Author: Evgeny Zhivoglyadov. Date of publication: November 23, 2022. Category: Automotive equipment.

Every car enthusiast wants to improve the technical characteristics of their vehicle to one degree or another. One of the recently quite popular tuning options that improves acceleration dynamics is replacing the standard flywheel with a lightweight version. Like any modification, this modification has both positive and negative sides. And before you start replacing the flywheel, you need to weigh the pros and cons.

What characterizes a lightweight flywheel?

A lightweight flywheel is a product from which a certain amount of metal has been extracted.

For example, many VAZ car owners from the classic series lighten their flywheel by one and a half, two, or even 3.5 kilograms. At the same time, the factory weight of the device is about 7.5 kg.

With the latter option, the product will weigh about 4 kg and it is believed that this is the limit for VAZ cars, since going beyond it to a lesser extent can affect the strength characteristics of the flywheel itself. It's not worth the risk. Although, with the right approach, the weight of the product on a VAZ can be reduced to 3 kg, but more on that later.

But usually on VAZ models the weight of the flywheel is reduced by 1.5 kg, which cannot negatively affect its strength characteristics.

But everything is not as simple as it seems; there are many pitfalls that are important to know about.

Price

Typically, the installation of these elements is carried out by owners of domestic cars. Now there are a lot of stores selling ready-made, lightweight flywheels. Their weight is about 3.9 kilograms for a one and a half liter engine.

What is the price for a lightweight VAZ flywheel? The cost of sports elements starts from 2.2 thousand rubles (for VAZs of the “tenth” family). There are also ready-made kits for classic Zhiguli models. For example, for a Soviet “kopeck” a lightweight flywheel costs 2.65 thousand rubles. The most expensive flywheel is for the VAZ-2181 cable box. Its price is 2.9 thousand rubles. Lightweight flywheels for Niva (including Chevrolet) are also available for sale. But experienced motorists say that this part is completely useless on an SUV. Such cars, on the contrary, must have good torque. Especially if this car is being prepared for off-road use.

How much power does a conventional flywheel take on?

On any vehicle, no matter a truck or a passenger car, the flywheel is an integral part of the engine starting system.

It is thanks to this device that the torque from the starter Bendix is transmitted to the crankshaft.

But after the car starts, the flywheel does not stop, but continues to rotate, as it is constantly connected to the crankshaft.

Having a certain weight, when accelerating, it takes away some of the power from the engine. And the more the product weighs, the more power is consumed. As a rule, this is 2 – 3%.

This picture is especially observed at high engine speeds, going beyond 4 thousand per minute.

It would seem that this is a design flaw that requires a technical solution, but it’s not that simple. It turns out that this has its advantages.

The fact is that during rotation, the flywheel absorbs many dangerous vibrations from side processes occurring in the motor, which are difficult to take into account when designing the latter.

In fact, the vibrations do not go into the car body, but are damped, which is important.

During the startup of the unit and at high speeds, the flywheel endures heavy loads, therefore, during its manufacture, indicators such as resistance to breakage, torsion and heavy loads are built into it.

Therefore, the product can weigh between 6 and 9 kg, depending on what model of car it is installed on and what power the unit has.

Function

As we said earlier, the flywheel is an integral part of the crank mechanism.

The item is intended:

- To reduce uneven rotation of the crankshaft.

- Transmits torque from the internal combustion engine to the transmission (the flywheel is the driven clutch disc).

Smoothing of torque pulsations is achieved due to periodic recoil and accumulation of kinetic energy by the flywheel. It is stored during the working stroke of the piston. Energy is consumed during the stroke of the piston reaching its dead center. The piston stroke increases with the number of cylinders in the block. And to ensure uniform transmission of torque, a flywheel is provided in the design. The lightweight element differs from the factory one primarily in mass (more on that later). But, regardless of the type, this mechanism is fixed in the end part of the crankshaft, at the rear main bearing. The latter is highly resistant to stress. It is the main bearing that bears the weight of the flywheel and all the loads from it.

Flywheel as an energy accumulator

Heavy flywheels are installed on ordinary, custom cars with serial engines for one more reason - they act as an energy battery.

The fact is that at the lower end, power transfer in such cars from the piston to the crankshaft occurs in a very narrow range - 500.

In this case, four strokes in the engine occur in 7200 (2 revolutions), of which the theoretical power stroke is only 1800.

Due to the fact that the standard engine has low speeds and power transmission occurs in a very narrow range, even idling it is difficult.

This situation is corrected by a heavy flywheel, which after 500 turns of the shaft cranks absorbs enough energy to then spin further by inertia and help the engine.

The same is true for the operation of the unit at lower levels. Those. a heavy device on engines with operating speeds in the range of 2.5 - 4 thousand, and idle speeds from 0.8 to 1 thousand plays a positive role and it is not worth making it lighter if you do not simultaneously make design changes to other elements of the engine.

Relationship with timing belt

The next feature is that the flywheel is directly connected to the gas distribution mechanism.

If a serial engine has a regular heavy product, as in our case, and a serial, non-tuning, timing belt, which ensures good cylinder filling and torque at low speeds, the engine operates in normal mode.

But if you replace a heavy flywheel on a conventional engine with a light analogue, then it turns out that at the lower end the inertial energy of the product will not be enough for the car to move smoothly in normal mode, since the cylinders will not be filled with the fuel mixture well.

But at the same time, high speeds will not appear on a standard engine because the gas distribution mechanism will be immediately crushed and, as in the first case, will also not have time to efficiently fill the cylinders with the fuel mixture.

Therefore, the choice of flywheel and the degree of its lightening will directly depend on the timing, i.e. depending on the speed of the engine.

If, on the contrary, you install a heavy flywheel and a tuned wide camshaft, then you can forget about the high-quality bottom end of the engine. High speeds, at the same time, will also be bad, since the motor will have to rotate a large mass of the flywheel and this will create an obstacle to high-quality filling of the cylinders.

Therefore, the speed mode of the engines primarily depends on the gas distribution mechanism, and all other parts, including the weight of the flywheel, are adjusted to this timing belt.

It all depends on the specific layout of the intake and exhaust tracts, the width of the valve timing, the number and diameter of valves, and so on.

What conclusion should be drawn?

The article specifically described all the pros and cons of installing a sports part. In conclusion, it should be emphasized that it is better to choose parts that are made of aluminum. This is explained by the fact that they reduce weight by using lighter materials, rather than reducing the amount of material per square centimeter, which reduces strength significantly.

If such flywheels are not of interest to you, and the choice fell on steel parts, then it is better to pay attention to the fact that the metal should be cut as close as possible to the edge of the part. This is despite the fact that the central part should be equipped with metal as much as possible.

Is a lightweight flywheel needed on a high-powered engine?

For a forced engine, the operating mode varies between 6 - 7 thousand revolutions. At such frequencies, a heavy product is a big obstacle, because such a mass needs to be turned quickly.

A lightweight product plus the rotation of a heavy crankshaft at high speeds will be sufficient to maintain stable rotation of the engine by inertia.

Therefore, in this case, a heavy flywheel will be superfluous; it can be lightened.

At the same time, a set of tuning measures has already been carried out on the forced engine.

Features of installing a lightweight device on VAZ cars

Installing only a lightweight flywheel on any VAZ model will not give a noticeable increase in power, although the dynamics of acceleration will certainly increase.

Before installation itself, it is advisable to tune the gas distribution mechanism, only then will it allow the cylinders to be filled well at frequencies within 7 - 8 thousand rpm.

In fact, with such a tuned timing belt, the flywheel will no longer be needed, but since it cannot be completely thrown away, it can be easily lightened to 3 kg, and it will perform well. But the idle speed on such a unit will already be within the range of 2 – 2.5 thousand rpm.

You can do less, but in this case the motor will work unstably and not in its proper mode, the piston may overheat and burn out.

Balancing

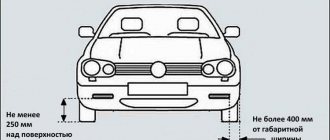

Usually the weight of the structural material removed from the surface of the workpiece is taken into account - 35% on average. More precisely, the weight of the outer diameter of the lightweight flywheel is reduced by 500 - 700 g/mm. On some cars there is a choice of several clutch sizes, so you need to consider:

- a basket and a larger diameter disk increase the contact surface and the quality of engagement, respectively;

- however, a clutch with a smaller diameter, similar to a lightweight flywheel, increases the dynamics of the car;

- on a standard M8 mount, the basket can dangle, throwing off the balancing settings, so when tuning, the diameter is often increased to M10 (drilled, threaded).

Balancing the flywheel assembly

To prevent an unbalanced part from destroying the bearings and crankshaft, the crankshaft is balanced on a bench as an assembly.

Balancing assembly with basket

Pros and cons of a lightweight flywheel

So, let's summarize briefly, what are the advantages of a lightweight flywheel compared to a regular one, and what are its disadvantages.

Pros:

- The lightweight version of the product has less centrifugal and inertial forces than the standard one, which means that the power take-off from the engine during acceleration will be less, this figure is approximately 2%;

- At high speeds, the efficiency of the motor increases, as inertial and centrifugal forces decrease;

- Starting the unit and reaching maximum speed occurs with less fuel consumption.

Minuses:

- If you install only a lightweight analogue on a regular engine, then the car will lose the low end, and the high end will not be added; as a result, the engine will not operate in its proper mode and will quickly die from increased loads. Therefore, an integrated approach is needed here where you need to correctly match all engine components to each other, and not just install a tuned product.

- After lightening the device, it is impossible to obtain a clearly visible result. A 2% increase in power and negligible fuel economy are not numbers worth bothering with. As a rule, the crankshaft is immediately lightened, and other work is carried out on tuning the engine, gearbox, clutch, camshafts, and exhaust system, which together provide a significant increase in power and savings. For example, a direct-flow muffler is installed.

- The method is not very effective when driving at low speeds, for example, when driving at 4 - 4.5 thousand rpm, and especially at 9, the result will be noticeable since the spinning torque will increase from 4000 to 8000 - 9000, and when driving up to 3 thousand rpm the result will be almost invisible. If the car constantly drives loaded, off-road, then with a light flywheel the car will jerk, quickly lose speed, stall, the reason is the lack of sufficient inertia. Therefore, it is advisable to install a lightweight flywheel only on sports cars or, as noted above, on ordinary ones, but with modifications to other systems.

- The need for precise balancing of the tuned product along with the generator belt pulley and the crankshaft.

- The strength characteristics of a lightweight device are significantly lower than those specified at the factory, so it is impossible to guarantee its stable and long-term operation.

- The difficulty of making it yourself, since the product must be perfectly balanced. To guarantee quality, the flywheel is lightened on a digital coordinate machine;

- High cost if bought at the car market.

How to choose the right part?

If the owner nevertheless decides to purchase and install a lightweight flywheel on his car, then he needs to carefully read all the necessary recommendations that will help him make a truly high-quality purchase. At the factory, a lightweight flywheel is made by using lightweight alloys, or by removing excess parts of the part. Therefore, before purchasing, it is important to study from which part the material was removed. You should never buy a flywheel whose central part is at least slightly cut out. The center must be completely fortified.

If the central part of the lightweight part is removed, then there is every possibility of failure, as a result of which the remains of the part may become stuck in the passenger compartment. A deformed sports accessory immediately shatters into small pieces that can pierce the thin metal of the body without any questions. This can lead to very serious injuries to the driver.