The VAZ 2103 engine with a displacement of 1.5 liters represents the third of four generations of Tolyatti classics. He was the heir to the 2101 1.2 liter and 21011 1.3 liter engines. And the 2103 engine itself became the basis for the creation of the 1.6 liter 2106 engine. This is where the classic line of engines ended, giving way to fuel injection and front-wheel drive.

What engines was equipped with the VAZ 2103

The VAZ 2103 power plant is a classic model, part of the AvtoVAZ OJSC engine line. This is a modernized version of the FIAT-124 unit, developed by domestic engineers back in the second half of the last century. The changes affected the camshaft and the inter-cylinder distance.

The tuning of the FIAT-124 engine was carried out with high quality, because in the future its mass production did not stop for decades. Of course, restylings were carried out, but the core of the engine remained the same. The peculiarity of the VAZ 2103 engine is that its timing shaft is driven by a chain and not a belt.

The 1.5-liter power unit represents the third of four generations of the classic. This is the heir to the 1.2 liter VAZ 2101 and 1.3 liter VAZ 21011 engines. It preceded the creation of the powerful 1.6 liter VAZ 2106 unit and more modern injection engines for front-wheel drive cars. All modifications of the VAZ 2103 engine were distinguished by improved technical capabilities.

VAZ 2103 appeared in 1972 and became the first four-eyed Zhiguli model. Maybe this was the reason for equipping the car with a new and powerful unit that develops 71 hp. With. It was rightly called the most “survivable” engine of its time - even a mileage of 250 thousand km did not have a detrimental effect on it if the driver adhered to the factory rules of operation and maintenance. The usual service life of this engine was 125 thousand kilometers.

The 1.5-liter power unit represents the third of four generations of the classic

The improved performance of the VAZ 2103 power unit is immediately noticeable in the design features. The engine is equipped with a different cylinder block - as much as 215.9 mm instead of 207.1 mm. This made it possible to increase the working volume to 1.5 liters and install a crankshaft with an increased piston stroke.

The camshaft is driven by a chain without a tensioner. It is not provided, and therefore the tension has to be checked and adjusted regularly.

More features.

- Valve clearances are subject to periodic adjustment, since the timing belt is not equipped with hydraulic compensators.

- The cylinder block is cast iron, the head is cast from an aluminum alloy.

- The camshaft is made of steel and has the peculiarity of 1 untreated journal with six edges.

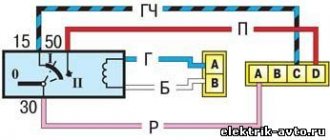

- It is paired with either a carburetor with a VROZ (vacuum ignition regulator) or an injection system, but with a corresponding timing belt - the design of the cylinder head has been changed.

- The lubrication pump is located in the engine crankcase.

The technical capabilities of the engine are as follows:

- the cylinder diameter was returned to 76 mm;

- The piston stroke was increased by 14 mm;

- Engine volume in cubic centimeters became equal to 1452 cubic meters. cm;

- two valves work with each cylinder;

- the engine is powered by gasoline with an octane rating of AI-92 and higher;

- The oil used is within the range of 5W-30/15W-40, its consumption is 700g/1000 km.

It is interesting that the subsequent VAZ 2106 engine received cylinders with a diameter increased to 79 mm.

Pistons

The internal combustion engine elements of the VAZ 2103 are made of aluminum and are oval in cross-section. The size of the piston at the top is smaller than at the bottom. This explains the peculiarity of the measurement - it is carried out only in a plane that is perpendicular to the piston pin and located at a distance of 52.4 mm from the bottom.

According to the outer diameter, VAZ 2103 pistons are classified into 5, every 0.01 mm. They are divided into 3 categories every 0.004 mm according to the diameter of the hole for the finger. All data on piston diameters can be viewed on the lower part of the element - the bottom.

For the VAZ 2103 power unit, a piston type with a diameter of 76 mm without a recess is suitable . But for VAZ 2106 and 21011 engines this figure is 79, the piston has a recess.

Piston with a diameter of 76 mm without recess for the VAZ 2103 power unit

Crankshaft

The VAZ 2103 crankshaft is made of super-strong material and has nine journals. All necks are thoroughly hardened to a depth of 2–3 mm. The crankshaft has a special seat for installing the bearing.

The neck joints are channelized. They carry oil for the bearings. The channels are plugged with caps pressed for reliability at three points.

The crankshaft of the VAZ 2103 is similar to the VAZ 2106, but differs from the internal combustion engine units of the “kopek” and the eleventh model in the size of the crank. The latter is increased by 7 mm.

Dimensions of half rings and journals of the crankshaft.

- The half rings have a thickness of 2.31–2.36 and 2.437–2.487 mm.

- Molar necks: 50.545–0.02; 50.295–0.01; 49.795–0.002 mm.

- Crankpins: 47.584–0.02; 47.334–0.02; 47.084–0.02; 46.834–0.02 mm.

Flywheel

The part is cast iron with a steel ring gear that is connected to the starter gear. Pressing of the crown is done using the hot method. The teeth are thoroughly hardened by high frequency currents.

The flywheel is secured using 6 self-locking bolts. The location of the clamps has only two positions according to the marks. Centering of the flywheel with the crankshaft is carried out through the front bearing of the gearbox drive shaft.

Table: main technical characteristics.

| Engine capacity | 1450 cm3 |

| Power | 75 hp |

| Torque | 104/3400 nm |

| Gas distribution mechanism | HE IS WITH |

| Number of cylinders | 4 |

| Number of valves per cylinder | 2 |

| Cylinder diameter | 76 mm |

| Piston stroke | 80 mm |

| Compression ratio | 8.5 |

Pistons

Many domestic and imported cars use repair pistons manufactured at the production facilities of the Kostroma manufacturer of piston groups, Motordetal-Kostroma. This company produces pistons with a diameter from 76 to 150 mm. Today the following types of pistons are produced:

- solid cast;

- with thermostatic insert;

- with an insert for the upper compression ring;

- with oil cooling channel.

Pistons produced under the specified brand have their own designations. In this case, information (marking) can be applied in two ways - laser and micro-impact. First, let’s look at specific examples of markings made using laser engraving:

- EAL - compliance with the technical regulations of the customs union;

- Made in Russia - direct indication of the country of origin;

- 1 - group by mass;

- H1—diameter group;

- 20-0305A-1 - product number;

- K1 (in a circle) - sign of the technical control department (QCD);

- 05/15/2016 - a direct indication of the production date of the piston;

- Sp 0.2 - gap between the piston and cylinder (temperature).

Now let's look at the designations applied using the so-called micro-impact, using specific examples:

- 95.5 - overall diameter size;

- B - diameter group;

- III - group according to finger diameter;

- K (in a circle) - quality control (quality control) sign;

- 04/26/2017 - direct indication of the production date of the piston.

It is worth noting here that for the production of different pistons, different aluminum alloys with alloying additives are used. However, this information is not indicated directly on the piston body, but is recorded in its technical documentation.

What engine can be installed on a VAZ 2103 instead of the standard one?

Domestic cars are good because with a sufficient budget it will be possible to implement almost any planned project. Even when connecting the engine to the gearbox there are no particular difficulties. Thus, almost any power unit is suitable for the VAZ 2103. The main thing is that it must fit in size.

Rotary engine

Until a certain time, only special police forces and the KGB were armed with cars with such engines. However, tuning enthusiasts in the USSR, folk craftsmen, found and installed a rotary piston engine (RPE) on their VAZ 2103.

The RPD can be easily installed on any VAZ car. It goes to Moskvich and Volga in a three-section version.

The rotary piston engine can be easily installed on any VAZ car

Diesel engine

The diesel engine is mated to the standard VAZ 2103 gearbox using an adapter plate, although the gear ratios of the engines are not at all suitable.

- Driving with a diesel Volkswagen Jetta Mk3 will not be very comfortable, especially after 70–80 km/h.

- The option with a diesel unit from the Ford Sierra is a little better. In this case, you will have to change the design of the tunnel, install a gearbox from a BMW and make some other changes.

Motors from foreign cars

In general, foreign-made engines have been and are often installed on the VAZ 2103. True, it is impossible to avoid additional modifications in this case.

- The most popular engine is the Fiat Argenta 2.0i. About half of the owners of tuned “threes” installed these engines. There are practically no problems with installation, however, the engine is a bit old, which is unlikely to please the owner.

- Engines from BMW M10, M20 or M40 are also suitable. We have to modify the struts, rework the flywheel and replace the axles.

- Engines from Renault Logan and Mitsubishi Galant are praised by craftsmen, but in these cases the gearbox has to be changed.

- And, probably, the best option is the power plant from Volkswagen 2.0i 2E. True, such an engine is not cheap.

Replacing piston rings

On VAZ cars, as well as on all other models of passenger cars, it is advisable to change only the piston rings only if:

- there is no exhaust in the cylinders;

- there are no signs of damage to their inner surface.

If the liners are significantly worn, they need to be bored, and if the last size was already used before, the cylinder block needs to be relined. You can replace the PC on any VAZ engine without removing the internal combustion engine; this will require removing the cylinder head and oil sump. PCs are replaced if the gap at the joints does not exceed 1 mm.

For example, let's consider replacing piston rings on a VAZ-2114 car with an 8-valve internal combustion engine; such work must be carried out on a pit or a car lift:

- turn off the ignition, put the gearbox in neutral, disconnect the negative terminal from the battery;

- drain the antifreeze, remove the air filter housing along with the pipe (injector corrugation);

- remove the valve cover, camshaft, loosen the timing belt and move it to the side;

- disconnect the wires and cooling system pipes from the cylinder head, unscrew the head bolts;

- unscrew the nuts of the exhaust pipe of the muffler;

- We completely free the cylinder head from all fasteners that prevent it from being removed, and we remove the cylinder head;

- if there is protection under the engine, remove it;

- place a container under the engine sump, unscrew the plug on the crankcase, drain the oil;

- remove the lower hatch of the gearbox housing (three bolts);

- Using a 10 mm wrench or a socket wrench, unscrew all the oil pan bolts;

dismantle the pan, remove the oil receiver;Unscrew the connecting rod nuts, remove the lower connecting rod caps, and carefully knock the pistons and connecting rods upward. Pistons should be knocked out through a soft metal drift or through a wooden block. First, you need to carefully knock out the connecting rod bolt without damaging the threads on it, then place the drift on the end of the connecting rod - in no case should you hit the bearings or the seat underneath them;

- It is recommended to remove the connecting rods one at a time, and immediately attach the caps to them; the caps should not be confused with each other, they are placed back strictly in their places, and a lock to the lock is required;

- remove the PC from the pistons, use a piece of the old ring to clean the piston grooves to bare metal. Be sure to check the cleanliness of the groove all around; there should be no coke left in it;

- We install new rings in the grooves, start with the lower MPC, then install the middle compression PK, and lastly the upper one. For installation, you can use a special device, but it is still more convenient to install the rings by hand. If the MPCs are cast iron, they cannot be bent along their axis, they can only be carefully moved apart. Compression rings also need to be bent carefully, to a minimum;

- we install the piston in place using a special mandrel, hammer it in with a wooden hammer handle or a brass or bronze drift;

- We install one piston-rod at a time, and immediately attach a connecting rod cap to each one. The connecting rod nuts should be tightened with a torque wrench, force - from 4.5 to 5.5 kg;

- then we put everything in place - the oil receiver, the engine sump, the cylinder head. We fill the radiator with antifreeze, oil into the crankcase, and start the engine to check. After replacing the PC, the internal combustion engine may initially smoke and consume oil - the engine needs to be run in for approximately 2 thousand km. It happens that despite the seemingly normal condition of the liners, the internal combustion engine continues to smoke even after replacing the rings after break-in. In this case, you will have to bore the cylinders and install a repair piston group.

| Piston stroke min Piston stroke min Minimum value of the Piston stroke parameter for all modifications of the VAZ model. | Piston stroke max Piston stroke max Maximum value of the Piston stroke parameter for all modifications of the VAZ model. | Modifications The total number of all modifications of the VAZ 2103 presented in our database | Value Value of pistons Data are presented for cars of various modifications and years of manufacture |

| 2103 1.5 MT (1972 - 1983) | |||

| Piston stroke | 80 (mm) | ||

| Compression ratio | 8.5 | ||

| 21033 1.3 MT (1977 - 1983) | |||

| Piston stroke | 66 (mm) | ||

| Compression ratio | 8.5 | ||

| 21035 1.2 MT (1972 - 1983) | |||

| Piston stroke | 66 (mm) | ||

| Compression ratio | 8.5 | ||

VAZ 2103 engine malfunctions

The most common defects found on the engine:

- large “gorge” of oil;

- difficult launch;

- floating speed or stopping at idle speed.

All these malfunctions are associated with various reasons, which will be discussed below.

The engine gets very hot

Experts call the main reason for overheating of the engine unit a lack of refrigerant in the system. According to the rules, before leaving the garage, the driver is required to check the level of all technical fluids each time. But not everyone does this, and then they are surprised to find themselves with a “boiling” internal combustion engine on the side of the road.

Engine overheating occurs due to a lack of refrigerant in the system

Antifreeze may leak from the system. In this case, there is a malfunction - a violation of the integrity of the cooling system. Antifreeze stains on the floor of the garage in which the car was parked directly indicate to the owner that there is a leak. It is important to eliminate it in a timely manner, otherwise there will not be a drop of liquid left in the tank and system.

The reasons for the leak are as follows.

- Most often, refrigerant leaks are caused by hose clamps that are not tightened tightly enough. The situation is especially bad if the clamp is iron and it cuts the rubber pipe. In this case, you have to change the entire segment of communication.

- It also happens that the radiator begins to leak. In such a situation, it makes more sense to replace the element, although small cracks can be repaired.

- Antifreeze leaks through the gasket. This is the most dangerous situation, since the liquid will go inside the engine, and the car owner will not notice any leaks. It will be possible to determine the “internal hemorrhage” of the system only by an increase in refrigerant consumption and a change in its color to “coffee with milk”.

Another reason for engine overheating is a non-working radiator fan. On a VAZ 2103, the quality of cooling by the engine blades is extremely important. The slightest sagging of the drive belt has a negative effect on it. But this is not the only reason for the element to be released.

- The fan can simply deteriorate and burn out.

- The fuse responsible for the electrical circuit fails.

- The contacts on the fan terminals are oxidizing.

Finally, overheating of the internal combustion engine can occur due to damage to the thermostat.

Engine knock

On a VAZ 2103, engine knock is detected without special equipment, by ear. A 1-meter wooden pole is taken and one end is applied to the motor in the part being tested. The other side of the pole should be clenched in your fist and brought to your ear. It turns out something like a stethoscope.

- If a knock is heard in the area of the connector with the oil sump, it is dull, and the frequency depends on the amplitude of rotation of the crankshaft - this is the knocking noise from the worn-out crankshaft main bearings.

- If the sound is heard above the crankcase connector, it intensifies as the engine speed increases - this is the connecting rod bearings knocking. The noise will become louder as the spark plugs are disconnected one at a time.

- If the sound comes from the cylinder area and is best heard at low engine speeds, as well as under load, it is the pistons knocking on the cylinder.

- A knocking sound in the head area when you sharply press the accelerator pedal indicates worn piston seats.

VAZ 2103 engine smokes

As a rule, at the same time as the smoke, the engine eats up oil. It may be gray in color and increase with increasing idle speed. The reason is related to the oil scraper rings that require replacement. It is also possible that one of the candles is not working.

In some cases, this happens due to a ruptured gasket or insufficient tightening of the head bolts. On older engines, there may be a crack in the block head.

Troubles the engine

The phrase “troubling engine” means that one or more cylinders are not working. The power plant is not capable of developing full power and does not have the required traction force - accordingly, fuel consumption increases.

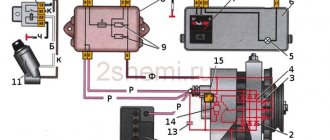

The main causes of tripping are: faulty spark plugs, incorrectly set ignition timing, loss of tightness in the intake manifold area, etc.

Engine misfire is caused by incorrectly set ignition timing.

Thermal clearance of piston rings

PCs are spring discs with one cut - when installed on the piston, they expand, and in the sleeve they are pressed tightly against its walls. In order to achieve maximum compression of the working mixture, the cylinder walls must be as smooth as possible (without defects), and the shape of the internal cavity must be perfectly round. On the piston, the PCs are placed in special grooves, moreover, they are not seated tightly, and on a cold piston they move freely in the grooves.

Piston rings have thermal clearances:

The clearances must be certain; if they are larger or smaller than the required value, the piston group will quickly fail. One should take into account the fact that when heated, the metal expands, and if the thermal gap of the PC is too small, the piston group will begin to overheat. With large gaps, tightness is not ensured and power losses occur.

For passenger cars, as a rule, the following clearances are established:

- between the grooves and the PDA - from 0.02 to 0.08 mm (for the upper ring the gap should be slightly larger);

- between grooves and MPC – from 0.05 to 0.06 mm;

- at the junction - from 0.25 to 0.5 mm.

As wear occurs, the gaps in the PC increase, and they should not exceed:

Some people like it hot

Young owners of VAZ “classics” sometimes tune their vehicles. Of course, a new body kit, straight-through exhaust or deafening music is not always enough. Therefore, they resort to modernizing the power unit.

The easiest way to tune the 2105 engine is to install the next generation DAAZ 21053 Solex carburetor. The increase, of course, will be insignificant.

A higher increase in power is provided by boring the cylinders and increasing the piston stroke. Possible options:

- Boring the cylinder bores to 82 mm increases the volume to 1400 cm³.

- Using the same pistons, but a longer crank (shaft 2103 with an 80 mm crank) and connecting rods shortened by 7 mm gives 1600 cubes.

- When both options are combined, the working volume becomes 1700 cm³. This tuning of the VAZ 2105 engine allows you to achieve a power of 100 hp. With.

A more radical way to improve technical characteristics is to replace the standard engine with a rotary power unit (VAZ 413 Wankel engine), produced at VAZ in small batches. Despite its small size, the tuning drive produces 140 horsepower. Of course, getting it is very problematic.

The engine with the VAZ 2105 index was underestimated because it was ahead of its time. It became the first domestic engine with a timing belt instead of a traditional chain. Time has shown the viability of this solution. On modern cars (especially small and middle class) belts are more common than chains. To a large extent, this was facilitated by the increase in the service life of these products.

Design Features

Engine Toyota 2NZ-FE

Initially, at the design stage, a feature for the engine was the overhead camshaft:

- The piston stroke decreased by 5.5 mm compared to the Fiat 124 standard;

- the cylinder diameter increased by 3 mm.

This modernization ensured acceleration and rapid acceleration. In addition, the 2101 engine had the following design nuances:

- timing chain transmission;

- unfinished carburetor models;

- major overhaul after 20,000 km.

Valve train chain

Immediately after the release of the first internal combustion engine of this series, the manufacturer AvtoVAZ released a manual in which it indicated which oil to fill in the engine and provided a description of the internal combustion engine parameters to increase the service life of the engines. Thus, the owners of the next three generations of engines had no questions about what oil to pour and in what quantity.

Timing mechanism