Marking of car wheel rims is divided into two types - standard and additional. Standard information includes information about the width of the rim, the type of edge, rim split, mounting diameter, ring lugs, offset, etc.

As for additional markings, this includes information about the maximum permissible load, the maximum permissible tire pressure, information about the methods of manufacturing the disk, information about the international certification of a particular disk. However, not every car rim will have all the information listed above. Most products provide only some of the information provided.

UGI2 UGIA Product Images

A car needs a propulsion device - a device that provides contact with the road and transmits forces and moments that set the car in motion. In other words, four wheels, each of which consists of a tire, rim, connecting element (disc) and hub. What is encrypted in the wheel markings? To read the “secret script”, use our hint.

The code by which you can select a wheel for a specific car is deciphered as follows:

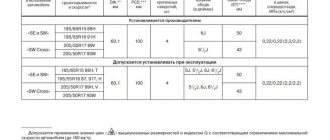

Disc markings, symbols, terms on discs, designations

To choose wheels for your car, it is not enough to know the required diameter and the number of bolts for fastening. The disk must meet a number of parameters. The full disk size looks like this: 6.5×16 5/100 ET48 d56.1 . The ability to decipher symbols on disks will help you avoid mistakes when purchasing and disappointments when installing them on a car.

So:

6.5 - rim width value . Indicated in inches. If you want to know the size in millimeters, then 6.5 must be multiplied by 2.54 (1 inch).

j (can be replaced by “ H2 ”) - for ordinary consumers these values are not important, since they are service designations for manufacturers and sellers.

J is a value that encodes data on the design features of the edges of the rim flanges, such as their angles of inclination, radius/radii of curvature, etc.

H2 (short for Hump) - the presence of this designation indicates that there are annular projections (humps) on the rim flanges that keep the tubeless tire from sliding off the rim. The letter designation H means single (simple) hump. H2 - stands for double hump. There is also a Flat Hump - FH , Combi Hump - CH , Asymmetric Hump - AH . If there is an x sign between the designations of the width of the disk and its mounting diameter (as in this case), this means that the disk rim is one-piece, without humps.

5/100 - indicates the PCD value of the wheel (Pitch Circle Diameter). The number “5” is the number of fastening holes for nuts (bolts) on the disk, and in millimeters “100” is the diameter along which the fastening holes are located. If necessary, and there are no special instruments at hand, measurements can be taken with a regular stationery ruler.

IMPORTANT: The wheel mounting holes can be located on different diameters, which have a very tight tolerance relative to the central hole.

Warning! The mounting holes may have a small plus tolerance in diameter, which visually makes it difficult to accurately determine the PCD if it differs from the standard one by only 2 millimeters. For example, a wheel with a PCD value of 4/98 is often installed on a hub with a PCD value of 4/100. IS IT DANGEROUS!!! Only one nut (bolt) will be fully tightened. The mounting holes of the remaining 3 nuts will “lead”, as a result they will be undertightened or tightened skewed. As a result, the wheel will not be completely seated on the hub. When driving it will “beat”, there is a high risk that the nuts will gradually unscrew by themselves.

d - (example: d 66.6) - in millimeters indicates the diameter of the hub , or the value of the diameter of the central hole of the wheel. It is important that this parameter exactly matches the diameter of the vehicle hub mounting cylinder. Matching the sizes will ensure preliminary centering on the wheel hub, which will facilitate installation of the bolts.

ET - letter designation of disk offset , i.e. the distance in millimeters from the mating plane of the wheel disk installed on the car hub, and the conventional plane that runs in the middle of the wheel rim.

ET “positive” - the mating plane does not protrude beyond the conventional boundary.

ET “negative” - the mating plane is behind the imaginary plane.

In some countries, there is another designation for ET - OFFSET or DEPORT.

Examples of departure designations:

ET 46 - positive offset, 46 millimeters.

ET-20 - negative offset, 20 millimeters.

ET 0—zero offset.

Warning! It is dangerous to install wheels on a car whose disc offset differs from the standard one recommended by the car manufacturer. In an effort to give the car a sporty look, some car owners install wheels with a reduced offset. The car becomes a little more stable on the track, because... the wheel track becomes wider. And at the same time, the load on the car’s suspension and wheel bearings increases. And vice versa, it is impossible to increase the wheel offset - its wheel rim will rest against the brake disc. All this can lead not only to car breakdown, but also to an emergency on the road.

The wheel may also have the following symbols:

— Date of manufacture — (example: 0309) — means that the release date of the disc is the third week of 2009.

- ISO, SAE, TUV - the mark that is given by the regulatory body. This marking is confirmation that the wheel complies with international standards/rules.

— MAX LOAD 2000LB is the most commonly used value for the maximum wheel load capacity (in pounds or kilograms). In this example, the maximum permissible load limit is 2000 pounds, i.e. 908 kilograms. — PCD 4/100 — parameters of connecting dimensions; — MAX PSI50 COLD — maximum air pressure in the tire. In this example, no more than 50 pounds per square inch (3.5 kgf/sq.cm). “COLD” - translated as “cold” - a reminder that pressure measurements must be taken in a cold tire.

Recommendation from specialists at the online wheel store Kolesa Darom

Even if you feel that the technical terms are more or less clear to you, it is still better to select disks by consulting with a specialist directly at the time of purchase. This, at a minimum, saves money and time. And, as a maximum, it will save you from mistakes and, as a result, dangerous situations on the road.

Vilet

Most tire centers and online stores sell exclusively Chinese wheels of the brands Replica, Nitro, etc. Do they meet safety standards?

As a rule, wheels presented in serious stores undergo mandatory certification and are approved for use. Don’t be shy, ask merchants for certificates for their goods.

How to choose a disk for a tire

To choose the right wheel for a tire, you need to take into account the difference between the width of the tire and the width of the rim. The width of the tire should be one quarter less than the rim. For example, if the tire width is 185, a quarter of it is subtracted from this number: 185 - 46 = 139. Next, you need to convert this number into inches - 139:22 = 6.3. Thus, for 185 tires, a wheel with a value from 5.5 to 7 inches will be suitable.

You also need to consider the offset number for soft or hard tires. A significant overhang will reduce the turning characteristics and increase the possibility of damage to the wing in the event of a tire puncture.

Understanding the information contained in the affixed code is important when choosing disks. Knowledge will help you choose products in accordance with the manufacturer’s technical requirements for a given car model.

Important! It is necessary to pay attention to the affixed code and its compliance with the markings indicated in the accompanying documents. Any discrepancy indicates a fake.

What is the tire width on 8j?

The rim size of the product must be 6.1 inches or 155 mm.

Interesting materials:

How to make animation on one slide? How to make an animation on the Windows 10 desktop? How to animate one word in a presentation? How to make animation in Canva? How to make animation in Photoshop from layers? How to make animation in Google Slides on your phone? How to make animation in a presentation on your phone? How to make animation in a presentation? How to make animated stickers in Telegram from your phone? How to make animated stickers in Viber?

How to take your own rim measurements

In order to obtain accurate data in inches, you must complete several sequential steps:

- release air from the tire;

- remove the tire, freeing access to the rim;

- using a tape measure, calipers or ruler, take measurements;

- it is necessary to measure the distance from edge to edge, maintaining perpendicularity;

- convert the obtained data into inches (divide by 25.4);

- Place the tire in its original place and inflate the air if the wheel is not intended to be completely replaced.

Each rim is about a quarter smaller than a tire, this is absolutely normal. For example, if the tire width is 28.5 centimeters, then the rim width can be 213.7 mm (75%). If you divide the data by 25.4, you get a parameter of 8.5 inches.

Disc ejection: what is it and what is it responsible for

Offset is the distance between the vertical plane of symmetry of the model and the plane of application of the tire to the hub.

Reach is an extremely important characteristic. After all, if it does not match the diameter and total number of holes for the bolts, then it will be impossible to mount such a tire. A model with a non-standard offset can often be easily installed on the hub and it seems to perform the task quite normally. But is it?

The tire offset must meet the vehicle manufacturer's requirements. In principle, there cannot be any deviations in any direction here.

Disc profile width: concept, measurement methods

Before changing rims, it is important to understand what rim profile width is. At the beginning of this article this concept was described a little. It is worth drawing the reader's attention. For a simpler perception, you should focus on the presented photo. The applied marking means:

- 195 — tire width;

- 65 — height to width ratio (in%);

- R – indicates that the tire has a radial cord;

- 15 – disk/wheel diameter (in inches);

- T – speed index shows the optimal speed for safe driving on a given tire;

- 91 – permissible wheel load index.

Thus, it is necessary to select the appropriate tires for each rim. This is an important point responsible for safety while driving.

What does parameter 700c mean?

This designation is used for large types of wheels on SUVs and Nivas. According to the accepted ISO classification, this figure is 29 inches. Typically 700c wheels are used for off-road racing.

Due to the use of 29 inch wheels:

- management indicators are improved;

- braking distance on unpaved surfaces is reduced and aerodynamics is increased;

- the vehicle's cross-country ability on soft soils and sand increases;

- it becomes possible to install powerful brakes.

To select wheels that match a particular type of car, it is recommended to determine the diameter of the wheel and analyze the markings indicated on the rim. Also, do not forget that safe driving ultimately depends on this element.

Disk options

To determine what the marking means, you need to know the width and diameter of the wheel product.

Drilling or bolting

This is one of the most difficult parameters to study, indicating the diameter of the mounting bolts. Drilling is measured from the center area of the stud to the opposite area where the element is located on the wheel.

Quite often, manufacturers indicate the disc bolt pattern parameters using shot depending on the number of holes for fastening.

Let's assume the figures are 6/222.25. The first number shows the number of drillings for fastening the bolts, and the second number indicates the drilling in millimeters.

Disc offset

This indicator is marked with the English letters ET. What is ET in disks and why is it needed? The indicator indicates the distance from the plane of the wheel product to the middle zone of the rim. The mating surface of the wheel product indicates the pressing plane of the disk to the hub.

Departure parameters can be:

- with zero indicator;

- with negative;

- with positive.

Zero offset indicates that the plane of the disc corresponds to its middle zone. Thus, the lower the indicator, the more the wheel product protrudes from the outside of the car. If the overhang indicator is increased, this means that the disc is deeper into the interior of the car.

It is also necessary to take into account the fact that depending on the width of the product, the overhang indicators differ. Manufacturers indicate in the documentation accompanying the vehicle a smaller offset value for wheels with a large width.

Diameter and other parameters of the disk schematically

What is HUMP(H)?

The hump is the protrusion of a ring on a disc rim. This element is used as protection against car tires coming off. Usually 2 humps (H2) are used for a wheel.

In some cases, a hump may not be used or only one may be used, depending on the vehicle configuration. Types of Humps:

- combined (CH);

- flat (FH);

- asymmetrical (AH).

PCD Disc Parameters

The PCD value refers to the diameter of the circle of the center holes on the wheel rim. That is, this is the diameter of the holes for fastening the bolts.

DIA drive option

The DIA parameter indicates the diameter of the hole located in the center of the disk. Casting manufacturers prefer to create a large DIA center hole diameter. This is done to ensure that the wheels are applicable and universal for all types of cars.

Despite the fact that the size of the hub may differ depending on the vehicle model, the auto disk is installed using an adapter ring or bushing.