The function of the steering rod in the Logan design is to connect the steering wheel with the rotary arms: it is thanks to this transfer of force from one unit to another that the wheel turns. The end of the mechanism is equipped with hinges, which are also responsible for the angle of rotation .

Most often, the rubber joint liners become unusable , but even because of this seemingly minor element, it becomes more difficult to control the Renault Logan. In addition, the assembly may not work due to contamination of the boot .

The rods themselves fail due to mechanical shocks or after driving into a deep pothole.

How to determine that Renault Logan steering rods need to be replaced, in what sequence to change the unit, what nuances to take into account - we have collected answers to all these questions in our material.

A little theory

The steering linkage performs the most important function - it transmits forces from the steering wheel directly to the wheels, and also provides different angles of inclination when cornering. As you know, the outside wheel travels a longer distance than the one that is closer to the inside of the turn. Structurally, on one side, the hub is movably mounted in the steering mechanism, and on the other, the element has a special ball joint that serves as a connecting element with the knuckle. Thus, the steering rod is an intermediate link in the system, transmitting forces further to the steering knuckles and the hub.

Naturally, malfunctions or wear of this unit will affect the control of the car. In the most critical situations, the deformation from the impact can be so great that the car will not be able to turn in one direction. Now imagine that you flew into a hole at speed, and the steering rod was in a dying state. There is an extremely high probability that the outcome of this situation will be a traffic accident. Be sure to monitor the condition of each rod and replace it if necessary.

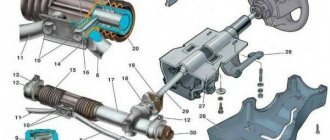

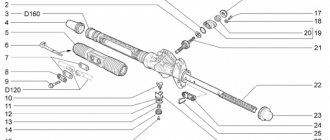

Brief description of the steering device

Before starting any actions to service the machine, it’s a good idea to get to know its main components and how they work. The bulk of French brand cars are equipped with a hydraulic booster control system

.

It includes

:

- steering column;

- rod ends;

- steering knuckles with hub;

- hydraulic booster and injection lines;

- fluid pressure sensor.

For ease of assembly, each tip has a right one - I, a left one - II. The design is made according to the “gear-rack” scheme. The mechanism connection is located in a special housing and is regulated by a special plug when the product is assembled at the factory. In the future, the gap between the parts cannot be changed.

Replacement frequency

Even with careful driving, drivers will still have to make changes. The tie rod ends are most often affected. On average, their service life varies from 40 to 60 thousand kilometers. A complete replacement of the Renault Logan steering rod most often takes place when the part is severely worn or largely deformed, when it is not possible to drive the car safely.

Technically, if you avoid getting into holes and drive carefully, it is enough to only replace the tips, while the traction will have an almost unlimited resource. The metal used in the design is quite durable. Naturally, the frequency of replacement is affected by the roads you drive on. During active off-road driving, steering linkages can quickly suffer. It is also important to check the condition of the anthers. The main enemies of the tie rod end are dirt, dust and water. They penetrate into the structure, destroy metal and increase play, which affects vehicle control.

Video lesson

Having bought the car a little over a year ago, I immediately went through diagnostics at Renault Service on Chicherin - there were no complaints about the chassis, except for the recommendation to replace the left wheel bearing, which was done almost immediately. The tie rods with ends had no play. But the year did not pass without a trace - I began to notice an unpleasant thud on our Belgorod side streets, broken during the winter... I did not feel any noise on the highway.

I decided to make diagnostics routine and it so happened that I did it three times over the last 2 months in different services - no, not on purpose, checking and comparing the quality of diagnostics, but mainly as a bonus, during scheduled visits to the service. I concluded, as a novice car enthusiast, that going to a service center specifically for chassis diagnostics is not financially profitable, so the first diagnosis, which I came specifically for, cost me 400 rubles. It’s better not to rush into this matter and ask the technician to check the chassis during a visit to the service center, solving other issues - for example, when replacing the brake fluid, the technician diagnosed the chassis for me for free, and when replacing the clutch cable, the diagnostics cost me 100 rubles .

So, the verdict of three independent services was the same - a slight play in the steering rods with tips, hence the noise from the front suspension on uneven surfaces. True, where I gave 4 hundred, the diagnosis was more scrupulous, versatile ones were rejected - one rod and one tip, but it was decided to change everything completely, especially since wheel alignment is required. As for replacing the levers right away, my ardor was cooled by the master at “Cruise” - good is better than new!

I didn’t have to worry about choosing a manufacturer for a long time - I took the proven Lemforder in Exist (1000+1000/900+900).

At the same time, the Sasic anthers, which forced the master to tinker, fit with difficulty from the side of the steering rack, but this is not bad - they will fit more tightly. They were tightened with plastic clamps.

Result: the noise of the suspension when driving over bumps and small potholes has disappeared - the suspension works smoothly without thumping, the positive result is obvious. So, I present a photo report...

Removing the old tips turned out to be not so easy - I had to resort to a gas torch.

Same thing on the second side...

Price: 5,900 ₽ Mileage: 80,900 km

Good day to all good people. In this article we will figure out how to replace a Logan tie rod end with your own hands without outside help. The average time to complete the job is from 60 to 90 minutes, depending on the driver’s experience.

The weak link of the tie rod is the tip. The average period of operation of the element does not exceed 30-40 thousand kilometers. Heavy use of the car and bad roads will bring the replacement period closer.

In the article you can find a video of replacing the Logan tie rod end, which will help the driver. It will complement the text material and help you understand the nuances of replacing the tip yourself.

Signs that replacement is needed

Only a visual inspection can tell for sure about the condition of the steering rod. The ideal option is to perform a complete disassembly to inspect the part for damage and play. Naturally, it will be inconvenient to disassemble it just to check the condition of the unit, so be sure to focus on a number of characteristic symptoms that will indicate the imminent death of the steering rods:

- The appearance of a dull knock when passing small potholes. Appears when there is a lot of play, when metal hits metal, creating these knocking sounds.

- Steering wheel vibration or stiffness.

- The car lost directional stability. Wear on one of the steering rods will cause the car to start to pull to the side when driving in a straight line.

Of course, the appearance of extraneous noise in the suspension area may indicate another problem. To be completely sure that the tie rod is faulty, you can perform several garage tests.

The procedure for visual inspection of tie rod ends:

- The steering rod elements are cleaned of dirt.

- The boot is inspected for damage to its integrity. If it is torn, it is replaced.

- The play is checked. One person turns the steering wheel, and the second from below watches the work of the tips. Movement along the length of the finger axis of more than 1.5-2 millimeters is a deviation from the norm.

- Deformed tip surface and obvious damage.

Timely maintenance of the car and its periodic inspection allows you to quickly detect faults and take measures to eliminate them.

We seem to have sorted out the consumables, now on to the running gear. I took up the task of replacing the tie rod ends. Although they didn’t bother me at all, I didn’t notice any play or knocking, so I decided to get it diagnosed.

With your own hand, naturally. In the absence of experience in such matters, we turn to the book for dummies).

On the left side, the free movement of the hinge was felt. Things were better on the right. I didn’t bother with the choice of tips; following the example of many, I chose Lemforder.

Everything changes easily. He took off the wheel and here he is.

First, I loosened the locknut.

Then unscrew the nut on the hinge. Everything lends itself easily, I only poured a little VD-hoy on it. You may have to hold the finger itself from turning with a Torx T-30 wrench.

Then we carefully knock out the hinge pin and unscrew the tip, while counting the number of turns so that we can then screw the new tip into the same position. But not all the way, otherwise you won’t get to the wheel alignment and the car will be torn apart) Here are the old and new tips for comparison. There are two marks on the left one.

There's one on the right.

The finger and the base of the boot are slightly different, but they fit like family. On the old ones, the hinge moved freely, you could easily move it with your finger. The new ones are very tight, dense, no play at all.

Install in reverse order. Here are the new ones.

After all the procedures, I went to the wheel alignment. Price 500 rub. Well, this is just convergence.

Well, now about the sad thing. I drove for a decent amount of time with an incomprehensible creaking noise that seemed to me to be coming from the steering column. Although at first I thought it was the same steering wheel boots that were creaking that many people were complaining about.

It didn’t bother me much, I even started to get used to it. But relying on the new tips, I hoped that the creaking would disappear, but no. I removed the steering wheel, disassembled almost completely the steering column, but all the bearings on top were completely pressed in.

I climbed up from below and immediately swept away the crosspiece, because the first thing I thought about was it, but the creaking went higher. Somehow I contrived and, using a mirror, looked deep into the steering column tube. I saw such a picture there.

I managed to take a photo as close as possible.

Inside there is some kind of plastic ring that has completely split, the pieces are not the same, so it shouldn’t be like that. In addition, some kind of shavings fell from there, only very small, more like metal dust. I poured WD-40 inside; there was no way to get oil or other lubricant into it.

The creaking completely disappeared, not a single sound. It didn't make it any easier, though. There is a leak in the steering column.

As I understand it, it is not collapsible, and can only be changed as a whole. I couldn't find anything on the Internet about this.

I would like to know what the consequences of further operation of the car in this condition are. Price tag: 2,250 ₽ Mileage: 80,000 km.

Methods for self-diagnosis

In most cases, it is possible to identify a problem with the steering rod even without qualified assistance from specialists. To do this you will need a friend and a pit (overpass). Raise the front of the car. The first person should rock the wheel in a horizontal plane. The second one needs to feel under the car the point under the boot where the finger connects to the ball. If the latter wobbles in the outer race, then the problem is with the steering rod.

Also note a few other important details:

- the maximum permissible range of deflection of the tips along the axis of the fingers is 1.5 millimeters;

- there should be no play on the balls;

- The hinge cover must be free of cracks and other visible defects.

The hole in the boots can be easily identified by the grease being squeezed out, so pay attention to drips. This is the basic information on how to check the steering linkage on a Renault Logan.

Such a simple inspection in most cases allows you to determine the breakdown of the balls. If everything looks intact, but the knocking invariably remains, then head for diagnostics. In many cases, the breakdown can only be identified after complete dismantling of the part.

Necessary tool

Keys and accessories:

- Rozhkovy on “16”.

- Hammer.

- Wooden beam.

- Balloon wrench.

If you have a little experience in carrying out such work, then you can replace the tips on Renault Logan yourself. To do this, you should only adhere to the rules listed below.

Let's start replacing (preparatory work)

To replace the tips, you need to put the car on supports. Then you should remove the front wheels. In this case, it is recommended to turn on the handbrake and place wheel chocks under the rear wheels to ensure the stability of the car.

Stages of work

Before repairing, all elements of the steering mounts must be sprayed with WD-40. You can also use water if liquid is not available. You should pour it over the bolts and wait a while until they are saturated with moisture. This will make it easier to unscrew the bolts.

The rod on the car has a lock nut. It must be loosened and left in this position.

The nut on the steering knuckle is loosened. The finger is kept from turning by the hexagon.

You can also use pullers to remove ball joints.

After unscrewing the nut, the finger is removed from the socket. After this, the car is reassembled in the reverse order with the new part installed.

A finger is inserted into the socket and the nut is screwed in until it stops. You can use a hydraulic jack.

When installing the steering rod, it is necessary to turn it to the number of revolutions by which it was unscrewed (to get to the wheel alignment). All elements must be carefully tightened

In this case, you should also work carefully so as not to strip the thread.

After completing this work, you should contact a specialized service station to set the wheel angle (wheel alignment).

Adviсe

It is recommended to lift the car on the side on which the part will be replaced. When carrying out work, the car must be on the parking brake. To clean dirt from the steering column, you can use a metal brush. In the event that you do not have a puller at hand to press out the finger, you can use a wooden block and a hammer

Using a hammer through the beam, you need to hit the mounting hole of the finger, freeing it. It is important to remember that the steering wheel tip on the right has a left-hand thread, and the one on the left has a right-hand thread (that’s why the part numbers are different, they are lower).

What to buy

If the steering rod is faulty, it must be replaced. Here the question arises about buying a new part. It is recommended to buy original products. In the technical manual for the car or from the official dealer, you can find out the catalog number of the steering linkage for your particular Renault Logan. A popular model is TRW catalog number JAR 1031. Its cost is 1000-1200 rubles. We also recommend taking a closer look at the products of the following brands:

- ABS (Netherlands);

- ASMETAL;

- Autolog (Germany);

- DELPHI;

- MONROE;

- PROFIT;

- Sasic (France);

- SWAG.

The cost of the most expensive models reaches 5 thousand rubles, but whether it is worth overpaying for the brand is up to you to decide.

Which brand should you prefer?

To select the required part, we use the article number, which will allow you to accurately select spare parts. To determine the treasured code, we consider the number indicated on the part itself. We recommend purchasing original products using the corresponding factory part number. We should not forget about the galaxy of brands that have their own items at their disposal. However, the quality aspects of the manufactured parts will not be able to guarantee their presence at the same level as the original products.

Preparatory work

Replacing a Logan steering rod requires a pit or a lift. Some of the work will have to be carried out in the area of the wheel arches. Naturally, doing this lying down will be extremely problematic. Also prepare the following tool:

- a set of keys;

- a puller for pushing the ball pin out of the steering knuckle can be found in stores under catalog number 0000130501;

- bright lighting;

- set of heads;

- hammer;

- WD-40 composition, with which you can more easily remove rusty fasteners.

For added safety, use wheel chocks. Please note that the tie rods do not have to be replaced as a pair. If the problem is observed on the unit on the right side, and the left one is completely intact, then it is enough to replace only the part on one side.

Which steering tips to choose: original and analogues for Renault Logan

The catalog of original spare parts for different René models contains parts with numbers 6001550442 and 6001550443. They are sold in pairs, the last digit in this case is the designation of the side. “Two” is for the left tip, “three” corresponds to the right side.

It is better to replace such parts as a set. If the tip is faulty, the steering column wears unevenly on one side. If you choose from analogue spare parts, the classification of a suitable replacement will be as follows.

Possible analogues:

| For left side: | For the right side: |

| ASAM 30138 (30666). | ASAM 30139 (30665). |

| DELPHI TA2329. | DELPHI TA2330. |

| FENOX SP30040. | FENOX SP30041. |

| RTS 91-02401-2. | RTS 91-02401-1. |

| PROFIT 2302-0474. | PROFIT 2302-0475. |

| SASIC 4006158. | SASIC 4006157. |

| MAPCO 49192. | MAPCO 49193. |

| TRW JTE1136. | TRW JTE1135. |

| SWAG 60 92 9623. | SWAG 60 92 9624. |

The best compatibility with Rene Logan can be boasted by tips produced under the TRW brand. Inexpensive steering parts can be purchased from the SASIC range. An excellent option would be to purchase LEMFORDER products. In terms of technical characteristics, they are superior to all possible analogues, but the main disadvantage here is the cost.

Replacement procedure

You can remove the old steering rods and install new ones according to the following instructions:

- With the car on a jack or lift, remove the wheel from the side with the faulty traction. For ease of access, you can turn the steering wheel all the way to the side.

- Using a 16mm wrench, unscrew the tip fixing nut.

- Loosen the locknut using a 22mm wrench. After this, you can knock the tip out of the caliper.

- When you twist the tip, be sure to count the number of rotations. This will be needed when installing a new part.

- Next, you can install a new rod on the seat.

- Using rubber clamps, secure the rubber casing.

- The steering end should be screwed on to a pre-calculated number of rotations.

- Reinstall the locknut and press the tip into place.

- Replace the wheel. If you need to change the second tie rod, then do the above steps on the other side.

The procedure is not over yet. Whenever any intervention is made to the vehicle's suspension, a wheel alignment must be performed. You won’t be able to do this without the help of a car service. Only after this can you conduct a quality test drive and check the operation of the steering rods. Make sure that the knocking noise has disappeared, the steering wheel begins to turn normally, and deviations from the straight trajectory no longer occur.

If extraneous noise remains in the suspension, then the problem is not in the steering rods. To save your time and effort, we recommend going to a specialized service station and finding out exactly what is the source of the problem. When the broken part is found, then you will have to choose whether to do the repair yourself or entrust the work to auto mechanics.

Let's start the renovation

To be able to carry out repair work, you will need an appropriate tool that allows you to dismantle the rod, its tip or boot. A lift will also greatly simplify the task.

- If an annoying play is detected in one of the tips, then we replace it according to the given algorithm and, not forgetting to check the article data.

- We remove the wheel from the corresponding side.

- We unscrew the nut that secures the ball pin of the tip in the eye of the steering knuckle.

- To release the conical part of the pin from the eyelet, we apply a lateral impact load to it (with a hammer) or, which is more civilized, use a puller.

- Lubricate the threaded part of the pin on the new tip with an appropriate lubricant, after which we screw the tip onto the rod. Tighten the locknut. To ensure a minimum error in wheel alignment, we ensure that the number of turns matches when dismantling and screwing the tip onto the rod.

- We head to the service center to monitor and adjust wheel alignment.

- During installation, we take “care” of the boot so as not to damage its rubber texture.

- The replacement algorithm is identical for both sides of the suspension.

- A failed rod should also be unconditionally replaced since it falls into the category of parts that cannot be repaired.

- Having dismantled the clamps (2 pieces), remove the boot from the rod and put it aside for a while.

- Armed with a special device that allows you to unscrew the rod, we will implement this action.

- We install a new analogue and put on the boot, securing its extreme sections with clamps.

- If it is not possible to remove the boot through the tip, we dismantle the latter. After assembling the unit, a wheel alignment is required.

- Now let's begin the process of replacing the rack, which can be done in several steps.

- First, drain the fluid from the power steering circuit.

- We disconnect the steering shaft from the seat on the rack gearbox.

- We unscrew several bolts that hold the rack assembly to the subframe. In the Renault Logan modification, 2 pcs.

- To ensure the correct angle of installation of the wheels, we first make the appropriate markings. The shaft is marked with only one mark.

- We disconnect the tips from both sides of the Renault Logan car.

- Now we take out the assembly assembly.

- We prepare a new unit and install it on the car in the reverse order of the dismantling procedure.

If the owner is faced with the need to replace the rack in a Renault Logan car, the equipment of which does not include power steering, then the technology is completely identical to the sequence of manipulations given here. The exception is that there is no need to drain the liquid.

How to extend the life of steering rods

The advice is banal, but very important. Drive carefully and try not to fly into holes and ruts at full speed. In more than half of the cases, the rods break due to impacts. It is also recommended to inspect the traction units every 20-30 thousand mileage. Anthers protect the structure, so it is necessary to monitor their condition. As soon as a defect or break is found, replace it immediately. Even a small hole in the boot will cause water and dust to enter the internal traction mechanism. The more often you carry out inspections, the less likely it is to have a critical breakdown. Please note that stores sell special repair kits that allow you to replace the fastest wearing parts. Their cost is lower than new parts, so they will help keep the rods in working order without large investments.

Repair technology

To replace the steering tip, no matter whether it is right or left, you should not only have a repair kit, but also a special tool, otherwise it is unlikely that you will be able to remove the rods. In addition, there must be a pit or a lifting mechanism for ease of operation.

How to change? Replacement of a worn-out part is carried out when there is play in one of the tips, meaning left and right. Before replacing, be sure to check the part numbers.

To get to the faulty element, you will have to remove the front wheel and only then will you be able to unscrew the ball mechanism nut. To disconnect the tip part, make several blows with a heavy tool (hammer) on it from below.

After this, unscrew the fixing nut and remove the entire steering tip. Before installing a new part, when purchasing which you must not forget about the article number, it is better to lubricate the threaded part with lubricant. The part is installed according to the same scheme in which the worn part was installed. Then the ball mechanism nut and the nut that controls the position of the steering rod are tightened.

Replacement is carried out according to the same scheme for both the left and right tips.

During the repair process of Renault Logan, special attention should be paid to the integrity of the boot. If it is damaged, the knocking will soon resume

- If play appears in the steering rod and a knock is heard, then this malfunction can only be eliminated by replacing the parts with new ones. The fact is that these elements cannot be repaired.

- To replace the rod, the boot is removed. But before that, you will have to remove two clamps, which are located on the inside and outside of the rod.

- After releasing the rod, remove the anthers by pulling them out and to the side. Using a special tool, the rod is dismantled and a new part is installed in its place. Assembly of the traction mechanism is carried out in the reverse order.

- How to change the boot? To replace the steering boot, you will have to disassemble the traction mechanism and the steering tip, and only after that the worn part is replaced with a functional one. After installing the working part, the traction mechanism is assembled in the reverse order. As a rule, after such actions it is necessary to adjust the wheel alignment.

- If necessary, replace the power steering rack. To replace it, you need to carry out several steps, which are described below.

- First of all, the fluid is drained from the power steering, and then the shaft is disconnected from the rack drive.

- At the next stage, the bolts are unscrewed, which secure the rack to the car subframe. Renault Logan has two similar bolts.

- To properly reassemble the mechanism, you need to take care of the markings, otherwise the angle of rotation of the steering wheel will be disrupted.

- Since the shaft moves only in one plane, it is enough to mark it with one point.

- Having disconnected the right and left steering tip itself, the part is carefully removed.

- Having prepared the working part, it is also carefully installed in place of the worn one. When purchasing a new item, do not forget about the article number.

- All assembly and adjustment steps are carried out in reverse order.

Replacing a rack without power steering is carried out in the same manner as with power steering, with the exception of the operation of draining the fluid.

Scheme for disassembling the dashboard and removing the part:

- To repair the steering switch, you should turn off the power to the car, since the work will be carried out on the electronic part of the system, and also turn the steering wheel 90 degrees to the left;

- Afterwards it is necessary to disassemble the steering column casing;

- Using T20, remove the first and second mounting bolts;

- Use a Phillips screwdriver to tighten two screws;

- Next, you should disassemble the lever and carefully inspect the switch and electrical wiring;

The most common cause of joystick malfunction is contacts that are sealed off from the pin. To remove the pin, you must open the switch housing. Figuring out how to solder the elements yourself is not difficult: you need to prepare a couple of more flexible wires, a soldering iron and solder. After soldering, assembly is carried out in reverse order.

If the switch is being replaced, then removing the element does not differ from the process of dismantling during repair, with the only difference being that instead of carrying out repairs, a new part is installed. The right steering column switch is removed in the same way. The cause of element malfunction can also be a stuck relay, which does not operate when the headlights are turned on due to oxidized contacts.

Faulty switches lead to unsafe vehicle operation. They are replaced only with similar parts with the corresponding article number, which will not be difficult to buy. When repairing and assembling the structure, the pinout of the contacts is taken into account. It is not difficult to repair spare parts yourself, but if you are not confident in your capabilities, then it is better to contact a car repair shop.

Repair of steering rack with power steering. Lada Largus

Finding and eliminating knocking in the steering rack

Lada Largus.

The steering rack is an integral part of any modern car, including Renault Logan. It is included in the design of the steering mechanism and ensures the transmission of force from the steering wheel to the steering rod of each wheel. If a malfunction is suspected and adjustment is impossible, the steering rack should be replaced as soon as possible. The procedure is not difficult and can be done with your own hands if you have a repair kit and know the repair rules.

On Renault Logan, depending on the version, steering racks of various types were installed - mechanical and hydraulic.

Cars of the first generation - phase 1 (2004, 2005, 2006, 2007, 2008, 2009) with a 1.4 engine in two offered trim levels were equipped with a mechanical steering rack, and cars with a 1.6 l engine were equipped with a hydraulic one.

Restyled models (2009, 2010, 2011, 2012, 2013, 2014, 2015) and second-generation versions (2014, 2015, 2016, 2022) in the simplest configurations are offered without power steering (hydraulic booster), which is ordered separately .

How to recognize the failure of the shock absorber strut and springs?

Shock absorber struts are a device that stabilizes the smoothness of the ride when the vehicle is moving. Together with the springs, the struts take on the load, eliminating excessive body sway and increasing ground clearance. A photo of the shock absorber strut (without spring) is shown below.

A faulty shock absorber strut can be recognized by the following symptoms:

- The appearance of an oil leak.

- Increased car sway when hitting a pothole on the road.

- Vibrations or knocking noises when driving on a flat road.

- Deterioration of car controllability, decreased sensitivity.

- Shocks and “breakdowns” when hitting uneven surfaces.

No less important devices are springs that work together with the struts. Malfunctions of these Renault units are recognized by a number of symptoms:

- Reduced clearance.

- Deterioration in smooth movement.

- The appearance of swaying or jolting in the event of hitting an obstacle.

- Tilt of the body in one direction or another without movement (when the car is static).

Note to car enthusiasts

Regular maintenance of Reno Logan will allow you to avoid significant expenses associated with the replacement or repair of individual components and assemblies. That is why all this is described in the official warranty and vehicle operation book. At the same time, the car owner must remember that even regular visits to a service station for preventive purposes will not always protect the steering ends from damage. Certain components and assemblies of the car require replacement due to wear and tear.

The second reason that can send you to a service station unscheduled is a driving style that is too harsh. In this case, the most likely victim may be the steering column switch or, which happens much more often, the steering column, which takes the brunt of the impact. In order to avoid this, you need to take into account a simple fact - the diameter of the Reno Logan steering wheel allows you to comfortably drive the car without excessive jerking from side to side.

Technical characteristics of operation

The most sensitive part of the Reno Logan is the steering mechanism, which is responsible for the direction of movement of the vehicle. Its direct replacement or adjustment occurs exclusively in a service center that has the necessary tools and experience. The same must be done when it comes to preventive examination.

The main part of this system is the steering rack - it is it that distributes the force received by the steering column. If everything works well, then the impact on the driver’s steering wheel should reach the rods and wheels without any problems. The most common failure is a leak localized in the hydraulic booster. The main symptom of this malfunction is a very tight steering wheel that requires a lot of effort to turn.

To find a fault, the car must be driven to a special stand. A pressure of 150 to 160 atmospheres will be created here. Within 5-10 minutes you can determine exactly where the steering rack rod has become corroded. Less often, leaking oil seals or seals are the culprits of failure. In any case, the steering rack needs to be repaired.

Snail installation

When reassembling, the front wheels must be aligned and the rotating contact plate must be locked in the middle position by the safety lock. For this:

- we determine the maximum number of revolutions of the contact disk (No. 2) by rotating it from the extreme left to the extreme right position (without using force);

- turn the contact disk to the middle position, counting half the maximum number of revolutions from the extreme position;

- align the holes (No. 4) for the fuse on the disk and the hole (No. 5) in the body of the rotating device and install the fuse (No. 6).

The screw tightening torque is 1.6…2.4 N.m (0.16…0.24 kgf.m).

Let us remind you that the website contains other instructions for servicing and repairing Vesta or XRAY with your own hands. The necessary information can be easily found using the search (in the upper right corner of the site) or by content (Vesta, XRAY).

Keywords: Lada Vesta steering wheel | Lada Xray steering wheel | turn signals Lada Vesta | turn signals lada xray | fog lights Lada Vesta | fog lights lada xray | headlights of Lada Vesta | headlights lada xray | tail lights of Lada Vesta | rear lights lada xray | windshield wipers for Lada Vesta | windshield wipers lada xray

1

Found an error? Select it and press Ctrl+Enter..

AvtoVAZ corporate sales statistics for 2022

History of the creation of LADA Kalina 1st generation (photos and videos)

Soundproofing of the Lada Vesta glove compartment (covered with carpet)

Checking and replacing door limit switches on Lada cars