It is quite possible that a considerable part of our readers do not even know the meaning of this word. Indeed, this term is extremely rare in everyday life, except in places such as service stations or car services.

But the word shock absorber is familiar to all car owners. Of course, it is associated exclusively with the chassis of the car. Meanwhile, shaking and vibration are harmful not only to parts and components of the chassis. Considering the quality of Russian roads, one can imagine the loads the power unit is subjected to. And although it has standard protection against such troubles, in some cases it is clearly not enough.

The same can be said about the steering wheel - an organ that for the driver is the very place through which he is constantly in contact with his car. And such contact does not always bring satisfaction - if the steering wheel shakes, it causes quite noticeable discomfort to the driver.

Special dampers help avoid such situations. Essentially, these are miniature shock absorbers that allow damping (smoothing) vertical and other types of vibrations and vibrations.

How to install a damper on a car

Before describing the damper installation procedure, it is advisable to say a few words about its design features. So, the standard device consists of the following elements:

- two chambers, which are separated from each other by a partition;

- small container with oil;

- adjustable valves;

- special spring (for certain models);

- fastening elements.

From everything described above, it becomes obvious that there should be no difficulties in attaching the damper. True, in some cases you will have to show some ingenuity. An important point is the ability to adjust the device for a specific type of car and load (vibration), which will need to be “pacified” in the future.

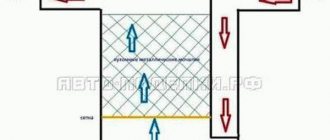

The most common way to enhance steering is by using a damper. To do this, one end of the device is rigidly attached between the steering rods, and the other is secured to the frame or body of the car.

When choosing an installation location, it is important to consider that the shock absorbing parts must have a minimum level of movement relative to each other

This is important because of the design features of the damper, which itself is quite rigid, and if you try to stretch it in the other direction, you may have the opposite effect when the vibration damping device resists during long turns and involuntarily pulls your steering in the opposite direction . It must be remembered that choosing the right damper depends on the type, weight, design of the vehicle, further loads that the vehicle will experience, as well as its operating conditions

Typically, the devices have a universal shape and size, which allows them to be freely attached to virtually any car. But due to the different levels of resistance to vibrations and the possibility of absorbing them, it is important to determine exactly what is suitable in your case, so as not to get the opposite effect

It must be remembered that choosing the right damper depends on the type, weight, design of the vehicle, further loads that the vehicle will experience, as well as its operating conditions. Typically, the devices have a universal shape and size, which allows them to be freely attached to virtually any car.

But due to the different levels of resistance to vibrations and the possibility of absorbing them, it is important to determine exactly what is suitable in your case, so as not to get the opposite effect

Share information with friends:

Furniture industry

Any modern design is equipped with a damper, because with such a component things can become much more practical and convenient.

The device is specially designed for each furniture model, the size and load are adjusted. Doors in rooms can open smoothly, the knock from closing is smoothed out as much as possible thanks to such a modern device.

It is no longer possible to imagine flaps without furnished samples, because they not only prevent noise, but can also make use comfortable. All parts are made from high-quality materials, the service life is quite long if the item was produced taking into account technological requirements.

Application

Hydraulic and pneumatic dampers are used in hydraulic systems, automatic regulators and measuring instruments. Hydraulic dampers are divided into pulsation dampers, flow stabilizers, pulsation dampers and water hammer dampers. Also, to varying degrees, standard piston, balloon and diaphragm accumulators are used as hydraulic dampers.

In electrical machines, a damper (damper winding) is an inductor that prevents a sharp increase in switching currents or voltages in electrical circuits; for example, in the event of a short circuit or interference.

In stringed musical instruments, a damper is a device for stopping string vibrations, consisting of separate blocks (for a piano) or strips (for a harp), covered with soft felt (filt).

Suspensions of cars and other vehicles use damping devices called shock absorbers.

In acoustic systems (so-called “speakers”), a damper is a rim that secures the membrane of the sound element to the frame. Usually made from polymer materials (for high-frequency elements), rubber or foam rubber (for mid- and low-frequency elements). Used to dampen residual vibrations of the membrane.

In aviation: aeroelastic oscillation damper of an aircraft is an independent on-board electronic system or subsystem as part of an automatic flight control system (ACS), designed to automatically dampen short-period oscillations of an aircraft in flight, which inevitably arise when flight conditions change and, most importantly, to prevent involuntary rocking of the aircraft by the pilot, which can lead to significant overloads and structural failure. In technical terms, it consists of a group of gyroscopic sensors that control the angular movements of the aircraft in space, an electronic circuit for processing and amplifying damping signals and actuators connected in series to the mechanical control wiring, or these signals are mixed with other ACS control signals

The problem of longitudinal progressive swing was acutely manifested on the supersonic bomber Tu-22, for the same reason the experienced Su-27 was lost. The problem of lateral movement is still relevant for almost all heavy (including passenger) aircraft, and is referred to as the “Dutch step”. Almost all large passenger aircraft have automatic damping.

- In risk management, a damper

is a threshold value of safe risk for an enterprise. The risk damping mechanism involves analyzing possible threats or factors that give rise to these threats, determining security thresholds, and identifying the range of conscious risks that an economic entity is ready to take. - In programming, a damper

is a system for balancing the load on system components during surges in the data arrival rate.

Types of devices

There are a huge number of types of products aimed at softening any process; a regular rubber gasket can also be called a damper, because the function is performed to the maximum, and the structure of the component is very simple.

Devices are divided into groups; it is customary to distinguish between hydraulic and pneumatic devices, which are divided into types, the first type is divided into:

- Stabilizing flows.

- Pulsating.

- With the ability to dampen water hammer.

- Dampeners.

Hydraulic devices can act in the form of membrane, piston and balloon accumulators aimed at mitigating any action.

Engine damper

Engine damper and its installation

Installing it, in fact, is not very difficult. One end of the damper is attached to the car body, and the other to the engine. But how to secure it is already a question.

Therefore, first we will look at the fastening of the damper, intended for installation only on Mazda 3 cars. The damper kit for this car includes the shock absorber itself, a mounting bracket installed on the engine, a mounting ring for the body, bolts and studs.

Installation is not particularly difficult. All this will be mounted in the engine compartment on the right side in the direction of travel.

The mounting ring has a special shape for installing it on the body at the attachment point of the front pillar. To install the ring, just unscrew the rack mounting bolts and place the ring so that the holes in it coincide with the rack mounting holes. Then the bolts need to be installed in place and tightened.

The mounting bracket is fixed to the engine, on the platform below the oil filler plug. To secure it, use the studs included in the kit.

Then a damper is installed between the fasteners and secured with bolts. At this point, the installation of the vibration damping device on the Mazda 3 can be considered complete.

This element is somewhat more difficult to install. If it is universal and does not have special fastenings.

The damper can be installed relatively easily if the car has a suspension strut running under the hood. It is to this that one end of the damper can be attached.

To attach to the engine, it may be necessary to manufacture a mounting bracket. The main thing is to choose the right mounting location. You can press the manufactured bracket with some engine bolts. In general, here it is already a matter of choice for the car owner himself.

If there is no spacer, some people make their own mounting ring to the car body. In general, the mounting method is not particularly important, the main thing is that one end of the damper is attached to the body, and the other to the engine.

What is the price?

You can purchase such a device for about $70. But there are devices that are more expensive.

If your hands grow from the right place, you can save money on installing a damper.

So it turns out that such a useful device does not cost the driver very much. Its features are well worth the price.

But we also note that such a device needs to be installed only on those cars that regularly drive off-road. There is no need for such an upgrade for ordinary small cars driving around the city.

But if you have already decided to equip your “iron horse” with such a device, perform the installation carefully so that the “pros” of the damper do not turn into its “cons”.

Advantages and disadvantages of auto dampers

If you have not yet decided whether you need such a device or can do without it, you should familiarize yourself with their advantages and disadvantages.

Let's start with the pros:

- significant shock mitigation. The wheel axle is the first to take on the load when hitting road irregularities, but standard shock absorbers do not cope with their task completely and not always. A modern damper reduces the vibration force by about 30%, both in relation to the steering wheel and in relation to the engine. Obstacles such as tram tracks, slab joints, wide cracks in the road surface, and even speed bumps will be overcome much more smoothly;

- Suspension knocks are always an unpleasant sound. Steering/engine dampers allow you to get rid of it, if not completely, then significantly;

- Vibration of a car during heavy braking is also not a pleasant phenomenon, as is the case when accelerating above 100 km/h. It is also worth mentioning a similar phenomenon with deformed disks, in the absence of proper wheel balancing. Additional shock absorbers will eliminate this problem;

- A steering damping device can improve vehicle handling when driving at above-average speeds.

But this node cannot be called ideal either, and here’s why:

- When installing a damper on the steering wheel, at first you will have to get used to the “wobbiness” of the steering wheel, and it is far from a fact that you will come to terms with it;

- the same can be said about the effort applied when rotating the steering wheel.

However, according to a statistical survey, over 80% of drivers who have installed additional shock-absorbing units on their cars are satisfied with their performance.

At the same time, there is a risk that you will fall into the opposite camp - every fifth car owner either did not feel the difference before and after installing the damper, or was dissatisfied with its performance.

Device properties

Although this device effectively eliminates unwanted vibrations, it is not noticeable when driving on smooth roads. If the mechanism is installed correctly, the driver should not feel additional resistance when turning the steering wheel.

The damper is only a shock absorber. He is not able to reduce the shaking to zero. However, he is able to make it less noticeable.

Easier to manage

When the wheel gets into the groove, the steering wheel begins to twitch. And because of the bumps, the steering wheel shakes and turns involuntarily. If you dampen the vibration created by driving over uneven roads, you can significantly increase the level of vehicle controllability on unpaved roads.

This is a very important property. After all, getting rid of the need to hold the steering wheel with all his might, the driver gets much less tired while driving.

Even tire wear

Often, when driving off-road, the tread pattern of your car tires wears off unevenly. This is a dangerous defect that can make the car uncontrollable on asphalt.

However, thanks to the damper, tire wear occurs more evenly.

Efficiency

Thanks to the damper, driving becomes more efficient. The car drives and maneuvers more obediently. This works well at high speeds.

Consequently, this makes the driving process not only more comfortable, but also safer.

Steering damper

Installing the steering damper

Such devices can also be sold as a kit with all fasteners. But some people simply purchase a damper from Mercedes Benz and install it on their car.

This is located along the steering mechanism. As in the case of the engine damper, one end of it is attached to the body, and the other is attached directly to the mechanism at the point where the rods are attached to the rack.

Some versions come complete with a special spacer, making the structure more rigid and reliable.

Let's look at how to install a damper from Mercedes Benz. So, there is only a damper, but you need to provide mounting points for it.

To do this, you need to unscrew the steering gear mounting bracket, the one closest to the expansion tank. Next, a plate with a hole for attaching the damper is welded to this bracket.

Something else useful for you:

- Reasons why the shock absorber knocks

- MacPherson suspension - design, principle of operation, advantages and disadvantages

- How to choose the right shock absorber for a car

Video: Installing a Damper on a UAZ Patriot

https://youtube.com/watch?v=yGliSjVdfqg

Then you will need an adapter to attach the damper to the mechanism rack. To do this, a plate shaped like a heart is cut out of metal.

Three holes need to be drilled in this plate. Two should coincide with the holes for attaching the rods to the rail. Below these two holes there should be another one - for attaching the damper.

After this, you can begin assembly. First, the mechanism fastening bracket is installed, and the end of the damper is already attached to it.

Then you need to unscrew the bolts securing the rods, press the prepared adapter to the rods and screw the bolts back. Then the other end of the damper is screwed to the adapter.

If you purchase a kit that includes a special spacer, then installing everything will not be difficult at all.

In this kit, in addition to the damper itself and the spacer, there are also brackets for fastening the mechanism, but modified to install a spacer and a vibration damping element. Usually the kit also includes an adapter.

All that remains for installation on the steering mechanism is to remove the factory mounting brackets and install them in place that come with the kit.

Then the spacer is installed and secured. All that remains is to secure the adapter and install the damper.

All this work is not so complicated, but the benefits of using dampers are significant. Car owners who have installed an engine damper note a decrease in vibration of the power plant, and gear shifting becomes “clearer”.

As for the steering dampers, it is noted that impacts from the wheels on the steering wheel are softened, vibration of the steering wheel during braking is reduced, and knocks from the suspension are reduced.

What materials are they made from?

In the production of dampers, different materials with unique performance parameters are used. To ensure that the fittings serve for a long time, are functional, and provide the user with silent operation of the cabinet, silicone and rubber dampers are used.

Such shock absorbers last quite a long time, although breakdowns sometimes occur. The material has an affordable price and incommensurable benefits.

Silicone

The silicone shock absorber is made in the form of a primitive round piece, which is highly soft. Silicone parts have an adhesive side, which is used to fix them to the surface.

The self-adhesive damper is also unique in that it can protect a small child from injury. Children often love to play with the doors of kitchen units and drawers in the closet, pressing their delicate fingers. Thanks to the presence of such shock absorbers, this can be avoided.

Manufacturers offer different options for silicone shock absorbers:

- transparent;

- white;

- beige.

This allows you to choose the most invisible option against the background of furniture.

Rubber

The rubber damper is a mortise part located in places where one surface constantly impacts another. For example, at the end of the shelf that is in contact with the door. Shock absorbers of this type perform the functions of a shock absorber, as well as a sealant for the façade vestibule.

The service life of such products is quite long. If necessary, it is quite possible to install them yourself at home.

Steering damper

What is a steering damper for? The reasons are the same: dampening the shaking of the steering column when driving over uneven roads. Such a buffer device is capable of effectively absorbing both vibrations and shocks, which are transmitted to the steering thanks to its rigid connection to the vehicle’s suspension. The looser the steering wheel, the more noticeable the vibration and shocks are on the fingers and hands holding the steering wheel. The steering damper is able to cope with this problem.

The secondary function of such a device is to return the steering wheel to the zero position, which helps maintain a straight trajectory of the vehicle. It is after falling into holes that the car usually goes off the track. The damper in this regard simplifies the driver’s task, but at the same time, without the presence of power steering (regardless of the type), quickly turning the steering wheel will definitely become more difficult.

As in the case of a damping device for the power unit, the steering vibration damper is structurally a smaller copy of the shock absorber. If it is a single-acting device, it is usually equipped with a spring. When assembled, such a kit resembles a shock absorber strut, but with much smaller dimensions.

The target audience for the steering damper is clear - these are cars that often drive on frankly bad roads (a fair question arises, where are our good roads?). Jeeps and other fairly heavy vehicles are characterized by increased hand fatigue, so for these categories of vehicles, steering shock absorbers will also be useful.

Physics of the process

An important property of the damper

is a decrease in the quality factor of the oscillatory system to which it is connected.

The principle of operation of the damper

is the irreversible conversion of the energy it receives into heat or destruction of the material. For example, oil in the shock absorber prevents its parasitic vibrations after the wheel passes an obstacle. The oil heats up.

Very good damper

is sand: when it absorbs energy, grains of sand rub against each other (

heating occurs

) and are crushed (

mechanical destruction

).

What is a steering damper used for?

photo: uaz.ru

Thus, the steering damper can be thought of as a kind of shock absorber operating in a horizontal plane (which it is from a technical point of view). But why is it needed?

In particular, if we take the main purpose of using a horizontally located damping element, we can say the following: the main purpose of the damper is to dampen unwanted vibrations of the steering elements, which can greatly interfere with the control of the car due to the accumulation of driver fatigue, and also affect the wear of suspension elements and steering, as well as other parts of the car, in particular tires.

Its use is especially relevant on uneven surfaces, which, when the car passes them, respond by twitching and moving the steering wheel from side to side. The driver has to fight with them, often jeopardizing the safety of driving the car.

Also part of the work of the steering damper is to return the steering wheel to its original position in order to keep the car in a straight line.

But, perhaps, the most important part of the damper’s work is to increase the vehicle’s directional stability when driving on asphalt roads and to avoid such a phenomenon as shimmy (also known as wobbling, in slang - “sausage”) - spontaneous vibrations of the front wheels when steering, arising from - for fastening play, deformation of the wheel support and lateral vibrations of the vehicle - a negative and extremely dangerous phenomenon:

Video taken from YouTube channel “Rare Parts Inc”

As you can see, with this phenomenon, the wheels, steering, and suspension begin to move uncontrollably in a horizontal plane, increasing their amplitude and trying to turn the car around its axis. It is almost impossible to drive a car in such a state.

The shimmy phenomenon is caused when hitting an obstacle or after one of the front wheels falls into a hole. The installation of a steering damper, also called a shimmy damper, can eliminate or minimize the negative behavior of the front suspension. It is this that will dampen all vibrations that will subsequently arise between the steering rods and the bridge.

From here you can draw several important conclusions so that your SUV does not end up in such situations:

1

It is important for jeepers to monitor the health of the front suspension and steering; 2

Monitor the serviceability of the steering damper;

2. Monitor the serviceability of the steering damper;

3. Do not make unauthorized changes to the steering elements and suspension of the car (tuning).

General information

Translated from German, the word “damper” means “to dampen, muffler.” By and large, this device is a kind of shock absorber, which is designed to prevent vibrations that occur in various systems, devices, machines, structures and structures during their operation. How to define the concept of “damper” in a general sense? What this is is quite simple to understand, since all devices that act soothingly and softly can be called this term.

Engine damper

A damping device for damping vibrations of a power unit first appeared in tuning studios as one of the important attributes of sports cars. But, as often happens with many innovations used in motorsports, they gradually migrated to production cars. Today this is still a rarity, but finding a motor damper in the most seedy auto shop is no longer a problem.

It is well known that vibrations with maximum amplitude on the engine occur during gear shifts. This behavior is especially typical on high-speed engines installed in luxury and sports cars. This is largely facilitated by the aggressive driving style, when a sharp change in the amount of torque is followed by a “sharp” pressing of the clutch and an equally rapid gear change. The result in most cases is a very noticeable and at least unpleasant jerk. On a regular car in city mode, such switchings are rare, but on the race track this is quite an ordinary occurrence. Standard pillows are powerless against it, regardless of their design. In addition, frequent jerks accompanied by shaking provoke accelerated wear of the pillows. An engine damper helps to avoid all these troubles.

So if you are asked what an engine damper is, you can safely answer: it is a miniature additional shock absorber that functions exactly like its larger brother, and is tailored specifically for the power unit. That is, vibration damping occurs due to the fact that the rod, together with the upper mount, moves in a chamber filled with oil under decent pressure, according to an inverse exponential relationship: first quickly, and then rapidly slowing down.

The principle of installing engine dampers is the same for all models, although the size and shape of the mounts are slightly different. Typically, these devices are attached to the studs of the body cups, at the location where the support bearing is mounted. The upper end of the damper is fixed to the block, most often in the area of the pillow.

When purchasing such a mini-shock absorber, you should take into account that they are manufactured focusing on a specific model or series, which allows you to take into account the parameters, shape, dimensions and features of the location of the motor. But you can also find universal products equipped with adjusting bolts that allow you to customize the damper to suit your needs.

Since installing a damper assembly is a one-time operation, it is best to do this at a service station. But if you want and have the appropriate skills, nothing prevents you from doing it yourself. The degree of rigidity is adjusted after installation in accordance with the individual preferences of the driver. The installation task is simplified if the kit includes fasteners - such kits are not uncommon.

How necessary it is to install a damping device on your car is up to you to decide. If the problem of vibrations practically does not bother you, if you are not a fan of tuning for the sake of tuning, then you shouldn’t bother buying and installing it. But when you often travel off-road, it’s worth considering.

Functions of the damping element

The damper is universal. The structure is installed where shaking is especially noticeable, and the car’s own shock absorption system does not work at 100 percent.

Properties of the auxiliary element:

- absorption of steering vibrations;

- creating a balance between vibration amplitudes while driving along complex routes;

- increasing the degree of ride comfort;

- improving safety indicators.

Installing a damper solves problems that arise when traveling on problematic roads. This element is especially effective during braking or impact. If the device is installed on the steering mechanism, the vehicle's handling at medium or high speeds is noticeably improved.

Source

Where is a damper used?

The most common use of dampers can be seen in the process of strengthening the protection of engines and steering systems.

It is in these places that the presence of additional vibration causes an increased level of discomfort. You need to understand that on modern sports or high-speed cars, the presence of dampers is provided structurally. But this does not mean that this device cannot be installed on a vehicle of another model.

It is important to understand here that the damper is technologically compatible with almost all types of cars. True, you will have to tinker a little with the fastenings, up to a small constructive intervention, in the form of welding special fastening brackets to the bottom or body, to which the damper will be attached

It should be noted that dampers are supplied with a minimum required set of fastening elements, which greatly simplifies the search for the necessary parts for their installation and fastening.

Now a little about when you should use a damper on cars. Of course, if the road is smooth, there are no potholes, and there are no various excess loads on the car. The role of the damper will be reduced to a minimum during car operation, so its use may not even be advisable. But if you are constantly driving on uneven terrain, where the car is subjected to tests of stability and structural strength, the occurrence of excessive vibrations is common.

It is in this case that the damper will be the ideal solution to reduce (and in some cases become the basis for its complete absence) the impact of vibration on the car body and on the steering. As a result, the driver, holding the steering wheel, will not feel hesitation, and during turns, the feeling that the steering wheel is not listening to you, or the wheels are turning in the other direction, will also not appear.

Damper devices are ideal for SUVs of various types and models, as well as vehicles that most of the time travel on country roads or roads with damaged surfaces.

Aviation technology

Modern models cannot be imagined without a damper, which is responsible for eliminating aeroelastic vibrations. This phenomenon can be found in any aircraft; the device dampens short-term excesses quite well, even in automatic mode, without direct human intervention.

The role of such a device is very important; it is impossible to talk about maximum flight safety if the aircraft is missing an integral part. The damper includes a whole system of gyroscopic sensors; without the device, the device will simply collapse or overloads will occur, and they pose a great danger when conquering impressive heights.

What is an engine vibration damper?

An engine vibration damper, or simply an engine damper, is a relatively new invention in the world of auto tuning. As a rule, such “tricks” are found on sports cars, but, like all other “bells and whistles” borrowed from motorsport, engine dampers have successfully “migrated” to production cars.

The largest engine vibrations occur during gear changes on high-speed engines of sports cars or cars “tailored” for sports. During a sharp change in torque and “sharp” clutch, the jerk when changing gears is quite serious and very noticeable by the driver. One or two of these jerks can be tolerated, but if it happens constantly, a drastic solution is needed. In such situations, engine mounts are either powerless or do not completely absorb vibrations and shocks; in addition, due to strong jerks and impacts, the mounts fail much faster.

As you can see, there are more than enough reasons to install an engine damper, provided that its installation is really justified, and the one who installs this part really understands what it is for and needs it. The dampers themselves are a miniature shock absorber that works on the same principle , like shock absorber struts, dampens vibrations through the tight movement of the rod in a chamber that is under high pressure and filled with oil. The principle of attaching engine vibration dampers is basically the same for all, the configuration or dimensions of the mounts may differ, but the attachment points, as a rule, are the same for all. The engine dampers are attached to the studs of the body cup in which the support bearing is installed, and the second end is attached to the engine block (for example, to the engine mount) or one of its elements. As a rule, dampers are made for a specific engine model, taking into account the characteristics of the motor, as well as the strength and amplitude of its vibrations. However, there are also universal engine vibration dampers, which can be adjusted, as they say, “to suit you” using adjusting nuts.

What is it for?

The auxiliary device is similar in appearance to a conventional shock absorber strut. This is a part with holes, valves and fasteners. If the vehicle is equipped with a steering damper, the driver controls vibration damping using a control lever. The engine damper mechanically follows the action of the suspension shock absorber.

damper on car suspension

Dampers are necessary to relieve vibrations in cars with high-speed engines or to eliminate vibrations in the steering mechanism.