Knocks in the car's control system are the most dangerous indicators of problems, because these components are responsible for the safety of the trip. If at one terrible moment the car does not react to turning the steering wheel, the consequences can be disastrous. Therefore, you must always pay attention to the normal operation of the steering rack and carry out all necessary repair work in a timely manner. A knocking sound in the steering rack is the most common symptom of problems with the steering system. We often hear excuses from careless drivers that the rack needs to be repaired a long time ago, but somehow they never get around to it. If the steering rack on your car is knocking, it is better to carry out repairs today and now.

You cannot determine from the sound which specific rack assembly has failed. If the tips become loose, the steering rods may become disconnected from the wheel steering systems. If the reason is in the inside of the rack, the steering wheel may begin to turn without any effect on steering. The mechanism body may also knock if its fastenings are broken. Any knocking noises from the steering rack should be immediately diagnosed and corrected through repairs. Let's look at the main stages of diagnosing and correcting problems with the rack.

A few words about the steering rack

Modern rack and pinion mechanisms use two main components: the rack and the pinion. Thanks to such a simple design, the part has a long service life and is capable of properly performing its functions for more than 100 thousand kilometers. However, failure is possible, and then you will have to carry out repairs.

The operating principle of this device is also quite simple. When you turn the steering wheel, the rack begins to move in a given direction, which sets the rods in motion and also ensures that the wheels turn. It is recommended to carry out diagnostics immediately upon detecting a knock, since this component is responsible for driving the vehicle.

Device

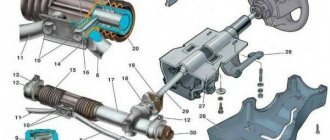

To check the mechanism for malfunction, you need to know how it works; the unit consists of:

- Aluminum housing.

- Gears rotated by the steering wheel, transmitting force to the rack (we do not confuse the worm in the worm mechanism).

- A rack with a toothed section that transmits force from the gear to the wheel rods.

- Amplitude limiters on both sides, consisting of a bushing and a power cuff.

- Seals, support bushings and other small items included in the repair kit.

Steering rack design

Steering racks of different types have different designs. The following types of slats are available:

- mechanical;

- hydraulic;

- electric.

It is important to consider the type of connection between the strut and the wheelbase (front-wheel drive, rear-wheel drive).

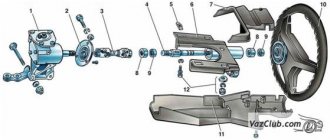

The mechanical structure consists of:

- gear rack;

- gears;

- shaft;

- steering gear;

- tips.

During the rotation of the steering wheel, a force is transmitted to the gear from the shaft, driving the rack. The rack converts rotational motion into translational motion and transmits it to the wheels.

In a mechanical design, the teeth change their pitch from the center to the edges, as a result of which it becomes more difficult to control the steering wheel at high speed and the maneuverability of the car is reduced. Modern cars, which are safe even at high speeds, are equipped with hydraulic and electrical mechanisms.

The hydraulic rack is attached to the body or to the engine - if located in the upper part. If the rail is located at the bottom, it can be mounted on a subframe, beam or body. What distinguishes it from a mechanical design is the presence of a hydraulic booster, which makes it easier to turn the steering wheel when maneuvering at high speed.

Read also: Why does the stork bring children?

Rack and pinion steering

Rack and pinion steering is installed in most types of passenger cars.

It is simpler in design and contains few moving parts, which means it is more reliable.

The main elements of a rack and pinion steering mechanism are a pinion and a rack.

Under ideal conditions, the entire mechanism can last up to 100 thousand kilometers of the car.

Also, the presence of a rack and pinion steering mechanism significantly reduces the cost of the car, which is also important.

But nothing is ideal, and problems occur with steering racks that require both a professional and non-professional approach.

How to extend the life of a steering rack

There are a few simple rules that will help extend the life of the steering rack of any car.

Firstly, you need to give up reckless driving through pits, the habit of sharply accelerating and braking at the last moment, since such maneuvers have a detrimental effect on the steering rack. The key to a healthy rack is a smooth driving style.

Secondly, you need to learn how to park correctly. When using a curb as a motion limiter, each blow to the wheel is transmitted to the steering, which gradually becomes unusable.

Thirdly, you should periodically carry out maintenance of the entire mechanism, monitor the reliability of the fastenings and the serviceability of the protective covers. Timely replacement of damaged parts and boots will help extend the service life of the steering rack.

Fourthly, when using a hydraulic steering rack, you need to promptly change the hydraulic fluid in the power steering system, and also not leave the wheels in the inverted position during the winter months, so as not to accelerate the wear of the rack.

Prevention measures

You can avoid knocking in the steering rack by performing several measures, among which it is worth noting:

- Reducing sudden braking and starting to zero (unless circumstances require it). Aggressive driving style greatly affects the wear of rack components.

- Do not use curbs as barriers when parking. As previously mentioned, the steering rack is extremely susceptible to shock loads.

- Drive over speed bumps, potholes, potholes and other irregularities at minimum speed. When driving at high speed over such obstacles, the steering rack will experience enormous loads.

- Carry out regular inspection of oil seals, boots and other structural components. By detecting their destruction in time, you will prevent accelerated wear of parts.

- As soon as any signs of malfunction appear, perform diagnostics.

- Do not hold the wheels at the maximum turning angle for more than 5 seconds, as this will negatively affect the gearbox.

All this will help eliminate the appearance of extraneous noise in the rack, and will also extend its service life.

Causes of knocking

Despite its reliability, the rack design has several disadvantages. These include sensitivity to shock loads, difficulty in installation and a tendency to constant vibration. Under the influence of external loads, any component, of course, becomes unusable, which is why a characteristic knock appears.

The main reasons for this phenomenon include:

- The plastic bushing installed on the right or left side of the rack is severely worn. There is a strong backlash in the design, due to which drivers hear extraneous noise. This is especially noticeable when driving on a bad road.

- Poor tightening of connections in the steering mechanism design. It can be fixed quite simply (you need to tighten all the fasteners well).

- The appearance of corrosion, which destroys the metal and contributes to the formation of backlash.

- Damage to anthers. Dust, sand and dirt get into the structure, increasing wear of the part.

- Deformation of the crankcase, resulting in an incorrect angle between the screw and the teeth.

- Development of the resource of the central tooth.

A common problem is leakage in cars with power steering (power steering). The power steering design uses a special pump, which creates additional force when turning the steering wheel, making the process easier for the driver. When the seals fail, the pressure in the system drops, the working fluid leaks out, and accordingly, the steering wheel rotates with difficulty. As a result, this will lead to accelerated wear and knocking.

Prolonged downtime can cause the shaft to rust and difficulty turning the steering wheel, accompanied by knocking. If a hum also appears along with the knocking, this indicates a breakdown of the power steering pump. It does not build up the required pressure. The way out of the situation is to replace this component.

Most slats are made of soft metal that will wrinkle over time, so this part should be inspected regularly. Now you know why the steering rack is knocking, which means you can fix the problem.

When is it time to change tie rods and ends? The main signs of breakdowns

Sometimes we drive a faulty car and put up with it, without even knowing about the presence of a breakdown. This is unsafe, since the manufacturer has provided complete protection against unexpected reactions of the car on the road only if everything works efficiently and properly. Therefore, you should carefully monitor the main components of the vehicle and do not forget that sometimes the car needs repairs. Otherwise, you will greatly regret that you did not make a high-quality diagnosis and did not replace the part on time. Many accidents in Russia occur precisely because vehicles have not been serviced for years. Every year it is worth undergoing a complete diagnostic of the chassis and steering at least once. It would also be useful to diagnose the power unit for sensor errors and various software glitches in the firmware.

But the most important components for safety remain the steering and braking system parts. Today we will touch on the first system - the steering of the car. The problem is that the gradual failure of most parts of this equipment is not always noticeable to the driver. Nothing knocks or rattles, or makes any other extraneous sounds. But the functionality of the elements gradually changes, and problems begin that are extremely difficult to find and eradicate. On almost all cars older than 5 years, after driving on Russian roads, the steering requires gradual, high-quality repairs. In particular, rods and ends fail and begin to change the characteristics of the steering. Of course, this leads to dangerous situations and other troubles. Today we will figure out when to change these parts?

Why is the steering rack knocking?

The steering mechanism begins to “rattle” when backlashes (gaps) form between its parts. The noise occurs as a result of the collision of parts of the mechanism in this free space.

Acceptable backlash values:

- trucks - up to 25°;

- buses - up to 20°;

- minibuses and cars - up to 10°.

It is impossible to determine on your own the degree of cracks formed. Only qualified car service specialists can carry out a quality check.

Important! The need to replace the rack can only be confirmed by high-quality diagnostics. Otherwise, the problem will not be solved, and replacing an expensive part will be pointless.

Reasons for gaps in the steering system:

- Exceeding the speed limit when driving on roads full of potholes and bumps.

- Wear leading during operation to an expansion of the permissible level of play.

- The assembly is filled with particles of dust and dirt as a result of wear of the belts of the protective covers and holes formed in the anthers.

Before completely changing the rack, you need to make sure that the problem lies precisely in it, and not in the traction or worn liners, for example.

Steering rack diagnostics - independent and professional opportunities

Diagnosing any problems with the steering mechanism must be done with extreme caution. Many car owners like to carry out manual diagnostics by turning the wheel and pulling the rods, and then shaking the rack itself. Not only will such diagnostics lead to nothing good, it can damage your car for a long time. In particular, problems with the rack can develop into problems with tie rods. If you hear strange knocking noises while driving or something rattles under the hood, follow these procedures:

- stop and do not continue driving until the problem has been identified and its impact on safety has been assessed;

- Try turning the steering wheel to the sides with the car turned off, checking its free play;

- if the play is increased, there is increased wear on the inside of the steering rack and the need for replacement;

- if at the extreme moments of play you hear tapping, the problem may be in the steering tips;

- then you can open the hood and visually assess the condition of the rack and the integrity of the rubber boots;

- it is better to carry out the remaining stages of the check at a service station, which can be reached carefully and with knocks on the rack;

- professional expertise will tell you everything about problems with the steering mechanism of your car.

It is enough to find a good technician who will carry out a diagnosis in a matter of minutes and give his verdict. In modern cars, steering rack repairs are rarely performed. Often the service will recommend a replacement. Despite the financial troubles from this process, it is better to obey and replace the steering rack. This way you can return the steering mechanism to normal operation and be guaranteed to get high quality work from your rack for the coming years.

Repair procedure

Having purchased the necessary repair kit, you can begin dismantling. Here it is necessary to follow a certain algorithm consisting of the following steps:

- Completely dismantle the steering rack.

- Remove the tie rods.

- Clean the structure from dirt accumulated during operation.

- Replace worn parts.

- Inspect the shaft and install a new one if necessary.

Why remove the tie rods? This will greatly simplify the process of installing new boots. By pulling them onto the corresponding protrusions on the rod, you can achieve maximum tightness. Before assembling the rack, be sure to lubricate the internal oil seal.

If your car has a hydraulic booster, then you will first need to disconnect the high pressure pipes and then drain the working fluid into a prepared container. It is not recommended to remove the gearbox with hydraulic power steering yourself. The procedure involves dismantling the subframe, and it is impossible to do it alone.

The described technique will eliminate knocking in the steering rack. To complete the procedure, you will need a set of keys and screwdrivers, a garage with a pit. You can also always contact a car service center, where all the above operations will be performed by auto mechanics. But be careful, as they may jack up the cost of repairs or supply low-quality consumables.

Directly, the repair itself

Before you begin the process of “healing” the steering rack, you need to acquire the necessary tools, or better yet, a repair kit. What should be in the first aid kit? — new elements for the rack gear mechanism (reducer, in other words), bushings, oil seals, all kinds of gaskets, as well as lubricant (Litol, Salidol). To carry out repairs, you need to have a size 17 octagonal wrench on hand; working with the bearing will require a puller, we will remove the retaining ring with pliers, and finally, a set of wrenches.

The “healing” process goes through a number of stages:

- First, the nuts are removed from the steering fingers. Then the fingers are pressed out of the swing arms (suspension strut) through the holes;

- you need to look at the spline connection, specifically the locking bolt. You can find it in the pedal area. After identifying it, we unscrew it;

- then we take a nozzle size 13 and unscrew the nuts that are intended to fix the steering mechanism;

- remove the fastening brackets of the mechanism;

- dismantle the steering shaft from the drive gear. After this, it is worth stopping to jack up the car on the right side;

- with the support of a chisel and a hammer, bend the sides of the stopper plate;

- take a size 22 socket and unscrew the bolts that are on the steering rods.

After this, we try to dismantle the connecting and locking plates, and disconnect the steering rods.

- remove the boot and rubber support;

- dismantle the rail;

- after that, the crankcase needs to be flushed and a new bearing installed.

Finally, lubricate the gears with Litol, and begin assembling the unit. The steps are carried out in reverse order. Important note: you will need to adjust the gap between the stop and the nut to 0.12 millimeters immediately after completing assembly. You can change the steering rack and pinion mechanism using a general algorithm, because the rack design is similar on almost all cars. Although, it will be necessary to clarify the type of steering mechanism and the presence of amplifiers.

Eliminating knocking noise in the steering rack

If there is a knock in the steering rack, this is not a reason to run to a service center and spend tens of thousands of rubles on purchasing a new unit. Sometimes it is enough to simply unscrew the bolt securing the locknut and clean the spring.

Over the years of operation, a huge amount of dirt, rust and other deposits accumulate on the spring. As a result, the part becomes blocked and the bushing stops moving. To restore functionality you need to do the following:

- Unscrew the locknut and bolt (in the figure they are indicated by numbers 8 and 6).

- Remove the spring and bushing.

- Perform cleaning. To do this you will need chemicals and a brush. In extreme cases, you can use regular diesel fuel. But you need to be careful, it can damage the parts. Before cleaning, the spring is coated with lubricant.

- Particular attention should be paid to the bushing. There should be no damage to it; if there is any, the part must be replaced.

- Before installation, the bushing seat must be cleaned. Then the part is lubricated and installed in place.

- Reassembly is in progress.

This is interesting: What are the best means to blacken rubber yourself?

At the end of the work you will need to adjust the tightening. To do this, you will need a partner to drive. The tension bolt must be adjusted so that the steering rack does not knock. Once the optimal position is found, it is fixed with a lock nut.

Also, the reason why the steering rack is knocking may be the output bushing. This is part number 11 in the picture. Diagnosing its failure is extremely simple. Play in the output shaft is strong evidence of a malfunction. Replacing it won't be difficult. Just unscrew the old one and install the new one.

A complete replacement of the entire assembly is only necessary when dirt gets inside the rack structure, and this leads to destruction of the shaft and seal. Dismantling begins with releasing the steering tips. You also need to remove the bolts and universal joints. After this the installation is carried out.

Troubleshooting a Toyota

Despite the Japanese quality, the Toyota Corolla steering rack often makes a knocking noise. And car enthusiasts have to solve this problem. These cars are very popular in Russia. Every now and then, car enthusiasts have to decide how to remove steering rack knock. The Toyota Corolla interests them most. Previously, it was very difficult to eliminate this problem, but thanks to the experts, a solution was finally found.

You need to purchase 6 or 8 grease fittings, high-quality lubricant and be patient in your work. It is best to carry out work in a garage in a pit.

Next, in order to eliminate the knocking of the steering rack, the Toyota Corolla is placed on a flat surface. Armed with a drill of the required diameter and a drill, you need to drill a hole in the rack so that it is convenient not only to turn the grease nipple, but also to fill the rack with lubricant using a syringe.

The thread for the grease nipple is cut using a tap. After this, you must use a special sealant that is only suitable for threaded connections. Once it is applied, you need to screw the grease nipple into the hole and pack the grease into the rail.

To completely remove knocks, you will need one 400 ml bottle. It is worth remembering that after injection, it is necessary to remove excess lubricant and close the oil can with a plastic cap.

You should only use lubricant that is suitable for the racks of Toyota vehicles. In this simple way, you can eliminate a knock in the steering rack (Toyota Tundra, among others).

In other cases, on these vehicles the steering mechanism or the pipe responsible for adjusting the height of the steering wheel knocks. The mechanism must be diagnosed for existing play in the crosspiece.

Unusual causes of steering wheel knocking when driving

It's not just the suspension and steering that can cause knocking noise. Under the influence of shocks and sudden braking of the car, poorly secured components and mechanisms are displaced. Two metal surfaces hit each other, inevitably accompanied by ringing sounds.

- Single dull knock when starting to move.

You should check the engine or gearbox mounts, as well as the clutch driveshaft. It is possible that the engine tilted when starting off, hitting the side member. - Clunking sound when driving on uneven roads and when turning.

Check if the steering wheel knocks when braking. A knocking sound will indicate wear on the brake caliper guides. - Irregular impacts, felt mainly at low speeds when turning.

If the car is front-wheel drive, the differential is faulty.

Sometimes knocking when turning occurs due to unusual situations that are difficult to diagnose. For example, there was a case where a small stone hit the subframe and got stuck while the car was moving. When the car turned, the steering gear parts naturally shifted, running over this stone. When the wheels were aligned, the steering mechanism parts took their original position and at the same time jumped off the stone with a characteristic impact sound. The problem was eventually resolved by removing the stone from the subframe.

In other cases, when turning or driving in a straight line, the subframe itself knocks in the suspension. This is due to the loosening of the bolt, which must be tightened to eliminate the knocking.

We recommend

“Why is an injector leaking on an engine: causes and repairs” Read more

Summarizing all of the above, we will give some tips for beginners.

To prevent the appearance of steering wheel knocks when driving and other extraneous noises, as well as the reasons for their occurrence, regularly service your car. Inspect it from all sides, including from below. Follow the speed limit and drive carefully. Only in these cases will extraneous noise in the car not disturb you over a long period of operation.

However, one day the moment comes when all kinds of hinges, supports and tips need to be changed. Unfortunately, each unit and mechanism has its own limited service life.

The steering rack is knocking. Why and what to do?

After driving on our roads, the car’s suspension begins to crumble, some faster, some slower. But this is a fact! There are a lot of knocking noises that can be caused by dozens of reasons. But perhaps the most unpleasant thing is when the steering rack knocks. It appears on small and large bumps, as well as when driving on crushed stone (small pebbles). When driving on a flat road, there are no days. That is, to summarize, they can appear almost always. But it is important to note that when turning, they can be heard, especially loudly. Today we will figure out why this happens and what to do...

Many people get scared at the mere word steering rack, although the structure of the latter is not as complex as it actually seems. To understand, we need to remember the structure.

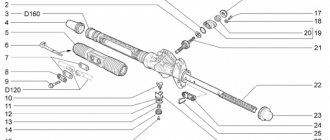

Steering rack structure

I will try to tell you in simple and accessible language what is being said for general understanding, so I will exaggerate a little.

- The steering rack housing, so to speak, is a long pipe.

- Main shaft with cut teeth

- Shaft with worm gear

- Two tie rods with ends on the sides

- Guide bushings

- Oil seals

- Anthers

I deliberately took a simplified image so that you can understand what is where.

The principle of operation is simple - you turn the steering wheel, through the worm shaft, the force is transferred to the main shaft, it begins to move to the right or left, depending on where you turn the steering wheel. To ensure that the main shaft does not “play” inside, it is pressed with special guides, which are made of durable polymer.

Why is there a knock?

There are several reasons, I would say only three, now in more detail:

- Wear of polymer guides. This is the most common reason. In simple words, the bushings on which the main shaft runs wear out. It begins to vibrate and a knocking sound appears. By the way, the oil seals that hold the pressure inside the rack can also wear out along with the shaft. Therefore, the steering wheel may leak.

- Wear of ball ends. Sometimes it is the tips that knock, and not the rack itself; first you need to check them. Therefore, if there are no leaks, then the knocking noise may be caused by the ball ends.

- Wear of shaft teeth, both main and worm. This happens extremely rarely, because wear occurs only from dirt, sand, and dust getting inside. And if this happens, this indicates that the seals, bushings, etc. — they simply have a huge output. However, in my experience it happened when the entire repair kit was replaced, but the knocking remained, especially when turning the steering wheel. After disassembly, it turned out that both shafts were worn out. But it is worth noting that, most likely, there will be no knocking on uneven surfaces, or very little.

Is it possible to pull it up?

I already have a detailed article about this, but when knocking, you can tighten it up. The thing is that the middle bushing has a special nut. Which allows you to tighten the shaft a little. We take a special key and tighten it. Thus, the worn bushing will be pressed more tightly against the shaft and the “backlash” will be removed. However, there is an edge here; you cannot tighten this nut too much, otherwise the steering wheel will be very difficult to rotate, or it may even become blocked.

However, even with maximum “tightening”, after what time the rack can still knock. There is nothing that can be done here; repairs are needed.

Why the rack fails, the main reasons

Of course, there are also two main points here. However, one is banal, but the second is quite serious:

- This is a mechanical effect. On our roads it’s easy to fall into a hole; of course, the struts will take most of the impact. But some of the energy will pass to the “steering”. It is polymer bushings that absorb such impacts; it is from impacts that they can be slightly deformed. Here's a knock for you.

- Wear of anthers. This is the most common cause of failure. What the anthers do is they keep the space inside sealed. Preventing dirt, dust, and moisture from getting inside. If it breaks, it all easily penetrates the main shaft. Corrosion, rust begins, the surface becomes rough. It works like sandpaper, erasing oil seals and bushings. I will say this, after a short run of 500 - 700 kilometers, after the boot breaks, the rack may start to knock.

What to do?

You can change the unit completely, that is, buy a new one. However, the cost is often just off the charts, buying an analogue is not always profitable, it may turn out to be of Chinese quality - and this is just a waste of money. After a year, the rack will leak or knock again.

You can try to repair it. This is a real solution, if you turn to a normal technician, then after repair it can last for many thousands of kilometers, you can read this useful material. In any case, if the rack rattles, it needs to either be changed or repaired. Indeed, in very advanced cases it may simply jam, which is not safe.

Now let's watch a useful video.

Steering wheel knocking when driving: common causes

Novice drivers pay more attention to the road situation, but they listen secondarily to the behavior of the car while driving. The habit of simultaneously feeling both the road and the car comes with experience. This is a very important skill that allows you to identify a likely fault at a very early stage, which not only significantly reduces the cost of repairs, but also ensures better safety.

Any modern car consists of many components and mechanisms, each of which can become a source of problems. Some of these mechanisms are responsible for the safety of movement, so it is necessary to monitor the serviceability of these components first of all. This includes the steering mechanism.

Most car faults manifest themselves as various extraneous noises, knocks and other sounds. Using these sounds, experienced car owners can detect the source of the problem.

Malfunctions of the steering mechanism are also accompanied by extraneous sounds. Basically, these are knocking noises when turning the steering wheel to the left while moving either to the right or in both directions. However, it is worth noting that such a symptom may also indicate a problem with another unit located next to the steering mechanism.

Steering noise can occur in a car of absolutely any make and model - from old Soviet VAZs to the latest modifications of foreign cars.

First of all, the nature of the knock should be identified. A loud, distinct sound may indicate two metal elements hitting each other. A more muffled knock will most likely be due to metal hitting plastic. In addition, you need to pay attention to where the sound is coming from. This will help narrow down the troubleshooting area.

1. Knock on the steering wheel on uneven surfaces when driving straight ahead

Sometimes a knocking noise occurs when driving on uneven roads. The cause may be worn-out shaft bearings located inside the steering column. As a result, radial play of the shaft occurs, accompanied by this knocking sound. If the O-ring or retaining ring is worn, this can also lead to end play. This can be partly solved by inexpensive repair of the column due to the provided supply of necessary spare parts.

Along with replacing faulty elements, specialists also replace related elements and parts that may be serviceable, but soon will probably again require repair of the entire assembly due to their failure while driving.

Some car models have a non-removable column that cannot be restored. In this case, the entire column changes.

2. Knock when turning the steering wheel while standing still or in motion

First of all, it is worth checking the tire pressure - differently inflated wheels can also cause knocking noise when the car is moving. Next, inspect the fastening of the plastic fender liners. Probably, one or more mounting screws have broken out, which is why the fender liner touches the wheel when turning and makes a corresponding knock. The problem can be easily fixed. You just need to replace the loose fasteners with new ones.

The greatest danger is caused by malfunctions accompanied by a knocking sound from the steering mechanism itself when turning the steering wheel. The sound may be localized closer to the suspension, wheels or steering wheel. Let's look at the reasons for its occurrence, starting with the most common.

3. Constant velocity joints

A knocking sound when the steering wheel is turned while driving is usually associated with the operation of the outer CV joint, which begins to creak or, in some cases, hit the wheel. Accordingly, when turning left, a crunch or knock will occur in the right CV joint, and when turning right, in the left one.

Internal hinges, as a rule, make a squeaking or knocking sound when moving at high speed over uneven surfaces. They do not react at all to steering wheel turns. Therefore, if turning or sharp acceleration of the car is accompanied by a knocking noise, most likely the outer joint needs to be replaced. But before replacing it, you should carefully inspect it. If there is little or no wear, it is enough to treat the CV joint with appropriate lubricant.

4. Tie rods and tie rods

Both the tips and the rods in the steering system wear out over time, causing play. As a result, squeaks and knocks appear when the car turns while driving.

To check the condition of the parts, jack up the car on the side where the sounds are coming from and remove the wheel. Then try to loosen the rods and tips, thus checking for possible play. Often, dirt and water accumulate inside the tip due to a torn boot, which is why the knocking occurs.

Sometimes a distinct metallic knock when turning the steering wheel in a stationary car or while driving appears due to the fact that the car owner forgot to secure the tie rod with the end after performing a wheel alignment. You can verify this by shaking the wheel left and right with your hands. If the wheel wobbles, making a characteristic sound, the problem is precisely the loose nut.

We recommend

“How to install radio control buttons on the steering wheel.

How to install cruise control» More details 5. Steering rack

A faulty steering rack quite often causes knocking noises when turning the steering wheel, both while driving and when the car is stationary. Why does this knock occur? There are several reasons for this:

- The steering gear fasteners are not tightened properly.

- The plastic support bushing of the steering wheel was severely worn, creating play.

- Play appeared in the steering rack shaft bearings.

- The gap between the rack teeth has increased, creating backlash and causing dull knocks when turning the steering wheel on a stationary car.

- The anti-friction gasket was completely worn out, as a result of which the clamping “cracker” began to vibrate and knock on the steering rack housing.

Detecting a knock in the steering rack is a rather difficult task. It is best to use the help of a partner by asking him to sit behind the wheel of the car, previously placed on the handbrake, and position himself under the car near the steering rack. Let the assistant rotate the steering wheel, and at this time you note the creaks and crunches coming from the rack, which will signal a malfunction.

6. Steering cardan

If turning the steering wheel is accompanied by a knocking sound from the steering column, the problem is most likely in the steering driveshaft. This malfunction occurs especially often in UAZ vehicles due to the increased gap in the spline joint. The same problem that occurs in VAZ cars indicates a damaged universal joint. Moreover, knocking noise when turning the steering wheel occurs both when the car is stationary and in motion.

The malfunction is easy to check. With one hand you need to grab the cardan shaft, with the other you need to rotate the steering wheel. If play is felt, the cardan must be repaired.

Also, owners of front-wheel drive models of the Volzhsky car, "Grant", "Kalina") may eventually detect the creaking of the driveshaft crosspiece. This malfunction is checked in the same way. If the creaking is confirmed and play is detected, the VAZ owner independently decides whether to buy a new cardan or try to repair the faulty existing one.

It is worth noting that repair is chosen not because of the high cost of a new cardan, but because of the high percentage of defects among new products. The splines of many sold universal joints function with jerks and jams after the start of operation. Therefore, before purchasing a new crosspiece, be sure to check that it moves freely in all directions. Often the defect is expressed in a mismatch between the axes of the holes in the bearings installed in the splined fork, which causes misalignment of the bearings. Whether to buy such a product or not is up to each buyer to decide for himself.

There is another solution to the problem, which is to replace the needle bearings in the cross with capolactan bushings. The reliability of such a replacement is confirmed by many taxi drivers who own VAZs, who choose this particular option, since they spend a significant amount of time driving behind the wheel.

It is worth considering the complexity of this repair operation. Removing parts typically requires a 13mm wrench and a flat-blade screwdriver. The bearings are knocked out by striking directly at the base of the fork, located under the bearing, using a small hammer.

Reviews about commercially available cardan shafts and bushings are quite contradictory. Owners of late-model VAZs usually prefer SS20 and Taya brand crosspieces, as well as more expensive Japanese analogues (Toyo, GMB).

7. Shock absorber struts or support bearings

Knocks coming from the support bearings or shock absorbers will be observed both when turning the steering wheel and when driving straight. But these parts will begin to knock the most during sharp turns (especially at high speed) due to the action of additional loads on these elements.

A knocking sound in the shock absorber may be caused by a broken spring. As a rule, the spring bursts from the top or bottom edge. If this happens, movement over uneven surfaces and the car's roll when turning will be accompanied by a characteristic metallic clanging sound. A left turn of the steering wheel will affect the right spring, a right turn - accordingly, the left one.

Bearings and shock absorbers are checked by assessing their play. To check for play, remove the wheel and move the parts being examined. They may knock less often due to an unscrewed nut in the mount.

8. Stabilizer link

A partially failed stabilizer link may be accompanied by a dull knock when the car turns. A knocking sound when the steering wheel is turned while driving begins to be felt when the wheels are turned approximately 50-60 degrees. If the strut is faulty, it may also begin to creak when moving straight over uneven surfaces. Moreover, the car may be difficult to control and requires constant steering adjustments. Other symptoms include increased car roll when cornering and severe pitching when braking.

9. Sounds from the cabin when turning the steering wheel

The steering wheel in modern vehicles is a multifunctional control device. In addition to its main function, the steering wheel allows you to change gears, turn on the headlights and control the audio system using controls located on the steering wheel. Many owners of modern cars begin to worry when they hear clicking sounds when turning the steering wheel, coming from inside the steering column. The sound is heard in the cabin approximately in the area of the horn button.

We recommend

“Why the steering wheel and ignition switch are locked: all the answers” Read more

But in this case, there is no need to panic. First of all, you should check whether the plastic steering column cover is installed correctly and assess its condition. It often happens that some elements of the steering column switch fail, which is why suspicious sounds occur. If the switch is faulty, it must be replaced, also checking that the plastic is securely fastened. Usually these actions are enough to make unpleasant clicks during turns disappear.

Sometimes the movement of the steering wheel is accompanied by shuffling and creaking sounds coming from the front of the cabin. The source of these sounds is located at the top of the column under the signal button on the steering wheel. At the same time, the indicator indicating a malfunction of the airbag in the steering wheel is on, and the cruise control function does not work.

The problem lies in a non-functioning steering column cable located under the airbag, which supplies electricity to the steering airbag mechanism itself, and also provides power to some other systems. This cable may be damaged, and in this case, some car owners try to solve this problem on their own. However, there is no guarantee that the loop will work normally again. And since his work is directly related to traffic safety, it is better to entrust the troubleshooting to specialists and not to engage in amateur activities.

Why the rack fails, the main reasons

Of course, there are also two main points here. However, one is banal, but the second is quite serious:

- This is a mechanical effect . On our roads it’s easy to fall into a hole; of course, the struts will take most of the impact. But some of the energy will pass to the “steering”. It is polymer bushings that absorb such impacts; it is from impacts that they can be slightly deformed. Here's a knock for you.

- Wear of anthers . This is the most common cause of failure. What the anthers do is they keep the space inside sealed. Preventing dirt, dust, and moisture from getting inside. If it breaks, it all easily penetrates the main shaft. Corrosion, rust begins, the surface becomes rough. It works like sandpaper, erasing oil seals and bushings. I will say this, after a short run of 500 - 700 kilometers, after the boot breaks, the rack may start to knock.

Therefore, the main task is to always monitor the condition of the rubber protective covers - “boots”, they are the key to the long operation of the steering rack; if they are torn, they must be replaced immediately.

Examination

Checking the steering rack is done in several ways:

- it can be checked by inspecting, removing and reassembling it, and on a stand. A visual inspection allows you to identify external damage, cracks in the housing, anthers, and leaking seals. For better inspection, it is recommended to remove it from the car; sometimes contamination prevents it from being properly examined.

- How to check a removed rack? After removal, its body is washed and the mechanism is disassembled. After disassembly, all parts must also be washed and inspected for defects. Replace damaged elements with new ones. Replacing the oil seal is mandatory. Assemble the mechanism, replacing all rubber elements with spare parts from the repair kit.

The assembled rack requires testing on a special stand, especially if it has a hydraulic booster.

An inspection stand is an expensive pleasure, so buying it is easier and cheaper to go to a service station where such a stand is available. By installing a part that has not been tested and adjusted on the bench, you are at great risk.

How to check for knocking, you ask, I answer. The rack and pinion mechanism can be checked for knocking by placing your hand on the body, and an assistant in the cabin turning the steering wheel from side to side. If there are no distinct knocks, then there is no slightest knock.

Video about rack knocking

If the repair is difficult or impossible, it is better to buy a new one, it is adjusted, all that remains is to install it in place of the broken one. For expensive foreign cars, spare parts can be difficult to obtain and prohibitively expensive. Therefore, you may be offered a refurbished mechanism at a discount, or a used one, but still working.

In this case, the decision is yours; I can only warn you that such a rail needs to be carefully examined from all sides, looking for obvious defects, so as not to “get” junk when purchasing.