What is a generator for and how does it work?

Electricity consumption in modern cars is very high. The result of such a large quantity is, first of all, the operation of the generator. Many drivers do not take generator failure seriously, and in such cases rely on the battery. In practice this works.

However, you won’t be able to drive for long on a battery alone, and besides, when driving like this, it’s not always possible to start the engine. Another reason not to drive if the alternator breaks down is the risk of driving in such conditions. Also, when a generator fails, the systems associated with it also break down. Thus, monitoring the correct operation of this part is very important.

If the generator bearing is humming, it needs to be checked. VAZ generator bearing is humming. It’s easy and quick. In addition, after such a check, you will be convinced that this important part of the car is in good condition and will avoid further unpleasant breakdowns, the correction of which will be expensive.

A passenger inside the car while driving will only hear what is happening outside the window and the sound of the car moving, and only if it has poor sound insulation. It is the driver’s task to listen to all unusual sounds that arise during vehicle operation.

An experienced car owner should be able to detect any malfunction of his car by hearing, even while talking with passengers and listening to music. The hum of the generator bearing is no exception, which at the next stage can develop into a grinding noise. consequences of a humming prior generator bearing This tells the driver about a malfunction of the generator - the most important part of the car. Therefore, in such a situation, you need to think: is it even worth continuing with such a problem?

A car generator howls, reasons

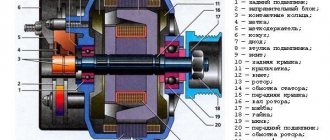

Let’s determine the causes of the malfunction “the generator howls” and try to find out on our own what exactly happened. Let's do all this using the example of the standard generator 37.3701 of a VAZ 2109 (2108, 21099).

Symptoms of a problem

Constant or periodic “howling” (high-pitched sound) from the car’s generator.

Disappearance of charging (either complete or decreased). The battery charge lamp on the instrument panel is on or blinking.

A car generator howls, causes of malfunction

The main reason is a short circuit of the stator windings to ground.

Without removing the generator from the engine, you can independently diagnose this malfunction only together with its other malfunctions. This can be done this way: turn on powerful consumers (stove, headlights), set the speed within 3000 rpm and measure the voltage at the battery terminals. There must be at least 13 V.

If less, the generator is faulty. But, there may still be a problem with the voltage regulator, rotor windings, diode bridge, and not just with the stator windings.

Therefore, in order to accurately establish that the stator windings are shorted to ground, you need to remove the generator from the engine. Take it apart. And using a multimeter in ohmmeter mode, check for the presence of a short circuit.

See photo at the beginning of the article.

We press the negative probe of the multimeter in ohmmeter mode to the stator, and the positive probe to any winding terminal. If there is no short circuit, the resistance on the device tends to infinity. We repeat the operation for each winding terminal.

If you do not have a multimeter, you can use a test lamp to check the generator stator winding for a short circuit.

When checking the generator stator for a short circuit with a test lamp, we apply a minus from the battery terminal to the stator, and a plus to the test lamp. With the other terminal of the lamp we touch any terminal of the winding. The lamp lights up - there is a short circuit, no - everything is normal. We repeat the procedure for each output.

In this simple way, you can determine the malfunction of the stator windings of the generator and find out the reason for its “howling”. A failed generator stator needs to be replaced.

Notes and additions

Along the way, you can check the generator stator windings for an open circuit.

We press the multimeter probes in ohmmeter mode to the terminals of the stator winding. If there is no “break”, the device will show a resistance within 10 ohms. If there is a “break” in the stator windings, that is, no current passes through them, then the resistance tends to infinity. In this way, we check all three conclusions in turn.

In some cases, a weakly tensioned alternator belt may “howl.” To accurately diagnose the problem, it is recommended to remove the belt and listen to the operation of the generator. If necessary, adjust its tension and/or replace it with a new one.

Twokarburators VK - More information on the topic in our VKontakte group, on Facebook Twokarburators FB and on Odnoklassniki - Twokarburators OK

More articles on the generator of VAZ 2108, 2109, 21099 cars

— Generator bearings for VAZ 2108, 2109, 21099 cars

— How to remove the voltage regulator from the generator on VAZ 2108, 2109, 21099 cars

— Checking the generator voltage regulator for VAZ 2108, 2109. 21099

— Malfunctions of the generator of VAZ 2108, 2109, 21099 cars

— We connect the wires to the VAZ 2108, 2109, 21099 generator

— Generator diode bridge, device and principle of operation

— How to check the generator capacitor?

Generator bearing humming consequences

Serious problems can begin with a simple humming noise. Therefore, when it appears, you should immediately contact a car service center. Firstly, they will tell you for sure whether the problem is in the generator or something else. If the problem is with the generator, then a competent car service worker will be able to determine the degree of bearing wear. how a generator bearing hums video The easiest deviation is a hum. In this situation, theoretically, you can even continue driving. If the sound resembles a grinding sound, you need to take the breakdown seriously and immediately send the car for repairs. In this case, you will most likely have to buy a new generator.

Factors affecting hum level

A humming sound occurs if the unit operates in certain modes. During one cycle of operation of the transformer, tension and compression of the core occurs twice. If the mains frequency is standard with alternating current (50 Hz), the device begins to hum.

Also read: Purpose of dielectric bots in electrical installations

The frequency of sound is twice that of electric current.

The strength of the transformer hum is determined by the following factors:

- Degree of workload;

- Overall dimensions of the constituent elements;

- Physical characteristics, material used to manufacture the magnetic core.

The hum may occur due to the following design features of the transformer:

- the effect of magnetic flux tends to move the windings of the device relative to the magnetic core. If the coil is not wound tightly enough, vibration occurs due to the loose fit of the turns with a corresponding hum (the black arrow shows the coil);

- If the core plates are poorly fitted, gaps appear between them. During operation, the vibration of the plates is accompanied by a characteristic metallic ringing, turning into a buzzing sound (the red arrow shows the core plates);

- if the copper wires of the windings are defective or damaged, the coil may spark, with popping noises with each spark. Powerful discharges are characterized by a more intense sound;

- The individual parts in the device are not sufficiently secured, resulting in vibration and noise.

A strong hum is typical of power transformers used in industrial production. But if the operation of a low-power household appliance begins to be accompanied by a significant hum, this is a reason to carry out diagnostics in order to identify and eliminate the malfunction.

Generator check

To check the generator you need to use a special device - a multimeter. This is not a scarce commodity. It is sold in any specialty store. You can also purchase a multimeter online. This option is not that expensive.

First you need to turn on the device at up to 20 volts and install it on the generator wheels. Next comes a series of simple steps, after which it will become clear what condition the generator is in.

You can do without a multimeter, but the result will not be as accurate. This check is not suitable for all cars.

You should also check the alternator overrunning clutch. It would be a good idea to do a full check of the generator. In this case, check:

- brushes and rings;

- diode bridge;

- generator rotor;

- stator.

Thus, to check the generator, you only need a multimeter, which is not difficult to buy. It is important to remember that you can only check the generator yourself, but if you find problems in its operation, you need to contact a specialist. At a car service center, after consulting with a technician, you will have to make a decision whether to continue driving (if you hear the bearing hum) or leave the car for repairs. The second option is useful when the generator bearing makes an unpleasant grinding noise. In this case, the generator will most likely have to be replaced.

Transformer testing and troubleshooting

Diagnostics will help identify the cause of the problem and eliminate the malfunction. Interturn closure is determined by external inspection. If damage to the insulating layer and dark marks on the winding are observed, this indicates the specified problem.

In this case, the device needs to rewind the coils.

If the external examination does not produce results, a more in-depth study will be required.

If you have a multimeter, you can do the following:

Also read: Transformer no-load mode

When studying a step-down device, you can measure the voltage value for the output winding by connecting the device to the network. If smoke or crackling appears when turned on, the device should be turned off immediately - this indicates a failure of the primary coil.

Often a self-rewinding transformer begins to hum. This happens for the following reasons:

- the core is incorrectly assembled or not tightly fitted - it should be arranged tightly, check the tightness of the connection of the plates;

- the winding is not secured enough - the coil needs to be strengthened;

- gaps between the turns of the winding - the coil is impregnated with paraffin, filling the gaps;

- The number of turns is incorrectly calculated - rewinding will have to be done again.

In order for the transformer to work correctly after repair, the work must be performed by a professional. If you do not have the appropriate knowledge, skills and experience, you should not interfere with the device.

If a strong hum appears during operation of the transformer, it is necessary to carry out diagnostics. Otherwise, continued use of the device may result in failure, jeopardizing the safe operation of other equipment.

The generator is broken: is it worth continuing driving?

If the initial stage of generator failure (bearing hum) has been detected, theoretically you can still drive. But if possible, it is better to refuse to travel, because this may jeopardize the health of the driver and his passengers. Over time, the hum can develop into a grinding sound, and this is a direct route to a car service center and replacement of the generator. But you can prevent the situation from getting worse and carry out a thorough technical inspection of the car at an early stage of the breakdown. Of course, you need to pay special attention to the generator.

Why does the generator hum in a car?

This question is often asked on forums. Why does the alternator on a car hum and stop doing so as soon as the terminal is disconnected from the battery? At the same time, the more electricity consumers are connected to the car, the louder it can buzz. As for the voltage, it shows 14.05V without additional consumers, however, as the car accelerates, the voltage drops to 12.3.

Reviews

This is not the first time I come to West Auto on Gogol 51. The guys are all friendly and sociable, masters of their craft. I would like to highlight the master Andrey and the manager Pavel. The guys solved the problem of my car quickly and efficiently. I recommend West Auto to everyone! More details

I really liked the service at the Zapad Auto service and the culture of communication with clients, i.e. with me. Thank you so much! More details

Passing through Ryazan. I am very glad that I came to you. They fixed it quickly. Thank you. More details

Bearings

First of all, experts see the reason in the bearing. Apart from him, there is nothing to hum there. Although in some cases the diode bridge may also produce a hum. You should know that the more consumers are involved in the car, the more difficult it is for the generator to turn. The load on the bearings automatically increases.

As you know, generator bearings are installed for easy rotation of the rotor armature. One of the bearings is placed in the front cover, the other is pressed onto the rotor. It is noteworthy that both bearings are pressed, so replacing them is not so easy.

As a rule, if the bearings fail, then in addition to the hum, the battery is no longer charged.

Experts recommend paying attention to the nature of the hum. If it resembles a whistle and is heard mainly under the hood, then the bearing is definitely worn out.

Before replacing bearings, you should find out what brand they are. If they are domestically produced, they are inexpensive. The price of imported spare parts is much higher.

The service charges at least 600-700 rubles for the work of replacing bearings. But this can be done with your own hands.

- the car engine turns off;

- the belt is removed;

- the wiring is dismantled, the generator is unscrewed and removed;

- disassembling the generator begins with removing the rear plastic cover;

- brushes and relays are removed;

- the diode bridge is dismantled, which should be freed from 3 screws;

- Next, the front part is disassembled, the rotor is carefully clamped in a vice, and the pulley is removed;

- the front cover with the bearing is removed;

- the rear bearing is pressed from the armature (a puller is used).

Cleaning and lubrication of bearings! | Topic author: Falit

LUBRICANT! Previously, bearing lubrication was considered a must, but modern players no longer lubricate bearings after washing, preferring to play on “dry” bearings with low response. Naturally, this only applies to String style players.

CLEANING CERAMICS! And one more thing: what to do if you are the happy owner of a clogged gold or ceramic bearing? Blowing and the following steps will help you: * Buy a compressed air cylinder at a computer store, or an enema at a pharmacy. * Didn't find either one or the other? Dont be upset. If you are not in the habit of spluttering as you exhale, you can use your own mouth. * Remove the anthers. * Direct a stream of air from a can, enema, or mouth into the bearing. * Repeat if necessary. * Wear boots (optional).

WASHING! * Buy gasoline for lighters. We recommend the original Zippo in a black oblong tin with a folding plastic spout, as it is almost perfectly clean and is guaranteed to clean your bearing from dust without clogging it with impurities. If you don’t have one at hand, then “Royal”, “Portland”, “Unilite” gasoline in the same cans as Zippo, only in different colors, will do. It is highly recommended not to use alcohol, motor gasoline, or gasoline for Russian-made lighters. In the case of Zippo, the quality is guaranteed, in the case of Royal and others like it, the quality depends on the batch, but in general there are rarely mistakes, and in the case of the rest, it’s better to wash the bottoms in a dirty puddle than with these means. * Find a small film or glass perfume jar with a wide neck. * Remove the boots from the bearing by prying the pressure rings with a needle. hold the rings with your hands, otherwise you risk being left without them - pressure rings tend to spring back and fly away in an unknown direction. * Place the bearing in a jar with gasoline. If the gasoline level covers the height of the bearing, that is enough. Just in case, throw some anthers with rings in there, because it won’t hurt. * Gently close the jar and shake it thoroughly for a minute. * Take the bearing out of the jar, put it on a sharpened pencil and rotate it until the characteristic sounds of torsion of a clean bearing appear. If the bearing is not clean, repeat the cleaning procedure again. *Put the boots back on. This step is not necessary, but is still recommended, since the boots protect the bearing from dust and dirt getting into it, and also slightly reduce noise. If you don't care how often to flush the bearing, or if your pressure rings flew off during disassembly, or if you're just lazy, don't put them on.

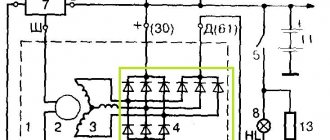

Diode bridge

The hum can also come from the diode bridge. To check whether the diode bridge is shorting, you should remove the cover on the back of the unit, remove the diode bridge, and adjust the washers under the clamps with which it is screwed. And if you add an additional puck, it will be even better.

It also happens that a wire falls off the diode bridge. It’s a banal reason, but until you figure it out, you won’t see it.

Belt and its universal functions

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

Belt drive is the best way to transmit torque to the rotor of a generating device, invented today. This method has been successfully used for many years, differing from other methods in its simplicity. Belt transmission does not require complex and numerous components - two pulleys with shafts connected to each other by an elastic belt are sufficient.

Here the belt itself becomes a universal part, because it has many functions. First of all, the main task is to ensure the rotation of the pulleys.

Note. It is important that the belt is not just elastic and moderately rigid. One part of the element is specially tightened to provide a difference in tension, and, accordingly, to solve the issue of traction force and its efficiency.

The belt gives transmission to the generator rotor, which must constantly rotate while the car engine is running. The belt in this case ensures not only this, but also the clarity of the transmission, smoothing out the shocks and jerks that inevitably come from the crank shaft.

The belt ensures silent rotation, and high-quality products can simultaneously be moderately rigid and durable, thereby withstanding long-term loads.

Another advantage of the belt is its compactness. It takes up little space while simultaneously performing tasks on a scale disproportionate to its size. The generator, water pump, air conditioning compressor, power steering pump - all of this works thanks to the rotation of the belt.

It is not surprising that after such loads the belt cannot withstand. The disgusting “clanging” emitted by a problematic belt is the very whistle we are writing about. The reason is belt slippage. Sometimes this whistle is so strong that it can be heard at a very long distance.

Why does the gene make noise?

Note that increased bearing noise, although it does not affect the performance of the unit, requires immediate intervention. A worn bearing is a threat that can easily destroy a generator at the most inopportune moment.

How can you make sure that it is the bearing that is making the noise? This is easy to do: you need to press the accelerator pedal. If the noise increases, it means that the generator, which is connected directly to the motor, is humming. The higher the engine speed, the stronger the output of the gene, and, accordingly, the stronger the noise.

However, the cause of noise should not always be sought in bearings. Yes, the percentage of them making a hum is quite high, but other cases are known.

For example, if a gene has recently been replaced. Nobody excludes the possibility of incorrect installation of the unit. In the service station today you can run into such amateurs with crooked hands that you wouldn’t wish it on your enemy. Such a well-wisher will give you a new gene, and after a while it will begin to make noise. You, assuming that these are bearings, will change them every time until you start thinking - why do they do it so often?

Incorrect installation of the gene also means lack of plastic protection. The latter, as is known, protects the unit from dirt and splashes from the wheel. There is no protection - the generator will constantly become dirty, which will lead to its rapid wear and noise.

Protection, boot, plastic side panel - you can call it whatever you like, but the essence is the same. Keep the generator away from moisture and dirt.

The generator can also make noise due to an incorrectly installed belt. Too much tension, that is, overtightening, leads to noise. To determine the normal level of tension, you must be able to rotate the belt from a vertical to a horizontal position using medium force.

The mutual alignment of the bracket and the crankshaft pulley is extremely important. If it is crooked, then it is clear that the belt will also move crookedly, touching parts, causing noise.

Alternator belt tension VAZ 2114

The tension of the generator belt is checked on a long branch, and the force should be about 10 kgf. To more or less accurately determine the force, you can use a simple household steelyard. If the belt deviates by no more than 10 mm at this force, the tension is fine. If it is less, the belt will be overtightened and this may end badly for the generator bearing, to which we are already returning.

But even if the alternator belt has always been in perfect condition, has not slipped or been overtightened, there is a possibility that the bearing may sing. Moreover, setting the sound source is quite simple. If a suspicious hum appears, it is enough to make sure that it is a bearing, since there are plenty of singers in that area. This includes the timing belt, the front cover bearing, the pump, and the timing belt tension roller. To accurately determine the malfunction, it is enough to remove the belt from the pulley and start the engine for a short time. If the noise disappears, it is our bearing that is making noise.

What can you do if the bearings are noisy?

So, if the reason is in the bearings, then they should simply be replaced, and that’s it. Replacement will not be difficult if you can disassemble the generator yourself. Otherwise, it is advisable to contact a good service.

The asking price at Moscow service stations costs no more than $70 if you come with your own parts (bearings + regulator with brushes). Considering that the worker simultaneously dismantles, disassembles and installs new components, including brushes (it is recommended to update), then this is quite inexpensive.

The bearings themselves cost approximately 500 rubles each.

You can also disassemble the generator and remove the bearings yourself. The most difficult thing is to press out the bearings, especially the front one. It sits firmly and is often corked. To remove it, you will have to drill out the core points and knock the bearing out of the cover with a hammer. The difficulty is that you have to work carefully so as not to damage anything inside the gene.

A short instruction on how to remove and disassemble the generator will help you do the manipulation yourself:

- dismantle the gene by removing the protection (if any);

- unscrew the tablet (regulator with brushes);

- separate the front cover from the rear of the generator;

- remove the stator shaft;

- press out the rear bearing;

- knock out the front bearing;

- install new parts, put everything back together, not forgetting to replace the brush assembly.

Other causes of whistling

Why does the belt slip? If the load is to blame, then after replacement everything should return to normal. However, the noise continues with the new belt. Some kind of opportunity. No need to panic. It is better to find the reason for all this in the first place.

Experts advise taking the following actions:

- visually inspect the belt, checking it for integrity (even new products today are found to be defective and of poor quality);

- check the shaft and pulleys for cleanliness (oil and other dirt can easily cause whistling);

- diagnose the degree of tension (weak tension also causes noise);

- check the alignment of the pulleys (if two pulleys are not located in relation to each other in the same plane, the belt will not rotate smoothly, thereby touching certain parts with its edges and whistling).