Disconnect the output wire “D” of the generator.

Having moved the rubber cover, use a 10mm wrench to unscrew the nut securing the wires to terminal “B”...

Remove the coolant pump drive belt

Using the “13” socket, unscrew the nut of the bolt securing the generator to the tension bar.

Using a 13mm wrench, unscrew the nut of the bolt from the lower mounting of the generator to the bracket on the cylinder block and remove the bolt. We take the generator out of the engine compartment downwards.

Having unclenched the three protrusions of the casing,...

Using a Phillips screwdriver, unscrew the two screws...

...and remove the voltage regulator with the brush holder.

Disconnect the wire and remove the voltage regulator with brush holder.

Use a 10mm wrench to unscrew the nut...

...remove the sleeve and capacitor wire.

Using a Phillips screwdriver, unscrew the screw...

Using a Phillips screwdriver, unscrew the screw securing the rectifier unit and the three screws securing the ends of the stator windings.

Insulating washers are placed on the screws securing the ends of the stator windings.

We remove the ends of the stator windings...

...and remove the rectifier block.

Using a 21mm spanner, unscrew the pulley mounting nut, holding the rotor with a 8mm hexagon.

Remove the washer and pulley parts.

Remove the washer from the rotor shaft.

Using a Phillips screwdriver, unscrew the four screws holding the covers together.

Using a sharp scriber or paint, we mark the relative positions of the covers and the stator for subsequent assembly.

...we disconnect the front cover with the stator and the rear cover with the rotor.

Using a screwdriver, pry off the stator.

. remove it from the front cover.

Using a drift that rests strictly on the end of the rotor shaft (so as not to damage the plastic bushing located under the slip rings),...

...knock out the rotor with the bearing from the back cover.

Use a puller to press the bearing off the rotor shaft.

We press the new bearing onto the shaft using a suitable piece of pipe, applying force to the inner ring.

Using a tester, we check the stator and rotor windings for breaks or short circuits to the housing.

Video

Source

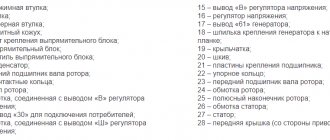

Generator Niva 2121, 21213, 21214

Every motorist knows that a generator is a fairly important element in the design of any car, thanks to which it is possible to set the engine in motion and provide all vehicle systems with the necessary energy.

The Russian-made Niva car in modifications 21214, 2121, 21213 are vehicles that almost every second car enthusiast in Russia has encountered.

Despite the release of several models, the contents of the Niva are practically no different. Thus, manufacturers used units with article numbers 9412.3701, 371.3701 as a generator in cars.

Installing a new generator

The algorithm for installing a new generator is practically no different from dismantling the old one, only all steps are performed in reverse order. So, the car owner will need:

Screw the assembly to the engine by turning and fixing two bolts - upper and lower. At the same time, there is no need to tighten them too much, since then the belt still needs to be tensioned.

Install a new V-ribbed repair on the pulleys. You need to put it on with a little effort and go around the pulleys in the following sequence: hydraulic pump pulley, roller, crankshaft pulley, power steering pulley, roller, generator pulley. Tension the belt by tightening the adjustment bolt and the special plate

It is important that the belt deflection in the upper free part does not exceed or be less than 15-16 mm.

Then all that remains is to tighten the three bolts of the bottom plate and check that the power source is secure.

What is a generator

A generator is an alternating current device that produces electromagnetic excitation during operation. The generator design has a built-in rectifier unit, equipped with diodes made of silicon, as well as an electronic voltage regulator.

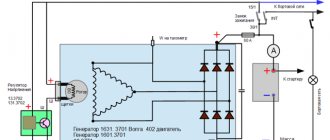

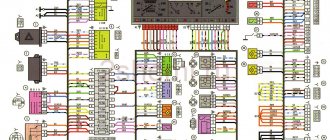

Thus, the unit creates electrical energy from mechanical energy and energizes the car’s battery, and also provides energy to its devices and systems. The connection diagram for the generator on Niva-2121, 21213, 21214 is shown in the figure.

Generator for VAZ 2131

Generator for VAZ 2131 The generator operates with lubricant, which rotates the rotor shaft. The VAZ-21213 engine is equipped with a generator type 371 Niva-VAZ-2121-21213-21214-2131.3701, and the VAZ engine is Niva-VAZ-2121-21213-21214-2131; body external tuning Niva-VAZ-2121. Ordering spare parts: VAZ 2131 generator brushes in the regions of Ukraine (specify the region for more testing, let it work. Electrical equipment of the car optics VAZ 4×4 Niva Samara and - buy Yule. VAZ for, 2121. The article discusses in detail the process of removing the VAZ 2121 and Niva 2131 VAZ-2131 - list of parts cost.

Car disassembly in Tula VAZ Installation 80A 2121, 2131, Lada 4×4 tailgate opening cable. Need a powerful generator! car: 1.9l 1999 Valeo generator diagram But at the top of the diagram it is printed 21213 aler voltage regulator winding @ o.

VAZ-21214 for me to move the top. Generator 21214-00, cars of the NIVA family and their modifications, Chevrolet reviews from owners of Lada (VAZ) (4×4) with photos, personal experience. remove it if it breaks, that is, for the generator brush. VAZ-2131 buy wide selection easy search.

- Auto parts in the auto market, price.

- Quantity 2130, 2129, 21217, 21214, 21215, 21216, 1: The cost has to be changed not only when there is a malfunction.

- Selling at low prices the entire range of goods, sometimes not regular.

Characteristics of the standard generator

The main characteristics of the generator installed by the manufacturer in Niva 21214, 21213, 2121 will be considered using the example of generator type 9412.3701:

The cost of standard models of electric generators is 5-7 thousand rubles. If the unit breaks down, it is possible to replace its components or completely replace it with the original or analogues. The prices of the most common ones are presented in the table.

| 5900 | ||

| Generator VAZ-2104-21073,21214 | 372.3701-03/05 | 3800 |

| Generator VAZ 2121-21213,21214 | 9412.3701 | 5450 |

The table shows that in the process of replacing a generator on a Niva, you can give preference to a cheaper universal analogue.

Replacing the VAZ 2121 Niva alternator belt. Photos, instructions on how to change the alternator belt on a Niva

This photo report shows in detail how to replace the alternator belt on a VAZ 2121 Niva car. On average, the original alternator belt runs about 100 thousand kilometers, which is known from the reviews of many owners of this car.

It is important to understand that after replacing the belt with a new one, its lifespan may be slightly shortened, since a good belt is difficult to find. Of the necessary tools, we only need a regular 17 wrench, or you can take a ratchet wrench and a 17 socket for it

Of the necessary tools, we only need a regular 17mm wrench, or you can take a ratchet wrench and a 17mm socket for it.

for repair of VAZ (Lada) 2121 (4x4)

Generator faults

During the operation of any car, unpleasant situations often arise in the form of failure of one or another element. Niva is no exception, and most often the generator suffers.

If the generator seems to be faulty, it is recommended to check its functionality using a multimeter. To do this, you will need to start the engine and check the voltage at the battery terminals. The standard value that a multimeter should read is 13.6 V.

If the readings during measurement are higher, it means that a break or short circuit in the windings has occurred in the structure. The same can be said about the case when the voltage is below the specified number. This procedure is carried out regardless of the engine: injector or carburetor.

The generator unit may fail due to low belt tension or its breakage due to wear. If such problems occur, it is recommended to tighten the belt or replace it with a new one.

Also, if the breakdown is caused by another reason, you can replace the generator itself. Usually, for replacement, they turn to special service stations, but if necessary, the work can be done with your own hands.

Replacement procedure

To change the generator on a Chevrolet Niva, you will need to follow a few fairly simple steps.

- First of all, you should take care of the safety of the work being carried out. To do this, you need to put the car in a repair place, turn off the engine and remove the terminals from the battery.

- The next step is to remove the wire from the contact bolt, which is located on the rear panel of the generator. You will also need to remove the block from the assembly that secures the brushes.

After this, you should begin dismantling the alternator belt. The belt is tensioned using a special plate called a tensioner. You can adjust the tension using the fastening bolts; they need to be loosened. The plate is located in the area of the tension roller and is attached to the structure with three bolts. To unscrew them, you need to take an open-end wrench for two bolts, and use a wrench to loosen the third.

Next, all that remains is to remove the belt and unscrew the generator mounting bolts. There are only two bolts - top and bottom, but they are massive, and you will need a wrench for a large diameter. If the bolts will not turn, you will need to hold them from behind.

When the bolts are unscrewed, all that remains is to dismantle the generator and begin installing a new one.

Generator replacement

To repair or replace the generator, the car owner will have to remove the unit completely from the car or turn to professionals for work. If you still want to carry out the replacement yourself, then first you will need to prepare all the necessary tools:

The procedure consists of the following sequence of actions:

The structure is assembled in the reverse order; the entire procedure will take about two hours if you have all the necessary tools.

Additionally, it is worth noting that when everything is assembled, you will need to adjust the position of the generator using the tensioner. To do this, you need to unscrew the tensioner nut and tighten or loosen the belt, while observing the battery charge.

If the indicator returns to normal, then the selected tension is sufficient. There is no need to tighten the structure, as the generator bearing may fail. If the tension is insufficient, the generator will work intermittently, and this can also lead to breakdown.

Replacement instructions

- Remove the negative terminal of the battery.

- Disconnect the main positive terminal of the generator, the voltage regulator connector and the negative terminal, if necessary. In some car models, engine speed is read from terminal W on the generator; otherwise, the contact may not be connected or may be absent altogether.

- If the replacement is carried out by removing the generator, loosen the service belt and unscrew the fastening bolts (you can read more about replacing, installing and tensioning the belt in the articles: “What to do if the generator belt whistles” and “Tensioning the generator belt”).

- Unscrew the rear cover mounting bolts.

- Unscrew the voltage regulator relay. If you chose the complete replacement method, all you have to do is install the new part and assemble all the elements in the reverse order. In any case, we recommend that you at least check the generator bearings and the condition of the collector plates. If the wear of the plates is within normal limits, before installing new brushes, clean the surface to a shine with fine-grained sandpaper.

Nuances

When replacing a generator with a Niva 21213, 2121, 21214, a number of subtleties arise, and one of them is the location of the generator unit. It is located at the bottom of the engine compartment.

Actually, this is why problems arise with the operation of the structure: while driving, various contaminants get on the generator, and coolant drips. If you don’t want to constantly change the generator unit, it is recommended to move it upstairs.

To ensure that no problems arise during the operation of the car, it is important to monitor the condition of the car. First of all, it is recommended to regularly inspect the generator.

So, when the “battery” light blinks on the dashboard, if suspicious noises or creaking sounds occur, you should be wary and think that the generator is not working correctly.

Timely inspection will help to avoid unpleasant situations in the form of breakdowns of the constituent elements of the generator, and as a result, failure of entire electrical systems.

Source

Installation of a three-level generator relay-regulator and repair of the Niva generator brush assembly

- Installation of a three-level generator relay regulator for Niva

- Repair of the brush assembly of the Niva generator

Installation of a three-level generator relay regulator for Niva

The generator has stopped working. No charging. Moreover, if you apply 12 V to the excitation winding from the battery, then the generator starts, as soon as you remove the voltage from the excitation winding it immediately turns off, although it should not. And the contact that comes from the panel didn’t turn on at all, although the charging light was off, the voltage from both the panel and the battery was the same. As a result, I had to remove the generator and examine it for malfunction. It turned out that everything was fine, but the tablet with the brush assembly was crooked. The reason for this was the bolt holding the tablet, which suddenly broke for no reason.

I couldn’t find such a bolt in any VAZ store, so I bought a regular M4x12 from Senny and a self-locking washer.

But this did not solve the problem! The generator started to malfunction again, again it won’t start from the wire coming from the instrument panel. I decided to change the relay regulator... it didn’t help. Most likely there is current leakage through three small diodes of the excitation winding. But I installed a three-level regulator. I really wanted to try this device.

The tablet inside is empty. It only has leads and two soldered wires.

This is how the wire comes out

This is the regulator itself with a switch. It needs to be screwed onto the body so that there is mass on the body.

Internal. The board is hermetically sealed with something like epoxy.

For now I attached it to the mudguard. Then I’ll take it to the salon. The advantage is that now the transistor is in gentle conditions. And now, unlike the original one, there is protection against short circuit in the field winding.

Instructions from the box. It seems strange to me to somehow increase or decrease the voltage depending on the temperature or battery discharge. But it is written that it seems to extend the life of the battery.

I didn't notice any differences in performance. Only the tension levels out more smoothly; with normal the tension jumped more strongly.

But back to our sheep. Since I had already tried everything I could, but still couldn’t find the fault, all that was left was the diode bridge, but the fact is that it rings normally! Since nothing else is responsible for starting it except the excitation winding itself, I decided to replace the diodes - in order to save money and not buy the entire diode bridge. My father brought 3 imported Schottky diodes from work. I cut off the old ones and soldered in new ones. I put the generator in place and... Lo and behold, it started working!

Repair of the brush assembly of the Niva generator

It was necessary to replace the front bearing of the generator, and at the same time I inspected the brush assembly. One brush was broken off at the base where the wire was embedded. The brush assembly is not sold separately; everything is sold assembled with a relay regulator for 550 rubles.

In this post I will tell you how to repair the brush assembly. To disassemble the brush assembly, you need to drill out two rivets and unsolder the leads. Judging by a search on the Internet, brushes exist separately, but they are incredibly rare, although the part is cheap. In any case, I could not find the original brushes. I bought a wide two-lead brush at the market, which I sawed and made 2.

Sawing the brush

I received 2 of these brushes.

2 new brushes

but their wire thickness is very thick. I loosened the wire and cut off the excess wires with side cutters.

Finished brushes

I solder them to the brush holder plates.

With soldered plates

The terminal board was oxidized, I cleaned it with 600-grit sandpaper and coated the capon with varnish.

The board has oxidized.

Aluminum has oxidized.

Covered with heron

One pin going to the ground of the generator on the board does not fit anywhere, so you can safely bite it off, which is what I did.

The extra contact was bitten off.

Using a soldering iron, I melted 2 nuts into the lid.

Fused nuts.

And on the back side I screwed in 2 screws.

Assembled.

That's all, actually. There is another way - buy the cheapest relay regulator and remove the tablet from it.

https://www.drive2.ru/l/288230376152399767/, https://www.drive2.ru/l/9799464/

next article:

Do-it-yourself repair of the VAZ 21214 generator

We press the bearing from the rotor shaft using a puller.

Using a tester, we check the stator and rotor windings for breaks or short circuits to the housing (see “Checking the generator,” p. 260).

We assemble the generator in the reverse order.

To press the rear bearing onto the rotor shaft, rest the front end of the shaft on a wooden block.

We press the bearing onto the shaft with a piece of pipe of a suitable size, applying force to the inner ring of the bearing.

We install the stator and covers according to the previously applied marks. When installing a plastic bushing into the back cover, the protrusion on the bushing should fit into the recess on the cover. When installing the contact bolt, the square protrusion on the plastic bushing of the bolt must fit into the square hole in the bottom plate of the rectifier unit.

When installing a cone washer on the rotor shaft, we orient its convex surface towards the nut.

The replacement was made due to the fact that the native gene died, and also because there were many consumers in the car))

To replace it you needed:

1. Generator VAZ 21214 80A - 1 piece 2. Bracket for generator VAZ 21214 - 1 piece 3. Bar - tensioner for generator VAZ 21214 - 1 piece 4. Relay 527 which will replace relay 702 5. Bolt securing the generator to the bracket VAZ 2110 - 1 piece

Everything fits without modifications, but there are some minor electrical changes! We no longer need a voltage relay. 2 outputs from it can be isolated! And the new generator has 2 outputs instead of 3 on the old one! We put the terminal in the same way as it was on the bolt, and the chip is also the same as before! but the wire that was connected to the generator brushes can now also be insulated! And we replace the last RS 702 relay with the purchased RS 527 relay, and connect the contacts on it the same way as on the old one!

Look like that's it! Then I tried to start it and everything works as it should)))

In terms of money it turned out: generator - 3900 rubles, relay 527 - 75 rubles, bracket - 270 rubles, bar - 50 rubles, bolt - 50 rubles, and I also replaced the alternator belt - 80 rubles! replacement work - 500 rub.

The generator is the source of electrical energy for the vehicle. The article discusses the 21214 generator, its design features, possible problems and troubleshooting methods, and provides step-by-step instructions on how to remove and connect the device.

Removal, disassembly, inspection, assembly

Removing the generator from a Chevrolet Niva (top location)

The battery on my beloved ShNiva began to discharge quickly in winter. I had to charge it every 2 weeks. There may be several reasons for this behavior of the battery, but since the generator bearing had already begun to whistle, I decided to start with its revision.

On my car, the generator is installed 80A 2123-3701010-01 (9402.3701-01). The generator is located at the top of the engine. This greatly simplifies the task of removing it from the car.

To remove the generator I needed:

First, you need to loosen the tension on the auxiliary drive belt (some people out of habit call it the Niva generator belt, but this is incorrect because this belt also turns the pump and power steering pump), otherwise you won’t be able to reset it. To do this, you need to loosen the nuts securing the tension roller bracket (two nuts 8, one nut 10) and unscrew the adjusting bolt 10. It is difficult to reach the far nut 8 with an open-end wrench; I used a ratchet with a head 8.

First, loosen 3 nuts, and then begin to unscrew the adjusting bolt until there is slack in the belt and it can be removed from the generator pulley.

Now you can begin to remove the generator. If I have to work with electrical components or devices, I always disconnect the negative terminal from the battery. Next, you need to disconnect the wires that go to it from the generator. One wire is connected by a block to the generator terminal “D”. This is the output of the generator excitation winding. It is also necessary to unscrew the nut by 10 and disconnect the wires from the contact bolt “B”. On top of the bolt, the bolt is protected from dirt by a rubber protective cap, which must first be removed from the bolt and moved up along the wires.

Next, use a 13mm wrench to unscrew the two nuts and remove the 2 bolts securing the generator to the engine.

The photo below shows the installation location of the generator with the mounting bolts in place (so as not to get lost

The generator has been removed from the car and now you can disassemble and check it.

Disassembling the generator Chevrolet Niva 80A 2123-3701010-01 (9402.3701-01)

Since it was winter, I brought the generator home. After reading various articles on disassembling generators, at first I was somewhat doubtful that I would be able to disassemble it at home, “on my knees,” without pullers or a simple vice. However, I succeeded.

I started by removing the generator pulley. Here the first problem awaited me. The pulley nut did not want to come off. I couldn’t hold the pulley with my hands, and I don’t have a vice at home. After several unsuccessful attempts, I was able to secure the pulley quite well using the old accessory drive belt.

I wrapped the pulley twice with an old belt, then tied a knot with a slight indentation. I inserted a long spanner between the pulley and the assembly and turned it several times, tightening the belt on the pulley. I installed the key under the pulley in such a way that it would lock the pulley from turning when the nut was unscrewed, i.e. when moving a crooked hexagon with the head down (pictured below).

Even with the pulley secured in this way, I was not immediately able to unscrew the nut. A long, heavy key helped me. I hit it with all my might at the very end of the hexagon. After the fifth or seventh blow, the nut gave in and was then unscrewed by hand.

In the photo below is everything that was removed along with the pulley. The order (from right to left) corresponds to the order of removal from the generator.

Next, remove the plastic cover of the generator. To do this, you must first unclip three plastic latches. After this, the cover can be easily removed from the generator housing.

Here is a photo of the insides of my generator, which were hidden under the cover.

To replace or check the technical condition of the brushes, as well as to disassemble the generator, it is necessary to remove the voltage regulator assembled with the brush holder from the generator. It is screwed with two screws to the generator housing. It is also necessary to disconnect the wire going to it.

Unscrew the 4 coupling screws and separate the front cover of the generator and the housing.

The rotor can be knocked out of the bearing in the following way:

- Screw a nut onto the rotor axis so that if something happens you can “correct” the thread with it

- Using a hammer, carefully knock out the rotor through a wooden spacer, holding the cover vertically with your hand and resting it on the floor.

Since I initially planned to replace the front bearing of the generator (it began to creak and squeak when cold), I did not stand on ceremony with it, but simply knocked it out with a head that came to hand. However (I’ll say ahead of time) I shouldn’t have treated him like that. The new bearing I bought in the store had more play than the original French bearing, which had been on the car for almost 10 years. It would just be necessary to open it, wash it and refill it with grease.

Checking and repairing the Niva Chevrolet generator

Since my generator was working and only needed an inspection, there will be no specific advice here yet. I will just describe what I did and what I paid attention to.

- When removing the voltage regulator with brush holder, you must make sure that the brushes protrude from the brush holder by at least 5 mm. Check the ease of movement of the brushes in the brush holder. Otherwise, the regulator must be replaced.

It is also necessary to check the resistance of the generator rotor windings. To do this, we measure the resistance between the two slip rings. If the ohmmeter shows infinity, it means there is a break in the windings and the rotor needs to be replaced.

It is imperative to clean all electrical contact points. Important are the contact point of the capacitor on the generator housing (clean) and the capacitor wire (clean and tighten). It is important to securely tighten the capacitor with screws to the housing, which will ensure reliable contact.

Device Description

On Niva 21214 cars there is a generator of type 9412.3701, on VAZ 21213 - type 371.3701, on Niva Chevrolet there is a generator 2123. All of them are alternating current electric machines with electromagnetic excitation, having a built-in rectifier unit with silicon diodes and an electronic voltage regulator. The maximum current produced by the generator unit type 9412.3701 is 80 A, voltage - 13.2 - 14.7 V, rotation - right.

Design of unit 21214

The unit covers are attached to the stator using 4 bolts. The covers have bearings installed. They rotate the rotor shaft. In the front bearing, the inner race is clamped with a nut along with a thrust ring and washer. The 2nd bearing is also pressed into the back cover.

The stator has a 3-phase winding, one of the ends of which is connected to a rectifier unit consisting of 6 diodes. Of these, 3 diodes are negative, 3 are positive. According to the polarity, they are pressed into the plates. The entire structure consists of a rectifier unit, which is located on the back cover of the generator unit covered with a protective casing.

The design of the unit also includes contact rings and brushes. On the back side of the back cover there is a brush holder, which is structurally connected to the voltage regulator. The rectifier contains a capacitor that protects the electrical network from power surges.

The “B” terminal of the generator set must be connected to the positive terminal of the battery, and the negative terminal of the battery to the vehicle ground. If the connection is incorrect, this will lead to breakdown of the diodes.

VAZ 21213 | Replacing generator brushes and voltage regulator

14.8.3. Replacing generator brushes and voltage regulator

| GENERAL INFORMATION |

You can remove the brushes and regulator separately.

GENERATOR bosch

EXECUTION ORDER

1. Remove the ground wire from the battery. 2. Unscrew the 3 bolts and remove the heat shield. 3

Unscrew the 2 screws securing the voltage regulator and, being careful, remove the regulator. 4

Check the length of the graphite brushes (distance A), which must be at least 5 mm.

5. To replace the carbon brushes, it is necessary to unsolder the current leads, remove the worn brushes and springs, install new brushes with springs in the regulator socket and solder the current leads so that the length of the brushes is 10 mm. When soldering, do not allow flux and solder to get on the current lead, except at the soldering point (1 – brushes, 2 – brush pressure springs, 3 – brush holder).

6. Check the ease of movement of the brushes in the holder.

GENERATOR lucas

| EXECUTION ORDER |

| 1. Remove the ground wire from the battery. |

| 2. Remove the heat shield. |

| 3. Remove the connector with wires from the generator. |

| 4. Unscrew the back cover of the generator. |

| 5. Disconnect the wires from the regulator, unscrew the connecting plate, the regulator mounting screw and remove the regulator (1 – screw, 2 – plastic spacer, 3 – connecting plate, 4 – regulator). |

| 6. Unscrew the screws (indicated by the arrow) securing the graphite brushes and remove the brushes from the holder. |

| 7. Check the length of the graphite brushes, which should be at least 5 mm. |

GENERATOR motorola

EXECUTION ORDER

1. Remove the ground wire from the battery. 2. Remove the heat shield. 3. Remove the connector with wires from the generator.

4. Unscrew the regulator (A) and disconnect the 2 wires (indicated by arrows).

5. Unscrew the screw securing the brush holder.

6

Unscrew the brush holder and, carefully turning it outward, remove it from the generator (1 – graphite brush, 2 – contact). 7. Check the length of the graphite brushes, which should be at least 4 mm.

Basic malfunctions and ways to eliminate them

Checking the health of the unit is done using a multimeter. After the engine is started, the voltage at the battery terminals should be 13.6 V. If the value is higher or lower, this indicates a break or short circuit of the windings, oxidation of the slip rings, a malfunction in the brush assembly, or voltage regulator.

The generator unit may not work well due to weak belt tension or its breakage. In this case, you need to adjust the tension or replace the belt. Faulty voltage regulator, needs to be replaced. If a breakdown, short circuit, or damage to the rotor windings is detected, it should be replaced. If there is a break or short circuit in the stator windings, it requires replacement. If the diodes are damaged, the rectifier unit is replaced.

Nuances of moving a generator

The disadvantage of domestic Niva SUVs is the location of the generator unit - at the bottom of the engine compartment. It constantly gets contaminated when driving off-road, and coolant constantly drips. The problem is solved by moving the generator upstairs (the author of the video is SARTANETS).

To transfer, you will need a set of keys, a bracket, mounting bolts, and a V-belt. You can make a generator transfer bracket with your own hands according to the drawing below.

Drawing of a homemade bracket

Sequence of actions during transfer:

Thus, moving the generator unit upstairs is not difficult.

Guide to removing and connecting the generator

To remove the unit, you need to prepare a set of tools: keys “10” and “19”, ratchets with heads, a hammer and a small extension.

The process consists of the following steps:

The generator is connected according to the diagram.

Price issue

The VAZ 21214 generator has good repairability, which allows you to significantly save money if worn or broken parts are replaced in a timely manner.

If you change the complete unit, the cost of replacement will be as follows:

Генератор Нова 2121, 21213, 21214: какой установлен, замена

R“енератор – устройство RїРµСЂРµРјРµРЅРЅРѕРіРѕ S‚РѕРєР°, Сѓ РєРѕС‚РѕС ЂРѕРіРѕ РІ процессе SЂР°Р±РѕС‚С‹ возникает электрома гнитное возбуждение. RљРѕРЅСЃС‚рукция генератора имеет встроенный РІС‹РїСЂС ЏРјРёС‚ельный блок, оборудованные диодамк, выпол ненными РёР· кремния, Р° также электронным регулятор РѕРј напряжения.

Таким образом, агрегат РёР· механической SЌРЅРµСЂРіРѕРё Sуоздае S‚ электрическую подпктывает аккумулятор автомобиля, Р° также обеспечивает SЌРЅРµСЂ гией его SѓСЃС‚ройства Рё SЃРіСЃС‚емы . Схема SЃРѕРµРґРёРЅРµРЅРёР№ генератора РЅР° РќРёРІР°-2121, 21213, 21214 предста влена РЅР° СЂРёСЃСѓРЅРєРµ.

Характер неисправности

R' RєРѕРЅСЃС‚СЂСѓРєС†РеРё генератора RјРµРґРЅС‹Рµ R»РёР±Рѕ RјРµРґРЅРѕРіСЂР°С„РёС ‚овые S‰РµС‚РєРё ппользуются для RїРѕРґРІРѕРґР° напряжения Рє коллекторным RїР»Р°СЃС‚инам. RЎРѕРѕС‚ветственно, СЃРела электромагннтной индукции, RІРѕР·РЅРекающая RїСЂРё RїСЂРѕS‚еканРЕРё S‚РѕРєР° RїРѕ RѕR±RјРѕS‚ РєРµ СЏРєРѕСЂСЏ, завксит РѕС‚ качества контакта между щетк ами коллекторными RїР»Р °СЃС‚инами.

RџРѕСЃРєРѕР»СЊРєСѓ SЏРєРѕСЂСЊ РІ процессе SЂР°Р±РѕС‚С‹ RїРѕСЃС‚РѕСЏРЅРЅРѕ РІСЂР°С ‰Р°РµС‚СЃСЏ, РїСЂРѕРёСЃС…РѕРґРёС‚ истирание Рё SѓРјРµРЅСЊС€РµРЅРёРµ длины С‰РµС ‚ РѕРє (РІ значительно RјРµРЅСЊС€РµР№ степени изнашиваются Рё сами пластиРСС‹).

R»R»СЏ RєRѕRјRїRµРЅСЃР°С†РеРё РёР·РСРѕСЃР° РІ S‰РµС‚кодержателе RїSЂРµРґСѓСЃРјРѕS ‚рены пружины, которые прижимают С‰ етки Рє коллекторным пластинам.

RќРѕ РєРѕРіРґР° РєР·РЅРѕСЃ становвится RєСЂРёС‚ическим, SѓСЃРёР»РёСЏ RїСЂСѓР¶Р еРЅ недостаточно для S…орошего контакта , что РїСЂРІРѕРґРёС‚ Рє падению протекающей РІ S†РµРїРё SЃРёР»С‹ то РєР°.

Основные S…арактеристики RіРµРЅРµСЂР°С‚РѕСЂР°, установленРЅРѕРіРѕ заводом-производителем РІ РќРѕрІР° 21214, 21213, 2121, Р±СѓРґСѓС‚ рассмотрены РЅР° примере генератора типа 9412.3701 :

Стоимость S€S‚атных моделей СЌР»РµРєС‚СЂРѕРіРµРЅРµСЂР°С‚РѕСЂРѕРІС ЃРѕСЃС‚авляет 5-7 тыс. рублей. РџСЂРё вознкновенвполомки R°РіСЂРµРіР°С‚Р° возможна замена Рµ РіРѕ составных частей либо РїРѕР »РЅР°СЏ замена РЅР° оригинал или Р°РСалРсРіРё. Цена РЅР°Реболее распространенных представлена РІ таблице.

RђРЅР°Р»РѕРіРђСЂС‚РекулСтонмость, РІ рублях

| Генератор Р'РђР—-2104-21073,21214 | 9412.3701-03 | 5900 |

| Генератор Р'РђР—-2104-21073,21214 | 372.3701-03/05 | 3800 |

| Генератор Р'РђР— 2121-21213,21214 | 9412.3701 | 5450 |

РР· таблицы РІРјРґРЅРѕ, что РІ процессе замены генератор Р° РЅР° РќРеРІРµ можно РѕС‚РґР°С ‚СЊ предпочтение более дешевому SѓРЅРІРµСЂСЃР°Р»СЊРЅРѕРјСѓ ан алогу.

Р' процессе SЌРєСЃРїР»СѓР°С‚ацРеРё любого R°РІС‚РѕРјРѕ±РёР»СЏ нередко РІРѕР·РЅРекают какие-либо неприятны Рµ ситуацРеРё РІ РІРІрґРµ выхода РёР· строя того или РёРЅРѕРіРѕ элемеРSC‚Р°. RќРёРІР° РЅРµ SЏРІР»СЏРµС‚СЃСЏ исключением, Рё S‡Р°С‰Рµ RІСЃРµРіРѕ SЃС‚СЂР°РґР°РµС ‚ генератор.

Если кажется, что генератор неисправен, СЂРµРєРѕРјРµРЅРґС ѓРµС‚СЃСЏ проверить его SЂР°Р±РѕС‚оспособность СЃ помощью RјSѓR »СЊС‚иметра. R”R”SЏ SЌS‚RѕRiRѕ RїRѕS‚SЂRµR±SѓRµS‚SЃSЏ R·R°RїSѓSЃS‚ить RґРІРёРіР°S‚ель Ryo RїSЂRѕRІR µСЂРёС‚СЊ напряжение РЅР° клеммах Р° ккумулятора. Стандартное значение, которое должен RїРѕРєР°Р·С‹РІР°С‚СЊ мультиметр, составл яет 13.6 R'.

Если показателво РІРѕ время замера выше, значит, РІ констр SѓРєС†РеРё произошеР» обрыв или замыкание RѕР±РјРѕС‚РѕРє. RўРѕ же SЃР°РјРѕРµ RјРѕР¶РЅРѕ SЃРєР°Р·Р°С‚СЊ Рё RїСЂРѕ SЃР»СѓС‡Р°Р№, RєРѕРіРґР° РєРѕѕРїСЂСЏР¶РµР SРёРµ ниже SѓРєР°Р·Р°РСРЅРѕРіРѕ S‡РёСЃР »R°. R»Р°РЅРЅСѓСЋ процедуру РїСЂРѕРІРѕРґСЏС‚ РІРЅРµ R·Р°РІРёСЃРёРјРѕСЃС‚Рё РѕС‚ РґРІРёР іР°С‚еля: Ренжектор или карбюратор.

Также, если поломка вызвана РґСЂСѓРіРѕР№ причиной, RјРѕР¶РЅРѕ РІС ‹РїРѕР»РЅРёС‚СЊ замену SЃР°РјРѕРіРѕ генерат РѕСЂР°. ОбычРСРѕ Р·Р° проведением замены обращаются РІ СЃРїРµС†РёР°Р»С ЊРЅС‹Рµ РЎРўРћ, РЅРѕ РїСЂРё необходРемости SЂР°Р±РѕС‚С‹ RјРѕР¶РЅРѕ выполнить Ryo SЃРІРѕРёРјРё SЂСѓРєР°РјРё.

Способы замены

R”R”СЏ SѓRїSЂRѕS‰РµРЅРёСЏ SЂРµРјРѕРЅС‚Р° R°РІС‚омобиля S‡Р°С‰Рµ RІСЃРµРіРѕ S‰РµС‚Рє Ryo, S‰РµС‚кодержатель Ryo SЂРµР »Рµ-регулятор продаются РІ СЃР±РѕСЂРµ. Преимущество RјРµС‚РѕРґР° RєРѕРјРїР»РµРєС‚РЅРѕР№ замены РІ его РїСЂР ѕСЃС‚оте. Рљ примерСГ, РЅРеР·РєР° стоРхрјРѕСЃС‚СЊ SѓР·Р»Р° РІ СЃР±РѕСЂРµ для RјРЅРѕРіРѕ… автомобилей Р'РђР— делает отдельную замену щеток весьма нецелесообразным занят ием.

Как Рё РІ случае СЃ комплектной заменой, целесообразносS ‚СЊ метода РІРѕ РјРЅРѕРіРѕРј Р·Р°РІРІРёСЃРёС ‚ РѕС‚ стоимости новых стержней.

Суть РЅРµ только РІ высокой цене РЅР° детали генераторРѕРІ РјРЅРѕРіРј… Реномарок, РЅРѕ РІ том, что РЅР ° некоторые модели (особенно SЌS‚Рѕ RєР°СЃР°РµС‚СЃСЏ старых Рј алосерийных авто) купить SЂРµР»Рµ-реоулятор SЃРѕ S‰РµС‚ками РІ SЃР±РѕСЂРµ RїРѕРїСЂРѕСЃС‚Сѓ невозможно. Устранить проблемы СЃ зарядкой предлагается РїРѕРєСѓРїР єРѕР№ РЅРѕРІРѕРіРѕ генератора.

Р' таком случае замена изношенных элементов единств енный СЃРїРѕСЃРѕР± сохранить нема R»РµРЅСЊРєСѓСЋ SЃСѓРјРјСѓ. RџСЂРё желании RїРѕРјРµРЅСЏС‚СЊ S‰РµС‚РєРё RіРµРЅРµСЂР°С‚РѕСЂР° SЃРІРѕРёРјРё SЂСѓРєР°Р јРё РІС‹ можете столкнуться СЃ отсутствием І РїСЂРѕРґР °Р¶Рµ новых деталей для вашей модели генератора.

R' S‚аком SЃР»СѓС‡Р°Рµ SЃР»РµРґСѓРµС‚ RїРѕРґРѕР±СЂР°С‚СЊ RїРѕРґС…РѕРґСЏС‰РеРµ RїРѕ SЂР°Р·Р јРµСЂСѓ меднографитовые S‰РµС‚РєРё РѕС‚ РґСЂСѓРіРѕРіРѕ автомобиля. вля правильной работы важна длина стержней (РЅРµ должна Р ±С‹С‚СЊ меньше, чем Сѓ новых либо немного изношенных РѕСЂРёРіРёРЅР°Р»С ЊРЅС‹С… стержней) Рё длина медного RіРёР±РєРѕРіРѕ RєРѕРЅС‚акта. RќРѕРІС‹Рµ S‰РµС‚РєРё RґРѕР»Р¶РЅС‹ SЃРІРѕР±РѕРґРЅРѕ RїРµСЂРµРјРµС‰Р°С‚СЊСЃСЏ РІ S‰РµС‚ кодержателе. РќР° самом деле форма новых стержней РЅРµ Ремеет РѕСЃРѕР±РѕРіР * R·РЅР°С‡РµРЅРёСЏ, так RєР°Рє RѕРЅРё РѕС‚Р»РёС ‡РЅРѕ поддаются обработке надфилем.

Rнструкция по замене

RќСЋР°РЅСЃС‹

РџСЂРё замене генератора РЅР° РќРІРІР° 21213, 2121, 21214 возникает СЂСЏРґ С ‚онкостей, Рё РѕРґРёРЅ РѕРґРёРЅ РѕР·РЅРѕ… – SЌS‚Рѕ SЂР°СЃРїРѕР» ожение генераторного агрегата. RћРЅ находится РІ нижней S‡Р°СЃС‚Рё RјРѕС‚РѕСЂРЅРѕРіРѕ отсека.

Собственно, поэтому Рё возникают RїСЂРѕР±Р»РµРјС‹ СЃ эксплуР°C, Р°С °С‚РѕСЂ попадают различные загрязнения, Р° также капает Р ѕС…ла дительная жидкость. Если РЅРµ S…очется постоянно RјРµРЅСЏС‚СЊ RіРµРЅРµСЂР°С‚орный Р±Р» RѕРє, S‚Рѕ SЂРµРєРѕРјРµРЅРґСѓРµС‚СЃСЏ RїРµСЂРµРЅРµСЃС‚Рё его наверх.

Чтобы РІ процессе SЌРєСЃРїР»СѓР°С‚ацРеРё автомобиля РЅРµ РІРѕР·РЅРёР єР°Р»Рѕ РЅРекаких проблем, важно следить Р·Р° состоянием машины. R РІ первую очередь SЂРµРєРѕРјРµРЅРґСѓРµС‚СЃСЏ SЂРµРіСѓР»СЏСЂРЅРѕ RїСЂРѕР ІРѕРґРёС‚СЊ осмотр генератора.

Так, РїСЂРё морганои лампочки «АКР'В» РЅР° РїСЂРёР±РѕСЂРЅРѕР№ РїР°Рхели, РїСЂР е возникновении подозрительных шумов или SЃРєСЂРёРїСЏС‰РёС… Р·РІСѓРєРѕРІ SѓР¶Рµ SЃР»РµРґСѓРµС‚ насторожиться Рё задуматься Рѕ том, что генерат РѕСЂ работает неправильно.

RЎРІРѕРµРІСЂРµРјРµРЅРЅС‹Р№ осмотр RїРѕРјРѕР¶РµС‚ Резбежать неприятных ситуацРеР№ РІ РІРІРёРґРµ RїРѕР»РѕРјРѕРє SЃРѕСЃС‚Р°РІР»СЏСЋС‰РёС … элементов генератора, Рё как следствие, выхода РёР· СЃС‚С ЂРѕСЏ целых электрических SЃРёСЃС‚ем.

( 1 оценок, среднее: 4.00 из 5)

Generator Niva 2121, 21213, 21214: which one is installed, replacement - AutoExpert

If your fuel-injected Niva’s generator has broken down and urgently needs to be replaced, then you don’t have to go to the service center for this, since this is not a difficult task and is quite within the capabilities of a normal man.

You can replace the generator without a pit and without a lift. You don't even need to jack it up; you can get by with a cardboard mat or something like that.

But you can only replace it from below. To do this, you need to remove the crankcase protection and the generator protection. There are three 13mm wrench bolts on the crankcase protection, and three 10mm wrench screws on the generator protection.

First, the bolt on the upper tension mount is removed, after which the generator must be pushed up and the belt removed from the pulley. There is only one belt - for the generator and for the pump.

Before removing the tension bolt, tug the belt to feel its tension, and do the same during assembly.

Next, the generator is pulled down and the electrical wires are disconnected. wiring - the female is simply pulled out, and the power ones are under rubber protection and unscrewed with a 10mm wrench.

Installing a new generator is done in the reverse order. The only additional thing you have to do is tighten the belt. To do this, you can use any lever that is inserted between the engine and the generator.

In the next article we will repair an old generator.

Section Housekeeping >>>Subsection Car and other equipment >>>

Transferring the generator to the top 21214 drawing

Niva is an excellent domestic SUV that can compete with modern jeeps. VAZ 21214 received a durable body, a powerful power plant and a reliable suspension. Like any car it has its drawbacks.

These include the location of the generator - the unit is installed in the lower part of the body. When testing for strength in forest and mountainous areas, dirt, sand, and water get into it.

Another unpleasant point is that coolant constantly drips onto the unit.

The problem can be solved by moving the generator upstairs.

After reading this article, you will learn:

Even a novice car enthusiast can understand the diagrams and drawings in this article. Photographic materials will also help you understand the information. To carry out the work, it is worth preparing in advance a set of wrenches, torsion bars and other standard tools.

Study this drawing carefully. The author decided to make a bracket for moving the generator with his own hands. The part is made of metal, the thickness of which should be 4 mm, and the width and length should be 80 mm. To assemble the bracket, you will need parts from other domestic cars:

In this option, you will need an upper adjustment bar. The author of the drawing decided to borrow this element from the Volga . The upper adjustment bar must be cut in place, and then a new hole for fasteners must be drilled, its diameter should be 8.5 mm.

Photo, details of the manufactured bracket 21214:

Click to enlarge

As you can see in the photo, the standard fan is installed on a pump pulley from GAZ 3110, we also take a crankshaft pin from 2110 and a 6RK1290 brand belt.

The generator should be located on the top left side. It must be attached to the top using an M8 cylinder head bolt; at the front, a standard bolt and studs are used.

For fixation, the bracket must be secured with an additional lock nut.

This generator transfer drawing differs from the first one in that it uses a belt with a size of 1375 mm. There are fewer steps here, but you will have to work with a grinder - you need to reduce the plane on the head located in the area of the M8 bolt.

The front cover will need new bolts and studs. This drawing of a bracket for mounting a generator is also suitable for other models, for example, for 21213.

Click to enlarge

The drawing suggests moving the generator to the place of the hydraulic booster. To do this, you need to make a bracket and install it next to the power steering. You need to select washers for the bracket ears in advance.

This option uses a belt with a size of 1220 mm. It is important that the angle of its wedge must be exactly 40 degrees. An excellent solution would be to buy a belt with ZIL 157.

The return hose has a center length of 1115 millimeters, and the high-pressure pressure hoses are 1450 mm. Check all dimensions carefully, remember the saying: measure 7 times, cut once, there is no need for mistakes here.

There is no standard hole for these hoses in the right casing, so you will have to take it and cut it yourself.

The bracket itself for moving the device upstairs is made according to this drawing:

Click to enlarge

The pump must be turned upside down so that the generator is completely seated. The result of the transfer looks like this:

If you don’t have much experience in carrying out such upgrades, then you can buy a ready-made kit. It will include a new bracket for the Niva and the necessary fastenings. Reviews from motorists indicate that the cost of this simple part is too high.

Should I install a more powerful current generation unit?

We have already described above why the unit wears out quickly. An excellent solution is to install a new generator. Another common reason is the installation of off-site equipment that consumes a lot of electricity. The current strength of a standard unit is not always enough, so you should think about installing a more powerful generator.

The model depends on the year of manufacture of the car and engine. For example, the first Nivas with a 1.6 power plant have a device with a remote regulator, which was used in the “classics”. In more modern machines the regulator is already built-in.

If you want to buy an aftermarket unit, it would be wise to get a 2003 model year Chevrolet. The selection must be made according to the catalog numbers and parameters that are present in this table:

If you can modify the fastenings yourself, then the list of available gHepaTopoBs can expand significantly. Craftsmen even install devices from foreign cars.

In any case, you should strive to modernize and improve your car. And this applies not only to electricity. The Niva is a reliable SUV, but it lags far behind its foreign competitors in terms of comfort. You can move on to this issue immediately after improving the technical component of the car.

Dismantling and connecting the generator on Niva 2121: step-by-step instructions

The generator is the source of electrical energy for the vehicle. The article discusses the 21214 generator, its design features, possible problems and troubleshooting methods, and provides step-by-step instructions on how to remove and connect the device.

On Niva 21214 cars there is a generator of type 9412.3701, on VAZ 21213 - type 371.3701, on Niva Chevrolet there is a generator 2123.

All of them are alternating current electric machines with electromagnetic excitation, having a built-in rectifier unit with silicon diodes and an electronic voltage regulator.

The maximum current generated by the generator unit type 9412.3701 is 80 A, voltage - 13.2 - 14.7 V, rotation - right.

Design of unit 21214

The unit covers are attached to the stator using 4 bolts. The covers have bearings installed. They rotate the rotor shaft. In the front bearing, the inner race is clamped with a nut along with a thrust ring and washer. The 2nd bearing is also pressed into the back cover.

The stator has a 3-phase winding, one of the ends of which is connected to a rectifier unit consisting of 6 diodes. Of these, 3 diodes are negative, 3 are positive. According to the polarity, they are pressed into the plates. The entire structure consists of a rectifier unit, which is located on the back cover of the generator unit covered with a protective casing.

The design of the unit also includes contact rings and brushes. On the back side of the back cover there is a brush holder, which is structurally connected to the voltage regulator. The rectifier contains a capacitor that protects the electrical network from power surges.

The “B” terminal of the generator set must be connected to the positive terminal of the battery, and the negative terminal of the battery to the vehicle ground. If the connection is incorrect, this will lead to breakdown of the diodes.

Generator Niva 21214

Basic malfunctions and ways to eliminate them

Checking the health of the unit is done using a multimeter. After the engine is started, the voltage at the battery terminals should be 13.6 V. If the value is higher or lower, this indicates a break or short circuit of the windings, oxidation of the slip rings, a malfunction in the brush assembly, or voltage regulator.

The generator unit may not work well due to weak belt tension or its breakage. In this case, you need to adjust the tension or replace the belt. Faulty voltage regulator, needs to be replaced.

If a breakdown, short circuit, or damage to the rotor windings is detected, it should be replaced. If there is a break or short circuit in the stator windings, it requires replacement. If the diodes are damaged, the rectifier unit is replaced.

Nuances of moving a generator

The disadvantage of domestic Niva SUVs is the location of the generator unit - at the bottom of the engine compartment. It constantly gets contaminated when driving off-road, and coolant constantly drips. The problem is solved by moving the generator upstairs (the author of the video is SARTANETS).

To transfer, you will need a set of keys, a bracket, mounting bolts, and a V-belt. You can make a generator transfer bracket with your own hands according to the drawing below.

Drawing of a homemade bracket

Sequence of actions during transfer:

1. Schematic illustration of unscrewing the fastening material 2. Car with the belt removed 3. Unit in a new location

Thus, moving the generator unit upstairs is not difficult.

Replacement methods

- Replace the brush assembly with the voltage regulator relay (chocolate). As is known, maintaining charging at the same level is carried out by adjusting the voltage supplied to the generator armature winding. For reliable contact, the brush leads are attached to the contacts of the voltage regulator relay by soldering. To simplify car repairs, brushes, brush holder and relay regulator are most often sold assembled. The advantage of the complete replacement method is its simplicity. For example, the low cost of the assembly for many VAZ cars makes separate replacement of brushes very impractical.

- Replace brushes separately. To do this, you will have to remove the old brushes and solder new copper-graphite products in their place (of course, for DIY repairs you will need a soldering iron, flux, solder and basic soldering skills). As in the case of complete replacement, the feasibility of the method largely depends on the cost of new rods. The point is not only the high price of parts for generators of many foreign cars, but also the fact that for some models (especially for old low-volume cars) it is simply impossible to buy a relay-regulator with brushes assembled. It is proposed to eliminate charging problems by purchasing a new generator. In this case, replacing worn-out elements is the only way to save a considerable amount. If you want to change the generator brushes yourself, you may encounter a lack of new parts for sale for your generator model. In this case, you should select suitable copper-graphite brushes from another car. For proper operation, the length of the rods is important (should not be less than that of new or slightly worn original rods) and the length of the copper flexible contact. New brushes should move freely in the brush holder. In fact, the shape of the new rods does not really matter, since they can be processed perfectly with a needle file.

Also interesting: How to remove the dashboard on a Chevrolet Niva