What is the difference between DPRV and DPKV

The design of both sensors is the same, and the tasks are similar. But the DPKV monitors the position of the crankshaft, and the DPKV determines the position of the camshaft.

Not long ago, cars did without a camshaft sensor (and still do). The main work is performed by the crankshaft position sensor. Engine operation will stop if this device fails.

Principle of operation of the sensor, causes of malfunction

Cars produced in the 80-90s of the last century used sensors based on the Hall effect. Such sensors are highly efficient. The Hall effect is based on a change in the potential difference of a semiconductor element in a changing magnetic field. During operation, as a result of exposure to climatic conditions and natural physical processes, the properties of the semiconductor element change, and the sensor fails over time.

Japanese manufacturers at one time used optoelectronic sensors. An optocoupler (LED-photodiode) was used as a sensor. Such sensors were also not reliable enough and were expensive.

Electromagnetic sensors have become most widespread since the 90s of the last century. Essentially, they represent an inductor located on a magnetic core.

Theoretically, such a sensor can have an infinite service life. It represents a conductor wound on a coil, inside of which a magnetic core is placed. To make the sensor, a very thin copper conductor in varnish insulation is used. The thickness of such a wire is less than 0.05 mm, the number of turns is more than a thousand.

During operation, the sensor located on the engine heats up and cools down; moisture can get to the conductor through microcracks, causing corrosion processes and destruction of the varnish insulation. All this contributes to sensor failure.

Mechanical destruction of the sensor when it is displaced is also possible. Metal shavings or emulsions entering the working area reduce the sensitivity of the sensor. Most modern camshaft sensors have built-in signal amplifiers/digital converters. They can also fail.

Why is DPRV needed?

For the internal combustion engine to operate, a crankshaft sensor is sufficient; for good operation, a camshaft sensor is needed. Without DPRV, fuel is injected into the cylinders in pairs. The working mixture is supplied to 2 simultaneously open nozzles.

In this case, one cylinder is in the compression stroke and, after fuel is supplied, begins to work, and the second cylinder simply throws fuel into the atmosphere. Environmentalists have drawn attention to this problem.

In addition, there was a need for economical consumption of fuel in transport. Installing a camshaft sensor allowed only one injector to be opened. In this case, the mixture does not flow into other cylinders.

Let's sum it up

As you can see, provided that there is a phase sensor, it is phased injection that allows you to get maximum power and efficiency from the engine. When the sensor is normal, the motor operates optimally in different modes, under load, etc. This is achieved thanks to the coordinated work of the DPRV and DPKV. In turn, the sensors allow precise control of injection and ignition.

We also recommend reading the article about what a mass air flow sensor is. From this article you will learn about the purpose, principles of operation, as well as signs of malfunctions, methods of diagnosing and repairing an air sensor using the example of a VAZ 2114.

Finally, we note that if the phase sensor fails, replacing the camshaft sensor is often the best solution. The fact is that such sensors are not particularly repairable and it is better to immediately replace the problematic element with a new sensor or a used one that is known to work. Taking into account the relatively affordable cost, it is replacement that allows you to quickly solve the problem and completely restore the performance of the internal combustion engine.

Converter device

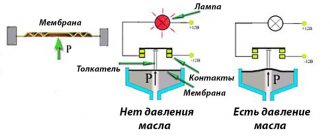

What does it transform? The device uses the Hall effect - conductors with direct current placed in a magnetic field create a potential difference (voltage). This property is used in smartphone compasses.

The sensor reacts to proximity to metal by changing the voltage on the wire. The system is the same as on the crankshaft.

- DPRV has the same design features as the crankshaft sensor. The main part of the device is the coil.

- It receives 12 V voltage through two wires when the ignition is on.

- The third wire is the signal wire, the voltage on it is about 95% of the nominal value.

When the reference point passes the sensor, the potential difference becomes equal to 0.2 - 0.5 V, depending on the make of the car. This signal is sent to the electronic control unit.

Auto parts and service stations

Unlike the crankshaft position sensor (CPS), it is by no means required in the system. However, it cannot be called unnecessary.Let's start from afar. Let's remember what the oscillogram of DPKV signals looks like:

A burst of pulses between two intervals is one full revolution of the crankshaft. It is from them that the control unit determines the current position of the crankshaft. The timing drive (be it a chain, belt or gear) ensures that the position of the camshafts strictly corresponds to each position of the crankshaft, and the control unit knows this correspondence. Of course, we do not consider cases of obvious malfunction - stretching of the belt/chain, or incorrect installation. So, on a working engine, these readings are enough for the control unit to determine the position of the crankshaft and cylinders.

Another thing is starting the engine. Let's imagine that the engine was turned off in the position corresponding to the second impulse after the break. In order for the control unit to at least “orient” itself to where the crankshaft is located, it needs to wait for a gap. That is, this is already at least one revolution of the crankshaft. Next, we need to remember that one revolution of the crankshaft is only half a revolution of the camshaft, and even after waiting for the interval, the control unit cannot say exactly which cylinder will now have the intake phase. That is, there is still a chance of injecting the mixture into the wrong cylinder, and the injected mixture will simply be thrown out through the open exhaust valves. Therefore, starting the engine in such a situation may take not the usual half a second, but 2-5-10 seconds - depending on the specific motor and the firmware of its control unit.

Therefore, another sensor was added to the control system - the camshaft position sensor (CPR). It can also be called a “phase sensor”. Structurally, it is completely similar to the DPKV, but the design of the drive disk on the shaft is somewhat different. Strictly speaking, you can’t even call it a disk. For example, on the ZMZ-406 engine this is the drive plate:

And on the Z18XER this design is more complicated, although the word “disk” still does not apply to it:

This design makes it possible to obtain approximately the following oscillogram Vp:

Thanks to additional signals from the DPRV, the control unit will be able to quickly understand “where it is” and start the engine without unnecessary “idle” revolutions of the crankshaft.

In addition, if the timing chain/belt is stretched, or if the phase regulators fail, the control unit, based on the discrepancy between the DPKV and DPVR signals, can record an error and light up the Check Engine lamp, thereby informing the driver about the breakdown.

On some systems, in addition, the DPRV provides emergency mode. If the DPKV fails, the system begins to focus on the DPKV readings and “pours” into both cylinders, which may correspond to the current phase. Both injection and spark supply are carried out very approximately, but still this allows you to at least start the engine and go to the repair site on your own, and not cut off the phone numbers of tow trucks - each of which cannot do it today.

But the failure of the DPRV will not lead to significant problems - the engine will not stop starting, and the car will not stop in the middle of the road. Which, of course, is not a reason to ignore failures associated with this sensor.

Symptoms of a faulty camshaft position sensor

The electronics that control the operation of a modern car engine receive information from a group of meters that record air flow, temperature, exhaust gas composition, and so on. In the latest generation of cars, the number of measuring elements has increased - an electromagnetic camshaft position sensor (abbreviated as DPRV) has appeared. Car enthusiasts who prefer to diagnose malfunctions on their own should familiarize themselves with the symptoms of malfunctions of the specified device and how to check it.

Meter design and location

The operating principle of the DPRV is based on the Hall effect - the sensor reacts to the approach of a metal mass by changing the voltage on the signal wire. The design of the device is similar to another element - the crankshaft position detector. Inside the plastic case there is a coil where the 12 V on-board voltage is constantly supplied.

The meter is installed on the engine cylinder head in close proximity to the camshaft. The latter is equipped with a special plate or gear, whose rotation affects the DPRV. The work algorithm looks like this:

- After turning on the ignition and starting the engine, a supply voltage of 12 V is supplied to the sensor. Through the third signal wire, the element supplies the controller with a voltage of 90–95% of the original one.

- When the protrusion on the rotating part of the camshaft passes next to the DPRV housing, the voltage at the signal contact drops to 0.2–0.4 volts, depending on the design of the device and the vehicle model.

- When the voltage drops, the electronic unit clearly “sees” the valve timing, promptly supplies the fuel mixture to the engine cylinders and directs the spark discharge to the desired spark plug.

Note. On cars with 16-valve engines, 2 sensors are installed - one for each camshaft.

When the meter is faulty, the electronics are unable to control the operation of the gas distribution mechanism. In such cases, the control unit goes into error and is guided by the signals of other meters. Spark generation and fuel supply are adjusted according to the programmed program, which affects the operation of the power unit.

Characteristic symptoms of the problem

Practice shows that a malfunction of the camshaft position sensor does not lead to engine failure and immobilization of the vehicle. The engine continues to operate with some deviations that interfere with the normal operation of the car. Symptoms of DPRV failure are quite vague and similar to problems with other measuring elements:

- Unstable engine operation at idle and while driving.

- Instead of dynamic acceleration, after pressing the gas pedal, there is a series of small jerks and a sluggish increase in speed.

- The power of the power unit decreases. The effect becomes noticeable when the load increases - on a hill, sharp acceleration, while towing a trailer.

- The Check Engine light on the dashboard does not always come on. But many drivers note that if the meter is faulty, the display flashes after the crankshaft speed increases to 3000 rpm or more.

- Fuel consumption is naturally increasing.

If the measuring element is faulty, the control unit prepares and supplies an enriched air-fuel mixture to the cylinders. This results in an increase in gasoline consumption and unstable idling. Jerks and drops in power are caused by untimely supply of a spark - the controller “does not see” the end of the compression stroke in the cylinder and cannot clearly determine the ignition timing.

On various car models, additional symptoms of a malfunctioning camshaft sensor are noted:

- the engine suddenly stalls while driving, but starts without problems;

- cold starting of the engine becomes difficult;

- on cars equipped with a robotic gearbox, difficulties arise with automatic gear shifting;

- the engine “troits” - skipping ignition cycles is heard, sometimes popping sounds are observed in the exhaust manifold;

- On some cars, the power plant fails due to lack of sparking.

Reference. The service life of the element is quite long. On domestically produced cars, the resource reaches 80–100 thousand km, on imported cars – 150 thousand km. When searching for the causes of a malfunction, you can focus on the specified periods.

Driving with a broken air pressure sensor is acceptable for a short period. Jerking, rich fuel mixture and electronic errors accelerate the wear of spark plugs and engine parts. After detecting the listed symptoms, you should send the car for diagnostics or find the source of the problem yourself.

How to make sure the DPRV is working?

The easiest way to check the camshaft sensor is to connect a car scanner or a computer with an installed program corresponding to the make of the car to the diagnostic connector of the car. If the element is faulty, then after starting the engine the device will display the following error codes:

- P0340 – there is no signal from the camshaft position detector;

- P0341 – valve timing does not coincide with the compression/intake strokes of the cylinder-piston group;

- P0342 – the signal level in the electrical circuit of the DPRV is too low;

- P0343 – the signal level from the meter exceeds the norm;

- P0339 – an intermittent signal is received from the sensor.

Since the vast majority of car enthusiasts do not have scanners and laptops with software at their disposal, a more affordable method is practiced - checking with a digital multimeter. Diagnostics is carried out in 3 stages:

- Visual inspection of the wiring and continuity of the circuit for breaks.

- Measuring the outgoing current at the control contact of the DPRV.

- Testing functionality by approaching a metal object.

At the first stage, you need to ensure the integrity of the wiring and reliable contact of the connecting block. Carefully inspect the supply cables for kinks, cracks and melted insulation. Testing the current-carrying conductors and searching for a break is performed with the same multimeter. Don't forget to clean the connector contacts from oxidation.

After checking the electrical wiring, proceed to diagnosing the camshaft sensor itself. Instead of standard alligator clips on the tester, you need to use wires with needles so that you don’t have to be tricky with connecting to the connecting block. Diagnostic work is carried out in the following order:

- Open the hood and look for the DPRV on the cylinder head. Usually the element is placed on the end of the engine or the side wall of the cylinder head next to it.

- Using the vehicle's electrical diagram or data for a specific sensor model, determine the location of the two power contacts and the third wire going to the controller.

- Turn on the ignition and measure the voltage between the vehicle ground and the control contact of the element (on VAZ cars this is the middle wire, marked “C”). Normal multimeter readings are at least 90% of the supply voltage, that is, 12 * 0.9 = 10.8 V.

- If the obtained values are below normal, the sensor is faulty and must be replaced. Otherwise, perform the third stage of verification.

For final diagnostics, the part will have to be removed from the engine. Typically, the element is inserted into a hole in the cylinder head and secured with one bolt. Unscrew it, remove the DPRV and wipe off the engine oil. Do not disconnect the block with wires.

After connecting the multimeter to the middle contact and ground of the car, turn on the ignition again. Bring a steel object (for example, an open-end wrench) close to the end of the element, monitoring the display readings. A working sensor should respond to the approach of metal with a voltage drop to 0.2–0.4 V.

If checking the camshaft sensor with an iron object does not change the tester readings, the DPRV should definitely be changed. When purchasing a new part, keep one thing in mind: even original spare parts can be sold without a thin O-ring. You will have to find and buy it separately or use an old seal, provided that the material is not cracked or “dull.”

Sources: YandexZen, autochainik.ru.

What happens if the sensor fails?

The electronic control unit will only receive a signal from the crankshaft sensor indicating that a piston is at TDC. But without a camshaft sensor it will not be able to determine which one.

And just in case, fuel will be supplied to two cylinders. The engine does not stall. Engine power will decrease. But not every driver will be able to feel this, and the check does not always light up. Excessive fuel consumption can be determined after traveling a fairly long distance.

- Additional symptoms of the problem may appear - jumps in idle speed, jerking of the car during acceleration, in some cases the engine may turn off.

- Starting the engine can also be difficult. However, similar things happen when other systems and mechanisms fail. An example would be a faulty ignition coil or fuel pump.

Failure can only be determined through diagnostics.

How does the phase sensor work and how does it work?

So, if we consider this sensor separately, then in terms of design it is similar to many cars.

In other words, the VAZ 2114 camshaft sensor in functionality and purpose will not differ much from any foreign car of a similar class. Today, sensors based on the Hall effect are actively used. This effect is that a potential difference occurs in a semiconductor wafer when a direct current flows through it and it is placed in a magnetic field.

The Hall sensor itself is relatively simple: a square or rectangular semiconductor plate, on four sides of which contacts are connected (a pair of inputs for supplying direct current, as well as a pair of outputs for transmitting a signal). This entire structure is made in the form of a small microcircuit, enclosed in a housing along with a magnet and additional elements.

There are two types of phase sensors:

- slot sensor;

- rod or end sensor;

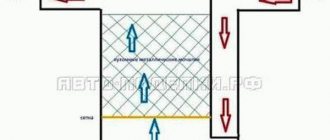

The slot sensor has the shape of the letter P; the camshaft marker (benchmark) passes through the section. The housing can be divided into two parts (one contains a permanent magnet, while the second contains a sensitive element). In both the first and second parts, specially shaped magnetic circuits are installed, which implement a change in the magnetic field at the moment the marker passes.

The end sensor is made in the shape of a cylinder, the camshaft marker passes in front of the end. In this type of sensor, the sensitive element is installed at the end, with a permanent magnet on top, as well as magnetic circuits.

It can also be added that the DPRV is an integral sensor, combining a sensing element (signal generation) and a signal converter-amplifier, which supplies a signal suitable for processing to the ECU. The converter is integrated into the sensor, which simplifies installation and configuration of the system

- Let's move on. As for the principle of operation, the sensor works almost the same on different cars (for example, camshaft sensor 2114). Such a sensor operates in tandem with a disk (drive disk), which is located on the camshaft. The specified disk may have a reference mark, which has one design or another. The main task is that during operation the marker must pass in front of the sensor (the passage can also be implemented in the sensor gap).

At the moment of passage in front of the sensor, the marker closes the magnetic lines coming out of it, this changes the magnetic field that crosses the sensitive element. In turn, the sensor is able to generate an electrical impulse. This impulse is amplified and then modified (converted), after which a fully prepared output signal is supplied to the ECU by the power plant.

Please note that slot and end sensors have different design disks. The slot sensor receives a disc with an air gap. This scheme assumes that the control pulse will be generated while passing the gap. An end sensor means that it uses a toothed disc (toothed drive disc). Short benchmarks can also be used. In turn, the control impulse is created at the moment of passing the reference point.

On engines with an injector, the disk and phase sensor are positioned so that the pulse from the DPRV is generated at the moment of passing TDC in the first cylinder. At the same moment, a signal is sent from the DPKV, after which the system takes into account the readings of these sensors. Next, the ECU sends signals for fuel injection and ignition, taking into account the order of operation of the internal combustion engine cylinders.

The synchronous operation of the DPRV and DPKV allows you to flexibly monitor any changes in the crankshaft speed and engine operating mode, as well as ensure accurate fuel injection and precise operation of the ignition system.

By the way, as for diesel engines, the system works exactly the same, but there is one distinctive feature. The system monitors the position of the piston in each individual cylinder. To implement this function, the master disk has several main and additional markers, which differ from each other in width.

When the system is operating, it is by different markers that it is possible to determine in which of the cylinders the piston is at TDC. In turn, taking this data as a basis, the ECU controls the operation of the injectors.

How to determine a malfunction without diagnostics

Determining the problem using a diagnostic computer is quick and easy and will show error codes that indicate a faulty camshaft sensor. But the breakdown can be determined without connecting a scanner.

To find the fault you need a multimeter. The easiest way to change the sensor. The replacement procedure is not at all complicated - unscrew the old one and screw on the new one. But hardly anyone has a new device in stock. To buy a new one, you need to know for sure what is broken in the car.

- To determine whether the sensor is faulty, you need to install needles as probes on the multimeter (included on some models).

- If not, you need to sharpen the ones you have.

- Having pierced the insulation of the wires, identify the two power wires and measure the voltage on them.

- There will always be more voltage on two wires - this is the coil.

- If the voltmeter shows a voltage of about 13.4 V, then the coil is working. In this case, the multimeter will show 12 V on the signal wire.

If the device indicates no voltage, what to do then. Then it’s worth checking the sensor’s reaction to metal. To check, you need to remove the sensor without disconnecting the wires.

With the ignition turned on, bring any metal object near the device. The multimeter must be connected to the signal wire at this time. As the iron approaches the sensor, the voltage should decrease to almost zero, no more than 0.5 V.

If this happens, it means the sensor is working. In general, to accurately determine the performance of the DPRV device, use an oscilloscope. Who has it hidden in the garage? In practice, the considered method using a multimeter is sufficient.

Verification methods

Like any other sensor based on the Hall effect, the DPRV cannot be checked by measuring the voltage on the contacts with a multimeter (“continuity tests”). Only a check with an oscilloscope can give a complete picture of its operation. The oscillogram will show pulses and dip fronts. To read data from an oscillogram, you also need to have certain knowledge and experience. This can be done by a competent specialist at a service station or service center.

Sensor signals are clearly visible on the oscillogram

If a malfunction is detected, the sensor is replaced with a new one; repair is not provided.

DPRV plays an important role in the ignition and injection system. Its malfunction leads to problems in engine operation. If symptoms are detected, it is better to undergo a diagnosis from competent specialists.

How to increase the resource of the DPRV

The engine camshaft position sensor is an electronic device that does not wear out. However, it may have a limited lifespan.

The duration of operation is influenced by the stability of the voltage in the on-board network, oxidation of contacts due to the influence of aggressive environments, including atmospheric fluctuations.

- Loose contacts due to inevitable jumps in engine temperature.

- To increase the service life of the device, it is necessary to keep the engine compartment clean.

- Most cars have a voltage indicator in the car's electrical circuit.

- You need to carefully monitor the readings of the on-board voltmeter.

- The DPRV body is made of plastic, so it is necessary to periodically carry out a visual inspection for cracks.

Their presence may indicate an imminent device failure. There should be no cracks on the wires connecting to the sensor. Hard wires indicate increased operating temperature.

The sensor cannot be repaired and will need to be replaced. And don’t think that you can do without it. The engine will require repairs in the near future.

Testing a two-wire inductive sensor

There are a number of common signs of a faulty DPRV. If you have these problems, you may need to replace it. These same symptoms can be caused by problems with the ignition or fuel injection systems. Thus, before replacing the DPRV, it is worth conducting tests to determine the real source of the malfunction.

If the check light comes on, your ECU is recording a trouble code. You can check for errors using a special diagnostic tool. Codes between P0335 and P0338 correspond to DPR problems.

This is probably the easiest and most accurate way to test and determine the problem of the DPRV. Unfortunately, the DPRV, as a rule, fails much earlier than the corresponding indicator lights up. To be constantly aware of the car's problems, it is worth conducting other types of testing.

RPM is the next method for checking the DPRV, which also requires a diagnostic tool. One of the scanner settings allows you to read the engine speed in revolutions per minute (RPM). Set up the scan tool to read engine speed and start it. The scan tool should read between 100 and 500 rpm. A low value indicates that the DPRV is not working properly. “0” means that the DPRV is completely out of order.