VANOS (Variable Nockenwellen Steuerung) is a technology developed by BMW in close cooperation with Continental Teves.

Find out the cost of vanos repair >>>here.

The VANOS gas distribution system changes the position of the camshaft (shafts) relative to the crankshaft, thereby adjusting the timing of the timing (gas distribution mechanism) during operation. This adjustment varies from 6 degrees advance to 6 degrees retard from TDC (top dead center).

The BMW Vanos system has been improved since its inception, and today there are several generations of it.

What is VANOS in an engine?

What VANOS looks like on a BMW engine.

This is an electromechanical device that interfaces with the engine gas distribution system. It is not difficult to guess that VANOS is needed in order to control the gas distribution phases - this is how greater engine efficiency is achieved. Here's how it's useful:

- Fuel consumption in the cruising (medium) speed range is significantly reduced;

- exhaust gases become cleaner and contain fewer toxic substances;

- the engine runs very stable at idle even at low temperatures;

- the graph of power growth depending on speed becomes smoother;

- at medium speeds maximum torque is achieved;

- At high rpm a fair amount of power is added.

VANOS first appeared in the mid-90s on the BMW 5 Series and has been improved several times since then. Now all BMW engines are equipped with the 4th generation VANOS system, which is distinguished by a gear camshaft control system.

Weaknesses of the system

Like any system, VANOS has both pros and cons. In particular, with a large number of moving parts, there is accelerated wear of these components. Most often, the o-rings on the pistons require replacement, since they are made of rubber. During use, it loses flexibility, becomes rigid, and then completely cracks. At the same time, the company does not produce rings for sale; it only accepts entire units for repair.

Bearings and washers are also often subject to wear. They are made of soft metals, which ensures their flexibility and tightness, but also relative fragility. And again, you cannot buy them separately from BMW, you can only take the Vanos for repairs.

Finally, all parts are damaged due to contamination with combustion products. In addition, various chips or scuffs may occur on the moving parts of the shafts or pistons. When they occur, tightness is lost, power drops, and the sound of the engine changes.

Good day, dear everyone! I want to warn you right away - there will be a lot of text, but I will try to make everything more or less readable. I also immediately apologize for possible grammatical and spelling errors. For we are all not without sin

What is the Vanos system, what types of this system are there, what engines are they installed on, and how does it actually work?

Many BMW owners, when asked what Vanos is, will answer something like this: “This is a system that moves the shafts and the car drives better and consumes less fuel.”

But it is very rare that a person will answer the question: Why is this actually happening?

Well, let’s deal with this issue once and for all. But first, a little excursion into history. The Vanos system has been improved since its inception, and currently several generations of this system can be distinguished.

1 - generation Single VANOS or “One Vanos”

Single VANOS first appeared in 1992 on the BMW M50tu engine, which was originally installed in the BMW 5 Series.

2 - generation Double VANOS or “Double Vanos”

Double VANOS first appeared on the S50B32 engine in 1996. Later, this system began to be installed on in-line 6-cylinder M52tu engines and then migrated without changes to the M54 and M56 engines

3rd generation. Vanos intake camshaft gears

Vanos gears first appeared on the V8 M62TU engine in 1998. The system with Vanos gears is similar in principle to Single Vanos, but has a more advanced and compact design due to the placement of the entire actuator inside the timing gears (sprockets).

4th generation. Vanos gears for all camshafts

This system is a logical continuation of the third generation Vanos systems, that is, it includes control gears on the intake and exhaust camshafts. This system first appeared on n-series engines in 2001.

Well, we seem to have sorted out the history, now all that remains is to figure out how it all works. In fact, if you look at it in detail, then everything will become very clear and understandable. We will understand it using the example of the very first generation, namely Single Vanos.

In the diagram shown in the leftmost figure, we can observe that the exhaust valve is open to approximately the same value as in the rightmost figure, but the intake valve is open to a smaller value and this helps supply the mixture with the optimal value into the cylinder to obtain maximum power from the motor. Which entails an increase in engine efficiency at low speeds, and as a result, lower fuel consumption.

As for the operation of an engine with a vanos at high speeds (4000 - 7000), here we can observe a similar picture as with a non-vanos engine, the valves are slightly open at the same level, both intake and exhaust.

We draw a logical conclusion from all of the above. A system called Single Vanos regulates the opening and closing phase of the engine intake valves by the oil pressure that is created in this system. The oil pressure, in turn, is regulated by a solenoid valve operating from the engine management system, based on information from camshaft position sensors. Accordingly, systems with two vanos also regulate the opening and closing phases of the exhaust valves.

I consider this article to be final. I kindly ask you not to kick me, because I’m still just learning. To those who read the entire text, respect for your patience)

How VANOS works

The VANOS solenoid opens and allows the shaft to move.

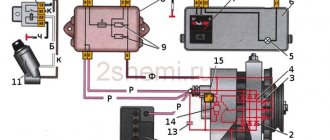

The design of the VANOS unit is relatively simple: there are oil pistons controlled by an electronic unit that act on the gas camshafts and change their position in one direction or another. According to these changes, the valve timing changes by 6° advance or retard. That is, the valves begin to open either a little earlier or a little later than in the initial position of the shafts.

The first versions of the system were called Single VANOS - only the position of the intake camshaft was regulated, and the intake phases were changed discretely, i.e. in leaps and bounds. Newer BMWs (since the late 90s) now use Double VANOS. Here the phases of both intake and exhaust are adjusted, and the adjustment occurs smoothly, without jerking. In addition to VANOS, Valvetronic is also installed - an electronic system for adjusting the valve stroke length. The VANOS operation scheme is approximately as follows:

- After starting the engine, VANOS operates in a special mode to reduce the warm-up time of the engine and catalytic converter.

- When operating temperature is reached, the standard low speed mode is activated - the valves open with a slight delay so that the engine runs more stable and produces more power.

- As the speed increases, the valves open earlier and earlier, until at cruising level they go “negative”, as a result - a maximum of torque and a little more on top. Plus fuel savings due to afterburning of exhaust gases.

- Further acceleration again increases the delays, and at high engine speeds the phases again become delayed, as at low speeds (but not quite).

Daimler-Benz plays on diesel

Daimler-Benz is also conducting research in the field of individual valve control. The engine in Ulrich Letsche's laboratory is equipped with a hydraulic valve drive (Fig. 2). “But many people misunderstand how it works at first,” Mr. Letsche says. “They believe that the valves are only hydraulically actuated.” In fact, the drive resembles a spring pendulum - the hydraulics serve only as a “trigger”, after which the spring controls the movement of the valve. A diesel engine requires greater power and drive force, since there is still quite a lot of pressure in the cylinder when the exhaust valve opens. Letsche's experimental engine - single-cylinder, with a displacement of about 2 liters - is assembled on the basis of the piston group of the Mercedes-Benz-Actros engine. The maximum speed does not exceed 2000 rpm, but the advantages of the new gas distribution mechanism are obvious. The opening phases of the intake and exhaust valves are optimal over the entire range of rotation speeds and loads, which allows saving up to 10% of fuel and reducing exhaust toxicity by approximately the same amount. And although diesel engines in trucks do not require high speeds, the hydraulic drive remains operational up to 6000 rpm, which makes it possible to use it in passenger cars as well. Particularly attractive for trucks is the control of the engine braking process by varying the width of the exhaust phase, as well as changing the working volume of multi-cylinder engines by turning off the cylinders.

Pros and cons of VANOS

Needless to say, the system turned out to be very successful in terms of squeezing maximum potential out of the engine, as well as the efficiency and environmental friendliness of its operation. But, as often happens, the big advantages turned into no less impressive disadvantages. VANOS seriously reduces the reliability and durability of the engine. At the same time, solving problems associated with this system costs a pretty penny.

Destruction of O-rings

The weakest point is the sealing rings of the oil pistons, which regulate the position of the camshafts. High temperatures and aggressive chemicals destroy the rubber material of these rings. The engine seems to be losing strength, requiring increasingly higher speeds to produce a certain power. And what’s most unpleasant is that BMW does not change these rings separately, only the VANOS unit completely. We have to look for alternatives and turn to unofficial service stations.

Wear of washers and bearings

And again, oil pistons - their bearings and washers are not made of the strongest metal, so over time the VANOS unit begins to perform its duties worse. Plus, the sound of the engine is mixed with an unpleasant, sharp metallic noise. Once again BMW does not offer any separate bearings! Therefore, those who do not want to shell out several tens of thousands of rubles for a new unit should order them from third-party manufacturers.

Chips and dirt on flanges and pistons

With an aggressive driving style, contamination in oil and gasoline, and simply a fairly high mileage, you may encounter problems with deformation of the metal parts of the block. Chips and scuffs appear on the front edge of oil pistons or gas distribution shafts. This leads to drops in power and torque, idle failures, and changes in the sound of the engine.

Similar negative effects are caused by the deposition of contaminants on the working mechanisms of the VANOS unit. Another option: violation of the integrity of the electrical wiring - a wire has simply broken or become disconnected. Fortunately, such problems are easy to solve, even in a garage, if you first read the exact instructions.

Advice for BMW owners

If there is a distinct, constant knocking noise under the hood, a noticeable decrease in engine power and problems with idling, you will have to remove and disassemble the vanos valve. Any motorist can do this using a standard set of tools.

You can check the degree of wear by simply pressing in the control piston. If it sinks in smoothly and is pushed back by the spring, it will be enough to replace the O-rings.

Otherwise, it is necessary to sand the element itself and the cylinder or completely replace the moving element. Solving problems with the Vanos solenoid valve should begin by checking the integrity of the wiring. Its restoration is often a sufficient solution.

VANOS service

With regular technical inspection, all potential problems with the unit are caught and resolved at an early stage, so prevention is the best way to save money in your wallet. Ignoring the above symptoms costs yourself more. After all, VANOS interacts closely with the engine, and malfunctions of the unit lead to engine malfunctions in a chain reaction.

Timely cleaning and replacement of unit consumables keeps engine performance at the level of a freshly purchased car. So it’s better to treat this product of technical progress with due attention, and not fall for BMW’s tricks, replacing the entire unit because of a torn rubber band.

Rubber wear

As you know, no one has yet managed to create an ideal metal piston. They always have microscopic gaps, which, however, are sufficient for gas leakage. In addition, deformations occur in the pistons during operation. They also do not benefit the tightness. To create it, special piston sealing rings made of flexible and durable materials are used.

The BMW company focused its attention on tires (also called Buna). Over time, this rubber, although very reliable, like everything German, begins to harden under the influence of powder gases and temperature changes

After this she can:

Because of this, tightness is lost and the piston requirement for oil pressure increases. And after a while Vanos stops working altogether.

The problem is solved by replacing the rings with new ones. However, BMW itself does not sell rings, it only repairs entire blocks. You will have to purchase components from other manufacturers.

Is it worth installing it?

If you bought a used BMW and want to go sideways like all the boys in the area, we hasten to upset you - this is not your option. Firstly, with an old engine, you won’t be able to fully reveal Vanos’ potential, and secondly, you’ll kill the engine, which is most likely outliving its time anyway.

As a result, you will simply waste money and time, and if you sell, you will not get back even part of the money invested.

It only makes sense to install it when you are confident in the service life of the engine. For example, they personally did a major overhaul on it (or are sure that the previous owner did it), or an option when replacing the engine with a contract one.

Transmission

In addition to a manual transmission, one of two 6-speed automatic transmissions could be used in tandem with the engines: ZF (6HP19 - before 2007, 6HP21 - after 2007) or GM (6L45R). The machine needs regular oil renewal, which is guaranteed to extend its life.

The first serious repair of GM gearboxes occurs after 200-250 thousand km. Oil pump, valve body or torque converter for rent. One common cause for complaint is jolting when transitioning between 2nd and 3rd gears. As practice shows, with such symptoms the box can travel more than 200,000 km.

In the case of ZF, intervention may be needed earlier. The service life of solenoids is about 100-150 thousand km. Later comes the turn of the bushings, torque converter and valve body. Mechatronics that are sensitive to the condition of the oil can also cause trouble.

The rear gearbox rarely fails. After 200-250 thousand km, oil seals may leak. If the leak is not repaired in time and the oil level is not monitored, a hum will soon appear, indicating wear of the bearings. For restoration repairs you will have to pay about 25,000 rubles.

Repair kits for BMW

BMW cars are the standard of safety, reliability and comfort, but they do not last forever: over time, individual components begin to “fail”, more fuel is spent than before, and with difficulty, especially if the thermometer drops below zero. In this situation, you have three options:

Give the car for repair. Buy a repair kit for BMW from an official dealer. Pay attention to repair kits for BMW from Bersa Tools.

Let's consider each option separately.

Repair

We, of course, know that there are honest auto mechanics who do exactly what is required and don’t charge a penny more than necessary, but such super-people are rare in real life. It's much more likely that you'll be billed not only for repairing the broken part, but also for half a dozen jobs you didn't order. To answer all your questions, the master will explain that “everything was on its last legs” there, and it’s simply a miracle that you turned up in such a timely manner.

Official dealer

“Native spare parts” are good for everyone: both in quality and appearance. The only bad thing is that they cost like an independent car: not a BMW, of course, but something from the domestic automobile industry - quite good. In addition, parts from the official manufacturer are sold in already complete sets, and even if you only need one membrane, you will still have to buy everything else to go with it. Unnecessary elements will safely find their place somewhere on the mezzanine or in the corner of the garage, and so they will disappear there - just like your overpaid money.

Repair kits for BMW from Bersa Tools

We manufacture all our products ourselves, and therefore guarantee their European quality at domestic prices. The repair kit includes not only the damaged spare part, but also the tools necessary to repair it, as well as consumables and components. The catalog of repair kits for BMW includes lock cylinders, air suspension compressors, Hall sensors, KVKG membranes, handbrake electric motors and many other kits. If you haven’t found the part you need, don’t despair, our range is constantly expanding and sooner or later we will definitely be able to offer you what you need. And if you call, it is possible that our consultant will already find an alternative option for you: some repair kits are suitable for several models at once.

Repair of Single Vanos BMW M50TU M52 S50 S52

12.07.2017

Symptoms of a non-working BMW vanos (Single VANOS BMW): - poor acceleration dynamics up to 3 thousand rpm - difficult start - increased fuel consumption - unstable idle speed - jerking during acceleration - knocking in the front part of the engine (most often when revving) A client came to us with complaints of poor traction during acceleration. Diagnostics using dealer equipment showed a malfunction of the VANOS BMW gas distribution system. Together with the client, a decision was made to repair the BMW vanos. For repairs you will need: - Repair kit for single VANOS BMW M50TU M52 S50 S52 11361748819 (11361748036) - Set for setting the phases of M52 (crazy hands can do without it, but it’s more difficult) - Set of tools for working with BMW - BMW valve cover gasket - Gasket for VANOS BMW - Rubber bands for valve cover bolts 15 pcs - VANOS hose (or hose repair) - Carburetor cleaner or gasoline So the BMW M52B28 engine with one Vanos. Vanos is highlighted in red. 1) Remove the decorative cover of the motor and coils. 2) Remove the valve cover, raise the piston of the first cylinder to top dead center. We fix the flywheel with a special pin, the camshafts with jigs at the back (before this you need to unscrew the rear studs for the valve cover bolts) 3) Clamp and fix the hydraulic tensioner of the intershaft chain. We twist the plugs on the VANOS with a 19mm wrench and unscrew the exhaust camshaft sprocket. We unscrew the VANOS BMW control unit using a 10 mm socket with a ratchet and the engine hinge, unscrew the oil line of the VANOS system, and disconnect the VANOS valve connector. If the vanos hose is sweating or damp, it must be replaced, or it can be repressed at services that repair hydraulics. Using a special tool, turn the intershaft chain clockwise and pull the VANOS unit towards you. So Vanos has been removed. 4) Unscrew 5 screws on the table and remove the piston from the housing. We unscrew the VANOS BMW control valve with a 32 wrench and inspect the wires for damage and broken insulation. We remove the piston and spring from the housing under the valve. 5) Thoroughly wash all parts of the VANOS system. Using a utility knife, cut off the old vanos rings and wash the seat of the rings. We inspect the vanos housing and piston for scoring; if there is scoring or wear is felt with your finger, then the piston or housing should be replaced. 6) We install new rings on the vanos piston, first soft (Viton) then hard (Teflon); it must first be heated either in water or with a hairdryer so as not to tear during installation. Then lubricate the rings and housing with oil and smoothly insert the piston into the housing. Reassemble the assembly in reverse order. 7) When installing Vanos, you need to rotate the intershaft sprocket with the chain clockwise until it stops. Install a new gasket under Vanos. Next, press the Vanos BMW M52 to the engine and slowly turn it counterclockwise until the Vanos is pressed all the way. Release the hydraulic tensioner of the intershaft chain. We wash the valve cover with a Karcher and reassemble it in the reverse order. Repair of the BMW M52 vanos system is completed. The vanos begins to work fully after grinding in at about 300 km. We also highly recommend repairing the VANOS BMW M50TU M52 gas distribution system together with an oil change. The repair kit VANOS BMW M50TU M52 S50 S52 can be purchased from us on the website www.Bersa-Tools.ru.

VANOS unit BMW M50TU M52 S50 S52 before installing the repair kit Bersa-Tools.ru: