worth noting that similar symptoms may also appear due to other breakdowns, for example, a heavily contaminated fine filter, a faulty mass air flow sensor (mass air flow sensor) or clogged injectors. Therefore, the fuel pump cannot definitely be blamed for the occurrence of such symptoms.

Read also: The engine consumes oil, but does not smoke

In fuel-injected cars, when you turn on the ignition, a buzzing sound is heard from under the rear seat, this turns on the electric motor that pumps fuel; if there is no sound, it means the fuel pump is not working.

Reasons for fuel pump failure

The pump can fail for various reasons:

- For carburetor engines, the main source of the problem is usually the fuel pump rod. During operation, it becomes shorter and the pump stops supplying the required amount of fuel to the engine.

- The device may stop functioning due to wear on the inlet valve or its O-ring.

- Injection engines are equipped with electric fuel pumps. In this case, the most common cause of device failure is poor quality fuel. The inlet strainer becomes clogged with dirt and restricts the flow of fuel.

- Electric pumps may become inoperable due to faulty wiring, relays, fuses, or terminal oxidation.

Some of these problems can be prevented by refueling with high-quality fuel at well-established gas stations. In addition, it is recommended to occasionally clean the gas tank and replace this and other elements of the fuel system when their service life has expired.

Checking the functionality of the relay

The fuel pump relay is a device that supplies or stops electrical power to the fuel pump. If it fails, the operation of the fuel system will stop.

Electrical power to the fuel pump is supplied through a relay

Checking the functionality of the relay and the corresponding one is carried out according to the following scheme:

Open the hood and remove the cover from the fuse and relay box.

Using your hands or special pliers, remove the relay and fuse that control the pump.

Inspect the relay and fuse and, if faulty, install new ones.

Check if current is flowing to the relay. This can be done with a wire with a 12 V lamp, connecting it to the connection point.

Often the relay stops working after installing an alarm system on the car. In this case, you should reset all settings from the alarm key fob.

Video: checking relay functionality

The mechanism works, but does not pump fuel

Sometimes the device makes a characteristic hum, but gasoline is not supplied to the engine. The fact is that the pressure in the fuel system should not exceed 3 atm. It can be measured by connecting a pressure gauge to the fuel rail. If there is no pressure or it is very low, the element has failed.

It may happen that the device simply does not receive voltage. To check this, turn on the ignition and determine by ear whether the pump is working. It should make a slight buzzing sound. If nothing is heard, power is not supplied to the pump. Relays, fuses and wiring should be checked.

Video: what to do if the pump does not pump fuel

Pressure in the fuel supply system is not maintained

The pressure in the fuel system is maintained not by the pump itself, but by its check valve. Fuel enters through the inlet valve, which supplies it under pressure through hoses to the engine, and the check valve does not allow gasoline to return.

Due to severe wear, the check valve may not operate. As a result, the mechanism loses its ability to maintain the required pressure.

Depending on the make of the car, the check valve can be located either inside or outside the device body. Replacing a valve is a rather complicated procedure. Therefore, it is more convenient to replace the pump as a set.

The car jerks at low speed

If the engine begins to make unusual noises and jerk while driving at low speeds, the filter screen is most likely clogged. The pump simply does not have enough fuel to operate properly. The problem will go away after cleaning the mesh.

Similar symptoms may also be caused by incorrect operation of the device valves. Due to wear, they cannot pass gasoline in both directions. In this case, it is necessary to replace the mechanism.

What is a fuel pump and how it works

The purpose of the fuel pump is to supply fuel to the car engine from the fuel tank. Since the engine and gas tank are located on opposite sides of each other, fuel supply is impossible without a gas pump.

There are two types of fuel pumps: mechanical and electric. A mechanical fuel pump can be found in a carburetor type car. Fuel must be supplied to the carburetor at low pressure. Electric fuel pumps are specially designed for fuel systems with injection type fuel supply (injectors).

The mechanical fuel pump is attached to the outside of the fuel tank, and the electric one is attached to the inside. Some engines have two fuel pumps at once: one of them operates at large volumes and at low pressure inside the fuel tank, and the other operates at small volumes and at high pressure, located near or on the engine.

Additionally, we recommend reading our expert’s article, which talks about what a fuel pressure regulator is and how to repair it.

Mechanical fuel pumps suck fuel from the tank into the engine. The distance between the pump and the carburetor is small. Thanks to this they can work under low pressure. The operating principle of electric fuel pumps is based on pushing fuel into the engine. The operation of such a pump is controlled by the vehicle's electronic system.

This control takes into account throttle position, fuel/air ratio and exhaust gas content. Electric fuel pumps heat up quickly and make a lot of noise due to the fact that they operate under pressure. Because of this, they are placed in the fuel tank as it muffles the noise and cools the pump.

The fuel pump is started by an electric motor. After turning the ignition switch to switch on, a signal is sent from the on-board computer to start the fuel pump. An electric charge enters the fuel pump. The engine rotates for several seconds, during which time the necessary pressure is created in the fuel system. If a signal is not sent to the on-board computer within two seconds, the fuel pump automatically turns off.

If an emergency shutdown does not occur, fuel enters the fuel pump through a tube and exits through a one-way valve. Next, it enters the fuel filter, which traps particles of debris and dirt, and only after that the purified fuel enters the engine. The fuel pump stops working simultaneously with the engine.

Pressure is the most important parameter for a fuel pump, affecting the amount of fuel injected into the engine. The gearbox is responsible for the stability of the fuel supply.

Adjusting the pressure in the fuel system

A simple way to regulate the operation of a worn-out fuel pump is to install a fuel pressure regulator. It connects to the fuel rail and shows the pressure, allowing you to change it either up or down.

The device allows you to adjust the fuel pressure in the system depending on the situation

To measure the fuel pressure in the system, you can also use a pressure gauge by connecting it to the fuel rail.

Car won't start after replacing fuel pump

Sometimes, after installing a new pump, the car cannot be started. There may be several reasons for this problem.

A defective product has been installed. It needs to be replaced.

The fuel inlet and outlet pipes are not connected correctly.

The power plug is not connected correctly.

The terminal contacts have oxidized. They need to be cleaned.

Proper connection of wires and fuel supply pipes guarantees proper operation of the fuel pump

The fuel pump is the main element of the fuel supply system. Any malfunction leads to the impossibility of further operation of the vehicle. You should pay attention to all symptoms of decreased performance of the mechanism, immediately identify them and take appropriate measures. Good luck on the roads!

A car fuel pump is a device designed to provide an uninterrupted supply of fuel to the installation in which the fuel mixture is formed. Even the slightest malfunction leads to interruptions in the operation of the engine, and in the event of more serious problems, you simply will not start it.

In this article we will look at situations where the gas pump does not pump fuel at all, or pumps it, but not in the amount required by the power unit for normal operation. We will also try to understand the possible causes of this or that malfunction of the fuel supply device and discuss methods for eliminating them independently using the example of domestically produced cars carburetor VAZ-2109 and injection VAZ-2114.

Causes of malfunctioning fuel pump

Fuel pumps are different. It all depends on the specific brand of car and the characteristics of the pump itself.

Knowing the causes of problems in the vehicle’s fuel system is a necessary condition for its successful repair. Problems may arise for the following reasons:

- Wiring problems: Wires have become dirty, rusted, or melted. As a result, the electric voltage decreases and fuel pumping becomes more difficult.

- Debris and dust getting into the gas tank. Rust in the tank. As a result, the fuel becomes unclean and causes problems. Poor quality fuel also pollutes the gas tank.

- Filter dirty. Fuel pressure decreases and the functions of the device are weakened.

- Driving with an empty tank. This leads to a decrease in pressure and overheating. It dries out and becomes damaged.

To effectively treat a living organism, it is important to know not only the symptoms, but also the causes of the disease. It’s the same with the operation of car systems: you need to find out the causes of problems in the operation of the fuel pump

The gasoline pump is one of the key elements of the automobile fuel complex. It is responsible for transferring fuel under pressure to the injectors (when the car uses a system in which fuel is injected) or to the carburetor. Like other parts of the car, the pump may stop working properly.

The device can be mechanical or electrical. It all depends on its functional characteristics and structure.

How to check functionality

This is easy to do at home. First you need to remove the pump and place it in a vice. Then connect a hose to each branch pipe. One hose must be directed into an empty container, and the other into a container with gasoline. The mechanism must be pumped by hand. If the fuel moves from hose to hose, then you can be happy. This means everything is fine. If this does not happen, then most likely the part needs to be replaced.

Knowledge of the operation of all vehicle systems and experience in troubleshooting them will help save money and provide invaluable assistance in the event of a breakdown far from populated areas.

What types of fuel pumps are there?

Cars with gasoline engines, depending on the make, model and modification, can be equipped with gasoline pumps of different designs. But they all fall into two main categories: mechanical and electrical. Most carburetor engines are equipped with mechanical fuel delivery devices. If we take the VAZ 2109 (carburetor), then from the factory it was equipped with a diaphragm pump manufactured by DAAZ. The main difference of this device is its simplicity of design, which is easy to understand even for a beginner. In the carburetor "nine" the fuel pump is located in the engine compartment of the car. It is easy to recognize by its characteristic hemispherical cap and fuel line hoses.

VAZ 2114 injection engines are equipped with electric fuel pumps. Their design is also based on a membrane, but unlike “mechanics”, the fuel supply devices in cars with automatic fuel injection are not under the hood, but directly in the tank.

How does a fuel pump work?

The main function of the gas pump is to transfer fuel from the tank to the engine. In injection engines, the fuel pump is connected to the fuel rail, and in carburetor engines - to the carburetor. Moreover, it is necessary not only to pump fuel, but also to provide a specific pressure.

Very high pressure usually leads to excessive enrichment of the mixture, as well as huge fuel consumption. And too low pressure leads to a decrease in the mixture, as well as a decrease in power. Both the 1st and 2nd cases negatively affect the life of the motor. That is, the fact that the pump pumps gasoline does not confirm its full serviceability.

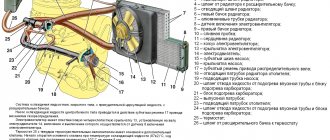

Design of a carburetor fuel pump VAZ 2109

To understand why the VAZ 2109 fuel pump (carburetor) does not pump, let’s briefly look at its design. So, the “nine” fuel supply device consists of:

- housings;

- pusher with mechanical pumping lever;

- diaphragm assemblies;

- covers with valves and fittings for attaching hoses;

- mesh filter;

- manual pumping lever.

Operating principle of a mechanical fuel pump

The fuel pump is driven by the camshaft cam, which moves the pusher in a horizontal direction, causing it to perform reciprocating movements. The pusher, in turn, acts on the mechanical pumping lever, and it already raises and lowers the membrane rod.

Thus, a certain pressure is created inside the fuel pump, which is maintained by the valves of the device cover. One of them lets fuel in without letting it back in, and the second pushes it into the fuel line going to the carburetor.

As you can see, the design is very simple, therefore, to determine the reason that the fuel pump does not pump, it is enough to disassemble it and check the condition of the main elements.

Pump filter and manual pumping lever

The first thing you will see when you disassemble the fuel supply device is the strainer. It is made of thin perforated plastic. The reason why the fuel pump does not pump can also be if it is deformed or severely contaminated.

In the first case, the filter must be replaced, in the second, it must be washed with carburetor cleaning fluid.

The manual pumping lever has nothing to do with the fact that the fuel pump does not pump fuel when the camshaft rotates. The only thing that can break in it is the spring that tilts it back to its original position.

The fuel pump does not pump: injector

As already mentioned, pumps in carburetor and injection engines have different designs. In cars with forced fuel injection, all processes associated with its supply to the combustion chambers are controlled by an electronic control unit, so breakdowns of various types of electronic devices can occur here.

The main reasons why the fuel pump of an injection engine does not pump include:

- malfunction of the device's electric drive;

- pump filter clogged;

- relay failure;

- fuse blown.

Why the fuel pump could break - the main causes of problems

The causes of breakdowns can be very different. The first thing to consider is resource completion. Original pumps serve, as mentioned above, from 100,000 to 200,000 km. Non-original substitutes can travel 5-10 thousand km or cover the same 100,000 km without problems. It all depends on the chosen brand, price and checking for possible counterfeiting. It is the end of the resource that most often causes the failure of this equipment. But often by our actions we shorten the life of the device.

Very often breakdowns occur for the following reasons:

- the pump filter (mesh), which purified the fuel from various solid impurities, became clogged, which is why solid particles began to enter the pump, which led to its breakdown;

- low-quality fuel, which contains solid particles and elements dangerous to the fuel system, enters the tank; you need to more carefully choose a gas station for your car;

- the tank began to rust from the inside, which caused a large amount of debris to get into the fuel pump, which caused the product to be damaged, resulting in its premature failure;

- there was always about 7-10 liters of fuel in the tank, this is a problem for thrifty car owners who do not fill the tank full, in which case the gas pump fails faster;

- a fuel pump from an unreliable manufacturer was supplied, which caused additional problems; this should be taken into account when subsequently replacing the device with a new one.

If there is a crack in the system that causes a loss of seal, this can accelerate wear on the pump. The device will work at the maximum of its capabilities, which is why it will break down faster. Some of the fuel will enter the injector ramp, but the pressure will still not be high and stable. Therefore, it is important to exclude the possibility of depressurization of the system. Otherwise, further problems may appear very quickly.

How to understand that the cause of engine interruptions is the fuel pump

Diagnosing problems with the fuel pump in a car with an injection engine is much easier than in a car with a carburetor engine. The fact is that when you turn on the ignition, you can clearly hear the sound of the electric motor of the fuel module. It lasts for several seconds. This sound indicates that the fuel pump is turning and pumping fuel.

If this happens when you turn the key, then there is nothing wrong with the device itself, and the cause needs to be looked for elsewhere. Well, if when you turn on the ignition you do not hear the characteristic sound of the pump, you can be sure that the problem is in it, or in the elements of its energy supply.

Weight

The fuel pump mass is located under the steering wheel, not far from the handbrake handle. It is its use that most often leads to wire breakage. In this case you will need:

- remove the cover;

- clean the ground contacts;

- attach it to its original place.

There is also a relay that controls the operation of the fuel pump. It is necessary so that when the ignition is turned on, operating pressure is immediately formed in the fuel supply system. It is important not to get confused, because there are three relays, and only one of them is related to the pump.

Start with the relay and fuse

Considering that the fuel supply module is located in the car tank, and it is not so easy to get to it, it is better to start diagnostics with the relay and fuse:

- Unscrew the screws securing the cover of the mounting block located to the left of the steering column.

- Underneath it, find fuse F3 (15 A) and relay R2. These are the elements that we need to check.

- As for the fuse, it needs to be “ringed” with a tester. If unusable, replace it.

Checking the relay in a garage is quite difficult. But you can take a similar one (from an adjacent socket), a known good relay, and install it instead of the one being diagnosed. Now turn on the ignition. Is the fuel pump pumping? The reason has been found! Well, if nothing has changed, move on.

What to do if the fuel pump does not work?

I think for those who do not understand at all what and how it works in a car. You should read one of the articles on the topic “car fuel system”. So at least you will have an idea of what will be discussed next. And for those who have an idea of what a fuel system is, let’s move on.

Read also: How to move to New York

Diagnostics

In order to understand what is wrong with the system. It is necessary to carry out diagnostics. You can create a checklist of possible faults for yourself:

- relay

- circuit breakers

- ECU

- fuel pump (wiring, motor)

CHECKING THE ECU, RELAYS AND FUSES KALINA

First, let's check the fuel pump relay. Its location is under the passenger's feet on the left. Where is the air duct located?

Unscrew the screw and tighten the panel. Next we will see the relay block. Unscrew the nut with a 10mm wrench or a socket. We take out the block with the relays and find what we need. Look at the photo below:

Relay 30A, 12V. In order to check for functionality. You can remove exactly the same relay, with the same parameters, and install it in place of the previous one. If the engine does not start, then the problem is not with the relay. It's working for us. So we are looking for the problem further.

You can also check the ECU there. The fact is that on the Lada Kalina the ECU unit is located under the heater radiator. And it often happens that antifreeze gets on the block. As a result, the ECU floods. Which, in turn, stops working correctly. And one of the reasons may be a refusal to start the car engine.

To check the ECU simply, look for the possibility of a leak in the heater radiator. When will you diagnose the fuel pump relay?

CHECKING FUSES

To check the integrity of the fuses. It is necessary to open the panel near the gear shift knob. Where is the diagnostic connector located? And there find fuse 3 (count from the driver). We take it out and see if it is intact. If it’s intact, then we look for the reason further.

Electric drive and filter

The fuel pump in the injection VAZ 2114 is an element of the fuel module, which is located in the car’s tank. It also includes:

- coarse filter;

- fuel level sensor;

- pipes for connection to the fuel line.

To get to the module, you need to remove the lower part of the rear seat, disconnect the wiring harness and unscrew the 8 screws securing its cover. Remove the entire device assembly. First of all, inspect the coarse filter. If it is clogged, replace it.

To test the electric motor, you will need to connect it directly to the battery terminals. If it is operating normally, “ring” the wiring and check the contact of the ground wire on the module cover. If the electric motor shows no signs of life, the question “why the fuel pump doesn’t pump” has finally found its solution.

It is not advisable to try to repair it yourself. Just buy a new motor and install it in place of the old one. And yet, you shouldn’t spend money on buying the entire module, which now costs about 3 thousand rubles. Buy the electric motor and a new filter separately. All this will cost you three times less.

One of the most important elements of the fuel injection system of a gasoline engine is the electric fuel pump, which is located in the fuel tank of the car. The fuel pump pumps fuel into the system from the gas tank, creating a certain pressure.

Auto repair experts identify the following common fuel system problems that are related to the fuel pump:

- The fuel pump pumps poorly and does not create the required pressure;

- the fuel pump does not pump when the ignition is turned on;

Considering that the fuel pump is an electromechanical device, the most common fuel pump malfunctions are related to both the mechanical and electrical parts. Next, we will look at what signs indicate a breakdown of the fuel pump and why the fuel pump stops pumping partially or completely.

Read in this article

Diagnosis and Troubleshooting

It is relatively simple to verify that the electrical network is faulty - this can be done without removing the fuel pump. When the sound of its operation is not heard when the ignition is turned on, you must immediately check the fuse responsible for this circuit. It is installed in a block mounted at the bottom in front of the front passenger seat. You need to remove the block cover, find the fuse marked F3, rated for 15 A, and replace it. This kind of work can be done on the road.

If the operation of the fuel pump has not resumed, you should switch your attention to relay K2, located in the same block. It closes the power circuit of the pumping device based on a signal from the controller. You can also check the serviceability of the relay in road conditions, for which you will need a piece of copper wire. Diagnostics are carried out in the following order:

- Remove relay K2 from the connector.

- Turn on the ignition.

- Using a wire, connect the contacts marked “30” and “87”; the numbers are marked on the relay. Another option is to apply power to pin “11” located in the diagnostic connector. The +12 V voltage can be taken nearby, from the cigarette lighter.

- If you hear the pump humming, then you need to change relay K2.

If after the above manipulations the unit is still “silent”, it is necessary to check the integrity of the wiring and the reliability of the contact at the place of its connection. This will require a device, so it will not be possible to carry out such work in the middle of a field. Unless you can check the serviceability of the fuel pump itself by disconnecting the connectors from it and supplying 12 V directly from any convenient source. If the pump still does not hum, it should be replaced.

Be careful when connecting wires directly and make sure that there are no drops of gasoline nearby, as a spark may cause it to ignite.

It will not be possible to diagnose insufficient fuel supply to the injectors under road conditions, unless you carry a pressure gauge with a corresponding hose for connection to the fuel rail. The amount of gasoline supplied is characterized by the pressure in the network, to measure which you will need a pressure gauge. The check is performed as follows:

- Twist off the plastic cap covering the diagnostic fitting. It is located at the end of the fuel rail and is a regular spool.

- Press the spool rod to release the pressure in the line. In case of gasoline leakage, place a small container under the spool. Perhaps the malfunction will make itself felt already at this stage if there is no pressure in the network and no fuel flows from the fitting.

- Unscrew the spool and put the hose from the pressure gauge onto the fitting. With the ignition off, apply 12 V directly to the pump. To clearly record the readings, it must work for at least 10 seconds.

If the pressure is below 3.6 bar, you must first change the coarse filter. If this does not help, then you will have to check the RTD and the tightness of the injectors. This is the only way to accurately determine the source of the problem.

Signs of fuel pump malfunctions

The main symptoms of fuel pump failure, as well as malfunctions in its operation, are:

- the car starts with difficulty, the engine runs unstable, there are dips, jerking when pressing the gas pedal, etc.;

- the pump does not pump after turning on the ignition, does not turn the starter and does not pump the fuel pump, the engine does not start;

There have also been cases when the fuel pump stops pumping while driving. In such a situation, the engine begins to malfunction and stalls immediately after the remaining gasoline in the fuel line is used up. The problem can occur either regularly or periodically.

How to check the fuel pump?

The most reliable diagnostic method is to check the gasoline pressure in the fuel line.

On sale you will find ready-made kits with adapters for connecting to the most common power systems. You can build the device with your own hands from a pressure gauge with a scale of up to 6 kg/cm2, a hose, adapters and fittings. To check the pump you need:

- Relieve the residual gasoline pressure in the line.

- Connect the pressure gauge across the engine power supply system. Some cars have a standard fitting to check the performance of the pump.

- Turn on the ignition. A value of 3-4 kg/cm² is considered normal. The exact parameters for a specific engine are in the repair and operation manual.

- Start the engine. A working fuel pump creates excess pressure (about 7 kg/cm²), which is released into the tank by the regulator. Therefore, in all engine operating modes, the pressure in the ramp should not deviate significantly from the standard values. When diagnosing, try to simulate the conditions under which the symptoms of a faulty fuel pump manifest themselves most often (engine temperature, load, etc.)

If the measured value is lower than acceptable, the fuel pump on your car is faulty or the fine/coarse filter is clogged. In this case, the fuel pump heats up, which can lead to melting of the housing and burnout of the electric motor.

The fuel pump does not pump: causes and diagnostics

Let's start with the fact that if the gas tank is full, the battery is charged, the spark plugs are dry and there is a spark, the starter turns the engine normally, but the engine does not seize, then you should pay attention to the gas pump. A common problem is that there is no power to the fuel pump after the ignition is turned on. In a similar way, the malfunction manifests itself in motion, when the power to the fuel pump is lost and the engine suddenly stalls.

An equally important point is how much the fuel pump pumps. In other words, the pump may hum and buzz (power is being supplied), but not create the required pressure in the fuel line. The pressure in the fuel system with a working fuel pump must be more than 3 bar (which depends on the specific car model). The indicated pressure is accumulated in the fuel rail and has an indicator of 300 kPa and above.

To check, you need to measure the pressure in the fuel rail with a pressure gauge, taking into account the indicators that are the norm for a specific car model. Using the example of injection VAZs, the pressure when the ignition is turned on is 3 atmospheres, at idle the figure is 2.5 atmospheres, when you press the gas 2.5-3 atmospheres. This method will help you accurately determine:

- malfunction of the fuel pressure regulator in the rail;

- breakdown of the fuel pump or a noticeable decrease in its performance due to wear;

- severe contamination of filters (fuel filter and/or fuel pump mesh);

How can you repair a fuel pump in a car?

If we are talking about a breakdown of an old-style pump, its repair is quite possible by installing a repair kit. It is enough to replace the seals, install the necessary parts that are worn out or deformed, put the old pump in place and continue to operate it. Such repairs significantly extend the service life of the equipment. If you have an injection car with a modern type of gas pump, repairing it becomes possible only in some cases.

It is better to replace it in case of such breakdowns:

- the internal working part is worn out - in this case, the motor will buzz, but will not work and create pressure in the fuel supply system, this is important to take into account when diagnosing;

- the housing is broken - in case of mechanical damage, it will be almost impossible to repair the damage; it is very important to carry out a full replacement, and not invent handicraft repair methods;

- the electric motor has failed - repairs in this case will cost much more than purchasing new equipment, and it is impossible to repair the pump at home;

- a cheap pump from one of the Chinese companies broke down, in this case it is better to mark even a minor breakdown with a full replacement, since there is no point in investing in repairs;

- diagnostics do not allow you to clearly understand what the problem is; in this case, you will not be able to repair the fuel pump yourself, and the services of a specialized technician can be very expensive.

It is worth paying attention to signs of failure of pumping equipment. The longer the device has shown specific problems, the more reasons you will have to replace the fuel pump. It is impossible to independently disassemble and assemble pumping devices from Bosch, AC, VDO, Denso and other well-known brands. You will have to go to a workshop, where you will have to pay money for disassembly and diagnostics. If the device has passed enough kilometers or years, it is better to simply replace it with a similar one. This is the most appropriate repair option in this case.

We suggest watching a video about malfunctions of the fuel supply system:

Other causes of fuel pump malfunctions

Quite often, unprofessional installation of additional electrical equipment or security anti-theft systems leads to the fact that the power to the fuel pump is lost due to mixed up contacts or other connection errors.

Finally, let’s add that the gas pump in the gas tank is immersed in gasoline, in which it is actively cooled. The habit of driving with an empty tank can quickly damage the electric motor of the fuel pump, as it burns out.

What functions does the fuel pump relay perform, signs of breakdown. Where is the fuel pump relay installed, how to properly check the fuel pump relay.

Why does the starter turn normally, but the engine does not catch and does not start? Main causes of malfunction, checking fuel supply and ignition systems. Adviсe.

Diagnose faults that may indicate problems with the fuel pump. Self-check of the device, measuring the pressure in the fuel rail.

The causes of whistling and increased noise during operation of the fuel pump are overheating of the pump. How to diagnose and fix the problem yourself. Tips and tricks.

How to change a fuel pump. Location of the fuel pump, releasing pressure in the system, unscrewing the fuel lines, removing the pump, reassembling.

What to do if the car accelerates worse, does not pick up speed, or has failures during acceleration. Why the engine does not pull, how to find the reason for the decrease in power.

Common faults

The fuel pump is humming

The fuel pump may hum or squeak for a variety of reasons. The fuel pump may hum due to the nature of the system design. If there is a suspicion of a malfunction of the electric fuel pump, you need to check the fuel system completely.

If the fuel pump makes noise at high ambient temperatures, you need to check whether the gas tank is breathing. Check the gasoline vapor pipe and absorber valve. If you cannot find the cause, drill a hole in the filler cap.

After replacement, the new fuel pump may make short-term noise. Wait about 5 minutes, if the pump continues to hum, carry out the procedures above.

Fuel pump overheating

The pump overheats if:

- There is little or no gasoline in the tank;

- Foreign materials have entered the fuel pump module or the motor itself;

- Water in the tank;

- Fuel lines and fine or coarse filters are clogged. The fuel pulses back to the fuel pump, so it heats up;

- Short circuit of the stator windings of the BN motor, as a result of which it heats up.

If the fuel pressure on the pressure gauge fluctuates, this indicates that the filters are clogged.

The fuel pump does not pump when the ignition is turned on

Modern engine management systems block the fuel pump before the starter cranks. That is, in order for the electric fuel pump to work, you need to start the engine. If it still doesn’t work, check the 12 V power supply by using a scanner to turn on the fuel pump relay.

Signs of low fuel rail pressure

The main symptom of low pressure is poor engine starting and loss of power. The reasons may be the BN itself, conductive lines, or filters.

Why does fuel pressure drop in the rail?

If, when checking, the fuel pressure drops quickly after the pump is turned off, the fuel pressure regulator must be replaced. Before replacing, you can try to revive it. To do this, we clamp the return line and turn on the pump, the pressure will rise to maximum and suddenly release the return line. Thus, the membrane in the valve sits in place and maintains pressure. The same symptoms may occur after stopping the engine. The pressure drops sharply, gasoline is drained into the tank and the next time starting the engine will be difficult.

If the fuel pump malfunctions, the pressure will drop at speed.

The alarm blocks the fuel pump

Blocking of the fuel pump can occur due to the closure of the non-standard alarm unit. In this case, you need to dismantle the alarm and replace it with a new one.

The fuel pump is constantly running

When the engine is stopped and the ignition is turned off, the pump does not turn off. The reason may be that the fuel pump relay is shorted and does not turn off. The 12V power supply is constantly supplied and the electric fuel pump pumps.

The fuel pump hums, but does not pump, what is the reason?

Car owners often encounter the problem that the car does not start, but the fuel pump is humming. The fact is that the motor itself works, and the impeller turns on the stator axis. Accordingly, pressure is not created and the engine does not start. In such cases, checking the fuel pressure with a pressure gauge will help.