Every driver who frequently travels not only on the highway, but also around the city, is familiar with the situation - a flat tire. Very lucky are those owners whose “four-wheeled” friends are equipped with a “spare wheel” and other tools for changing a wheel: the first place of which is a jack. After all, without it, even if you have a spare tire, you certainly won’t be able to replace it right on the road!

Recommendations for using a jack.

Ways to jack up a car correctly

Every driver who frequently travels not only on the highway, but also around the city, is familiar with the situation - a flat tire.

Very lucky are those owners whose “four-wheeled” friends are equipped with a “spare wheel” and other tools for changing a wheel: the first place of which is a jack. After all, without it, even if you have a spare tire, you certainly won’t be able to replace it right on the road! Recommendations for using a jack.

How to jack TLK Prado

There is a glove compartment on the rear door of the car that contains the necessary tools to change the spare tire.

- You need to get the parts of the knob. 3 elements are assembled into each other, tightened with a bolt.

- Using a screwdriver, unclip the latch and insert the knob at an angle. Rotating counterclockwise lowers the spare wheel.

- Pull the lowered wheel towards you and unscrew the nuts of the lifting mechanism.

- Also, do not forget to loosen the nuts on the broken wheel.

- Disable air suspension.

- Remove the lift from the trunk wall.

- Install it in the required place. Front under the frame or rear under the axle, depending on the wheel being replaced.

- Add 4 links to the collar.

- Using a crank, raise the car to the required height.

- Unscrew the nuts from the wheel on the car and remove it.

- Roll up the spare wheel and replace the removed wheel. Tighten the nuts.

- Use the crank to lower the lift.

- Tighten the nuts on the replaced wheel well.

- Roll the removed wheel to the lifting mechanism, push it in and tighten the nuts. Rotate the crank clockwise until the spring is fully raised and secured.

You do not need to have special knowledge when changing the spare tire using a standard lift. The main thing is to do everything right. Place the jack on the Prado 150 under specially designated places, this will secure the car body.

What is a jack

This is a unit that is used during scheduled repair work, as well as when unforeseen situations arise: getting out of a hole or mud, replacing a wheel, etc. Car owners who often have to drive off-road do not allow themselves to move without this assistant. And in general, it is recommended for absolutely everyone to carry a jack with them in order to get out of an unexpected unpleasant situation “unscathed” as quickly as possible. Otherwise, you will have to call a tow truck, whose services will not be cheap. Of course, the jack, as well as the spare tire, are helpers in solving many problems. BUT! Agree, if you don’t know how to use it, you will not only not achieve the desired results, but will damage your car even more (for example, by bending the sills, etc.). And in the worst case, improper lifting can threaten to cause certain (and not always minor) injuries to the car owner.

Jack installation

How effective, easy to use, and reliable your future jack will be must be determined before purchasing it! It is important, first of all, to pay attention to its maximum load capacity - this value should not be lower than the weight of the car. For example, if the weight of the TK is 800 kilograms, it is best to give preference to a device that can raise at least one tone.

Important! If your four-wheeled friend weighs more than the jack can lift, then we strongly recommend NOT using it. Such actions lead to overload, which ultimately leads to damage to the vehicle.

In addition, a car that falls off the supports can not only damage the car, but also harm your health (at a minimum, cause bodily injury).

So, the rules for lifting a car with a jack

- First of all, make sure that the car is on a level surface;

- If an unpleasant situation happens to you (a tire breaks in the middle of the highway), try to find the safest place, a little away from the highway;

- The next step is to turn off the engine and secure the car using the handbrake and gearbox (the first or second are the most optimal);

- Secure the front wheels using special shoes;

- Let us remind you once again that in order to carry out all work related to the jack efficiently, the vehicle must be on a level road surface (without uneven surfaces, slopes or the presence of foreign objects);

- Before installing the jack, make sure that it does not rest on important components of the technical specification, which may become deformed after such actions;

- Note that the safest places for installing such equipment are considered to be the front beam or rear axle;

- In the event that the car is stuck in the mud, it would be wise to place some support before installing the jack.

Important! It is highly not recommended to lift cars with a plastic body kit using rack and pinion jacks! In this case, a pneumatic modification is suitable.

Note that when replacing the rear wheels, it is not necessary to use the handbrake, and to be even more precise, it is not necessary at all. Do not forget that the lifting should be carried out as smoothly as possible (regardless of the device used - mechanical, pneumatic or air). To increase the level of safety, we recommend securing the vehicle with special supports. Please note that these do not include stones, bricks or other objects...

Tips from the professionals

Yes, of course, your main tasks are to choose the right place, as well as to install the jack efficiently (of proper quality). But! Do not be too confident in yourself; before performing these operations, carefully check the reliability of the jack, and also make sure how well your “four-wheeled” friend is fixed. Well, now you know that you shouldn’t be too careless with such “everyday” things as a jack. Yes, we wish that you don’t need it, but we nevertheless recommend that you always have it at hand in case “if something happens.”

How to use a jack: general operating rules

Like any other technical device, the jack requires compliance with safety precautions during operation. Its use is not difficult, the main thing is to know where to put the jack and what to do with it next. This is far from a new device; most samples have been tested by time and personal experience.

Classic rack and pinion jack

Driver's courses do not teach how to properly use and install this device. You need to study everything yourself. In addition, most people, not knowing clear rules, believe that with its help you can not only lift and lower a load, but also hold it for a long time. To avoid possible health risks, you need to learn how to install a jack correctly.

A specially developed list of rules can help with this:

- The vehicle must only be placed on a level surface. There should not be any slopes or other irregularities. The machine must be parked in such a way that there is no likelihood that it will move.

- All wheels must be locked very securely. Bricks, wooden wedges, stones or any other objects are suitable for this.

- The car should rise and fall very smoothly, without sudden movements or jerks.

- It is important to clearly know where to place the jack correctly. To lift the car on the bottom there are special mounts for the jack hook. Under no circumstances should you attach it to the front or rear bumper, or to any other parts of the car that are not intended for this purpose.

- It is necessary to engage reverse or forward gear, put the car on the handbrake and block the wheels on the opposite side from the side being lifted.

- It is necessary to use a support because the jack can only lift loads, but not hold them. A do-it-yourself jack stand is suitable, but it is important that it is made of wood, iron or any other material other than brick or other unreliable material.

- Before lowering yourself under the car, it is important to check the security of the machine and the device several times. To do this, you can simply rock the car in different directions.

- After completing the work, you need to know how to lower the jack along with the car. The same rules apply here - no sudden movements, smoothness.

Jacks exist in three types: mechanical, hydraulic and pneumatic (inflatable). Each of these types has its own specific operating rules.

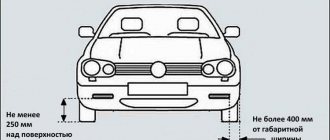

Where to put the jack pad

The jack pad must be installed under the stiffening rib of the car; this applies mainly to sedans and hatchbacks. If there is none, then a cushion is installed under the frame or wheel lever; this applies more to SUVs. Often on new cars the entire bottom is covered with plastic, including the stiffener. In this case, you need to find a place where the plastic on the edge has a plastic island measuring 10-15 cm. If you are afraid to jack up under the plastic, try doing it under the lever. In Mercedes, BMW, Bentley and several other brands of cars, there are special jack pads on the bottom, but there are times when these pads are torn off, you can safely jack the car to the place where these pads are attached.

It is necessary to jack up smoothly; after reaching the required height, fix the jack; if there are supports, install them.

So you have learned the theory of how to jack up a car correctly. Although in practice, it happens that everything turns out to be much more complicated. If you are not ready or are afraid to do the above on your own, our mobile tire service is ready to come to your aid around the clock and do all the necessary work related to your wheels.

How to Use a Rack and Screw Jack

When using rack and screw jacks, the above rules and recommendations, plus some specific ones, apply.

Screw device

Rack and pinion devices, like screw devices, have become widespread due to their simplicity of design. They are mainly popular among off-road enthusiasts. The design of such devices allows you to lift a lot of weight, which plays a decisive role. They can be used in any conditions due to their unpretentiousness and small dimensions, which is an advantage compared to hydraulic lifts, which are massive and take up a lot of space in the trunk.

Safety precautions when working with rack and pinion devices:

- Install the lift at an angle so that it does not rest against the hood.

- Place the jack perpendicular to the surface of the support.

- Check fixation and tightness.

- Press the switch firmly with your whole hand, since it moves tightly.

Maintenance Recommendations

Any maintenance should be carried out in a specialized service center, especially for complex hydraulic mechanisms that require periodic oil changes, and for this the jack will have to be disassembled, so it is better to entrust this work to professionals.

Using a jack is simple, but you should know safety precautions and be careful, because human health depends on its proper operation. A rack and pinion jack such as a hi-jack is especially dangerous.

Source

How to use a hydraulic jack

Hydraulic devices have become widespread in auto repair shops. They can be rolled or bottled, have a lot of weight, but are easy to move. They can lift a car to a height of 40 centimeters. For the correct use of such devices, the following set of recommendations must also be observed:

- Before lifting it is necessary to check the fixation. The surface should be as level as possible and the wheels should be locked.

- When working with the front wheels, it is necessary to block the rear ones and vice versa. If you need to move the device to another location, you need to make sure that the strength is sufficient to hold the machine.

- Do not lift more weight than specified in the instructions.

- The hydraulic jack operates smoothly, but do not raise or lower the vehicle too quickly.

Hydraulic lift

How to use an inflatable jack

This type of lift is a pneumatic device. In this case, a special pillow is installed under the bottom of the machine, which is subsequently inflated with a special device. To work with such a device you need:

- Place the cushion under the car and spread it evenly.

- Place special mats on top and bottom that are included in the kit. They are designed to avoid pillow punctures.

- Close the lock connecting the valve and hose tightly. This is necessary to avoid air leakage from the pillow.

- Connect the end of the hose to a source of air or gas supply. Special compressors are used.

- The pillow is inflated with air or vehicle exhaust gases.

It is important to monitor the process of inflating the pillow. It should pass evenly in all directions. If any side lags, then it is necessary to check and correct the position of the pillow or lower it and start the process again.

HOW TO JACK THE CAR CORRECTLY

In the trunk of every car there should be a set of tools and automotive accessories for unexpected repairs on the road. The first place among other things in the trunk is occupied by a jack and a spare tire. And accordingly, every car enthusiast has a question: how to jack up the car correctly? This will be discussed in this article.

Where to put the jack A jack is used only for changing wheels. Before placing the vehicle on a jack, be sure to unload the vehicle. You should never lift a loaded car. Place the vehicle on a horizontal surface and block the wheels well. Never lift the car without first blocking the wheels. If you jack up the front wheels, then the rear ones must be blocked, and, conversely, in the process of raising the rear wheels, the front ones must be blocked.

Before using the jack, engage reverse or first gear and apply the handbrake (if you are jacking the front wheels). The jack should be installed only in specially designated places so that at the stop its recess fits into the edge of the sill closer to the wheel being replaced. On the thresholds, special stamps mark the places for the correct installation of the jack.

If there are side trims on the car, simply remove them. To do this, press on the edge and pull out the pads. Place the bumper pads as close to the wheel as possible, approximately 30 centimeters from the end of the bumper.

The jack must be in a vertical position relative to the point of contact with the body itself.

If the proposed work requires installing a jack in a non-standard place, then it is necessary to ensure that it is strong to support the weight of the car. Do not place the tool anywhere where the weight of the machine rests on anything that could break or bend. If it is difficult to choose a place for the jack, it should be installed so that it rests against the beam that supports the front suspension, near the axis of the rear wheels or the body.

Raise the car smoothly using a jack, without sudden movements.

If you have safety stands, place them together where the jack rests on the car. Raise them to the required height and lock them. Lower the jack so that the car is supported on supports.

Raise the car using a jack smoothly, without sudden movements.

If you have safety supports, place them in the place where the jack rests on the car. Raise them to the required height and lock them. Lower the jack so that the car is supported.

How to properly jack a jeep

Have you ever had to change the spare tire on a jeep? Many will think that this is a rather stupid question, what could be so difficult about replacing a spare tire? Except, perhaps, the opportunity to get dirty from head to toe?

However, we didn’t just start covering this topic. There is a very significant nuance in this, to the naked eye, primitive matter, and not every young jeep driver knows it. Because the need for a spare tire in our city life arises very rarely. Jeeps have large wheels, deep tread, plus the prevalence of tire centers and the presence of compressors - and the chances of a city jeep driver to get a jack rapidly drop to almost zero.

But there are rare cases when you go out into nature and suddenly...

We focus our lives on the experience of past years. And for a young SUV driver, this is usually experience in using a passenger car or, in extreme cases, an SUV. A kind of sub-jeep.

And this very experience tells us what needs to be done. And you need to do a fairly simple thing - unscrew the nuts from a flat tire, jack up the vehicle, install a spare tire, lower the car and, desperately getting dirty, continue on your way.

Experienced comrades already know what we will talk about now and, I think, they cannot contain their smile.

Let’s follow our “passenger” algorithm carefully, as applied to a jeep.

Step one: Unscrew the nuts. This shouldn't cause any difficulties. If you didn’t do anything clever with the nuts.

Step two: jack up the car. This is where the first difficulty appears. Rather, it is of a psychological nature, since jeeps are heavier than cars, and therefore are equipped with unusual hydraulic jacks. Nevertheless, the technology of their operation is simple - install it, shake it with a lever, and the machine goes up.

This is where the very essence of the problem lies. Some people, having reached the maximum, discover with surprise that the entire jack has come out, the jeep is raised quite high, and the wheel continues to stand on the ground, while being pressed tightly. And there is no way to remove it. Did the manufacturer deceive you with the jack?!

What to do if you are faced with a similar situation? There are only a few options:

If there is something quite strong and larger in the area, then you can put something under your jack and try again. If you are not standing on asphalt, then under the flat tire you can dig a hole deep enough to remove it. You can spit on the tire and drive to your destination on a flat tire. And, in the end, you can read the instructions. It is quite possible that there are other exotic options; we have listed only those that we have encountered in practice.

The whole problem lies in our experience. Drivers who have switched from a passenger car begin to jack up the body of the jeep out of habit. Forgetting at the same time that one of the main advantages of these warhorses is the “long suspension travel”. What does this mean in practice? This means that if we lift a jeep, its wheels will remain on the ground much longer than on a passenger car.

Ways to lift a car for repairs on the street

There are more opportunities for lifting a car on the street than in a garage. Most car owners use a jack; if there is no lifting device, they ask fellow car enthusiasts for help. Let's consider the existing options for lifting a car.

Raise the car onto a homemade mini-overpass

Car enthusiasts, having purchased a personal car, are faced with the problem of lifting the car. For convenience when repairing a car, they independently or with the help of familiar welders make a mini-overpass. The manufacturing process will take a long time and require maximum effort, but the result will satisfy any picky car owner.

Watch a video with a mini-overpass option.

There are several types of mini-overpasses; they can be solid or collapsible. If the garage area allows for storing a large structure or there is an additional shed, then they make a solid one. If there is not enough space, a collapsible version is made. Mini-overpasses are divided into subtypes.

- One-sided pyramid. It is made from a wooden board and requires a minimum of time and money.

- Rectangular trapezoid. Consists of two elements in the form of a half-trapezoid. It is made from a metal corner by welding.

- Collapsible design. Consists of several connected parts. Made from a metal profile by welding.

Hang the car on racks

Some car owners use special racks to repair their cars. They are sold at auto stores. Experienced car owners make the devices themselves. Purchased options have a load capacity of up to 5 tons. Homemade structures are not inferior to purchased models and are capable of holding a truck.

The car lifting scheme is similar to the lifting scheme for wooden stands. Raise the desired side with a jack and place a stand under the spar. This procedure is done on all four sides. As a result, the car will be suspended, held by the racks. The maximum lifting height reaches 60 cm.

Other ways to lift a car yourself

There are situations when you need to lift the car, but the possibilities are limited. If you don’t have the necessary tools at hand, you can try to find a small hill and run over the desired wheel. A regular border is perfect for this purpose.

Every car has a spare tire. Find a board of short length, and the lifting problem is solved. Place the spare tire on the ground, attach a board and drive in. An amateur car owner posted an example video on the Internet:

The lever method will help you lift the car. If there are two logs nearby: a long one and a short one, then the short one is used as a support, the long one as a lever. A child can do this lifting procedure.

To make sure, watch the following video:

You can lift a car for repairs using either special devices or improvised means. Knowing a few simple secrets, any car owner will try to solve the problem of lifting a car with his own hands.

I can jack up like a motherfucker. Instructions for beginners on jacking up a car.

In this post, I want to share my experience mixed with factory recommendations on how to and should NOT jack up your favorite cars.

First: in any tire shop, in any service, always check BEFORE lifting the car where the workers put the jacks/lift legs. The threshold can only be crumpled or not crumpled, and between these states there is exactly one act of lifting the car. If the lifter's foot slips off the seam, the threshold will immediately be pressed through (I've seen this more than once). A straightened threshold and an initially intact one are not the same thing.

What you definitely can’t

:

1)

You cannot jack up the center of the sill to change both wheels on one side at once.

The tire fitter is too lazy to push the jack twice, and your threshold may come to an end (maybe not the first time, but you definitely can’t

). At risk: schoolchildren who have watched enough on YouTube where cool guys change tires at races in one lift. There are several explanations: either they have a missl with overcooked reinforced thresholds, or the car is so lightweight that it doesn’t push through, or they don’t care. If you try to lift your poor GX81, 90 or 100 like this, then the sill edge deflection will not take long to occur. Don't ever do that.

2)

Do not use a rolling jack without a sufficiently thick rubber cushion. Most jacks are sold without a cushion. Hamsters think that it is not needed. But if they sold you skis without boots, would you squeeze your fingers into the bindings just like that? The pillow is a consumable and is sold separately (it costs 150 rubles). The jack manufacturer doesn’t care about your thresholds, they have a different goal - the jack should jack you up and cost as little as possible. So buying a pillow is your task. The same thing happens at tire shops and services - if there is no cushion on the lift or jack, or it is very worn out and the threshold rises iron on iron - abandon the repair idea in this place. Or offer to change the pillows before the lifting procedure. Again, nothing noticeable will happen at one time, but do you need to get it fixed in such a service? And begin the destruction of your threshold, which is either intact or not.

3)

The standard diamond-shaped jack cannot be used. This little thing is placed in the car as a last resort. If you have a flat tire on the highway and just can’t get to the tire shop, then you can lift the car and put it on. But I would prefer (let’s say in the city) to do nothing and get there on a broken tire. Maybe 5, maybe 10 km (although in fact I drive a rolling jack with a cushion and could change a tire, but only if the road is not busy and it is daylight). I don’t care about punctured tires; they may not be repairable anyway. But the threshold will not be damaged. And I won’t have to change a tire on the side of the road; even a small chance of being hit by some idiot doesn’t suit me. I don’t care about this tire, I’d rather live and buy a new one than drive on a sealed one with holes and squirm under the car on the side of the road.

How to jack correctly:

An obvious point, but nevertheless useful for absolute beginners: the threshold of a car is a box-shaped section of the body, located at the bottom of the doorways between the wheels. At the bottom there is usually a seam, a piping:

The jack is inserted exactly into the edging and only along the edges of the threshold in places marked with small cutouts. Attention: the rear part (trunk) is not a threshold! You cannot place a jack behind the rear wheel (I wouldn’t write this if I hadn’t seen the trunk niches dented by the jack). Although the threshold looks generally uniform, on many cars it is reinforced only in designated areas. If you place a jack in the middle, the threshold will not hold up and will collapse. This is unsightly, besides, it reduces the safety of the car in an accident and causes corrosion.

Also, before jacking the car, it is important:

1) Make sure that the car is not standing on an inclined plane and does not roll on its own in neutral and without the handbrake. 2) Turn on the handbrake. 3) Loosen the wheel nuts in advance before lifting. A small shift of half a turn is enough. This is done to prevent the car from falling off the jack due to a jerk. 4) Place wheel chocks (or at least any lugs) under the wheels.

The main principle of raising a car:

An old joke from traffic rules exams: - What to do if you are standing in the center lane, and you needed to turn right from the right lane?

- Nothing. Go straight! If you are not already in the turning lane, then you CANNOT turn. Same with a jack. If you do not have a suitable jack, then you simply should not lift your car under any circumstances (except for emergencies that affect people's health).

It’s better to forget about the jack in the sills altogether; lift the car with 4-arm lifts. If you really want to, a rolling jack can be placed according to the car manufacturer’s recommendations: for example, Mark 2 can be lifted under the rear gearbox and under the front subframe.

Lada Granta Red Lux Mechanics › Logbook › Stay alive. Raising the car with a jack

Everyone knows what a jack is and why it is needed. But, it’s amazing! Some people here sometimes use jacks, if not illiterately, then rather frivolously.

And this can lead to the car falling off the jack. Moreover, this may cause the car to fall directly on you, dear reader.

And nowadays, thanks to the widespread use of phones with FullHD cameras, you can’t really count on help.

How not to drop a raised car is the first question of this post.

Second question: What qualities should a car jack, which is so necessary on the farm, have? I'll start with this.

It is believed that it should be stable, durable, reliable, comfortable, light, small and cheap. Everything is clear, I think.

Durable and reliable means heavy and expensive. Light and cheap means it will collapse at any moment. And so on.

I'll say something blasphemous - the jack can be anything. If only it didn’t fall apart without declaring war. You just need to be able to use them correctly, and also know the weaknesses of different types of jacks.

The only caveat is that the passion for ultra-reliable rolling jacks, capable of lifting ten to fifteen Grants at a time and weighing over a hundred kilograms, is irrational. This type of jack is simply inconvenient! Due to the huge gear ratio, it will take half a day to pump the lever. And moving it across the floor does not apply to any other sport except weightlifting.

Which of the constantly carried jacks is the most versatile and convenient?

Personally, it has long been clear to me that there is nothing better than a diamond jack. When executed correctly, it is closest to the ideal.

In general, to put it simply, it is from the diamond jack that the car will fall last. From anyone, even not ideal.

The second place is deservedly occupied by the semi-diamond jack, a sample of which is available for study to every owner of the Grant. This type of jack has at least two weaknesses. The first is a small margin of lateral stability. Due to the rocking bottom heel, you need to use it wisely. When lifting a machine, it always moves by some amount from the lifter. The upper support of the jack moves along with the car. If initially the vertical axis of the jack was strictly perpendicular to the surface, then after lifting it will turn out to be inclined, so to speak, inside the car.

This is very dangerous, because no one can predict what angle of inclination will lead to the lower support of the jack “slipping out” and the car falling. This happens something like shooting out an orange seed held between your fingers - quickly and unexpectedly. It's better not to take risks. Therefore, when starting to lift, you need to place the bottom of the jack slightly under the upper support. Then, at the end of the lift, the vertical axis of the jack will become vertical.

The second problem with the semi-diamond jack is the reduced margin of longitudinal stability. Unlike a diamond, there is no necessary rigidity between the upper and lower supports. Therefore, if the car is not properly secured, it easily and naturally slides forward or backward from such a jack. In this case, the jack is twisted by the propeller, until it is completely unsuitable for further use.

The third place among mobile jacks is occupied by Y-shaped ones.

Vertical screw jacks are hardly worth considering as mobile or even garage ones. Their stability is fine, but the inconvenience of use is the highest of all jacks, in my opinion. But they are good to use as tragus, i.e. additional supports.

There are many similarities between them, but there are two fundamental points. The first is that a dolly requires much more space on the side of the car. Sometimes this is critical. The second is when lifting the car from both sides (i.e. the entire front or rear) using a rolling jack, you need two of them. I'll explain why below.

Finally, for those jobs that do not require (or directly prohibit) hanging the wheels, stands that you can drive onto are convenient. Such microoverpasses exist in many implementations, among which there are examples of grace and a complete collective farm. Some are difficult to make, and some are very simple. I use the simplest micro-overpass made of timber, which almost anyone can make. Here is one of its halves:

Then I’ll move on to the main question - how to lift and how to work with a raised machine. The first step is always chocks for the wheels. The stops should be placed under the diagonal wheel in relation to the one being hung. You don’t have to put the handbrake on, or engage any gears in the box, but the stops must be installed!

Why not a handbrake? But because there is never one hundred percent confidence in its uniformity. Just because it works doesn't mean it works equally on both wheels. As for engaging the gear, this is beyond good and evil, because the suspended front wheel automatically switches the gearbox to neutral))). Therefore, stops and only stops.

Then many people lift the car and quickly climb under it.

What cannot be used in this case are bricks. They do not withstand point loads well and collapse instantly, without the slightest warning.

The task of lifting a car, which already has so many important rules, is greatly complicated when it is necessary to hang the entire front or the entire rear.

The most common mistake is to borrow a rolling jack from a friend and start lifting the second side while the first side is hanging on a standard jack. The probability of the car falling from a standard jack in this case is close to one hundred percent. This is due to the fact that the rolling jack rolls freely on wheels wherever the car pulls it. Here, even additional support will not help the matter at all - the car will simply slide along it outwards from you, as if from a hill. And it will slide far if the support is stable, that’s the point! I was once convinced of this personally, and I testify to this. The car drove away a good thirty centimeters.

If it happens in a narrow garage, then the situation easily becomes tragicomic. The side is almost at the wall - no way to crawl through, no putting on a wheel, no jacking, no moving away. At least cry.

Therefore, if you need to hang the front or rear, be sure to use either two rolling jacks or two diamond-shaped ones. And be careful!

It is not without reason that they say that caution is the best part of courage.

When you're done working on the car, it's so nice to wash your hands! But there are no running water in garages. I recommend: the water consumption is small, it lasts for a long time:

UPD:

For everyone who is interested in the stand, I give its dimensions. This design is much more difficult to manufacture than simply fastening together two pieces of timber cut into a cone with a chainsaw. But it guarantees that the car will not roll off the stand. Because the wheel falls slightly (by 20 mm) into the hole.

All connections are made using screws of suitable length and metal plates.

— Height of end stops. If they are too high, the car will catch on them when driving. If they are too low, then when the wheel hits them, the stand will turn over and screw along the bottom.

— The size of the depression of the horizontal bar relative to the conical parts of 15-20 mm is the maximum at which the bottom of the structure can not be brought to the horizon at all. Those. do not process.

— Length of the horizontal platform. 370 mm is not much of a margin, less is not needed. More, however, too.

Source

Safety precautions

Every driver has heard stories about cars falling off jacks. This happens infrequently, but the effect is so strong that the motorist does not forget about it for a long time and willingly tells his friends and acquaintances. As a result of a fall, the machine may damage the threshold or dent the overhangs. The worst thing is if a person is hit. Then things could end badly, especially if the driver reached under the car for inspection.

When working with a jack, it is important to follow safety precautions.

It is important to make sure that the machine is not standing on an inclined plane and will not roll after being lifted.

It is necessary to tighten the handbrake and put the gearbox in first gear or in park mode if it is an automatic transmission.

Before lifting, it is necessary to loosen the bolts on the wheel to prevent the machine from swinging when suspended when actively working with a wheel wrench. This is done so that the car does not fall off the jack due to the jerks produced.

Do not install the jack leg in unstable ground, soft mud, or frozen ground that will be pressed down over time. The body can only be jacked on asphalt. In this case, the risk of falling off the support is minimal.

Don't make dangerous mistakes!

Follow the rules, do not act at your own risk. Otherwise, you will have to resort to expensive repairs later. Under some types of jacks you need to put thick rubber as a gasket. Make sure that the area you are working on is level.

Don't forget, a jack is a tool that lifts a car, not keeps it raised. Don't make dangerous mistakes, otherwise the car may land on your foot.

How to protect thresholds?

When lifting the car, the jack must be installed correctly. There are two specially reinforced places on the threshold, which are located at the front or rear wheel. The jack foot has a special recess for fixing it by the edging of the threshold.

The jack must be attached exactly to the prepared places and only along the edges of the body in places marked with small cutouts.

It is also important to keep an eye on young service station workers who are just starting out. If someone rolls a powerful hydraulic jack to the middle of the body, it is better to ask him not to do this again.

Do not lift the car by resting the jack on the rear or front overhang. There are no supporting platforms and the metal is easily pressed through.

Hydraulic rolling jacks cannot be used without rubber pads. They are needed to prevent the metal of the paw from coming into contact with the bottom of the car, resulting in deep scratches. The rubber gasket helps keep the paint and anti-corrosion protection intact.

A similar rubber cushion can be purchased at any spare parts store.

Opel Insignia Hatchback ♦Gran Turismo♦ › Logbook › Where to rest the rolling jack?

How to properly wash a car?

I bought myself about half a year ago this rolling jack ( AJ-3F-390P

):

Load capacity 3 tons, lifting height 390mm.

But that’s not the point. After the purchase, the question arose: where should one rest his “foot” when lifting? I Googled, but didn’t get a definite answer, people are getting rid of it as best they can

With the standard one everything is clear, there are arrows on the threshold and there are slots in the stiffener rib... Actually, for some time I rested it there through a special washer. After a while the washer was cut in half:

But, as it turned out, sometimes it is useful to read the instruction manual

:

These are the places by car:

I bought a couple more new washers to replace the old one:

Mileage: 22700 km

Correct and safe lifting of a car on a jack (watch video)

Before we begin with the advice from the foreign video clip, let’s remember what kind of jacks there are by nature and type.

Screw jack

Classic models of jacks, which have been widespread both here and abroad since the early 70s - 80s of the last century. The screw jack is designed for lifting passenger cars weighing up to 1 ton. Although I remember that the 124 Mercedes of 1989 also had a native Mercedes jack of the same type, despite the fact that the curb weight of such a diesel car was 1.4 tons.

Lever and screw jack

Maximum load up to 800 kg.

Diamond jacks

This is a common type of car jack due to its ease of use, compact design when folded and high load capacity from 0.7 to 2 tons. It can be called a universal car lift.

In addition to the main types of devices intended for lifting cars and SUVs, there are a number of devices with a similar operating principle, for example: rack and pinion jacks, rack-and-screw devices, hydraulic jacks, rolling and other types of lifting devices.

The video shows as an example how two types of jacks are used, that is, diamond-shaped and rolling jacks.

1. What you MUST do before jacking up the car: first - Choose a flat asphalt, concrete or any other area with a hard surface.

2. Second, DO NOT jack up a loaded car!

3. Third - Put the car in gear (first or reverse) and apply the handbrake.

4. Well, fourthly, place wheel chocks under the wheels of the car. That is, depending on which wheels will be lifted into the air, you must place “shoes” under those wheels that will remain on the ground (under the rear or front wheels).

To install a diamond-shaped jack, you must determine in advance the place or places where it will be placed under the car (they are marked with special stamping). The video at 1.45 minutes shows those places (front and back). Gentlemen, pay your attention to the stampings on the jack itself; they should coincide with the place marked on the threshold of the car when the jack comes into contact with the threshold.

Now we turn the handle of the jack. After the desired car wheel is in the air, we take it and replace it. You should not use a diamond jack to work under a car; it may not be safe. We just change the tire and then put the car on the ground. The best insurance policy is to use a new or removed tire. Take it and simply place it between the threshold of the car and the asphalt. Even in extreme cases, if the car falls off the jack, it will receive minimal damage.

Rolling jack (working with the front of the car). The following video explains where to install the rolling jack. Its installation locations may vary. In the video, it is recommended to use: towing eyes, a car's anti-roll bar or body power points to lift the front wheels (shown from 2.30 to 4.25 minutes of this video series).

At the same time, they warn that it is necessary to avoid contact of the jack with the engine crankcase, as well as with the elements of the exhaust system and the gearbox.

After lifting the car to work under it, unless you just want to change a tire, you need to install chocks. The stops are placed in the reinforced parts of the thresholds intended for this purpose (shown at 1.45 minutes of the video).

Let's jack up the rear of the car. Just like in the front, you can roll the jack under any reinforced parts of the body, namely: under suspension elements, under the towing eye, etc. places.

The video also shows and says that it is strictly forbidden to lift the car by jacking it up through the suspension arms and unreinforced body elements (shown at 6.53 minutes), as well as through the muffler and exhaust system as a whole, if you do not want to cause damage to your car.

Thus, the video explains the main points of installing two types of jacks on a passenger car.

Next, the author gives and makes several important explanations when lifting a heavy frame SUV. Everything is much simpler here. But don’t forget, friends, the four-point precautions we mentioned above.

We avoid getting the jack on the fuel tank and on elements like the transfer case. Good places to install a jack are shown in the following video fragments:

In the third example of installing a jack under a car, the author advises placing the jack platform specifically on the frame closer to the rear of the SUV, so that the car is better secured, this is stated in the video.

The car was lifted over the rear axle (shown at 9.03 minutes). Be very careful! If the bridge is made of aluminum or other soft metals, this can lead to damage to the structural elements of the vehicle!

From the front, the SUV can be jacked up at the towing eye attachment point. But the best place to install the jack is shown at 9.52 minutes of the video. This is where the lower control arm attaches to the frame.

And one more important tip. If you doubt the correct installation of the jack, you can ask for help from more experienced garage colleagues who will demonstrate the operation of the jack in practice. If there are no competent car enthusiasts nearby and you have the opportunity to get to the nearest car service center, then go there. They will definitely do everything right for you and jack up your car. REMEMBER, FRIENDS, THAT IMPROPER INSTALLATION OF THE JACK CAN NOT ONLY CAUSE YOU MATERIAL DAMAGE, BUT ALSO CAUSE SERIOUS HARM TO YOUR HEALTH IF THE CAR SUDDENLY SLIDES FROM THE JACK!

Content:

- 1. Basic rules for safe lifting

- 2. Each type of jack has its own approach!

- 3. How to extend the service life of the lifting device?

The rolling jack is suitable for servicing almost any vehicle.

Its versatile design allows it to lift both low and standard vehicles, as well as SUVs, vans and trucks. Ground clearance can be as little as 10 cm! And due to the pneumatic or hydraulic drive, it is easy to lift cars weighing 5-10 tons. That is why it is most often used in car repair shops, service stations, tire shops, and in the repair area of automobile and bus fleets. It would seem that there could be no difficulty in lifting a vehicle with a rolling jack... Could this really cause any problems? Unfortunately yes. And in most cases this happens due to neglect of the basic rules of working with lifting equipment.

For example, you can often see the following picture in roadside tire shops: a car is standing on the street in front of the garage door, they jack it up and immediately begin to remove the wheels. The entire time the mechanic is servicing the wheels in the garage, the vehicle is supported on a jack. How many cases have there been when a car fell off such a support? Damage to the body and deformation of the bottom are unpleasant consequences of such negligence. It is also possible that the jack itself may break. But more tragic consequences can occur if there is a person nearby when the car falls. Why take such a risk? And all because they neglected the rules described in the instructions.

But those who have not yet purchased a jack do not have the opportunity to read the instructions. And sometimes it is difficult for a beginner to understand what is described in it, because there are no examples, or often the instructions are even written in a foreign language. Practical buyers want to know everything about using equipment before purchasing, in order to take into account as many nuances as possible when choosing. Therefore, they collect information on the Internet, ask questions on forums, and watch videos. Why spend a lot of time searching? We will tell you everything in this article, and you will learn:

- about basic safety requirements,

- about the rules of working with different types of jacks,

- about how to keep this equipment in full working order for many years.

You will understand that there is nothing complicated in all this, and in practice it will be easier for you, and everything described in the instructions will be much clearer. Let's start with the main thing.