The causes of fuel pump failure are not always the same, and the devices themselves can be electrical or mechanical. Diagnostics of the performance of these types has differences, so we will consider ways to check the operation of gasoline pumps separately. However, the operation of the fuel pump can be checked in a maximum of 7 stages.

The need to check the fuel pump appears when the following signs of malfunction occur:

- the engine stalled;

- the car moves unevenly, jerkily;

- the engine idles unstable and does not start;

- there are “floating” speeds;

- increasing noise, whistling when the car is moving.

Symptoms of a faulty fuel pump

Fuel pump for VAZ

Actually, these are rather two stages of the same malfunction, although it happens that malfunctions in the operation of the fuel pump do not lead to its complete failure. Especially when these failures are caused by some extraneous factors. And so, the fuel pump either simply fails or does not work at all. These are all his breakdowns. Another thing is that there are many breakdowns of other elements, which in their symptoms are very similar to fuel pump breakdowns.

As for the signs of a fuel pump malfunction, there can be a lot of them, and as already mentioned, they may coincide with symptoms of problems in other components and systems of the car. Therefore, we will describe only the most common and most characteristic of these symptoms.

- the car does not start or stalls frequently;

- engine troits;

- extraneous noise in engine operation;

- drop in engine power;

- absence of characteristic noise when the fuel pump operates;

The signs are very eloquent, but it’s not always possible to understand what they are talking about. And here we cannot do without methods for diagnosing the fuel pump.

Replace with a new one or not

If the malfunction concerns a mechanical part, the driver has two ways to solve the problem. The first thing is to buy a repair kit. Includes all necessary parts that may break in the pump. The second is to replace the entire element with a new one. This is a more reliable and reliable method. But it is worth considering that submersible pumps are very expensive. Among the manufacturers on the market there are both originals and analogues.

How to determine if a fuel pump is faulty

Be that as it may, most of the signs indicating a fuel pump malfunction may indicate problems in other systems and components of the machine. The car is malfunctioning - maybe the spark plugs, maybe the ignition, maybe some sensor is acting up. Extraneous noise in the engine can generally be caused by various breakdowns. Even when the engine stalls immediately after starting, you cannot blame only the fuel pump. For example, without readings from the crankshaft position sensor, the ECU can stop the pump, which is quite a normal car reaction to such a problem. And even a decrease in pressure in the system can be caused by leaks in the fuel lines, breakdown of the bypass valve and other failures.

What can you do right away? First of all, you can check the operation of the fuel pump before starting the engine. To do this, open the fuel tank cap and have someone turn on the ignition without turning the starter. In the first seconds after turning on the ignition, you should hear a specific noise from the fuel pump. If it is missing, most likely the pump will have to be replaced, although it is possible that the reason for the failure is the power supply to the device.

Measuring the pressure in the fuel rail is another way to check the fuel pump. Normal pressure readings, as well as the correct procedure for installing a pressure gauge, should be found in the documentation for your car.

Most often, in modern cars, when the fuel pump fails, it is replaced. But there is no need to rush into this. Perhaps the cause of the failure is not the fuel pump itself, but, for example, a coarse filter that is simply clogged. In this case, simply cleaning this mesh will help and you won’t need to change anything. It is also worth checking the wiring, fuse, as well as the fuel pump relay; perhaps the reason for the failure of the device lies here. Again, checking the fuel lines, the bypass valve, and even the injectors themselves will also not be superfluous.

Fuel pressure measuring device

As mentioned above, the operation of the fuel pump is controlled by a special device - a pressure gauge. The most common MP is 100 produced by NTS LLC. We have been using it in our service since 2008, the accuracy of the readings has remained at the factory level. Includes adapters and safety valve.

Pressure gauge MP – 100

It allows you to measure fuel pressure both in the rail with the fitting and at any point in the fuel line. The kit with pressure gauge includes adapters:

The adapter extension UP-2 allows you to take measurements on rear-wheel drive classics.

Adapter TPB-2 for quick connectors.

It allows you to easily measure pressure on most modern cars.

There are many similar fuel pressure meters. Differences in price, size, dial. Structurally, all counters are similar. You can make a pressure gauge with your own hands, but the price is not worth it. It is much easier and more effective to contact diagnostics or any service. They will draw a conclusion and fix the problem.

Preventing fuel pump malfunctions

What should you pay attention to so that the fuel pump runs as long as possible? First of all, this is the quality of the fuel and, of course, timely replacement of the fuel filter. If the gasoline you fill contains various foreign inclusions, this will most likely negatively affect the condition and service life of the fuel pump, and not only it. Therefore, it is not worth saving on the quality of fuel, since such savings then result in very significant expenses for car repairs.

Monitor the fuel level in the tank. The fact is that the fuel pump is cooled by the same gasoline that it pumps. Accordingly, if there is little fuel, or the pump runs idle, it may overheat and therefore fail. Knowledgeable people also advise cleaning the gas tank at the appropriate time and not neglecting this procedure. This is, perhaps, all the prevention of problems with the fuel pump.

How to check without dismantling? Signs

There are several symptoms by which you can determine the malfunction of this unit:

- Deterioration in acceleration dynamics. The car does not accelerate well even when the trigger is fully pressed.

- Shots while driving.

- Difficulty starting the car.

Also note that similar symptoms can occur if the mass air flow sensor or throttle position sensor is faulty. It would be a good idea to check and replace the filter, both gasoline and air. The resource of the latter is 10 thousand kilometers. Its wear can be determined visually.

Measure the fuel pressure in the rail

As mentioned above, to measure the pressure of the fuel pump in the rack, the pressure gauge must be sequentially screwed into the fuel supply. The measurement is carried out in different ways, depending on the symptoms of the malfunction:

- How to check the fuel pump in the wall. This procedure is necessary to avoid clogging of the filter and fuel pressure regulator lines. The pressure value at the nozzle in the wall should be 6 atm.

- The craving is gone. First you need to measure the fuel pressure at the ignition switch, if it gives normal readings, measure it at idle. The pump should produce 2.5 - 4.2 atm, depending on the type of engine. 2.5 – RTD on the ramp, 4.2 – RTD in the tank.

- There are cases when the owner complains of a short-term loss of traction or due to heat. In this case, you need to check on the go. We attach the pressure gauge and check the tightness of the contact with the fitting so that there are no gasoline leaks. We fix the device on the windshield, under the wiper and off we go. If the fuel pressure drops while driving, it is necessary to replace the fuel pump, filter, and purge lines.

- The car won't start. We take measurements with the ignition on. Through the diagnostic scanner, you can turn on the fuel pump through the actuators. Working pressure from 3 to 4 atm.

With these simple steps you can measure gas pressure on any car. The main thing is to follow safety precautions when working with flammable liquids.

Checking the fuel pump of a carburetor car (mechanical)

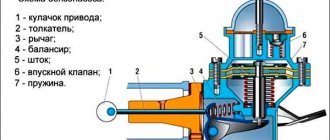

Mechanical fuel pump - diagram

To check the operation of the fuel pump, you should:

- Remove the fuel hose from the carburetor inlet fitting.

- Immerse the hose in a specially prepared transparent bottle. By actively using the pumping lever manually, we notice how strong and dense the fuel is supplied. Air impurities should not be visually noticeable.

Delayed jet output is not a sign of a breakdown, especially if the car has been parked for a long time. As a rule, diaphragms eight and nine are the main cause of malfunction.

Be that as it may, you need to inspect both the strainer and the inlet/outlet valve.

Even if the gaskets are replaced, fuel may leak. In this case, the problem lies in the tightness of the fuel pump housing due to deformation during repairs.

Let's summarize:

The causes of fuel pump problems, both electrical and mechanical, are varied, and the need to find/fix a breakdown may take you by surprise along the way. By following the above recommendations, you will be able to independently carry out the entire necessary set of measures to diagnose this device. And you should start with the power supply (if it is an electric fuel pump) and the operation of the diaphragm when checking a mechanical fuel pump. Very often, the unstable operation of a fuel pump is not due to its breakdown, but to related parts - a filter, check valve or injectors.

Signs of a Bad or Failed Fuel Pump Relay

The fuel pump relay is an electronic component found on almost all vehicles equipped with an internal combustion engine. It is often located in the fuse box located in the engine compartment and acts as the main electronic switch that controls power to the fuel pump. The fuel pump relay is usually controlled by the ignition control module or transmission control module and, when turned on, supplies current to the fuel pump so it can operate. Since the fuel pump relay controls power to the fuel pump, any malfunctions in it can cause problems with the fuel pump, which can cause vehicle drivability problems. Typically, a bad or faulty fuel pump relay will cause several symptoms that can alert the driver to problems.

The engine stalls

One of the first symptoms of a fuel pump relay problem is the engine suddenly stalling. If the fuel pump relay has a problem while the vehicle is running, it will cut off power to the fuel pump, causing the engine to stop. A faulty relay may cause the car to restart after some time, but a completely faulty relay will not.

Engine won't start

Another sign of a bad fuel pump relay is that the engine won't start. If the fuel pump relay fails, the fuel pump will be left without power. The engine may still start when you turn the key, but it will not start due to lack of fuel. This symptom can also be caused by a number of other problems, so it is highly recommended that your vehicle be properly diagnosed.

No noise from the fuel pump

Another symptom that may hint at a problem with the fuel pump relay is a lack of noise from the fuel pump when the key is turned on. Most fuel pumps make a quiet hum or whine that can be heard from inside the car if you listen carefully, or from outside the car near the fuel tank. If the fuel pump relay fails, it cuts off power to the fuel pump, rendering it inoperable and therefore cutting off the sound when the ignition is turned on.

Although the fuel pump relay is a very simple component, it plays a very important role in the proper operation of the vehicle. If your vehicle exhibits any of the symptoms listed above, or you suspect that your fuel pump relay has a problem, have your vehicle inspected by a professional technician to determine if the component needs to be replaced.

What is a pump for?

The fuel pump is a critical component that pumps fuel towards the engine carburetor. At the same time, it is important that fuel is supplied to it under some pressure, which guarantees uninterrupted operation of the engine.

Additional information: On cars with direct injection and a high-pressure pump (HP pump), this device is used as a booster unit.

Based on the type of drive and design features, two types of pumps are distinguished: mechanical and electric.

In mechanical samples, the diaphragm of the unit, when pumping, vibrates with a cam mechanism, creating a vacuum. Due to this, fuel under pressure enters the engine. Their electric or injection analogues contain an electric motor with a miniature pump powered by the on-board network. In these systems, all information about the state of the fuel line is collected and transmitted to the on-board computer. And the latter, based on it, ensures optimal engine operating conditions. Below we will mainly consider just such systems (they are called injectors).

Fuses and relays

The cause of a fuel failure may lie not only in the fuel pump. The fuse on the device's power line, which is located in the fuse box, may blow out.

To check, just open the fuse box and remove it from there.

- To check the relay, just turn the ignition key to the highest position - it should click.

- In this case, it is best to ask someone for help.

- Also, the relay may not work due to lack of contact. We remove and clean the contacts.