Passat B5 2.0 2002 ran over some stone and a crack formed in the pan. The oil immediately leaked out of the engine and the car had to be towed. The formation of cracks on the crankcase pan that is not covered by engine protection is a common problem for all drivers driving on our roads. There is a hole somewhere, and somewhere there is a bump and oil is already leaking from the pan.

Engine protection helps against this problem, although there is still no 100% guarantee. If there is a strong blow, then a crack will appear through the protection.

On the 2.0 Passat B5 engine, the pan is made of aluminum. To restore it, you need argon and an argon welder. To remove the pan, you will need to lift the engine and lower the subframe. It is quite difficult to do this work at home. But the photo instructions, if you are planning to do similar work, will help you do it yourself.

Design and purpose

The engine oil pan is a metal structure usually made of aluminum, but in older cars it could be made of steel. The shape of the oil pan resembles an elongated rectangular basin; it is attached to the cylinder block from the bottom side through a gasket on studs or bolts. There is a plug on the bottom or side surface designed to drain oil from the engine.

The pan is designed, firstly, to protect the oil receiver, crankshaft, and other parts of the engine crankcase from mechanical damage, dirt and dust. Secondly, it serves as a container for motor oil. It is from this that the oil pump delivers it upward through a filter - to the cylinder head, from where, having lubricated the parts of the gas distribution mechanism and connecting rod-piston group, it flows back.

Where is the oil pan located and what does it look like?

In passenger cars, this element is located under the engine. The part is attached to the cylinder block from the bottom side. Bolts or studs with a gasket are used as fasteners. There is a type of fastening where sealant is poured instead of a gasket. For Japanese engines, the part is usually bolted without seals and the joint is additionally filled with sealant.

External view of the oil pan

A pallet is a rectangular container, most often with ribs. These ribs give the structure rigidity; they are necessary if the structure is part of the hull. Usually in old cars the container is made of steel, in new and foreign cars it is made of aluminum, often black. For some foreign cars, models made of high-temperature plastic are produced.

There is a plug located at the bottom or side of the pan through which oil is drained from the engine. To prevent oil from freezing at subzero temperatures, a heater is often installed that heats the liquid. If necessary, the ten can be quickly dismantled.

Drain plug on the oil pan

While the engine is running, the oil from the sump is filtered and then rises to the cylinder head. When all elements of the internal mechanism are lubricated, the remaining oil returns inside the container. The reservoir is intended not only for storing lubricant. This element protects the crankshaft and other engine parts from mechanical damage. It prevents the ingress of road dust and soil, and serves as a container for chips formed as a result of friction of metal elements.

When to remove the engine sump

Usually the part is dismantled in case of breakdowns or severe corrosion. It happens that there is no damage on the pallet, but it leaks. The cause may be the sealing gasket; it is damaged in the following cases:

- Deformation of the seal due to temperature changes.

- Mechanical damage due to impact with the road surface.

- Increased pressure in the crankcase, which ruptured the seal.

- Damage due to exposure to caustic chemicals.

Oil pan gasket for Mitsubishi

It is not difficult to identify a gasket-related problem. In this case, oil streaks remain on the pallet or under the car. The oil level drops sharply, and the pressure in the oil system drops noticeably.

Possible faults

Malfunctions of this part do happen, and it is dangerous to ignore them, since loss of oil threatens serious and expensive repairs of the internal combustion engine. They can be easily diagnosed by oil leaks - a characteristic small puddle that remains on the asphalt after an overnight stay and a wet sump. The causes of leaks may be:

- loose oil pan bolt;

- gasket wear;

- loose drain plug;

- cracks in the metal.

Cracks in metal are a much more serious problem than a poorly tightened bolt. They can appear as a result of impacts with large stones, curbs, etc. Even if protection is installed under the crankcase, it can crack due to non-compliance with the bolt tightening torques recommended by the manufacturer. A crack can also occur if the drain plug is overtightened after an oil change or repair. It has a slightly conical shape, is made of a harder metal, and can tear the pan. Such a crack is difficult to see, and some service workers, trying to eliminate the leak near the plug, tighten it even more, which subsequently aggravates the situation.

It is worth noting that a slight “sweating” around the oil drain plug, in the absence of drops or streaks, is normal.

Engine sump: repair

You can often repair or restore the engine oil pan yourself.

When a leak occurs in the area of the gasket between the crater pan and the cylinder block, first of all it is worth checking the tightness of the mounting bolts/nuts. It is necessary to tighten the bolts according to the tightening torques recommended by the manufacturer, otherwise you can strip the threads or cause a crack to appear - then you will have to make more complex and expensive repairs, restoring the tightness of the engine crankcase.

If tightening the bolts does not eliminate the leak, the gasket must be replaced. In this case, you cannot do without removing the pallet. This is not difficult to do from a viewing hole, on an overpass or a lift. We will look at how to remove and install the engine sump yourself below.

The most easily corrected malfunction can be considered a poorly tightened drain plug; they could simply have forgotten to tighten it well after the next maintenance. It is tightened using the appropriate key, by hand, without using additional levers or pipes.

But if you have diagnosed a crack in the oil pan in your car, then the best way to repair it is to completely replace it. However, there are situations when a car of a rare model or a new part is quite expensive, there are several ways to restore its integrity. For example, using glue, dry welding or argon welding.

Removing and installing the engine oil sump

Tools:

- Sealant

- Torque wrench

- Driver for 3/4″ socket bit

- 6mm wrench attachment

- 8mm wrench attachment

Parts and consumables:

- Crankcase gasket

Gasoline engines

1. Remove the engine mudguard.

2. Drain the oil from the engine crankcase.

3. On engines 1.0 l, 37 kW and 1.4 l, 50 kW, disconnect the cooling system pipe from the brackets under the oil sump.

4. Remove the oil sump mounting bolts. On engines of 1.4 l, 50 kW, also unscrew the bolts 14 (see Fig. Parts of the lubrication system of the engine 1.0 l, 37 kW and 1.4 l, 50 kW) securing the support 10 with the lower shield 9 to the clutch housing and remove support.

5. Remove the oil sump from the cylinder block. On engines 1.0 l, 37 kW and 1.4 l, 50 kW, press out the cooling system pipe. On 1.0 l, 37 kW engines, remove the oil pan gasket.

6. Thoroughly clean the mating surfaces of the oil crankcase and cylinder block from any remaining oil and old sealant.

7. On 1.0 L, 37 kW engines, install a new crankcase gasket and apply sealant in the area where the timing gear cover connects to the cylinder block.

8. On other engines, apply a 2-3 mm thick layer of sealant to the oil sump flange as shown in the figure. Make sure that the layer of sealant does not exceed 3 mm, otherwise excess mastic will be squeezed into the oil sump, which will lead to clogging of the oil receiver. Be especially careful on the flywheel side of the flange. In the area indicated by arrow “A”, apply more sealant according to the dimensions shown in the figure.

9. Install the clutch housing lower shield onto the support.

10. Reinstall the oil pan, pressing out the coolant pipe if necessary. The work should be carried out with an assistant.

11. Install the bolts securing the oil sump to the cylinder block in the sequence shown in the figure. Then screw in, without tightening, the two bolts securing the support with the lower shield to the clutch housing.

12. Tighten the bolts securing the oil pan to the cylinder block in the sequence shown in the figure, and finally tighten the two bolts securing the support with the lower shield to the clutch housing.

13. Finally tighten the bolts securing the oil pan to the cylinder block in the specified sequence.

14. Secure the cooling system pipe.

15. Let the sealing mastic dry for 30 minutes and only then pour oil into the engine crankcase.

Tightening torques, Nm

Bolts securing the support to the clutch housing - 45

Bolts securing the oil sump to the cylinder block:

- M6 - 10

- M8 - 20

Diesel engines

1. Remove the engine mudguard.

2. Drain the oil from the engine crankcase.

3. Remove the oil sump mounting bolts.

4. Remove the oil sump from the cylinder block.

5. Thoroughly clean the mating surfaces of the oil crankcase and cylinder block from any remaining oil and old sealant.

6. Apply a layer of sealant 2–3 mm thick to the oil sump flange, as indicated by the arrows in the figure. Make sure that the layer of sealant does not exceed 3 mm, otherwise excess mastic will be squeezed into the oil sump, which will lead to clogging of the oil receiver. Be especially careful on the flywheel side of the flange.

7. Reinstall the oil pan.

8. Install the bolts securing the oil sump to the cylinder block crosswise. Then tighten, without tightening, the three bolts securing the oil pan to the clutch housing.

9. Tighten the oil pan mounting bolts to the cylinder block in a cross pattern and finally tighten the three oil pan mounting bolts to the clutch housing.

10. Finally tighten the bolts securing the oil pan to the cylinder block in a cross pattern.

11. Let the sealing mastic dry for 30 minutes and only then pour oil into the engine crankcase.

Tightening torques, Nm

Bolts securing the oil pan to the clutch housing - 45

Bolts securing the oil sump to the cylinder block - 15

The article is missing:

- Photo of the instrument

- Photos of parts and consumables

- High-quality photos of repairs

Source: https://www.navigator.mn/skoda-fabia.html

How to remove and install the oil pan yourself

This is not a complicated procedure, and most car enthusiasts can do it, although it does require some repair skills and tools. Depending on the brand of the car, nuances are possible. For example, in VAZ cars of the classic family, with a longitudinal engine, you need to lift the engine. Therefore, before you start disassembling it yourself, read the repair manual for your car.

Procedure for removing the oil pan:

- Prepare a clean container - it can be a canister with a wide neck or a cut one. Its volume must correspond to the amount of oil in the engine of your car;

- Drive onto an inspection hole or overpass; it will be more convenient for you if it is deep enough so that you can stand under the car at full height;

- Warm up the engine to a temperature of 50-60 degrees, the engine oil will become thinner and more fluid;

- If the engine compartment protection is installed, remove it; it is usually secured with 3-4 bolts;

- Carefully unscrew the drain plug, placing a previously prepared container under it, be careful - the oil will definitely flow onto your hands and possibly somewhere else;

- Unscrew the oil filler plug. After unscrewing the filler plug, the flow of escaping oil will increase sharply, make sure that it flows into the canister and losses are minimal;

- Wait until all the oil has drained and begin unscrewing the fastening bolts/nuts;

- If all the bolts are unscrewed and the oil pan cannot be removed by hand, this means that the parts have been glued together. You need to tap it with a rubber hammer, carefully pry it with a screwdriver or other flat object, but so as not to damage the joints. Scratches may cause leaks in the future.

Which oil and oil filter to choose for VW Passat B5 2.0

The volume of engine oil with filter is 3.5 liters . Specification: VW 500 00|VW 501 01|VW 502 00, extended service life (longlife) - VW 503 00.

Characteristics of motor oils

The physical and chemical analysis of motor oil includes: viscosity index, ash content, alkaline numbers and other indicators. What does this mean? Let's consider the influence of the main technical characteristics on the quality and properties of engine lubrication. Read more

| Manufacturer | vendor code | price, rub. |

| Original | ||

| VAG | 6A115561B | 474 |

| Analogs | ||

| BOSCH | 451103314 | 254 |

| MANN FILTER | W71930 | 342 |

| MAHLE KNECHT | OC264 | 356 |

Pad

It is the gasket that ensures a tight connection between engine parts. When purchasing, be sure to match the article number. It is not possible to repair a worn gasket. It is recommended to replace it after each removal of the oil pan during installation. In this case, you need to carefully and very carefully clean the surfaces that will be in contact from the remnants of the old gasket and sealant.

To improve the properties of the gasket, you can use graphite lubricant, a special sealant for the engine crankcase, or any heat-resistant silicone-based sealant.

Graphite lubricant is applied to both sides of the gasket in a thin layer; after assembly, it fills micro-cavities, and hardens under high temperatures.

It is preferable to use a special sealant; it is applied in a thin, uniform layer over the entire contact area, on the pan and on the cylinder block. After assembly, the sealant will dry and, as it were, glue the surfaces, ensuring a tight fit and sealing.

Some craftsmen use sealant instead of a gasket, in which case its layer should be thicker, but it is better to leave this method in case the car is so rare that it is difficult to find the right gasket for it.

Removing and installing the Nissan Sunny oil pan

To seal the oil pan, use a regular sealant, such as Loctite. Warning

Don't apply too much sealant, be especially careful around bolt holes. The parts must be assembled together within 5 minutes after applying the sealant. After this time has elapsed, the sealant must be removed and reapplied. Removal

Execution order

1. Disconnect the ground cable from the battery.

Warning This erases the electronic memory, for example, the engine fault memory or the radio code. Before disconnecting the battery, read the instructions in subsection 7.2.

2. Raise the car.

3. Remove the engine underbody protection.

4. Drain the engine oil.

5. Remove the center beam.

6. Remove the muffler exhaust pipe.

7. Unscrew the oil pan mounting bolts.

8. Drive a wedge into the seal between the cylinder block and the pan (arrows indicate the location of the seals). For this purpose, workshops use the KV-10111100 device, which is driven between the cylinder block and the oil pan.

9. If there is no device, you can use an old knife

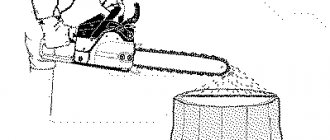

Carefully drive the knife between the block and the pallet with a hammer.

Warning Do not pry the pallet with a screwdriver or chisel under any circumstances without first cutting the seal. When removing, make sure that the sealing surface of the oil pan is not damaged.

10

Remove the oil pan.

11. It is recommended to remove the mesh filter with the pan removed and clean the filter with a cold cleaner.

12. Check the mesh for damage, such as tears, and replace if necessary.

Installation

Execution order

1

Carefully clean the pan and block sealing surfaces of seal residue using a triangular scraper and razor blade.

2. Gently wipe the block, crankshaft mechanism and oil pump

Otherwise, oil will drain onto the pan seal.

3. Screw the strainer with a new gasket with a force of 20 N.m.

4. Degrease and dry the mating surfaces of the pan and cylinder block. You can use alcohol or acetone as a cleaner.

Warning Do not use cleaners that corrode the varnish surface.

5. Place new gaskets in both semicircular recesses of the oil pan and cover both ends with sealant.

6. Apply a strip of sealant 4–5 mm wide around the entire perimeter of the sealing surface of the oil pan. At the same time, apply a strip of sealant between the bolt holes in the groove (1) of the pan. Apply a strip of sealant to the bolt holes (2) on the inside of the pan at a distance of 7 mm.

7. Install the oil pan onto the cylinder block. Tighten the bolts first by hand, then crosswise (from 1 to 15) with a force of 8 N.m.

Warning Wait 30 minutes for the sealant to cure before adding oil.

8. Install the muffler exhaust pipe.

9. Install the center beam.

10. Install engine underbody protection.

11. Lower the vehicle.

12. Fill with engine oil.

13. Connect the battery ground cable.

14. If available, set the clock and enter the radio security code.

15. Carry out a test drive, check the oil level and the tightness of the oil pan seal, if necessary, carefully tighten all bolts.

Video about “Removing and installing the oil pan” for Nissan Sunny

Removing the oil pan in a Nissan Qashqai with your own hands

Nissan Cefiro A33 Part 5.5. Removing the engine sump, replacing gaskets. HOW DID I GET IN?!

repair of a broken pan on a Nissan March K-12

Cold welding

The cheapest way to repair a crack is by cold welding. It is no different in terms of reliability, because it is not brewing, but rather caulking/sealing. Cold welding, as a rule, consists of two components, which are mixed together, applied to the damaged area and allowed to harden. Before doing this, be sure to degrease and thoroughly clean the damaged area. In the case of a small crack, you can try to seal it without removing the pan. When choosing cold welding, pay attention to the temperature at which it retains its properties - it should be at least 200 degrees.

Argon welding

Argon welding is the most effective way to remove damage. This type of welding can be used to weld both aluminum and any other non-ferrous metal alloys. A good welder can easily fix a crack or weld a small hole, and the seam will not affect the functionality in any way. The disadvantage of such repairs is the high price. You can, of course, save money if you remove the part yourself and contact welding specialists directly. But in the case of common brands of budget cars, it will cost less to replace the oil pan with a new one.

You can also use glue for repairs. There are many different types that allow you to seal metal, but epoxy remains wear-resistant, heat-resistant and water-resistant. It is based on resins, substances to accelerate curing, and other fillers. The application of epoxy adhesive is similar to dry welding, it is also two-component and comes in paste or liquid form.

How to protect the oil pan from damage

The oil pan can be damaged as a result of driving on bad roads, hitting a large stone or curb. Therefore, we cannot turn away from the question of its additional protection.

There are several types of engine protection:

Polymer or plastic options cannot guarantee reliable protection, despite their low cost; they should not be installed in bad road conditions.

Aluminum protection is lightweight and corrosion-resistant, but due to its high cost and soft metal, it is also not recommended to use it when driving on bad roads.

Titanium would be an ideal option, in all respects, if not for their high cost. For now, they remain the prerogative of premium cars.

The optimal solution would be engine protection made of steel. It will reliably protect the engine crankcase at its low cost. On many modern cars, the manufacturer provides the possibility of installing engine protection. Therefore, to simplify installation, you need to select it taking into account the make and model of your car. It would be a good idea to seal the protection by installing special inserts so that it does not rattle when moving, or periodically check the tightening of the fastening bolts.

Not only internal combustion engines have a sump. It can also be with an electric motor or gearbox, be it a CVT, manual or automatic. There it performs almost the same functions and in some cases, for example, if it is an SUV for trophy rally, more powerful crankcase protection is required, not only for the engine, but also for other mechanisms.

Replacing the VAZ-2107 oil pan

Remove the engine splash guard.

Drain the oil from the crankcase (see Changing the oil).

Drain the liquid from the engine cooling system.

Disconnect the upper radiator hose and the lower radiator hose.

We unscrew the four nuts securing the exhaust pipe to the exhaust manifold and, using a 13mm wrench, unscrew the bolt securing it to the gearbox bracket.

Remove the exhaust pipe from the manifold studs and lower it.

We unscrew the four nuts securing the exhaust pipe to the exhaust manifold and, using a 13mm wrench, unscrew the bolt securing it to the gearbox bracket.

Remove the exhaust pipe from the manifold studs and lower it.

We unscrew the two upper nuts securing the engine mount cushions (see Replacing the engine mount cushion).

Using a wooden block, we rest the jack against the clutch housing (the engine can be lifted with a hoist).

We lift the engine, “helping” the pillow studs with a screwdriver to come out of the holes in the brackets.

Using a 10mm socket, unscrew the nineteen bolts securing the oil pan

We install the removed parts in reverse order.

We recommend replacing the oil pan gasket, preferably with cork chips in the rubber.

We tighten the pan mounting bolts gradually, just as we did when replacing the cylinder head gasket.

We lower the engine, using a screwdriver to adjust the studs of the pillows into the holes of the engine brackets.

Fill the engine with fresh engine oil.

Replacing the oil pan and its gasket on a VAZ 2101-VAZ 2107

Welcome! Today, many people already know such a thing as an oil pan, but not everyone knows what it really is, when it needs to be changed and how to properly replace it on cars of the “classic” family - we will look at these questions today.

Note! To replace the pan and its gasket, you will need to prepare a few things in advance: First, be sure to stock up on wrenches, or you can use an extension, universal joints and sockets instead!

Summary:

Where is the oil pan and its gasket located? The pan is located at the very bottom of the car engine; unfortunately, in order to fully see the pan it is necessary to remove the crankcase protection, which is done in the figure below:

Note! The blue arrow indicates the gasket that is located between the cylinder block and the crankcase pan!

When do you need to replace the oil pan and its gasket? The pan must be replaced if it is deformed, due to which the engine oil that was located in it begins to flow out of the pan itself.

The pan gasket must be replaced if it is strongly compressed and if it is torn, how do you understand this, you ask? Usually, when the gasket is deformed, engine oil begins to flow through it, but the leak can also be treated by simply tightening the bolts that secure the oil pan, but if tightening the bolts does not produce any results and the leak does not stop, then replace the gasket with a new one.

Question? Which of these two parts are you replacing, the pan or the gasket? (Write your answer in the comments)

Tools and materials required for work

- Jack or lift;

- 10mm, 13mm, 16mm, 18mm and 19mm wrenches ;

- Screwdriver “-“;

- Hammer;

- 5 mm hexagon ;

- Engine support or jack;

- Container for used oil;

- Sealant REINZOSIL +300 Victor Reinz;

- Oil filter puller F-61901 “FORCE” ;

- Mount;

- Sandpaper.

And of course you will need new engine oil.

How to remove the oil pan of a VAZ 2107

Before you begin removing and replacing the pan on a VAZ 2107, you need to understand its purpose, location and damage that entails the need to change the crankcase.

The pan is located at the bottom of the car, and in order to see it and gain access, you will need to remove the protection. Structurally, the device consists of a steel base that resembles a lid. This container contains engine oil, so to ensure tightness, there is a gasket between the crankcase and the cylinder block.

Removing the VAZ 2107 oil pan must be performed when deformations occur, which leads to engine oil leaking out of the engine. There is a lowest point on the cover body where the engine oil drain plug is located. Before removing the oil sump, you must first drain the engine oil.

An oil leak can occur not only when the crankcase is deformed, but also when the integrity of the gasket is damaged. To eliminate the leak, you need to tighten the fastening bolts, and if this does not help solve the problem, then you will need to resort to changing the gasket.

Now, when the need arises to replace the pallet on the seven, we must resort to such manipulations. It is worth noting that the gasket needs to be changed more often, and crankcase defects occur only if there is no protection on the car. Removing the engine oil pan on a VAZ 2107 should be done in the following sequence:

- To begin with, the car should be placed on an inspection hole or overpass. Carrying out work under the bottom without placing the car on a pit or overpass is simply very inconvenient.

- The next step is to begin dismantling the protection, which is secured with 4 bolts.

- After removing the protection, you need to unscrew the oil drain plug. If you plan to change the oil after completing the procedures, it is recommended to warm up the engine to 40-60 degrees before removing the plug. Before unscrewing the plug, you need to place a container into which the oil will drain. You can use an old plastic oil can for this.

- Next, you need to loosen the nuts securing the two engine mounts from under the hood. The nuts need to be loosened, but not completely unscrewed, to avoid the possibility of the engine moving. After loosening the nuts, you need to lift the engine to remove the cover. Without lifting it, it will not be possible to remove the crankcase on the seven.

- There are different ways to raise the engine. The first method is to use a traverse in the form of a wooden block, which is laid parallel to the radiator. A pin, pre-attached to the motor, is passed through the traverse. Screwing the nut onto the stud causes the engine to slowly rise. The second method involves using a winch. The third method is the simplest and most accessible - using a diamond-shaped jack, which is located under the box and, by acting on it, the engine is raised. When the engine rests against the nuts of the mounting brackets, you can continue further manipulations to replace the bottom cover.

- Along the perimeter it is necessary to unscrew all the crankcase mounting bolts, of which there are 19 in total. These bolts are screwed together with the nuts, so when unscrewing them, it is important not to lose them. Some bolts are difficult to reach, so it is recommended to use special hinged wrenches with socket or socket heads.

- After this, you can begin to dismantle the cover, as well as its subsequent replacement. The new crankcase should have a similar design. After the change, the assembly process is performed in the reverse order of dismantling.

When replacing, it is important to consider such points as the plug and gasket. The plug also has a sealing material that wears out, so a new pan must come with a new plug. If it is not there, then it is not recommended to use the old one, and it is better to buy a new one or a seal for it. We will consider the features of replacing the gasket below.

Replacing the seven crankcase gasket

More often it is necessary to replace the oil pan gasket on the seven, since the rubber material tends to wear out. Changing the bottom cover also involves installing a new gasket, since leaving the old seal is strictly contraindicated. It is necessary to change it in order to prevent oil leakage. It is not expensive, so at the first sign of oil leaks, you should change the gasket.

The process of installing a new gasket is similar to the procedure for replacing the crankcase, but some features should be taken into account:

- If the gasket is replaced, the end of the cover where the new seal will be located must be cleaned.

- Before installing the seal, it is recommended to treat it with sealant on both sides. This will increase the tightness of the connection and also eliminate the occurrence of oil leaks.

- When removing the pan, the gasket must be changed in any case.

How to remove the oil pan on a foreign car

Instructions are provided for the 2003 Mitsubishi Space Star 1.6. In this case, the pan is bolted and located above the muffler. First you need to drain the oil and unscrew the bolts securing the exhaust pipe to the muffler.

Now place a stop under the muffler and remove the rubber bands (usually there are two of them). The stop is necessary to ensure that the lambda probe is not overly stretched and the wires are not damaged.

First you will have to unscrew the gearbox casing, which prevents you from removing the necessary part - you need to remove the casing itself and the plate under it.

Cover that needs to be removed

Next, unscrew the bolts located around the perimeter of the pallet (with a 10-point head), due to which it is held in place.

After this, the tank is still held in place by the sealant. In order for the pan to begin to detach, it is necessary to tap its body with a rubber mallet. If the spare part is not yet worn out, do not hit it too hard, otherwise you may pierce the metal.

Now the part will come off easily. After removal, it is important to check the condition of the oil sump mesh. If there are deposits, the mesh is unscrewed and washed in solvent. It is also important to remove any remaining sealant and then treat the surfaces with a degreaser.

Old and new oil pans

Then everything is put together in reverse order.

In addition to the instructions given, you can also watch a video with step-by-step removal of the pallet:

Replacing the oil pan gasket

Replacing the oil pan gasket in many car models is not a complicated process. You can replace the gasket yourself at home, for example, if you devote a couple of hours to this task on a weekend. This guide shows you the process and the key points you should pay attention to.

And it's better to do it sooner rather than later. A damaged or worn oil pan gasket under your engine can lead to serious oil leaks, overheating of the engine and sometimes catastrophic failure; if the oil level drops significantly without you noticing it, you can trap the engine.

Invest a few hours of your time and follow the systematic procedure described here. This will save your engine from severe damage and your wallet from costly repairs.

This article will cover:

- Preparing for removal

- Removing the oil pan

- Tips and tricks

- Some Important Notes on Gaskets and Seals

- Installing a new gasket

How to remove the oil pan on a Mitsubishi Karizma

To remove the oil pan on a Mitsubishi Karizma, you will need a lift or inspection hole.

The engine protection, if installed, must also be removed. It is better to combine removing the oil pan with changing the oil and filter, therefore, if possible, this operation is recommended to be carried out at a certain service interval. You will also need a set of sockets, a short 10mm socket wrench, an impact screwdriver, sealant and solvent. So, the engine protection was removed.

Now you need to unscrew the two nuts securing the muffler to the engine. They become very sticky due to high temperature, so you need to spray them with WD and wait a few minutes for it to start working. We unscrewed these nuts using a 19 mm socket and a wrench with a long lever. Remove the muffler from the studs and lower it down.

Next you will need to remove the part, which is indicated in the diagram as a bracket. Let's use two heads again. The bracket is secured with 6 bolts: 2 by 14, and 4 by 12.

Now access to the bolts that hold the oil pan is open. Before unscrewing them, do not forget to drain the oil and remove the filter.

To unscrew the bolts, you need a 10mm socket. The bolts unscrew easily, especially if you use a wrench with a large lever. It is impossible to insert a regular head onto the bolts on one side of the pan; the engine housing is in the way. For these purposes, you need to purchase a short thin-walled socket wrench and use it to unscrew the remaining bolts.

When installing the Mitsubishi Karisma pan, gaskets are not used; here a sealant is used to seal the joint. Therefore, after unscrewing all the bolts, the pan will remain in place. To remove it, you need to take a thin impact screwdriver, insert it between the pan and the engine and apply a few gentle blows to create a gap.

Then it must be carefully expanded and the part removed.

If you remove the pan for some manipulation, for example, to eliminate an oil leak, then it must be thoroughly cleaned before reinstallation. We remove the oil with a rag soaked in gasoline, and remove the remaining sealant with a knife or sandpaper. Some of the sealant also remains on the engine, so it is necessary to remove all excess there too.

To seal the pan, the German sealant Victor Reinz Reinzosil is used. Along with the tube, a plastic cap is included in the package, which is cut to the desired diameter.

Before applying the sealant, the edges of the pan and engine are thoroughly degreased with a solvent.

The sealant is applied in a small continuous layer, avoiding the bolt holes. The instructions indicate that the parts are connected immediately after application, so there is no need to wait for it to dry. To seal the oil pan on a Mitsubishi Karizma, half a tube was used.

Having connected the pan and the engine, we immediately tighten the bolts, not in a row, but one opposite the other. First, tighten the bolts lightly, and then tighten them all the way. For these purposes, it is better to use a torque wrench and tighten them with the recommended torque. But most car enthusiasts tighten the bolts in the usual way. After tightening all the bolts, install the bracket, screw on the exhaust pipe, oil filter and secure the engine protection. No earlier than 5 hours later, when the sealant has completely hardened, fill in the oil and use the car. If you liked the article, share it on social networks.

VIDEO

Preparing to remove the oil pan

NOTE. On some models, replacing the oil pan gasket is more difficult. For example, you may need to remove the engine from its mounts using a lift to gain access to it. If you don't know how to access your car's oil pan, look up the manual for your specific make and model online or ask a mechanic at a service station.

The manual shows the location of each bolt and any components you may need to remove for easier access.

1. Raise your car so that it is convenient for you to work on the bottom of the engine

- Drain the oil by unscrewing the drain plug3. Allow the oil to drain completely4. While under the vehicle, look for components and parts, if any, that will prevent you from gaining easy access to the pan with the keys and remove them. The most common items you may have to deal with are cross members, exhaust components, or support brackets.

Removing the oil pan

- When everything is ready, loosen all the bolts located around the pan flange. Sometimes you need to use ratchet handles or ratchet extensions to get better access to some bolts.

- Then finish removing all the bolts and remove the pan from the bottom of the engine block by hand if necessary. If it seems stuck, tap it lightly with a rubber mallet. *However, when the pan does not come loose, make sure that you have removed all mounting bolts and that no other component is holding it in place. * If this doesn't work, use a gasket cutter to cut the seal by pushing the cutter with a rubber mallet between the flange and the engine block in several places around the pan. Do not use a screwdriver to release the pan, otherwise you may damage it or the mating surface of the engine.

- Once you've removed it, check the bottom surface for metal shavings. You may find a few chips, but a large number of them may indicate excessive wear on some engine components. If necessary, contact a repair shop.

- Thoroughly clean the area where the tray is located. You must remove old gasket material and deposits. The gasket scraper speeds up the task without damaging the surface.

- After removing any traces of gasket or silicone, use solvent to clean the mating surfaces and, if necessary, wash the pan with cold detergent. If the grease and silicone are difficult to remove, use carburetor cleaner or engine degreaser and a wire brush to remove this sealant.

- Next, check the pan for damage, such as cracks, and double check the pan flange for bends. You can do this by placing it on a flat surface. The glass surface is perfect for this. * Take a close look at where the flange and glass meet, especially around the bolt holes. * You should not see any spaces. If not, straighten the flange by lightly hitting the curved areas with a hammer.

Possible problems when removing the engine sump

Usually it is not possible to remove a part if the bolts are rusty. They need to be unscrewed carefully so that the pins do not break off. It is necessary to preheat the mounting location, and then slowly unscrew the bolt. In domestic cars, the bridge often gets in the way after unscrewing the fasteners. In this case, you should not try to cut off the interfering strips. The problem is solved by removing the oil pump.

It is important to raise the engine to a sufficient height. Otherwise it will be impossible to get to the pallet. The engine is raised until it reaches the nuts securing the mounts. It is convenient to use a diamond-shaped jack for this operation. It needs to be installed under the box; when lifted, the engine will move. Procedure:

If there is no jack, a traverse made of timber will do. The beam must be positioned parallel to the radiator. Next, the pin is attached to the engine and threaded through the yoke. Then you need to carefully tighten the nut on the stud. The motor will begin to rise slowly.

It happens that when you try to pry the pan with a screwdriver, it does not budge. In this case, the part gets stuck somewhere inside. First you need to check that all the bolts are unscrewed. In most engines, the cover is held on by 15 bolts, less often by 14. If everything is unscrewed, this means that the oil intake tube is stuck. To solve the problem, you will have to unscrew the tube from the pump.

Tips and tricks

It is possible to dismantle the part only if the preparatory work is carried out correctly. First, the car is placed above the inspection hole; if this is not possible, the body is raised with a jack. After this, it will be possible to get to the crankcase and adjacent parts.

To carry out manipulations, good lighting is required. Without illumination, it is difficult to remove a spare part from a hard-to-reach area. If you have a powerful lamp, it will be possible to inspect the pallet and make sure that there are no dents or holes on it. You will also have to check the condition of the gasket.

If a hole has formed in the housing, repairs can be made using argon welding. Minor cracks are repaired by cold welding, but before doing so, the oil is drained and the surfaces are degreased. Leaks at the junction of the engine block and the sump indicate the need to replace the crankshaft oil seal. Slight sweating around the drain plug is not considered a deviation from the norm.

Welded engine sump

The pan can be accidentally punctured when driving off-road, even with high ground clearance. Many car owners install protection that covers the pan from impacts and complicates access to it. The protection is dismantled in advance; it is usually held on by several bolts and can be unscrewed without any problems.

Before dismantling, it is advisable to wipe the tray and surrounding elements with a rag. This makes it more convenient to carry out work, and it is easier to see damage to the body. If oil spills out, the location of the leak is determined visually. To check the integrity, you need to turn on the engine at idle speed. In this mode, oil will quickly begin to flow out through the hole. If after removal you find damage to the gasket, do not throw it away. It is better to take the old seal with you when going to the store. Then it will be easier for the seller to select a similar spare part.

Some Important Notes on Gaskets and Seals

- If you are installing an engine oil pan gasket (as opposed to a rubber seal or compound), you may need special adhesive to hold the gasket in place during installation. If so, apply a light layer of adhesive or high-temp sealant to hold the gasket in place.

- Also, keep in mind that a component at the bottom of the engine may create a connection to another engine component along some portion of the oil pan flange, such as the rear main bearing cap, timing cover, or oil pump. With this configuration, you need to apply sealant where these sections meet to prevent leakage in that area once the gasket is installed.

Some engine pans use rubber seals at each end along with side gaskets. You will need to apply sealant where the rubber gasket meets.

If you are going to use sealant as a gasket, apply it evenly over the contact area to a thickness of 3 millimeters.

3.4.7 Removing and installing the engine oil pan / Renault Symbol

The process of removing and installing the engine oil pan is described in relation to the engine installed on the vehicle. Removal procedure: – disconnect the negative cable from the battery; – engage the parking brake, lift the front of the car and place stands under the body; – remove the protective cover under the engine; – drain the engine oil from the engine, then install the drain plug; – remove the front wheels and remove the protective plastic shield from the right wheel arch; – set the steering wheel to the straight-ahead position and secure it against possible turns; – slide the protective cover on the steering shaft and unscrew the bolt securing the intermediate shaft of the steering column (see section “Steering”); – disconnect the hinges of the lower suspension arms from the steering knuckles (see the “Chassis” section); – disconnect from the steering knuckles and remove the tie rod ends, as described in the “Steering” section; – disconnect the front suspension subframe ties from the body and the gear shift rod from the gearbox (on engines with an automatic transmission, disconnect the selector cable); – Unscrew the lower fastening of the front bumper; – loosen the bolts securing the rear engine mount rod to the body;

| Rice. 3.11 . Removing the subframe reinforcement (arrow) |

– unscrew the bolts of the subframe reinforcements (see Fig. 3.11); – disconnect the front suspension arms from the subframe, as described in the “Chassis” section;

| Rice. 3.47 . Lowering the engine subframe using zip ties |

– unscrewing the bolts securing the subframe to the body one at a time, replace them one by one with pre-prepared racks with threaded threads and nuts. The subframe must be lowered by dimension X=130 mm in the area of the front support and by dimension X=90 mm in the area of the rear support (Fig. 3.47) in order to remove the engine sump

At the same time, disconnect the steering gear shaft from the intermediate steering shaft; – make sure that the removal of the pallet is not interfered with by associated parts and assemblies, and unscrew the bolts securing it to the cylinder block; – carefully hitting the pan with a plastic hammer, disconnect it from the gasket and remove it from the engine, keeping the semicircular gaskets. Installation procedure: – thoroughly wash the inside of the sump to remove oil deposits. Clean the mating surfaces of the pan and cylinder block from gasket residues;

| Rice. 3.48 . Applying sealant at points A when installing the engine oil pan |

| Rice. 3.49 . Applying sealant at points B when installing the engine oil pan |

– apply a small amount of Rhodorseal 5661 sealant to the surface of the pan in zones A on both sides of the 1st main bearing (Fig. 3.48) and in zones B (Fig. 3.49) of the front cover of the cylinder block;

| Rice. 3.50 . Installing the engine oil pan gasket |

– install a new gasket on the pan (Fig. 3.50); – install semicircular gaskets on the pallet and, attaching it to the block, secure with bolts, tightening them crosswise, first with a torque of 8 Nm and finally with a torque of 14 Nm; – lift the subframe and remove the temporary threaded posts, replacing them with bolts; – connect the steering gear shaft to the intermediate steering shaft and tighten the fastening bolt; – perform the remaining operations in the reverse order of removal; – fill the engine with oil, start it and make sure there are no leaks.

Replacing the Renault Symbol pan

Renault Clio 2, Simbol, engine repair, removal of cylinder head 1

Oil pan gasket for Renault K7J, K7M, K4M replacement. Oil pump inspection. | Video lecture #2

Repair of K4J engine on Renault Symbol (1st part)

Renault Symbol (Logan) — Cylinder head repair and piston ring replacement (K7J)

Installing the oil pan gasket

Once the pan is in place, begin to tighten the bolts by hand and lightly tighten them, following the criss-cross technique to distribute the force evenly.

NOTE. Some manufacturers recommend applying a small amount of sealant to the bolt threads before installation. Check your service manual if necessary.

Tighten the bolts with a torque wrench in a crisscross pattern to the torque specified in the manual. Do not over-tighten to avoid over-tightening the bolts and damaging the flange or gasket and ultimately causing an oil leak.

- Also, tighten the drain plug to specifications using the same wrench to prevent future oil leaks.

- With the oil pan installed, replace any components that you had to remove to access it. Check that there are no unnecessary parts, as is often the case with master craftsmen.

- Lower the engine from the mounts and tighten the mounts if necessary.

- Lower the vehicle and add the required amount of engine oil to the engine.

- Check for oil leaks after filling, and look under the bottom for the next few days to ensure that you have successfully completed the repair by replacing the oil pan gasket and that you are not dripping or leaking anywhere. Watch the following video for a visual reference. replacing the gasket.

Of course, on some car models it is simply impossible to remove the engine oil pan without the appropriate equipment.

The job of replacing the pan gasket is not an easy task. But in many car models, this task is within the reach of the average owner. However, you must follow the precautions and proper procedures outlined in this manual to complete the job successfully and save money on repairs.

Oil pan - removal and installation

Removal

1 Apply the parking brake, then jack up the front of the vehicle and install safety stands. Remove the lower protective cover from the engine.

2 Drain the engine oil and remove the oil filter (see Chapter 1 B). Pull out the oil dipstick.

3 Disconnect the wiring connector from the oil level sensor (see Fig. 12.3).

Rice. 12.3. Oil level sensor outside the engine oil pan

4 After unscrewing the mounting bolts, remove the engine oil pan. If it is “grown” to the block, carefully pry it off with a small screwdriver or plastic knife, pushing it into the joint (see Fig. 12.9). When removing, try not to damage the mating surfaces of the pan and the block, so as not to cause leaks.

5 If necessary, unscrew the mounting bolts and remove the oil level sensor and its gasket (see Fig. 12.5).

Rice. 12.5. This is what the oil level sensor looks like inside the oil pan

Installation

6 Using a soft scraper, remove any traces of old gasket and sealant from the mating edges of the block and pan, then wipe them with a rag soaked in lacquer thinner or acetone.

7 If removed, install the oil level sensor along with a new gasket and tighten the mounting bolts.

8 Apply a strip of sealant 4-7 mm wide to the mating flange of the pallet, bypassing the bolt holes from the inside (see Fig. 12.8, a, b).

Rice. 12.8, a. Apply sealant to the oil pan mounting flange...

Rice. 12.8b...as shown in this diagram

9 Carefully install the pan onto the engine block and tighten the mounting bolts. Starting from the center, gradually tighten the pallet mounting bolts to the torque prescribed in the Specifications (see Fig. 12.9).

Rice. 12.9. Installing the oil pan

10 Install the remaining components in the reverse order of removal. Fill with oil and install a new oil filter. Start the engine and check for leaks.