The gasoline pump serves to supply fuel from the tank and maintain the pressure in the line necessary for the operation of the injectors. Interruptions in the supply of gasoline lead to a disruption in the composition of the air-fuel mixture, which leads to poor-quality combustion and misfires, the engine begins to stall, respond sluggishly to the gas pedal or stall. If the fuel pump (FP) does not pump, the engine will not start at all.

The main signs of a malfunction - how to understand that fuel is not supplied?

First you need to figure out whether the fuel pump is to blame for the problem. Very often, car owners come to a service station and declare the need to replace fuel equipment, but in fact, only a fuse or a certain filter needs to be changed. You should take a closer look at how the car behaves, what errors are shown on the on-board computer screen, and how the engine reacts to an attempt to start. All these features will tell you whether the fuel pump is to blame for the problem, or whether you need to look for other problems.

The main signs of fuel pump failure:

- when you turn on the ignition, you can’t hear the operation of the fuel pump, which should turn on at this moment and pump up pressure (in some cars the fuel pump turns on when the driver’s door is opened or when the security system is disarmed);

- when trying to start, the engine does not start at all, the starter turns the power unit monotonously, there is no hint of an attempt to start - this happens when the pump is completely faulty;

- at the moment of starting, the engine starts, but then it starts to work very unstably, the speed fluctuates, errors appear on the BC screen, the engine stalls, knocks, “chokes” - this happens when the functions of the pump are disrupted;

- Also, at the initial stage of failure of the fuel pump, problems are possible while driving, when the engine starts to run unevenly, stalls or reduces speed while accelerating, and dips appear;

- if the pump suddenly fails, the engine gradually reduces speed and stalls, despite the driver’s attempts to press the gas pedal, and then the engine simply does not start.

There may be other symptoms, it all depends on the nature of the breakdown. You should pay attention to the overall operation of the engine. Sometimes the fuel pump begins to fail due to minor problems. At some moments, the fuel pressure is not enough for stable operation of the unit, and it may stall. After restarting everything starts working normally again. But very often the failure is spontaneous and occurs unexpectedly while driving or after the car has been parked for a long time. If the spark plugs are dry, there is fuel in the tank, the starter turns the engine without problems, the battery is charged, you need to carefully examine the fuel pump.

Pusher

Since the housing does not affect the operation of the fuel pump in any way, unless it is damaged, of course, we will start with the pusher. This element is made of steel and cannot simply break. But wear and tear is welcome, especially if it is not original, but purchased as a separate spare part. As soon as its length decreases by a few millimeters, the fuel pump does not pump fuel.

Or rather, it pumps, but the amplitude of movement of the diaphragm is significantly reduced. This results in low fuel pressure in the system, and, as a result, interruptions in engine operation. The standard pusher length for DAAZ pumps is 84 mm. Measure its length and, if necessary, replace the worn part.

How to diagnose a fuel pump?

Do not rely solely on the auditory effect. If you cannot hear the fuel pump in your car, you should not immediately go to the store to buy a new device. Also, do not dismiss problems with the pump if you hear it working when you turn on the ignition. Just because the fuel pump is “buzzing” does not mean it is working correctly. It is quite possible that the internal part is worn out, or leaky elements have appeared that relieve pressure from the fuel system and prevent the fuel pump from collecting the required fuel pressure in the fuel line and in the injector rail.

Diagnostics should include several stages:

- checking the fuel pump fuse is an important point that should be performed if the buzzing of the device is not heard when you turn on the ignition, since power may simply not be supplied;

- checking the wiring is also one of the important points, because many power failures are associated with broken or oxidized wires, this needs to be checked before going to the workshop;

- checking for errors in the on-board control system - ECU diagnostics can tell you which sensor has failed, because often fuel equipment does not work well precisely because of incorrect sensor readings;

- measuring the pressure in the injector rail - on many cars, using a special pressure gauge, you can measure the pressure in the rail in order to understand what indicators the fuel equipment shows;

- checking the fuel pump directly - this can be done at a service station to obtain reliable information about the condition of this unit, but there are also opportunities for self-diagnosis.

Please also note that the failure of such devices is almost always spontaneous. Sometimes the fuel pump begins to show problems long before the final breakdown. But most often we are talking about a sudden failure. Therefore, you should also remember about the service life of the equipment. For example, in a standard injection car, the fuel pump most often lasts 100-150 thousand km. In the most reliable cars, the service life of this device can be up to 200,000 km. Rarely do pumps last longer. If your pump is already approaching this date, you should prepare to replace it.

Power check

You can establish the presence of voltage at the TN connector using a simple test to check electrical circuits. To check the fuel pump, in the electrical diagrams for your car model, find the pinout of the electrical connector of the fuel module. For the pump motor to operate, “–” and “+” are required. If, after turning on the ignition and connecting the control contacts to the corresponding pins of the block, the light comes on, then everything is in order with the supply voltage. Using this method, you can check for the presence of +12V and ground in the fuel pump relay connector, and establish the presence of supply voltage from the ECM to the relay. If the fuel pump does not turn on, but there are no problems with the components of the electrical circuit, the reason is in the fuel pump itself.

The most convenient way to determine why there is no power to the fuel pump is to use a multimeter. Let's say that + 12V to the pump comes from the relay, but does not reach the fuel module connector. In this case, it is necessary to ring the wires from the relay to the fuel section. In ohmmeter mode, you will not only find an open, but you will also be able to see the parasitic resistance in the circuit. When considering possible reasons why the fuel pump does not pump, do not forget about the immobilizer failure. Often in such cases the engine starts, but stalls after a few seconds.

Why the fuel pump could break - the main causes of problems

The causes of breakdowns can be very different. The first thing to consider is resource completion. Original pumps serve, as mentioned above, from 100,000 to 200,000 km. Non-original substitutes can travel 5-10 thousand km or cover the same 100,000 km without problems. It all depends on the chosen brand, price and checking for possible counterfeiting. It is the end of the resource that most often causes the failure of this equipment. But often by our actions we shorten the life of the device.

Very often breakdowns occur for the following reasons:

- the pump filter (mesh), which purified the fuel from various solid impurities, became clogged, which is why solid particles began to enter the pump, which led to its breakdown;

- low-quality fuel, which contains solid particles and elements dangerous to the fuel system, enters the tank; you need to more carefully choose a gas station for your car;

- the tank began to rust from the inside, which caused a large amount of debris to get into the fuel pump, which caused the product to be damaged, resulting in its premature failure;

- there was always about 7-10 liters of fuel in the tank, this is a problem for thrifty car owners who do not fill the tank full, in which case the gas pump fails faster;

- a fuel pump from an unreliable manufacturer was supplied, which caused additional problems; this should be taken into account when subsequently replacing the device with a new one.

If there is a crack in the system that causes a loss of seal, this can accelerate wear on the pump. The device will work at the maximum of its capabilities, which is why it will break down faster. Some of the fuel will enter the injector ramp, but the pressure will still not be high and stable. Therefore, it is important to exclude the possibility of depressurization of the system. Otherwise, further problems may appear very quickly.

Trouble-shooting

To repair a mechanical fuel pump, you will need to purchase a repair kit, which includes a diaphragm and valves - you can change these parts yourself. It will also not be difficult to replace the pusher with a spring. If the breakdown is more serious, then there is no point in resuscitation; it will be cheaper and easier to install a new fuel pump.

The electric fuel pump has a non-separable body, and it is not worth trying to repair it without certain skills; it is better to entrust such work to specialists. The only thing you can do yourself is to replace the mesh of the internal coarse filter. But even here you need to know that there are different types of meshes, so you will have to remove the filter from the tank to get a sample.

How can you repair a fuel pump in a car?

If we are talking about a breakdown of an old-style pump, its repair is quite possible by installing a repair kit. It is enough to replace the seals, install the necessary parts that are worn out or deformed, put the old pump in place and continue to operate it. Such repairs significantly extend the service life of the equipment. If you have an injection car with a modern type of gas pump, repairing it becomes possible only in some cases.

It is better to replace it in case of such breakdowns:

- the internal working part is worn out - in this case, the motor will buzz, but will not work and create pressure in the fuel supply system, this is important to take into account when diagnosing;

- the housing is broken - in case of mechanical damage, it will be almost impossible to repair the damage; it is very important to carry out a full replacement, and not invent handicraft repair methods;

- the electric motor has failed - repairs in this case will cost much more than purchasing new equipment, and it is impossible to repair the pump at home;

- a cheap pump from one of the Chinese companies broke down, in this case it is better to mark even a minor breakdown with a full replacement, since there is no point in investing in repairs;

- diagnostics do not allow you to clearly understand what the problem is; in this case, you will not be able to repair the fuel pump yourself, and the services of a specialized technician can be very expensive.

It is worth paying attention to signs of failure of pumping equipment. The longer the device has shown specific problems, the more reasons you will have to replace the fuel pump. It is impossible to independently disassemble and assemble pumping devices from Bosch, AC, VDO, Denso and other well-known brands. You will have to go to a workshop, where you will have to pay money for disassembly and diagnostics. If the device has passed enough kilometers or years, it is better to simply replace it with a similar one. This is the most appropriate repair option in this case.

We suggest watching a video about malfunctions of the fuel supply system:

Tags

Why is the fuel pump not pumping? The fuel pump and the fuel pump are not malfunctioning. The fuel pump is connected. The fuel pump is broken and the fuel pump is partially malfunctioning. Fuel pump that the fuel pump masses of the fuel pump in the fuel line. in the fuel line. in the fuel system a certain pressure. the required pressure in Pressure in The indicated pressure is accumulated by the pressure gauge pressure in the VAZ pressure at the fuel pressure regulator gas pressure not the fuel pump pumps the fuel pump is the fuel pump pump the non-fuel pump its pump work according to

vaz very repair method what kind of wear voltage regulator wiring

Let's sum it up

High-quality car parts allow you to operate your car for a long time without any problems. It is worth paying attention to components of original origin or close in quality to the originals. If the fuel pump in your car has failed, you will most likely have to replace it. In some cases, repairs are possible when the problems do not directly affect the pump itself and its working part. With a faulty pump, it is impossible to even get to a service station, so you should pay attention to signs of breakdown in time and take action in advance to eliminate such a problem.

If your car has trouble starting the engine, the sound of the pump from the tank, floating idle speed and other signs of problems with fuel pressure in the rail, you should immediately run diagnostics and find out what the problems are related to. It is quite possible that the troubles are related to other devices, but the gas pump is working properly and performs its tasks without problems. A good diagnosis will help you definitively answer this question.

Types of fuel pumps

Serial production of the “ten” began in 1995, that is, at a time when domestic cars were still equipped with carburetor systems. Mechanical fuel pumps were installed in them to pump fuel. This pump operates directly from the car engine.

For proper operation of the carburetor, high pressure is not required, and therefore the pump has a relatively simple design, similar to water pumping systems. It is installed directly under the hood of the car, which certainly makes it easier to service or replace.

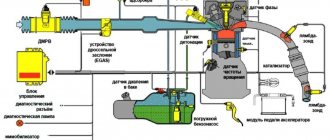

With the advent of injectors, the design of the fuel pump was also modified; it became electric. The principle of its operation has also changed. If the operation of a mechanical pump requires the starter to start rotating the crankshaft, then in the injection system the fuel pump is first energized, which, using a built-in electric motor, creates the required pressure in the line, and only after that the engine starts.

This type of fuel pump is installed directly into the fuel tank.

Thus, there are two types of fuel pumps: mechanical and electrical.

Start with the relay and fuse

Considering that the fuel supply module is located in the car tank, and it is not so easy to get to it, it is better to start diagnostics with the relay and fuse:

- Unscrew the screws securing the cover of the mounting block located to the left of the steering column.

- Underneath it, find fuse F3 (15 A) and relay R2. These are the elements that we need to check.

- As for the fuse, it needs to be “ringed” with a tester. If unusable, replace it.

Connection diagram

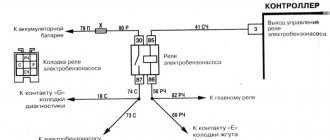

Above is an electrical diagram of a standard fuel injection pump. After successful interrogation of the immobilizer, the ECM (controller) supplies power to the coil winding of the fuel pump relay (terminals 85, 86). As a result of electromagnetic induction, contacts 30 of the power source (constant “+” from the battery protected by fuse X) and 87 are closed, which turns on the fuel pump. Main disadvantages:

- blown fuse; Attention! Replace the blown fuse with one of the correct rating. Installing a fuse with a higher current rating may cause the vehicle to catch fire.

- Oxide deposits in connectors, burnout of power contacts of the fuel pump relay. Parasitic resistance leads to a decrease in current in the circuit and a decrease in pump efficiency;

- abrasion, kinks of wires;

- break the clamp of the power connector leading to the fuel module. Contact is often broken when driving over uneven surfaces.