01/26/2022 8,790 Engine

Author: Ivan Baranov

Over time, any component or unit of the vehicle will need repair. Many motorists are faced with the issue of crankshaft grinding as a result of wear on the working surfaces of various bearings. This material is dedicated to the technological process of restoring crankshafts.

[Hide]

Main Reasons for Grinding

The first and main condition for starting grinding is the uneven installation of the cylinder head gasket and its subsequent burnout. The reasons for this appearance may be overheating of the engine, the ingress of small mechanical parts, or water, which, if detonated, can damage the gasket.

The gasket itself is not so simple; it consists of several layers and a frame; it is made from perforated sheet steel. The main purpose is to seal the joints of two parts. Boiling of the engine, bubbles in the cooling system, change in oil color are the first indicators that the cylinder head gasket has become unusable.

Engine tuning is often considered the second reason for grinding. A sign of this is a decrease in engine power when you press the accelerator pedal, or simply the engine stops pulling. I would like to say right away that the process is not easy and will require the expenditure of both time and money.

To bore the crankshaft or not

Now you need to determine whether the crankshaft should be bored or not, pay attention to the crankshaft journals, marks and wavy grooves are visible on the journals, run your finger along the journal, if marks and grooves are visible on the journal and by running your finger you will feel the slightest waviness, don’t even think about it, take it to boring crankshaft. But don’t buy liners for the crankshaft right away; after boring, the driller will tell you which liners to buy, as it happens that due to excessive wear on the crankshaft journals, they bore two sizes larger

Photo. Heavily worn-out crankshaft journal of the Volga

It rarely happens that the crankshaft journals look good, pay attention to the main bearings and if you see shiny abrasions on the bearings, this indicates that the crankshaft is weakened and has a large gap, and hanging in the bearings it fills with shiny strips

Photo. Liners with signs of heavy crankshaft wear

But don’t get confused, shiny stripes on the liners may also appear when installing the crankshaft when tightening the cushion with the liner, when the crankshaft becomes clamped and barely turns or jams. In this case, firstly, the grinder made a mistake when grinding the crankshaft, secondly, debris got under the liner, so when installing the liners, carefully wipe the beds (the place where the liner is installed is called the bed).

If you simply replace the liners without grinding the worn crankshaft, then it’s like throwing money away; the effect will be zero. Also, if the engine had very low oil pressure before the repair (the pressure light is on at idle), this already indicates that it is necessary to bore the crankshaft for repair bearings.

It’s better not to be lazy and take the crankshaft for boring, and pay a little extra money, than to simply replace the bearings.

You can't fool iron!

Using these tips, you can easily determine without a micrometer whether you need to grind the crankshaft or not.

Replacing bearings without removing the engine

Sometimes a car requires very minor repairs, just replacing the liners, but is it really necessary to remove the engine, look for a hoist or several assistants for such a simple procedure?

When it comes to such a need, replacing the liners without removing the engine will help. This simple type of repair does not require a large number of tools, but it does require some skill, so you should immediately evaluate your skills. Inside the engine on the crankshaft, the liners are attached to a tendril, which is responsible for fixing the bearing in the engine bed when it is running. And lubricant is supplied to them through a special groove; a lack of lubrication always leads to the appearance of snags and jamming. Due to such liners, the wear time of the part is reduced, so they must always work at one hundred percent, otherwise major repairs cannot be avoided in the near future. However, during the trip you may find:

- Rotating the liners. If the fastening tendril has jumped out of its place (sometimes due to lack of lubrication), then it begins to rotate. Due to its rotation, scuff marks will appear on the journal, leading to the need to grind the crankshaft.

- Backlash. This breakdown can be easily heard by the knocking sound of the crankshaft. As soon as you hear suspicious knocking noises, repairs should be made immediately, without the need to remove the motor from the mount.

General types of grinding

Today, there are three main types of shaft grinding: fine, preliminary, and finishing. When using a preliminary type of grinding, it is possible to achieve an accuracy of 8-9 in terms of quality

As for the second important factor - roughness, it ranges from 0.4 to 6.3 microns. Grinding of finishing type shafts is possible only after the workpiece has undergone heat treatment

This procedure allows you to increase the accuracy to 6-7 quality and reduce the roughness to 0.2-3.2 microns. The most accurate method is fine grinding, which allows you to achieve a roughness of 0.025-0.1 microns. The process is also divided into two types - round and centerless.

Round grinding

The machine for grinding crankshaft journals or for any other round and cylindrical products is performed on cylindrical grinding machines. In this case, the workpiece will be mounted in the center, in the chuck or collet of the device. Today, there are two main types of cylindrical grinding: longitudinal feed and plunge method.

As for the first type, this is a procedure that takes place using reciprocating movements. In this case, the part moves relative to the grinding wheel.

Grinding by plunge method is carried out with a circle, the width of which should be greater than the length of the area that needs to be processed. In this case, the circle will have only a transverse feed. If you use a shaped wheel, you can process several parts at the same time. Since this method is more productive than with longitudinal feed, it is used much more often in large-scale and mass production.

In what cases is it necessary to grind the crankshaft?

The crank pulley is a rather complex engine element in design and operation. Its purpose is to convert the reciprocating movements of the pistons into torque. To explain in a nutshell, the crankshaft allows the vehicle to move; without it, no engine can operate.

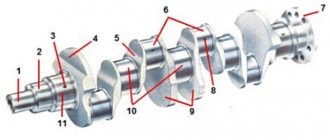

Engine crankshaft

Before we tell you what crankshaft boring is, let’s figure out what affects its wear:

- In the engine block, the crankshaft is mounted in the lower part on at least five bearings (main bearings). In addition, there is also a number of connecting rod bearings (depending on the number of cylinders). The need to bore a component arises as a result of wear on the connecting rod or main elements.

- This is also affected by the connecting rods, which are connected to the pistons. They are mounted to the eccentric rings using plain bearings.

- If the car is operated for a long time without servicing the rings and so-called bearings, the level of lubricant pressure in the system is significantly reduced. Even the engine can fail from this.

It is in such cases, if you do not want to purchase failed components, that the crankshaft is bored, that is, the process of restoring its performance. Professionals in this industry have long known that the design of the main and connecting rod sliding elements of the crank pulley is carried out using replaceable liners. In the event that their wear reaches critical limits, it is necessary to disassemble the engine and install new components.

Reasons why boring is necessary

In fact, the reasons why the process of restoration and grinding of the crankshaft is carried out are very banal. And they are related exclusively to the operation of the vehicle.

The reasons for the need for restoration are as follows:

- If you regularly use low-quality lubricant. Poor quality lubricant directly affects the wear of all components.

- If you change the engine fluid much less often, without observing the replacement period. This includes filter elements. In addition to this, if the oil is of low quality, then the need for boring will come much earlier.

- Another drawback in operation is insufficient warming up of the engine before driving. This is especially true for operating a vehicle in the winter season. In this case, the car needs to be warmed up properly.

- If the vehicle is regularly used under heavy loads.

- If moisture somehow gets into the internal combustion engine.

- In the event that increased wear of the seats occurs, since the mating elements of the internal combustion engine were initially of low quality. Or, during the operation of the car, the heat treatment regime was violated.

Symptoms of the need to repair crankshaft journals

So, under what symptoms does it become necessary to restore the node and repair the necks?

This usually occurs when the following defects occur:

- If, when dismantling the unit, you notice that scratches have formed on the rubbing surfaces as a result of mechanical impact.

- If the permissible gap sizes have increased significantly, this is also a disadvantage.

- If ring marks have formed on the surface of the necks.

- If the engine overheats, the liners jam or melt.

crankshaft

#1 savich200

- City: Kovel

- Car: Opel Vivaro 1.9, 74kW

- @Mention

- Top

- Answer

- Quote

#2 Aviahim1971

- City: Ukraine, Lviv region.

- Car: opel vivaro 1.9 CDTI 2004 L2H1

- @Mention

- Top

- Answer

- Quote

#3 savich200

- City: Kovel

- Car: Opel Vivaro 1.9, 74kW

- @Mention

- Top

- Answer

- Quote

#4 Aviahim1971

- City: Ukraine, Lviv region.

- Car: opel vivaro 1.9 CDTI 2004 L2H1

- @Mention

- Top

- Answer

- Quote

#5 ParovozVed

- City: Scotland. Falkirk

- Car: Vauxhall Vivaro 1.9 cdti 2005 Hunday i30 2009 Triumph street triple675 2008

- @Mention

- Top

- Answer

- Quote

#6 fasttoomas

Experienced Opel Driver

- City: Narva, Estonia

- Car: OPEL VIVARO

- @Mention

- Top

- Answer

- Quote

#7 vectra20

- City: Kyiv (Irpen)

- @Mention

- Top

- Answer

- Quote

#8 fasttoomas

Experienced Opel Driver

- City: Narva, Estonia

- Car: OPEL VIVARO

- @Mention

I think that there are similar advertisements on the net. We can also grind the journals of the F9Q crankshaft - to fit the existing liners with a repair increase of 0.25 - 0.50 mm.

Other auto parts "Glyco"

Ch0024598 Main bearings Renault F9Q/F8Q/F4R/F4P 97-> (w/w) +0.25 Glyco, Germany kit 249.00

bedtime horror story

Yes, there are main and connecting rod bearings as well as side wedges for repair +0.25 +0.50

Crankshaft loose

The crankshaft driller may make a mistake and loosen the crankshaft, then the engine will not have good oil pressure, and also because of this the engine may knock quickly.

Photo. This way you can turn the crankshaft on a VAZ engine with a key.

You can check for weakness in the crankshaft like this. Tighten the cushion and spin the crankshaft; if it spins very easily, it doesn’t hurt to check whether the crankshaft is loose or not.

Usually, after a good boring, the crankshaft does not clamp and turns easily. Remove the cushion, take out the liner and place chocolate foil under the liner, tighten the liner, if the crankshaft gets tight or starts to turn noticeably more difficult, it means that this crankshaft journal is bored perfectly, pull out the foil from under the liner and check the next pillow.

Photo. It is shown how to place foil under the liner, and be sure to cut off the excess foil with the tip of a knife; it is shown here that the foil is cut off on one side and not on the other.

If, after placing foil under the liner, the crankshaft does not turn more difficult, it means that this crankshaft journal is weakened, place more foil under this cushion between the liner until the crankshaft begins to turn more difficult. After all the pillows have been checked and found to be loose, and if more than one foil had to be placed under the liner, then you will have to completely remove the crankshaft and under those journals that had to be placed more than one foil, you will need to divide the foil strips into two and place half of the foil under the liner in the block. Install the crankshaft, tighten it, that's it, you have perfectly adjusted the liners, and the crankshaft will work perfectly in the engine.

Be sure to put a nail in the foil under the liner and make a hole through the holes in the liner for the oil to pass through.

Machining the crankshaft end directly on an Audi/VW engine (once again)

WRH2E Annihilator

My car has a 1.9 TDi engine.

After purchasing it a year ago, I purposefully set out to check the tightness of the central bolt of the crankshaft gear: the new gear turned out to be screwed on almost by hand. I tightened it properly with a proper powerful wrench and drove slowly, fighting my fears. Now, finally, I have the opportunity to get serious. Having removed the entire timing belt, I found the flat on the shaft for the protrusion in the gear to be quite satisfactory, not dented - I was lucky. And the end of the shaft was leveled. The design of the device was looked at on one well-known resource: https://vwts.ru/forum/index.php?showtopic=79754 For trimming, a STANDARD CUT-IN D 40.17, d 13, L 45 was used (easily found on the Internet using these parameters) . It was necessary to turn only a guide for it: in one clamp of the workpiece in a lathe, a cutter was made (you can’t use a die!) an M14×1.5 thread on a length of 30 mm for screwing into the crankshaft. Next, at a length of 50+65 mm, the guide body was sharpened to fit the internal diameter of the counterbore (13 mm). Then an M12 thread was made at the end in order to use a nut to press down the spring that presses the cutting tool to the part. In general, everything is in the photographs:

I installed the tool (the length of the thread for the crankshaft had to be reduced to 28 mm), made half a turn, saw that it was removed smoothly, turned it a couple more turns - and it was done. I poured a generous amount of anaerobic adhesive on the end of the shaft and clamped the new gear with a new bolt.

Source

Grinding technology

As noted earlier, the process is quite complex and responsible. You need to start sanding from the weakest point. In most cases these are main or connecting rod journals. This is especially true for small-diameter necks that do not have a full counterweight. They wear out first. If restoration has already taken place before, then you need to start from substandard points. For example, from the crankshaft shank. This is due to the fact that you can lose the parallelism of the necks and everything will need to be redone.

Some companies are collecting information about engines whose crankshaft grinding did not give the desired result and the internal combustion engine quickly failed. Most often, the cause is a crack that starts from the fillet at the processing site and moves into the area untouched by grinding. The reason is poor quality work of a specialist

Particular attention should be paid to modern forced engines

Grinding the steering rack

Grinding the steering shaft is also a fairly common operation. Experts recommend using it only if the rust on the device is surface type. In addition, the maximum reduction in diameter is allowed no more than 0.1 mm. If the corrosion is considered deep, then it is allowed to grind down the part by 0.5 mm, no more. If grinding occurs independently, it is very important that the working area of the shaft is perfectly ground. Most often, when processing manually, sandpaper is used for this. Processing usually starts with very coarse P80 paper. Next, the grain size is reduced, and the finest sandpaper is used for final processing.

HOW TO GRIND A CRANKSHAFT WITH YOUR OWN HANDS

Designers and engineers from all over the world are struggling with the force of friction, this is the main cause of damage to parts. The working surface of the sliding bearings constantly wears out and car enthusiasts have to think about grinding the crankshaft. The process of processing parts is quite complex and must be approached with full responsibility. It must be carried out by specially trained workers using turning equipment for the appropriate purpose. The owner of the car only needs to understand for what reasons the crankshaft is being treated and take timely actions to help prevent frequent engine repairs; for this, the crankshaft is checked in Minsk and other cities in order to avoid serious damage to the internal combustion engine.

WHY IS CRANKSHAFT GRINDING DONE?

The crankshaft is a complicated part. In simple terms, thanks to him the car drives. And without it, the engine refuses to work.

- the crankshaft is mounted at the bottom of the engine block on five (sometimes more) bearings, the number of connecting rod bearings is equal to the number of cylinders

- connecting rods connected to the pistons are attached to the eccentric journals using bearings

- An area of special attention for a car owner is the connecting rod and main bearings. Oil flows through hidden oil channels

- During operation, the liners and journals wear out, the pressure decreases and the engine may fail

The main and connecting rod bearings use replaceable liners made of special steels. When wear reaches its final limits, you need to disassemble the engine and install new liners, they are slightly thicker than the old ones. The diameter of the journals, although it decreases with wear, still does not allow the crankshaft to be installed on new bearings right away.

The outer surface of the neck will have to be ground down to a diameter that allows you to install a new repair kit of liners. The work of adjusting the diameter of the journals to fit the new liners is called crankshaft grinding. The diameter changes by 0.01 mm, or even 0.01 mm, and the number of grindings is limited by the number of repair sizes of the liners.

CRANKSHAFT - HOW IS IT GRINDED?

Some car owners like to repair their vehicles themselves. Russian-made cars are especially suitable for this. But there are some types of work that are naturally impossible to perform in an ordinary average garage. One such procedure is grinding the crankshaft yourself. For this, a high precision lathe must be used.

In addition, the turner performing the work must undergo training, and in order to carry out the work efficiently, he must also have experience. It is advisable to give the crankshaft removed and cleaned to the turner.

Do-it-yourself crankshaft polishing – Do-it-yourself crankshaft polishing

Once upon a time, at the dawn of entrepreneurial activity, when I decided to get into car repair, I discovered that the country’s former communist leadership did not care at all about producing a sufficient number of spare parts, in particular crankshaft liners, for the cars available to the population.

And it is necessary to repair, despite the fact that you can’t buy liners! This is now, the engine is disassembled and the liners are removed without looking in the trash. In any store you want. And then you could look for a poor box with eight inserts for half a month and not find it. So, back then, nothing removed from the engine was simply thrown away; everything was checked, measured, and sorted. for possible further (not from a good life) use.

It was then that the phenomenon with the inserts that I mentioned was discovered. When the crankshaft journal is worn by one tenth of a millimeter, the wear of the liner usually fits into one hundredths, or even less for the upper, less loaded liner, and no more than a couple of hundredths for the lower, more loaded one. So they collected those slightly worn inserts in a separate box in case the appearance of this type and size in the retail chain was not expected in the coming months.

And so not only with liners, but also with rings and pistons. everything was carefully checked, measured, sorted. And when foreign cars are used, then in general you can write novels. At first there were no spare parts for those at all. This is where there was room for technical creativity!

Not now! The stores are bursting with spare parts, what kind of new inserts do you want, who will measure the old ones? Nobody. So this interesting fact about their low wear has been lost.