- home

- Brands

- VAZ

29.09.2020

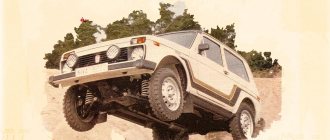

VAZ Niva (Lada 4x4) is a compact off-road vehicle, produced with a three- and five-door body. Production of the model began in 1977. In the 2010s, under the leadership of AvtoVAZ President Bo Andersson, an updated version of the Urban was developed with modified bumpers and improved finishing. In 2020, the car received a new front panel, adapted to modern safety and comfort requirements. However, the design remains the same. The original name “Niva” was relevant until 2006 in connection with the release of the more modern Chevrolet Niva SUV. However, in 2022, AvtoVAZ regained the right to use the Niva trademark, which previously belonged to the General Motors concern.

Steering gearbox repair

Drain the oil from the gearbox housing, unscrew the adjusting nut and remove the lock washer. Using a 13mm wrench, unscrew the four bolts securing the upper gearbox cover.

We remove the head of the adjusting screw from the groove on the bipod shaft and remove the cover.

When replacing the bipod shaft, the axial clearance between the screw head and the shaft groove is set by selecting the thickness of the adjusting plate. The gap size is allowed no more than 0.05 mm. The plates have a thickness of 1.95 to 2.20 mm in increments of 0.025 mm.

We remove the bipod shaft with the roller from the crankcase.

Using a 13mm wrench, unscrew the four bolts securing the worm shaft cover and...

...remove it together with the ball bearing adjustment gaskets.

Gaskets are available in thicknesses of 0.1 and 0.15 mm. With light blows of a soft metal hammer, knock out the worm shaft along with the bearing from the gearbox housing.

On the end surfaces of the worm there are raceways for the bearing balls.

Using a screwdriver, we remove the cuff of the worm shaft.

Similarly, remove the cuff of the bipod shaft. We use a punch to knock out the outer ring of the second bearing.

We wash all parts in kerosene or diesel fuel. We carefully check that there are no signs of wear, scuffing or damage on the working surfaces of the roller and worm. The gap between the bipod shaft and the bronze bushings should not exceed 0.1 mm. Ball bearings must rotate freely, without jamming, and there must be no damage or signs of wear on the surfaces of the rings, cages and balls. Cracks of any length are not allowed on the crankcase itself. We replace worn and damaged parts with serviceable ones. We replace the cuffs with new ones in any case. Before assembly, lubricate all internal parts with transmission oil. Using light blows of a hammer on a piece of pipe of suitable diameter, press the inner bearing ring into the crankcase.

You can press in the bearing ring using a tool for replacing rubber-to-metal hinges on the front suspension (see Appendices).

We install a separator with balls into the bearing ring and insert the worm shaft. We put the outer bearing separator on it and press the outer ring into place with light blows of a hammer. We put the cover with gaskets and... ...press in the cuffs of the worm shaft and bipod, lubricating the working edges with Litol-24 lubricant.

We install a worm in the crankcase. Using a set of adjusting shims, we set the moment of its rotation from 2 to 5 kgf•cm. We install the bipod shaft and adjust the engagement gap according to the moment the shaft rotates. It should be 7–9 kgf•cm when the worm shaft is turned 30° to the left and right and smoothly decrease to 5 kgf•cm with further rotation until it stops. Fill the crankcase with transmission oil to the bottom edge of the filler hole (0.215 l).

Cooling liquids

LLC "TC Tosol-Sintez", Dzerzhinsk

JSC "Technoform", Klimovsk, Moscow region.

JSC "Technoform", Klimovsk, Moscow region.

CJSC "Obninskorgsintez", Obninsk

LLC "TC Tosol-Sintez", Dzerzhinsk

CJSC "Dolfin Industry", Pushkino

Note. Service life and replacement of antifreeze in accordance with the vehicle service book. Mixing coolants of different brands is not allowed.

The air conditioner is filled with ozone-safe freon R 134 "A" Quantity - 0.4 kg

The air conditioning system uses ATMOSGU10 oil.

FLUID FOR SHOCK ABSORBERS

Fluid GRZh-12 Front shock absorber - 0.12 l Rear shock absorber - 0.195 l.

Features of the GAZ 3302 steering gear

Lada Priora hatchback Logbook Steering rack repair

Like the whole car, the GAZelle's steering mechanism does not suffer from sophistication of design, but many believe that this is for the better. Regardless of whether the car has power steering or without power steering, repairing and adjusting the steering is extremely simple and does not require deep encyclopedic knowledge or special tools from the driver. The very minimum of both – and you can move on.

It is still different from the prehistoric GAZ worm-roller gearboxes, and even has its positive aspects. The most pleasant feature from the point of view of car architecture is that the GAZelle gearbox mechanism is quite compact and at the same time has good efficiency. What is especially noticeable on cars without power steering is that driving even a loaded car does not require the use of brute physical force. The designers achieved this by using rolling instead of sliding. It cannot be said that this introduction brought revolutionary changes to the global auto industry at the end of the 20th century, but the steering wheel became noticeably lighter. This made it possible to increase the service life of the entire assembly, since it does not wear out as intensively as a worm pair, and rarely requires adjustment.

There were some shortcomings, although the designers had nothing to do with it. The working pair of screw/ball nut is a non-removable element, and during the first 10-15 years of the car's production it was quite difficult to find a replacement pair. Now this stuff is enough, so replacing a working pair can cost 5-6 thousand rubles. Adjusting the steering gear requires its complete dismantling, which also does not delight users. Moreover, to adjust the gap, in addition to a special profile wrench, you also need level and skillful hands, since the bearings can be skewed in no time if you do not use a torque wrench.

In GAZelle, control does not require the use of brute physical force, even if the car is loaded

But the main surprise for the driver who decides to adjust or repair the gearbox is the removal of the bipod. This is not hellish work, but in the cold, dismantling the bipod can cause some discomfort.

General ideas about steering gears

Replacing the steering rack of Vito W639

It's probably no secret that mechanical engineering developed gradually. With each step in the development of this industry, cars were improved and acquired more and more new devices. Thus, many modern auto parts were added much later than the creation of the car. But there are units that initially appeared already at that stage in the history of the engineering industry at which the vehicle acquired its final shapes and outlines. One of them is the steering gear. It is a special steering mechanism that plays a significant role in driving a car. The main task of the steering gear is to increase the force applied to the steering wheel. It is this applied force that causes the wheels of the vehicle to turn in the desired direction.

Replacing the gearbox

DIY steering rack repair

https://youtube.com/watch?v=–HYiizjMVo

https://youtube.com/watch?v=–HYiizjMVo

When replacing a unit, the labor intensity is lower than when repairing:

- I removed the fastening of the coupled mechanisms, dismantled the gearbox, there is no need to disassemble it;

- During repairs, parts are reassembled, if necessary, the shaft is welded and ground, then we select the oil to fill, and after assembly we tighten the adjusting screw.

Using the Grand Cherokee as an example, replacing the steering gear consists of the following sequence of actions:

- jacking up the front axle and installing it on temporary supports;

- by removing the front left wheel and the fender liner inside the arch, we gain access from below;

- remove the washer tank;

- unscrewing the bolt that secures the steering cardan to the gearbox;

- dismantling the power steering tubes going to the gearbox;

- The bipod of the steering gear and 4 crankcase mounting bolts are removed.

Removing the steering gearbox

Thus, regardless of the design of the gearbox of the steering system of the machine, most often the gap between the transmission parts is adjusted or the entire unit is replaced. For repairs, sets of gaskets and shaft seals, transmission oil and gear packing are produced. The shafts are restored by folk craftsmen; the manuals do not contain information on the dimensions of the seating surfaces, since the unit is considered non-repairable.

Main elements of the system

The largest and most basic element is the fuel tank, but the total number reaches sixteen. Their volumes vary greatly.

- They are necessarily included in the engine cooling and lubrication systems.

- Axle housings and gearboxes are also extremely important for safety during travel.

- Chevrolet Niva filling tanks include power steering systems and hydraulic brake lines, front and rear shock absorbers.

- An integral part are tanks for windshield washer and air conditioning.

Lubrication

Experienced users often change the lubricant, even in the absence of breakdowns, for the following reasons:

- The standard blue padding is too thick;

- Possible decrease in plasticity in winter;

- it accumulates near the lid and minimally reaches the friction pairs.

Standard gearbox lubrication

Graphite grease with Motul 4100 10W40

Some cars, for example, VAZ 21213 Niva, use transmission oil, as indicated in the official manufacturer's manual for the service station. To do this, the upper crankcase cover has a hole protected by a threaded plug; oil can be added without disassembling the gearbox.

VAZ 21213 gearbox with lubrication hole

Transmission

Replacing lubricant in machine engines is a simple procedure that you can perform yourself, without the help of specialists. The main thing in this matter is to know what kind of oil and where to fill it.

If we talk about the VAZ 4x4 2121 Niva, then the engine should contain approximately 3.75 liters of oil product. Moreover, you need to fill in one brand of oil; different types cannot be mixed. Otherwise, the entire proportion will be ruined.

When mixing a mineral and a synthetic sample, the result will be a substance of low quality. It forms pieces that are not acceptable for the normal operation of the unit.

Replacing lubricating fluids is provided not only for the engine, but also for other components of the VAZ 4×4 2121 Niva. Places, filling volumes, names of oils are given in the table.

Page 68

The Niva 4x4 transmission system has the following filling volumes:

- transfer case - 0.79 l;

- gearbox - 1.6 l;

- rear axle - gearbox - 1.3 l;

- front axle - crankcase - 1.15 l;

- steering column - crankcase - 0.18-0.2 l.

| Lower limit of ambient temperature, °C | -15 | -25 | -25 | -30 | -40 |

| Upper limit of ambient temperature, °C | 45 | 45 | 35 | 45 | 35 |

| SAE lubricant viscosity grade | 85W-90 | 80W-90 | 80W-85 | 75W-90 | 75W-80 As stated in the operating instructions, transmission lubricants must be changed once every 30 thousand km. mileage At the same time, replacement is not provided for in the steering mechanism housing, only an addition through the top plug. The “native” oil for Zhiguli transmission units is considered to be TAD17I. Transmission oils have good penetrating ability. Therefore, poorly clamped plugs and worn gaskets of units begin to gradually leak lubricant. In such situations, it is allowed to add oil of the same viscosity class and, preferably, the same manufacturer. If you do not top up during a leak, the lubricant level in the unit will decrease, which will lead to accelerated wear of expensive mechanisms. |

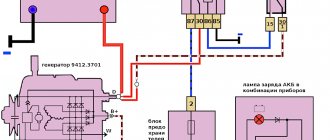

Steering

Steering

The Niva uses a worm-type steering gearbox. It provides reliable vehicle control at any speed and in different road conditions. The worm mechanism is equipped with a globoid type worm (variable shaft diameter) connected to an intermediate shaft and roller. A bipod is installed on the outer part of the roller shaft, which, through rods, activates the rotating mechanism. The rotation of the steering wheel ensures the movement of the bipod through a worm gear; it turns the wheels with rods.

The worm steering mechanism has a low level of sensitivity to shocks and impacts transmitted from the wheels on uneven roads. It has the ability to direct a VAZ vehicle to large turning angles and, accordingly, provides excellent maneuverability of the vehicle. The disadvantage of a worm gear is that it is difficult to manufacture. Worm steering has many connections and therefore requires periodic adjustments and adjustments.

The worm steering mechanism is used on off-road passenger cars with dependent wheel suspension, light trucks and buses. The simplicity of the design has an increased service life and a high degree of maintainability. A slight drawback may seem to be a slightly increased effort on the steering wheel, which occurs for a number of reasons. Having analyzed the design of the steering gear and the loads acting on it, we determine problem areas and ways to solve problems.

The basic one is equipped with a worm pair, which during operation causes steering resistance due to friction between the worm and the worm gear. This is the operating principle of a worm gear; therefore, it is not possible to completely get rid of this factor. The solution is to use high-quality lubricant in the gearbox and monitor the condition of the working surfaces.

The steering gearbox has two rolling bearings (worm shaft), two plain bearings on the bipod shaft (also known as the worm wheel shaft). The bearings themselves, in good and lubricated condition, reduce friction of the main parts (and, accordingly, reduce the force on the steering wheel).

In addition, the pendulum arm, which rotates on two plain bearings and ensures the movement of the steering rack, makes its contribution. The use of high-quality lubricant and periodic monitoring of the condition of boots, connections and rods will reduce the possibility of increased force on the steering wheel.

Thirdly, the six steering fingers must provide a high-quality connection, work correctly in the same planes with the system, and ensure the mobility of the steering mechanism.

Flushing fluids for the engine lubrication system

Pentiosin Werke AG, Germany

List of products containing precious metals in LADA 4x4 cars

| Product number | product name | Location of precious metals | Weight in grams | ||

| gold | silver | palladium | |||

| 2115-3801010 | Instrument cluster | In semiconductors | 0,000263 | 0,016414 | |

| 2105-3747010-03 | Turn signal and hazard warning light switch | Gold in semiconductors, silver in contacts | 0,0180561 | 0,0208012 | 0,103 |

| 2105-3709310/-01 | Three lever switch | Coating | 0,1664 | ||

| 2101-3704010-11 | Ignition switch | In contacts | 0,14078 | ||

| 2105-3710010-03/-04 | Hazard switch | In contacts | 0,107 | ||

| 21213-3709607 | Heated rear window switch | In contacts | 0,11517 | ||

| 2113-3709609-10 | Rear fog lamp switch | In contacts | 0,115169 | ||

| 2104-3709612 | Rear window wiper and washer switch | In contacts | 0,403093 | ||

| 2107-3709608-01 | Heater switch | In contacts | 0,265997 | ||

| 21045-3709280 | Fuel heating switch | In contacts | 0,170288 | ||

| 2108-3720010-10/-11/-12 | Brake light switch | In contacts | 0,1681 | ||

| Generator voltage regulator | In semiconductors | 0,0534 | |||

| 2106-3828110 | Water temperature indicator sensor | In contacts | 0,0161637 | ||

| 2105-3747010-02/03 | Relay-breaker for direction indicators and hazard warning lights | Gold in semiconductors, silver in contacts | 0,00021 | 0,0731 | |

| 2105-3747210-12 | High beam relay | In contacts | 0,055 | ||

| 2105-37470-1010-12 | Low beam relay | In contacts | 0,055 | ||

| 2105-3747210-02 | Headlight wiper relay | In contacts | 0,137 | ||

| 2114-3747610 | Rear fog light relay | Gold in semiconductors, silver in contacts | 0,000998 | 0,034935 | |

Steering gear location

Since under the hood of a car there is the main “culprit” of vibrations – the engine, the steering gearbox is attached exclusively to the car body. Its location differs among different brands and modifications, but access to the fastener is always extremely difficult.

Gearbox location in Jeep WJ Limited

To adjust the steering gearbox, you will have to remove the protection from below, at a minimum. Driver injury safety in a frontal collision is ensured in the following way:

- the upper mounting bolts are welded to the gearbox housing;

- At the bottom there are tear-off bolts, the edges of the fixing plates of which pass into special slots in the bracket.

Breakaway bolts for driver safety

When impact occurs, the steering wheel folds forward upward, which is safer for the driver's chest than any other option.

FakeHeader

Comments 18

They are only available for 2121 and 213: The old model has a long shaft, the new model has a short shaft, 214 is already a steering wheel. and those without steering wheel, those come with a regular gearbox 213 Our price tags are: 21210-3400010-00 Steering gearbox 2121 - 2210r 21213-3400010-10 Steering gearbox 21213 VAZ n/o (short shaft) 2513r 21213-3400010-00 Gearbox steering 21213 VAZ s/o (long shaft) 2542r

Steering gearbox 21214 short shaft for the domestic VAZ car. Article 21214-3400010. Price per piece 2439.00 rub.

Of course, I could be wrong, AvtoVAZ has made a lot of hybrids))) But not a single catalog contains 214 gearboxes separately. Here are all the options:

Catalog of spare parts for VAZ-2121 Modifications: 2121, 21211, 21212 - Article: 2121-3400010 and 21212-3400010

Catalog of spare parts for VAZ-21213 catalog 1997 Modifications: 21213, 21214, 21215, 21216, 21217, 21218, 212146 - Article number: 21213-3400010-01

Catalog of spare parts for VAZ-21213-214i catalog 2005 Modifications: 21213, 21214i, 21214-20i, 21215-10, 2129, 2129-01, 2130, 2131, 2131-01, 21312, 21312-01 Article: 21216-3400010 21213-3400010 21216-3400010-10 21213-3400010-10

And the design itself makes it clear to us that we have a 2101 body, 2121 and 21213 bipods, and the length of the shafts was only different.

They are only available for 2121 and 213: The old model has a long shaft, the new model has a short shaft, 214 is already a steering wheel. and those without steering wheel, those come with a regular gearbox 213 Our price tags are: 21210-3400010-00 Steering gearbox 2121 - 2210r 21213-3400010-10 Steering gearbox 21213 VAZ n/o (short shaft) 2513r 21213-3400010-00 Gearbox steering 21213 VAZ s/o (long shaft) 2542r

How can you tell which one is worth it without removing it? I have 213 2002

Repair and assembly

Correct and timely maintenance of the steering gear is the key to long-lasting and reliable operation, but there are times when breakdowns do occur. In this case, repairs with complete or partial disassembly simply cannot be avoided.

When repairing, it is necessary to pay attention to some features and important points, the use of which will increase the reliability of the mechanism and improve its characteristics

Steering gear repair

To remove and disassemble the gearbox, it is necessary to hang the front of the car and remove the steering rods. From inside, unscrew the bolt securing the supply shaft from the gearbox shaft. Adjusting the steering gearbox of the VAZ 2107. Next, disconnect the gearbox

from the spar, by unscrewing three bolts with spanners. In the engine compartment, remove the hoses and parts that are located in the line of the steering rods.

When the gearbox is unscrewed and removed from the shaft in the cabin, we pull it out of the engine compartment by turning the bipod to the left

Particular attention should be paid to the condition of the gaskets, their location and degree of wear. An unreliable seal can lead to loss of lubrication or contamination of internal cavities

The next step is to unscrew the plug and remove the oil from the steering gear housing, after which you need to unscrew the bipod.

Gearbox

We put it on a stand made of two boards so as not to damage the shaft splines and unscrew the nut, then remove the bipod. Additionally, you can screw the nut onto the shaft until the ends are mutually aligned. Next, disconnect the steering gear cover by gradually unscrewing the locknut of the adjusting bolt and remove the cover, gradually moving it towards the worm.

In this case, you need to be especially careful with the gaskets if they are in good condition; at the slightest jam or pressing out, the gasket must be replaced. The next step is to remove the bipod shaft, press in the worm shaft and remove the seals. All cavities must be washed and wiped with a rag, checking for dents, chips and any other damage. It is also necessary to check the crankcase for the presence of metal shavings, which indicates wear of certain parts. It is imperative to check the gaps and play in the mating parts and check the wear of the working surfaces. After carrying out a defective inspection of the steering gear, we replace damaged parts if necessary.

We carry out assembly in the reverse order, making sure to lubricate the parts with oil, and all oil seals with grease (lithol). Install a new cover gasket with an adjusting screw. Replacing the steering gearbox on a VAZ 2104, VAZ 2105, VAZ 2107. We mount the bipod, tightening the nut as much as possible

Then we install the steering gearbox in its normal place, special attention must be paid to the connection of the worm with the intermediate shaft, distortions and misalignments are not allowed here

It is also necessary to align the direction of the bipod and the steering wheel. The average position of the bipod can be determined by counting the number of shaft revolutions and dividing by two. Next, tighten the gearbox mounting nuts (it is advisable to install new ones), attach the steering rods to the bipod. Fill the gear housing with oil and use the adjusting bolt to select the play in the steering gear. To avoid damage to wheel tires and loss of controllability of the VAZ vehicle 2121

, it is necessary to diagnose the camber (toe) on a stand.

By adhering to these simple recommendations, you can improve the handling of the VAZ, increase driving safety, and the durability of the steering gearbox and the mechanism as a whole. Application of steering gear

the worm type on the VAZ

2121

has been paying off for many years, not to mention decades.

Having the need for periodic adjustment and maintenance, the gearbox ensures trouble-free operation throughout its entire service life. The simplicity of the design makes it possible to confidently operate the car in any road conditions, without fear that the steering wheel will fail. The gearbox

has high maintainability and is easy to maintain.

Motor oils

| Oil brand | SAE viscosity grade | Group | Manufacturer | Regulatory document | |

| AAI | AP1 | ||||

| LUKOIL LUX | 5W-30, 5W-40 10W-40,15W-40 | B5/D3 | SJ/CF | LLC "Lukoil-Permnefteorg-sintez", Perm | STO 00044434-003 |

| LUKOIL LUX | 0W-40, 5W-20, 5W-30, 5W-50, 10W-30 | B5/D3 | SL/CF | LLC "Lukoil-Permnefteorg-sintez", Perm | STO 00044434-003 |

| TNK SUPER | 5W-30, 5W-40 10W-40 | B5/D3 | SJ/SL/CF | TNK Lubricants LLC, Ryazan | TU 0253-008-44918199 |

| TNK MAGNUM | 5W-30, 5W-40 10W-40,15W-40 | B5/D3 | SJ/SL/CF | TNK Lubricants LLC, Ryazan | TU 0253-025-44918199 |

| ROSNEFT MAXIMUM | 5W-40, 10W-40 | B5/D3 | SL/CF | OJSC "Novokuibyshevsk Oil and Additives Plant", Novokuibyshevsk | TU 0253-063-48120848 |

| ROSNEFT OPTIMUM | 10W-30, 10W-40 15W-40 | B5/D3 | SJ/CF | OJSC "Novokuibyshevsk Oil and Additives Plant", Novokuibyshevsk | TU 0253-062-48120848 |

| ROSNEFT MAXIMUM | 5W-40, 10W-40 | B5/D3 | SL/CF | OJSC "Angarsk Petrochemical Company", Angarsk | TU 0253-391-05742746 |

| ROSNEFT OPTIMUM | 10W-30, 10W-40 15W-40 | B5/D3 | SJ/CF | OJSC "Angarsk Petrochemical Company", Angarsk | TU 0253-389-05742746 |

| ROSNEFT PREMIUM | 0W-40, 5W-40 5W-40 | B5/D3 | SJ/CF SL/CF SM/CF | OJSC "Angarsk Petrochemical Company", Angarsk | TU 0253-390-05742746 |

Continuation of the table. 2

| Oil brand | SAE viscosity grade | Group | Manufacturer | Regulatory document | |

| AAI | API | ||||

| EXTRA 1 EXTRA 5 EXTRA 7 | 5W-30 15W-40 20W-50 | B5/D3 | SJ/CF | OJSC "Omsk Oil Refinery", Omsk | TU 38.301-19-137 |

| EXTRA | 5W-30, 10W-40, 15W-40 | B5/D3 | SL/CF | OJSC "Omsk Oil Refinery", Omsk | TU 38.301-19-137 |

| ESSO ULTRA | 10W-40 | B5/D3 | SJ/SL/CF | Exxon-Mobil, Germany | |

| GTTURBO SM | 10W-40 | B5 | S.M. | Hanval INC, Korea | |

| LIQUI MOLY OPTIMAL | 10W-40 | B5/D3 | SL/CF | Liqui Moly GmbH, Germany | |

| MOBIL 1 MOBIL SYNT S MOBIL SUPER S | 0W-40, 5W-50 5W-40 10W-40 | B5/D3 | SJ/SL SM/CF SJ/SL/CF | Exxon-Mobil, Germany | |

| MOBIL 1 ESP FORMULA | 5W-30 | B6/D3 | SJ/SL SM/CF | ||

| RAVENOL HPS RAVENOL VSI RAVENOL LLO RAVENOL TSI RAVENOL Turbo-C HD-C | 5W-30 5W-40 10W-40 10W-40 15W-40 | B5/D3 | SL/CF SL/CF SL/CF SL/CF SJ/CF | Ravensberger Schmirstoffvertrieb GmbH, Germany | |

| SHELL HELIX: PLUS PLUS EXTRA ULTRA | 10W-40 5W-40 5W-40 | B5/D3 | SL/CF | SHELL EAST EUROPE Co, UK, Finland | |

| ZIC A PLUS | 5W-30, 10W-30, 10W-40 | B5 | SL | SK CORPORATION, Korea | |

Note. The oil change period is in accordance with the vehicle service book.

RECOMMENDED TEMPERATURE RANGES FOR APPLICATION OF MOTOR OILS

| Minimum engine cold start temperature, 0C | Viscosity grade according to SAE J 300 | Maximum ambient temperature, 0C |

| below -35 | 0W-30 | 25 |

| below -35 | 0W-40 | 30 |

| -30 | 5W-30 | 25 |

| -30 | 5W-40 | 35 |

| -25 | 10W-30 | 25 |

| -25 | 10W-40 | 35 |

| -20 | 15W-40 | 45 |

| -15 | 20W-40 | 45 |