The first time the rack bushing was changed at a service station with a mileage of approximately 80 thousand km. Installed from BMW (number 32111116 910).

This time I did it myself. I removed the rail from the car so that it would be convenient to check everything completely. The boots were intact, everything inside was greased, no rust or dirt. The bushing appeared intact in appearance, but the rack shaft in it had noticeable transverse play, and the inner hole of the bushing was damaged. Therefore, I did not save it; I broke it with a screwdriver and pulled it out piece by piece. If you need to remove it intact, then you need the skill of picking it out with a thin screwdriver and pushing it with a shaft.

I ordered a new bushing through the online store “one hundred parts” for 150 rubles, the delivery time turned out to be at least 19 days and on “Exist” it was about the same. Two weeks passed and then the poet’s soul could not stand it, it suddenly burned and, without waiting, he decided to put it out of repair. set of VAZ 2110. I bought it at the first stall I came across for 200 rubles))). The configuration of the bushing turned out to be similar to that of a BMW, but the inner diameter is 26 mm and the outer diameter is 34 mm, which is 1 mm higher. more than necessary. But due to the longitudinal slots, the bushing compresses well and, after installation in the rack body, tightly compresses the shaft. I inserted the bushing with rubber bands, they fit into the belt. complete. The orientation of the bushing during installation is with the lugs facing you. (I don’t know exactly how to do it correctly, but if the lugs were away from you, then part of the bushing would stick out cantilevered beyond the bore diameter). I used Litol-24 as a lubricant. After the replacement, I had a wheel alignment done at a service station for 700 rubles.

In the whole process, the hardest part was picking out the old bushing. If there is no need to disassemble the rack and clean it from rust, then you don’t have to remove it, then it’s even easier and faster. Before repairing the rack, I recommend removing the airbag cable. If you do not remove it, there is a very high probability of tearing it. It takes 5-10 minutes to remove the cable.

In my case, due to inexperience, everything took about 6 hours. Next time, already knowing what and how, it will actually be done in 3 hours.

The savings on replacing the bushing amounted to 8,000 rubles. Although at the service station it was supposed to grind the bushing on site, apparently from fluoroplastic. Of course, I don’t think that the bushing from a VAZ 2110 lasts longer than from a BMW, but now I have the skill to replace it.

Price tag: 900 ₽ Mileage: 155150 km

FakeHeader

Comments 26

Please help me with advice. In the spring, the service center condemned the steering rods. I bought ASAM 70530 rods. After replacing the rods, they started doing camber and couldn’t set the steering wheel straight. One of the rods was cut (I don’t know which one), it became better, but the steering wheel did not stand perfectly straight. There was quite a bit of play in the steering wheel and I drove until the summer without even feeling that the steering wheel was a little crooked (this was simply not visible due to the play in the steering wheel). Recently I felt a grinding and clanking noise when turning the steering wheel. On the bumps, too, in the area of the river, something rattled. There were knocking noises when the steering wheel was swayed. I bought a bushing for the steering rack from a BMW, rubber rings for it from VAZ wells, an acquaintance gave me his used rack, which did not play or rattle, but its shaft was rusty. With all this, I went to a friend’s service center (they don’t do slats there, but they promised to help with the repairs). They took my rack off. After disassembling it, it was revealed that the needle bearing of the worm shaft had fallen apart and all the needles had spilled into the rack. The worm was all chewed up, but the rack shaft itself remained intact. The upper ball bearing was very loose and the rack bushing turned into a sponge, although it remained intact. In general, we assembled one of two slats, washed everything and coated it well. We set it approximately so that both ends of the rack shaft protruded from the body equally and gave it to the mechanics to install the rack back on the car. After the rail was installed they began to do the camber. The steering wheel did not stand straight at all. It costs about 45% to the left. The mechanic said that the left rod is completely tightened and the right one is screwed in. They say there is nowhere to regulate further. I drove for a day and this time I clearly feel that when the car drives straight, the steering wheel is crooked. All the play in the steering wheel went away after the rack was rebuilt. The car doesn't go anywhere if you let go of the steering wheel. I returned to the service center and told the locksmiths this. They said that you can turn the steering wheel a little on the splines of the steering shaft (if there are double splines, they can be sawed off). But if you turn the steering wheel on the steering shaft, the steering column cable may break (although it can probably break now because the steering wheel turns 1.5 turns in one direction and a quarter turn more in the other direction)? Or they say you can try swapping the rods and suddenly something will change. Or perhaps when assembling the rack we missed one tooth of the rack with a worm

How can I fix this now? I would really appreciate your help

Sorry, I didn’t understand, should there be a bushing without cuts? Today I bought this repair kit, but there is a bushing with gaps one to one like from a BMW, but the inside diameter dangles more on the rack shaft, somehow they stuffed it there without rubber bands, and at the end it burst, so I didn’t understand if there was any play, a day remained, how did you stuff it into the rack with rubber bands, and can you be more specific about which bushing from the 10k?

Welcome! Steering rod silent blocks - They consist mostly of rubber, the rubber hardens over time, which is why it cracks later, which is why there is play in the steering wheel (If the silent blocks are in good condition, then take a look at the steering rack, because of it too there may be some play, read the article: “Adjusting the rack on the tenth family”) and by the way, if the rods in your city don’t cost much money, then we recommend that you immediately buy them entirely with silent blocks, because when everything is manufactured at the factory, it will be better.

Replacing the front lower arm silent block

To replace the lower arm bushing, you must first remove the arm itself. To do this, first unscrew the nuts of the extension, ball joint strut and stabilizer. The lever must be removed from the ball joint using a puller.

Lastly, the nut securing the lever to the body is unscrewed, the bolt is pulled out, after which the lever can be removed. After this, you should remove the stretch. Since it is already disconnected from the lever, all that remains is to unscrew the nut that secures it to the cross member. Lastly, the stabilizer is dismantled. It is attached to the arms via struts on both sides, so you can either unscrew it from the other side and start removing it, or unscrew the nut that attaches to the strut and remove the arm and brace later.

Having unscrewed the stabilizer from the arms, all that remains is to unscrew the nuts securing the body brackets and remove the stabilizer along with the bushings. After the necessary suspension elements have been removed, you can begin to replace the silent blocks according to the scheme described above.

Video on replacing the front lower arm silent block on a VAZ 2110 using a puller:

How to replace silent blocks in steering rods on a VAZ 2110-VAZ 2112?

1. First, remove the steering rod you need, or both at once, to remove them, you will need to unscrew the bolts that attach the rods to the steering rack (How to do this is explained above), then you will have to remove the tie rods from the holes and you can remove the rods (Regarding tips, it is written in the article: “Replacing steering tips on a VAZ”).

2. After which you will have to use a bolt of the appropriate size, the bolt that secures the wheel (One of the fastening bolts), it will need to be inserted into the hole of the silent block and using a hammer, you will have to hit the bolt several times and it, together with the silent block, will come out , but just keep in mind that you need to hit in such a way that the silent block can be pressed out without problems, that is, putting a rod on the asphalt and hitting the bolt with a hammer simply won’t work, you will have to either look for a vice and knock out the silent block as shown in the photo below, or just a couple of bricks Place it side by side, they will replace the same vice and the silent block will easily come out the third or fourth time (Instead of a bolt, you can use a head of a suitable diameter).

3. To press in a new silent block, lubricant will be needed for them, any long bolt of the same size (So that the silent block fits into the hole), one nut for this bolt and a washer, when you have stocked up with all this, lubricate the inside of the steering rod, where the silent block will be installed (see photo 1) and collecting special. a device made of a bolt, nut and washers (see photo 2), install the silent block in its regular place, while holding the bolt itself with the help of a head and a wrench from turning and at this moment tightening the nut, which will press the silent block into its regular place.

Additional video clip: Watch a video that shows the process of replacing silent blocks on steering rods from a VAZ 2108 car, in these rods the silent blocks are used, but they are changed in exactly the same way as on the tenth family of cars, but only in this video everything is done with a hammer is done, we do not advise you to press the new silent block as shown in the video, because it can be damaged very easily.

1.Which steering rod silent blocks are better?

Recently, there have been many samples of low-quality products, especially in the range of auto parts. The silent blocks of the front levers of the VAZ 2110 are being replaced, including the VAZ 2109. The silent blocks of the front levers of the VAZ 2106 are being replaced. The silent blocks of the steering rods of the VAZ 2110 are being replaced. Among the main manufacturers of high-quality auto parts are the following Korean and Polish companies CTR, GUMEX. The main thing is not to fall for cheaper Chinese-made analogues. Replacement of silent blocks on steering rod from VAZ 2108 -. The part must be manufactured with high quality and meet the necessary requirements, both in size (width and diameter) and rubber quality. for a beginner to decide on a quality part, so you should rely on the seller’s recommendations.

I would like to note that steering rod silent blocks for VAZ-2110, VAZ 2111, VAZ 2112, Balakovo (BRT) production fit perfectly into steering rods of Daewoo Lanos, Daewoo Nexia, Daewoo Sens, ZAZ Sens (ZAZ Sens).

Repair of steering rack on VAZ-2110, 2111, 2112

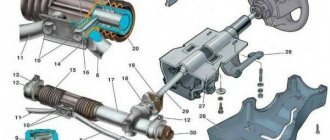

The steering rack is designed to transmit force from the steering wheel to the steered front wheels of the car.

Its design consists of the rack itself, which is a steel strip with notched teeth, a metal body, as well as additional elements in the form of bearings, bushings, seals, anthers, etc.

The rack is driven by the teeth of the steering shaft drive gear, which rotates and moves the rack to the left or right.

Steering rods are attached to the rack, which, in fact, force the wheels to turn in one direction or another.

The steering rack is located in the engine compartment at the rear of the engine, and is attached to the lower part of the partition of the engine compartment and passenger compartment.

With the exception of the latest versions equipped with electric power steering, the “dozens” were not equipped with power steering devices.

How to choose a steering rack

In the case where a defect in a unit does not allow for easy repairs, it is more advisable to completely replace the unit. But here you will have to shell out a considerable amount: a standard VAZ rack will cost about 3,000 rubles, tuning versions cost much more, up to 15,000 rubles.

That’s why the number one question is the correct choice of reiki, so as not to get into trouble.

- It is better to give preference to original parts rather than copies, as they guarantee not only perfect compatibility, but also good quality. Although today there are a lot of companies and small businesses that sell cheap copies under the brand of the originals. Therefore, you should not purchase components from dubious shops and markets, but from serious and trusted sellers.

- Don't pay attention to parts that are too cheap, as they are unlikely to last long.

- When choosing a rack for a ten, it is necessary that the product number ends with “10”, remember that the steering rack is a purely individual part, there is one for each model, so don’t go wrong.

- Of course, it is necessary to conduct a visual inspection of the product before purchasing to identify defects, damage to anthers and other components.

Basic faults

Like any other mechanical structure, the steering rack, due to certain circumstances, may show signs of malfunction. These include:

- crunch (knock) when turning the steering wheel;

- “tight” steering wheel;

- increased play in the steering wheel or steering shaft drive gear;

- vibration of the steering shaft when driving;

- uneven tire wear caused by improper alignment of the front wheels.

The listed symptoms indicate that it is time to repair or replace the steering rack. However, do not rush into replacement. The rail itself is made of durable steel, and it is not so easy to damage it. Most often, auxiliary structural elements become unusable:

- support sleeve;

- drive gear bearings (ball and needle);

- seals;

- anthers, etc.

There can be any number of reasons for the failure of these parts, from spent resources to mechanical damage due to off-road driving. If you are sure that the rack itself will not have to be changed, you can get by with minor repairs to the steering structure, which consists of replacing the listed “consumables”.

How to recognize steering rack faults

Any mechanism does not last forever, including this part. Most often, a malfunction of the steering rack is indicated by a knock that can be heard when turning. But there are other signs. To accurately determine the cause of the knocking noise, which lies in the steering rack, you must:

- take the steering shaft with your hand where it connects to the rack and move it up and down (if there is a knock, then the steering rack needle bearing in the steering rack needs to be replaced or simply lubricated);

- hold the joint of the steering rods with your hand and check the play of the bushing, as well as the steering gear.

Often the cause of knocking is poor adjustment of the fasteners and then nothing, everything works without dismantling. But if knocking is still observed in the rack itself, then you need to do the following:

- purchase a new steering rack;

- restore it to a service station;

- carry out independent repairs.

Attention: All three options have their advantages, but the most profitable from an economic point of view is, of course, the third method. It will allow you not to spend money on expensive parts and auto mechanic services. But this method will require certain initial knowledge about the mechanisms of the car, dexterity and patience.

DIY steering rack repair on a VAZ 2110 (video)

Using the steering mechanism, the driver determines the direction of movement of the car. The steering rack plays an important role in the reliable functionality of the system. It is she who transmits the force that the driver applies to the steering wheel through the tips, rods, and to the turning levers connected to the wheels via a pin.

Photo of the steering rack for VAZ 2110

To be sure that the car is safe to drive, you should make sure that the steering rack is in good condition. If problems are found, they should be corrected immediately. It is quite possible to replace the steering rack on a VAZ 2110 with your own hands. In most cases, it is enough to tighten it.

Replacing silent blocks VAZ 2110

Car silent blocks require monitoring and timely replacement. The service life of a silent block is up to 100,000 km , but Russian conditions dictate their own rules; silent blocks have to be replaced every 50,000 km .

Broken silent blocks of the front suspension arms on VAZ-2110 vehicles are indicated by a characteristic knocking or grinding sound that is heard when the car is moving. The car not only begins to rattle, but also loses stability on the road and becomes more difficult to control. It happens that when a car undergoes a wheel alignment, it is discovered that the silent blocks are faulty.

It is quite possible to change the silent blocks of a VAZ 2110 with your own hands. Of course, you will have to get dirty and spend several hours of your time to repair the car. The same procedure for replacing a set of silent blocks at a service station will cost 1100-1400 rubles . You can decide whether to take on the work yourself or entrust it to others after viewing this photo report.

It is worth noting that the photo instructions are based on the experience of car enthusiasts and contain tips for drivers with a minimum set of necessary tools. In the repair instructions you can find another solution to this problem.

Steering elements

- Steering rod ends (internal and external);

- The bracket that holds the steering mechanism;

- Support;

- Anther;

- Carter;

- Tie bolt;

- Flange for flexible coupling;

- Adjustment rod;

- Turn lever;

- Ball joint tip;

- Bolt for holding the inner rod ends.

The drive gear is mounted on the crankcase bearings. It engages with the rail. The metal-ceramic stop is sealed in the crankcase using a rubber ring and presses the rack with a special spring to the gear.

Steering rack diagram

Due to the work of the locking ring, the unwinding nut is fixed. There are marks on the boot and crankcase that make it easy and quick to assemble the entire assembly.

Polyurethane silent blocks, what is the advantage

The service life of the hinge is influenced by a number of other circumstances. For example, the rubber used in the silent block design is very badly affected by petroleum products and chemicals used to treat the road surface in winter. Temperature changes also have an extremely negative effect on the part - in the summer the rubber softens, and in the winter it begins to freeze and becomes too hard. Under conditions of severe mechanical loads, rubber begins to wear out, “age”, lose elasticity, delaminate, and fail.

Tools and materials

To replace the steering rack on a VAZ 2110, we recommend watching training videos. This will allow you to understand the structure of the system, perform the work competently and without any problems.

Also, to repair the steering rack with your own hands on a VAZ 2110 car, you will need a certain set of tools and materials. Their list is as follows:

- Aerosol Movil;

- 3 plastic clamps measuring 200 by 4 millimeters;

- Cotton rags;

- A can of WD40;

- Feol grease - for processing bearings.

From spare parts, take:

- Silent blocks;

- Cover for rack;

- Tips;

- Tubes;

- Repair kit (special for repairing steering racks).

And the tools you need are:

- Ratchet socket wrenches;

- Cardan with extension;

- Hammer;

- A puller used to remove tips;

- Key for 22;

- The chisel is about 7 millimeters wide, but no more;

- Octagon key.

Tools, accessories, consumables, pro tips

The work itself of replacing silent blocks is not difficult, but special tools may be needed to press out the hinges.

In total for work you will need:

- actually, new silent blocks

- spanners and open-end wrenches of the required size (heads and ratchet)

- puller for silent block

- lubricant (soap solution)

- jack

- vice

- hammer, small chisel.

The hinge fits very tightly into place, and to dismantle it, most likely, you will need a special puller. A necessary condition for high-quality replacement of hinges is their correct selection. Before you go to the store, you need to find out which silent blocks are most often installed on the BA2110, their serial number, size parameters, etc. Let us repeat, the hinge fits very tightly, and a discrepancy in size of just a few millimeters will result in the new silent block simply not being pressed in.

For this work, special pullers are used, with the help of which it is easy to remove the old part and press in the new one. Sometimes it happens that to replace the silent block you have to remove a suspension element, for example, a lever. In this case, the puller can be successfully replaced with a conventional bench vice. True, in this case it will be quite difficult to remove the silent block. Then you can simply burn it out with a blowtorch or over an open fire. Sometimes craftsmen cope with it using a sledgehammer and a metal punch.

Before installing a new part in place, it must be lubricated with soap or a soap solution. This will make installation very easy. You cannot use lubricants made from petroleum products - grease, litom, oil, etc., as they have a negative effect on the rubber. This does not apply to polyurethane hinges, which are practically unaffected by petroleum products. To make installation even easier, a small chamfer can be removed from the rubber surface of the part from the end. The main thing is not to overdo it and not to cut off too much.

Carrying out replacement work

Again, watch the video on how to repair the steering rack on a VAZ 2110 with your own hands. This will make it easier to go through each stage.

Before pulling the steering rack off your VAZ 2110, treat all fastening joints with WD40 . Wait an hour and a half and repeat the procedure again. This must be done a day before the repair itself. This will make it easier for you to unscrew all connections.

Proceed in the following sequence:

- Before repairing the steering rack, your VAZ 2110 must be firmly fixed so that the car does not move.

- Place supports under the rear wheels.

- Put the car on the handbrake.

- Lock the steering wheel.

- Disconnect power from the battery.

- Place the car on a jack.

- Remove the front wheels.

- Buy a new boot for the rack in advance, as it will require replacement. Even if its condition is satisfactory, it is better to change it immediately.

- Unscrew the nuts from the ends.

- Remove your fingers from the strut levers. To do this you will need to arm yourself with a puller. It is mounted on the lever, the screw is tightened until it stops and the lever is hit with force with a hammer. In this case, be sure to hold the puller screw with a wrench.

- Unscrew the nuts from the clamps.

- Unscrew the bolt located in the passenger compartment on the steering floor near the floor.

- Pull the bar towards you using progressive and oscillatory movements.

- Please note that disconnecting the gear shank from the shaft is problematic. When the rail is just detached through the hole, tilt the assembly to the right side and remove the entire structure. Make sure the splines on the element are intact.

- Through the right hole on the body, remove the entire assembly.

Replacing the suspension arm

Front suspension design for VAZ 2110

Replacing the suspension arm on a VAZ 2110 is necessary when cracks, chips, wear and tear of rubber are detected. To do this, you need to place the car on a flat surface (it should have its wheels on the ground), and place shoes under the rear wheels. Loosen the bolts of the front wheels, and only now place the front of the car on supports. Remove the wheels and then the crankcase protection of your VAZ 2110.

When unscrewing the nuts holding the suspension arm, and then the ball joint, you should hold the bolts from turning on the reverse side. As you remove the washers from the guy wire, count them and mark which one comes next. When installing a new lever, they must be placed in the same order. Typically, a complete replacement of the lever is carried out if the hinges are damaged. Before tightening all connections, it is better to lower the VAZ 2110 to the ground.

https://youtube.com/watch?v=5oZihfXdmRE

Hi all! It's time for me to replace the front control arm bushings. When I was about to do this, I was sweating just at the thought. They are HEALTHY! How to press them in. It was decided this way: if there is a strong problem, then I will take the beam to a service station and let them press it there. Got it. To remove the beam, I placed the car in a pit. I unscrewed the nuts from the levers (using a two-meter pipe and “some kind of mother”) and all the fastenings to the body. Stripped off.

Set of tools: - sharp knife; - hammer; - Silicone Grease; — soap (without rope); - a 12 pin, about 20 cm long, with nuts; - two wrenches; — corner No. 45 with a hole along the hairpin; — front washer from the same silent; - two-inch coupling (or a piece of suitable pipe).

Pressing out old rubber bands We secure the beam in a good vice.

After thoroughly spraying with silicone, we cut off the extra “ears” from the silent tape. Without silicone it is very difficult to cut rubber, there is a lot of friction.

Having cut off the “ears,” we protrude the rubber from the metal and spray more silicone there. After that, with a couple of blows of the hammer, everything pops out with a whistle.

Installing a new silent Installation requires: a stud, nuts, an angle and a washer. We smear everything that rubs with soaked soap.

Tighten the nuts on the stud. The silent begins to sink into the beam.

Let's stop here for a moment. When twisting, the silent every now and then tries to slide away from the axis of the hole to the side. The rubber band starts to go in on one side, but the other doesn’t go in at all. It's warped, in short. The corner helped a lot here (see photo). When a distortion is detected (in the initial phase), press the corner in the direction opposite to the distortion. Editing rules

So the whole skirt went into the beam.

The corner is already in the way for further pressing. We disassemble the entire coupler and insert the coupling like this:

Let's move on. Result:

There you go! One silencer takes 15-20 minutes with a smoke break.

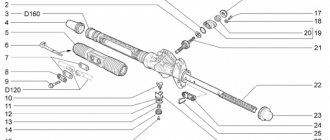

How to make repairs

- Fix the rail in a vice in a vertical position. Clean the surfaces with a brush or cotton cloth previously soaked in white alcohol.

- Take out the steering rods. To do this, unscrew the bolts on the bracket that hold the rods, bend the force at the locking plate using a 22mm wrench.

- Remove the plate rods - locking and connecting.

- Pull out the tie rods.

- On the right side of the steering assembly housing, remove the retaining ring and support.

- Cut off the clamps that hold the protective cover. These are disposable items made of plastic. Replacing them is very easy and cheap.

- Remove the cover.

- On the left, remove the support and protective cap.

- Armed with a 17mm wrench, unscrew the nuts that are located on the rack stop. Remove it, take out the spring and ring.

- Knock the rack stop out of the socket. Hit the crankcase against a wooden base. To seal the groove, install a rubber ring on the stop.

- Remove the seal, remove the gear boot by prying it off with a screwdriver.

- Remove the lock washer.

- Using a 24mm wrench, unscrew the nut that holds the gear bearing.

- Remove the nut from the shaft.

- Using a 14mm wrench, unscrew the gear from the crankcase, simultaneously with the bearing itself.

- Remove the rack and remove the bushing. The element is pryed off with a screwdriver so that the protrusions fit into the holes in the crankcase. This will allow you to get the part without any problems.

- Install a new bushing. It is recommended to attach new damper rings made of rubber to it. This must be done so that the thin part of the ring is opposite the cuts in the bushing, and the protrusions on the bushing are freely placed in the crankcase hole.

- The rings need to be cut along the edges of the sleeve and the excess elements removed.

- Remove the retaining ring from the gear shaft.

- Use a two-jaw puller to compress the wide bearing.

- Press out the needle bearing with the same device, or make two holes with a diameter of 2 mm in the end of the crankcase, and then the bearing will come out onto the ring.

- Rinse the crankcase thoroughly, press in the needle bearing using a piece of pipe. Treat the holes made with cold welding.

- Using Fiol 1 lubricant, treat the bearings, rack and gear teeth. Place UNIOL 1 grease into the cavity under the nut securing the drive gear bearing.

- Reassemble the structure in reverse order.

- Place the new cover in place.

- Be sure to try to maintain a gap of 0.12 mm between the rack stop nut and the stop itself.

- Tilt the nut after adjusting the gap, which will prevent it from unscrewing.

If such a DIY repair of the steering rack on a VAZ 2110 does not give the desired result, simply replace the element. You have already become familiar with the process of dismantling the rail. Having taken out the old unit, put a new one in its place, following a strict sequence of steps.

To illustrate the repair of the steering rack on a VAZ 2110, we recommend watching the video. With their help, the process will not seem as complicated as described above. The work will take some time, but you won't have to hang around in the garage all day.

Replacing the silent blocks of the front upper arm

The procedure is as follows:

The front wheels are lifted with a jack and fixed. The front wheel is removed. The upper arm is removed. Before dismantling it, you need to check whether the silent blocks inside the lever do not slide; they must sit there tightly.

In order for the upper arm to be removed freely, the upper support must be removed. This is quite difficult to do, since it is very difficult to unscrew the nuts. To do this, turn the wheel out and lightly hit the bipod with a hammer. After this, the support should pop out without problems. Unscrew the upper bolt of the lever. It is long, so the operation will take some time. After the bolt is removed, you can remove the lever and begin replacing the silent block.