The handbrake is one of the most important elements in the safety system while driving. It is not only an element of the braking system, which is needed in order to effectively prevent a parked car from rolling, but also in order to avoid an accident. Some motorists are concerned about the question of how to tighten the handbrake on a VAZ 2114. In the article you can find a detailed answer to this question.

Handbrake VAZ 2114

How to tighten the handbrake on a VAZ 2114

The handbrake plays an extremely important role in ensuring driving safety. This element of the braking system not only serves to prevent a parked car from rolling, but can also help avoid a traffic accident. That is why it is necessary to always monitor the serviceability of its entire system. Now let's try to figure out how to tighten the handbrake.

Handbrake

Handbrake tension on VAZ 2114

During operation, wear often (usually always) occurs on the moving elements of the brake system. The first thing that suffers is, of course, the cables, which tend to deform and stretch. In such a situation, the sensitivity of the handbrake weakens, and, accordingly, its effectiveness. As a result, tension is required. We'll look at how to tighten the handbrake on a VAZ 2114 below.

The process itself takes place in stages and first the car must be prepared:

- We drive the car onto a highway overpass (optionally, onto an inspection hole), or use a jack.

- Set the gearshift lever to first gear

- We count the number of clicks of the handbrake before the wheels lock (less than two - you need to loosen the cable tension, more than six - on the contrary, strengthen it)

- Fully release the handbrake

- We are looking for two keys for thirteen. These are probably all the tools we need

- We go under the car and look for the muffler there (it’s not difficult)

- Remove the manifold and muffler mounts. This will greatly simplify the procedure

- We see a cable equalizer - that’s what we need

- Use the first wrench to loosen the lock nut, and hold the nut with the second to prevent twisting.

- Adjustment of the lever stroke occurs as follows: by tightening the nut, we reduce the lever stroke, and by loosening it, we increase it accordingly. We adjust and periodically check the progress. From 2 to 6 clicks is the norm.

- When the desired result is obtained, we jack up the rear of the car so that the wheels hang. Now we check whether the brake pads are interfering with the growth. Raise the lever - the wheels should be firmly in place.

- Now you can tighten the locknut.

Some craftsmen manage to tighten the handbrake without loosening the muffler. They use the notorious homemade keys. Due to the fact that tensioning is done quite often, such devices are quite relevant

Repairs are carried out in a similar way on the VAZ 2115 and VAZ 2113 models. The handbrake circuit for them is identical to the VAZ 2114, so the problems and methods for eliminating them are the same for all these cars.

HANDBRAKE CABLE REPLACEMENT PROCEDURE

The moving parts of the brake system tend to wear out. The working condition of such parts must be diligently monitored, since brakes are an extremely important part of the car. Timely repairs and diagnostics will help protect yourself and your car from unforeseen situations. The most unpleasant breakdown is a broken parking brake cable.

If the cable breaks, it must be replaced immediately. We'll look at how to replace the handbrake cable below.

As in any other case, DIY repairs require some tools. First, you need to find a car overpass or a hole (as a last resort, you can use a jack, which we will need anyway). You also need to prepare certain tools, such as thirteen wrenches (preferably 2), pliers, a hammer, plastic clamps and gloves. And the actual new hand brake cable for the VAZ.

When everything you need is prepared, you can start working. Replacing the handbrake of a vase takes place in stages:

- First of all, we put the car on an overpass or a pit, or jack it up and climb under the car;

- By removing the muffler can from the mounts, we will greatly simplify our work. If this is not done, it will be difficult to unscrew the cable tension nut;

- Unscrew the locknut and the adjusting nut of the handbrake. This concludes the work on the overpass for now;

- We drive the car onto a flat surface and jack up the rear;

- Remove the wheels;

- We knock down the locking pins from the pads;

- Remove the brake pads;

- Now you need to disconnect the cable ends from the equalizer. This is where pliers come in handy; you can use them to remove the clamps;

- You need to remove the cable loops from the hooks of the spacer lever;

- Unscrew the bolt securing the cable sheath and remove it;

- You can pull out the parking brake cable of the VAZ 2114.

We recommend: How to care for car paint in winter?

Pulling a new cable will no longer be a problem. Similar to the removal procedure, we do everything in reverse order. We start by pulling through the washers and loops on the hooks of the lever, and finish by tightening the handbrake in the cabin. The cable sheath also needs to be replaced sometimes, as it is also subject to wear. You can secure it after replacement with ordinary plastic clamps. This is how the VAZ 2114 parking brake cable is replaced.

Replacement is carried out in a similar way on VAZ 2115 and VAZ 2113 cars. These models have an absolutely identical brake system, so there can be no differences in repairs. An exception may be “amateur tuning” or unscrupulous repairs inherited from the previous owner.

Causes of handbrake malfunction

Breaking the handbrake is not such a rare occurrence and cable stretching is not the only problem. It happens that even after tightening the handbrake of the VAZ 2114 does not hold. We will take a closer look at the most common causes of this phenomenon.

The parking brake has a simple design, however, there is something to break in it.

There may be several reasons for this:

- Worn brake pads;

- Rope rupture or deformation;

- Drum wear.

Any elements of the handbrake system may also be worn out or subject to mechanical damage. In such cases, the problem is detected by eye or at service stations.

The handbrake does not work even if the cable falls off the lever. Any high-quality sealant that can prevent slipping will help here, or you can simply tighten the handbrake cable.

Front brake mechanism

The design of the front brake mechanism on the VAZ 2114

The front brake mechanism consists of the following components:

- Brake disk. Directly connected to the wheel hub and rotates with it. Slowing down the rotation and stopping the disk leads to the slowing down and stopping of the wheel.

- Pad guide. Serves as a holder for the pads and a base for the guide pins.

- Caliper. It combines the pads, cylinder, and piston into a single unit and ensures uniform transmission of force from both pads to the disc.

- Brake pads. They directly act on the disc, squeezing it on both sides and slowing down the movement.

- Cylinder. A sealed cavity in which the piston moves.

- Piston. Under the influence of hydraulic fluid pressure, the pad is pressed against the disc. Thanks to the “floating clamp” system, the second block is pressed simultaneously. This ensures uniform wear of their linings and discs and guarantees effective braking.

- Seal ring. Prevents fluid leakage and ensures system tightness

- A cover to protect the guide pin from dirt, allowing for unhindered movement of the pads.

- Guide finger. Allows the pads to move evenly and adhere to the disc with their entire plane.

- Protective cover. Protects the disc from road dirt.

The front wheels are equipped with disc brakes. They automatically adjust the clearance from the pad to the disc. The caliper and cylinder form a floating caliper, which creates the same even force on both pads. This ensures uniform wear of the linings. To monitor their wear, there is an indicator on the inner block.

Repair methods

A quick but costly way to get rid of handbrake problems is, of course, to go to a service station. The cost of such a service is about 400 rubles. However, is it worth spending money on something that you can do yourself, especially without much effort? Applying the parking brake yourself is not that difficult, and the savings are not small.

If you practice enough, tensioning the cable or replacing the pads will take no more than half an hour. Experienced car enthusiasts can handle this faster. Some operations require welding, so having the appropriate equipment and skills will not hurt. But this usually only applies to those who do not want to replace old parts with new ones, and prefer to repair worn-out elements with their own hands.

What does a handbrake consist of?

To successfully carry out any repair work, you need to know what the element that requires it consists of. The handbrake device is not complicated, but still, you need to pay attention to it.

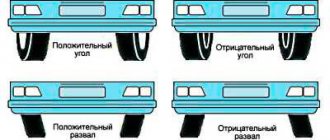

The visible elements of the handbrake drive include the locking button and the lever itself. The remaining parts are hidden, including: a protective cover, a handbrake rod, a cable equalizer, an adjustment nut, a control nut and a sheathed cable.

There is a mechanism on the rear wheel that is responsible for braking directly. This is where the pads are located, which need to be changed regularly, the drum, the condition of which also needs to be monitored, and other parts that make up the wheel locking mechanism.

Drawing conclusions

The serviceability of the brake system must be monitored first of all, because your safety and the safety of the car depend on it. Moreover, such a VAZ hand brake has a simple design, and repairs do not require complex tools. Domestic cars do not have complex elements or non-standard fasteners and are repaired with the usual garage equipment of the average motorist.

Take care of your car, and it will repay you with longevity and trouble-free operation.

How to tighten the handbrake on a VAZ 2113, 2114, 2115

The handbrake is a very important part of the car. Many novice drivers cannot imagine driving without it. The handbrake is used in a parking lot, when parking on a slope, while performing stunts on a car. That is why it is important to ensure that it works properly. If the handbrake on your car rises 6 clicks or more, this is a sign that it needs to be tightened.

How to tighten the handbrake

1. We prepare the car for work.

2. Raise the parking brake lever all the way up, determining the amount of its stroke. If it is less than 2 clicks, it is necessary to lengthen the drive, and if it is more than 6, shorten it.

3. Fully lower the parking brake lever. While holding the adjusting nut from turning with a 13 mm open-end wrench, use a 13 mm spanner to loosen the locknut.

5. When the adjusting nut is unscrewed, the drive lengthens, and when screwed in, it shortens.

6. Periodically, during the adjustment process, we check the stroke of the lever.

If the length of the threaded part of the rod is not enough to adjust the stroke of the lever, it is necessary to replace the drive cables, and if the linings are heavily worn, the brake pads must be replaced.

7. Having adjusted the travel of the parking brake lever, we hang up the rear of the car. We check the ease of rotation of the rear wheels and the reliability of their fixation with the parking brake.

8. If the brake pads do not interfere with the rotation of the wheels, fix the adjusting nut with a lock nut.

9. We check the functionality of the parking brake system: on an incline with a slope of 23%, it should reliably hold the car stationary.

Get ready for the fact that the handbrake needs to be tightened quite often. It is enough to drive the car without removing it from the brake and that’s it, you need to adjust it again. The handbrake is also adjusted after replacing the cable, repairs, or replacing the brake pads and brake cylinder.

Pro Tips

If you do not want to waste your time and energy on mastering a fairly simple handbrake design and tightening the handbrake yourself, you can contact a car service center. The price of the issue is at least 400 rubles, depending on the region of the country, but the event is not a one-time event. After a certain time, you will need to adjust the handbrake cable again, for which you will have to go to a car service center again. It is worth noting that the cost of the procedure will increase with each new visit.

After a tightening, it often happens that a strong cracking sound appears. It is possible that a cable or two cables were not installed correctly during tightening. Make sure that the cable does not catch on the fasteners or anything else. You can unscrew the bolts that hold the cable and see what condition they are in. If there are signs of rubbing, it is necessary to lay the cable correctly. In addition, the cable may crack because it is overtightened (even when the parking brake clicks fall within the required interval).

You have to tighten the handbrake quite often. This is due to the design of the parking brake. In addition, you will have to adjust the parking brake when replacing brake pads, repairing the handbrake, repairing the cable, and replacing the rear brake cylinder.

Handbrake tension on VAZ 2114

The VAZ 2114 car has good performance, reliability and maintainability. But this does not allow you to completely insure yourself against possible breakdowns.

Considering the state of domestic roads, it is not surprising that most often car owners turn to service stations with problems in the braking system or suspension.

A striking example of a breakdown is problems with the handbrake. More precisely, with cables that are responsible for blocking the rear wheels and do not allow the car to move until the handbrake is returned to its original position.

Whether you use a handbrake or not, sooner or later you will need to use the system. And if the handbrake has to survive regularly, then there is no debate at all regarding the need to urgently solve the problem.

Handbrake cable

Pulling up the handbrake

It is likely that you just need to tighten the parking brake on the VAZ 2110 to fix the problem.

- Drive to the inspection hole, from where it is most convenient to make adjustments. Another option is a lift. You'll find something here. This way you can easily get to the necessary nodes.

- Make sure the brake lever is in its lowest position.

- Take two keys. You will loosen the lock nut first and tighten the adjusting nut second.

- Tighten the adjustment nut until the cable is properly tensioned.

- It is strongly recommended to hold the rod when tightening the adjustment nut with pliers.

- Now make sure that the lever makes full travel in 2-4 clicks, no more.

- If after checking everything turned out to be good and the working stroke is correct, tighten the equalizer locknut while holding the adjustment nut with a second wrench.

- Release the handbrake lever down and turn the rear wheels by hand. Rotation should occur evenly without any jamming.

- But if the adjustment did not allow the cable to be tensioned, then the element must be replaced.

Design

Many people mistakenly believe that the handbrake is a simple lever located near the gearbox, on the right hand of the driver. In fact, it is a whole system of elements that are connected to each other.

When the hand brake fails, in 90% of cases the culprit is a cable or a pair of cables that go to the rear brake pads from the equalizer.

To determine the reasons for the failure of the handbrake, it is necessary to understand the circuit diagram of the device and its components.

Handbrake diagram

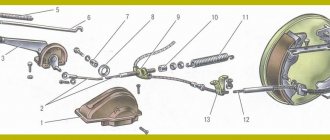

The device includes a number of structural elements. Namely:

- Lever arm;

- Traction;

- Springs;

- Lever button;

- Main cable axis;

- Bolts;

- Washers;

- Drive unit;

- Equalizer;

- Case;

- Locknuts;

- Cotter pins;

- Right and left lever;

- Expansion left and right strip;

- Lock washer, etc.

Tension

So, having understood the diagram, you can begin the procedure of tightening the handbrake cables.

Stretch

The tensioning procedure is as follows.

- Place the car on an overpass or pit. If you don’t have a garage and you have the opportunity or desire to carry out the procedure at a service station, use a jack. The rear of the car is raised on a jack. The most extreme option is a curb onto which the car is driven and all you have to do is crawl under it.

- Engage the gearbox in first gear and put the car on the handbrake by pulling the lever up.

- The ideal number of handbrake clicks is from 2 to 5. If there are fewer or more clicks, it is easier to take appropriate measures to tension the cable.

- If there are less than 2 clicks, then the cable will need to be lengthened. If there are more than five clicks, then the cables are shortened.

- Lengthening the cable means relaxing it. To do this, unscrew the locknut. When tightening the cable, the locknut must be tightened in reverse.

- Before you start looking for the required nut on the bottom of the car, release the handbrake lever all the way.

- Take a 13mm wrench under the car and head down.

- Find the handbrake cable equalizer. This is the same element from which the main handbrake cable is divided into two cables.

- In some cases, it is simply not possible to gain access to the equalizer, since the muffler holders made of rubber are in the way. In such a situation, it is better to remove them. This is not difficult to do, but working with the handbrake will be much easier.

- Now there are two nuts in front of you. One is a simple nut and the other is a lock nut. Having two keys in your hands, fix the nut with the first one, and with the second one begin to unscrew or tighten the locking nut. Be careful that the nut does not start to turn.

- Taking into account the condition of the handbrake and the need to loosen or tighten the lever, turn the locknut in the appropriate direction. Remember what is the optimal number of clicks.

- Tighten or unscrew the locknut to obtain the required degree of tension.

Examination

But if you twisted the nuts there, this is not a guarantee that the handbrake now works perfectly. This needs to be clearly verified.

To do this, it is enough to go through a successive stage of verification activities.

| Stage | Explanation |

| Spin the wheels after tensioning is completed | The wheels are lifted one by one on a jack. When the handbrake lever is turned off, they should rotate freely without obstacles. By squeezing the brake, the wheels should lock. |

| Drive up a slight slope, stop and engage the handbrake | The fact that the wheels do not spin when suspended is good. But you need to make sure that the handbrake holds the car even when exposed to gravity. |

If the check shows that the handbrake still does not hold, even if the cable was tensioned exactly according to the instructions, the handbrake is probably simply worn out and the cable needs to be replaced.

Signs that replacement is needed

It is not uncommon for the VAZ 2114 handbrake cable to rust, as a result of which it breaks or weakens so much that no tightening can restore its previous functionality.

At the first sign of cable wear, you should consider replacing it. This problem may manifest itself as follows:

- The handbrake is not able to withstand the required traction;

- Drum brakes overheat;

- When you pull the parking brake lever, the cable does not respond to your actions;

- The cable sheath is seriously worn.

To check the operation of the handbrake, it is enough to perform one simple action. Place the car on a level surface, apply the handbrake, get out of the car and try to push it hard. If movement begins, the cable is dead and needs urgent replacement.

Malfunctions and their symptoms

Determining that a cable needs adjustment or replacement is quite simple. Signs of a faulty mechanism appear as follows:

- The handbrake is pressed effortlessly - the cable is loose, you need to tighten it.

- The mechanism does not respond to pressing the lever - the drive is torn or flew out, or the reason may be the wear of the rear pads.

- If the handbrake is stuck, the drive is damaged and needs to be replaced.

Read more: Muffler VAZ 2107 injector and carburetor: malfunctions, replacement and repair, instructions with photos and videos

Having taken out the main element, you can visually determine its condition. Replacement is required in the following cases:

- Up to 2% are damaged or torn.

- The cable moves with difficulty even after applying lubricant.

- The drive tips have grooves.

Dismantling and replacement

It is difficult to confuse the cable from the handbrake with anything else under the bottom of your VAZ 2114, which greatly simplifies the repair and replacement procedure.

Dismantling works

We provide detailed instructions for replacement, and additionally recommend watching the video.

- We advise you to get the car in order in terms of cleanliness in advance. This will make it easier for you to find all the nuts and fasteners.

- Additionally, treat the nuts with the almighty WD40. This will make it much easier for you to unscrew the sometimes sticking and rusting nuts.

- Place the handbrake lever all the way down.

- Start with the adjusting nut and locknut that you used recently to try to tighten a loose cable. In this situation, you should loosen the nuts and remove them from the handbrake rod.

- Remove the washers and cable equalizer. Although this can be done after you jack up the car. But be sure to do it before removing the wheels.

- Raise the rear of the car with a jack, unscrew the wheel bolts and remove them.

- Tap the brake drum locking pins. This will allow them to be removed from the brake pads.

- Remove the block.

- You now need to disconnect the ends of the two cables from the equalizer. The fasteners can be removed from their places with the simplest pliers, so don’t bother.

- The shifted spacer lever has hooks from which the cable loop can be removed.

- The cable sheath must be removed from the entire suspension of the rear of the car. To do this, the mounting bolts are first unscrewed.

- Pull the cable out of the holes through the brake flaps.

- We got rid of the old cable, so all that remains is to replace the old one with a new element. The procedure is performed exactly in reverse order.

- Thread the new cables through the washers and hook the loops. You can additionally make bosses - this is a special clamp that allows you to fix the cable even more tightly.

- Reassemble the entire disassembled wheel structure.

- Route the cable along the suspension through the sheath and secure the bolts.

- Pull the handbrake in the cabin.

- Check the correct tension and operation of the new hand brake, or rather the cable.

It is not uncommon for the parking brake to cause an unpleasant squeaking noise from the rear. By changing the cable, you can get rid of this problem at the same time. To do this, rubber seals are installed under the cable fasteners on the body frames.

How to remove the parking brake cable?

- Removing the wheels

- Removing the brake drums

- Remove the rubber cushions (holders) of the muffler and manifold.

- Loosen the locknut of the handbrake adjusting nut on the cable equalizer.

- Using keys “13”, unscrew both nuts and remove them.

- We remove the equalizer and disconnect the cable ends from it.

- From the rear wheels, use a large slotted screwdriver to move the spacer lever forward and remove the cable eyelet from the hook of the spacer lever.

- Using a “10” wrench, unscrew the nut securing the cable to the rear suspension arms.

- Remove the cable end from the hole in the body bracket.

- Next, having removed the additional holding mechanisms, we take the cable out of the hole in the support shield of the rear brake mechanism and remove it.

Cable eyelet on the hook of the spacer lever