A tachometer is a device designed to measure the speed of a car engine. It helps to monitor the number of rotations so that their number does not lead to engine damage. When the device stops showing speed, drivers begin to look for the reason why the tachometer does not work. There are several types of faults that should be taken into account.

Interesting fact!

Today you can find digital and analog tachometers.

Analog tachometers are more popular than digital ones, which is explained by their ease of use. There are not many tachometer malfunctions. Basically, problems can be determined by the behavior of the arrow itself. She starts jumping or doesn't move at all. If you observe such a picture, you should find out the reason for this phenomenon. Most likely, the device is broken and will need repair, and possibly replacement.

Important!

Failure of the tachometer does not affect the basic functions of the car, but if the driver does not receive information from it, this may result in engine repair or an accident.

Causes of malfunction and their elimination

There are a number of reasons why the tachometer does not show revolutions. If the tachometer does not work, the causes of each individual malfunction may be different. For example, car enthusiasts often encounter such a nuisance as “arrow twitching”. The reason for this is often the installation of silicone ignition wires, which differ from the standard wiring. The resistance of silicone wires differs from that of the wires that were installed by the factory during the manufacture of the car. Therefore, a change in the current pulse occurs. The cause of this breakdown can be corrected by reducing the value of the resistor on the gearbox board.

Tachometer needle jumps

If you notice that the needle has started to jump and the tachometer is not showing, you should pay attention to the engine speed sensor. Most likely it has crashed and is unable to transmit correct data. This problem can only be solved by replacing the sensor.

The arrow doesn't move

Another of the most common reasons why the tachometer does not work is poor contact quality or faulty wiring. If this happens, then the impulses from the engine simply do not arrive to the tachometer and the speed arrow does not work.

The device does not respond and does not show data. It's easy to fix this problem. To do this, carefully inspect all the wires. If you see cracks or breaks, replace the damaged parts of the wiring.

Sometimes the reason that the tachometer needle does not move is a breakdown of the device itself. If you have not identified any damage to the wiring or sensors, then you cannot do without repairing or replacing the tachometer itself.

Interesting fact!

More recently, there were no tachometers on cars at all. Cars were produced without these devices.

Failure of the internal combustion sensor

Sometimes situations arise when a breakdown of the internal combustion sensor causes the tachometer speed to not work. The arrow begins to behave incorrectly and show incorrect data. If you find a breakdown of the internal combustion sensor, replace it with a new one. After this replacement, the tachometer will start working normally.

Screen breakage

Probably the most common cause of device malfunction is failure of the LED screen. If you notice that data is not displayed on the digital display, it is best to replace the device display with a new product.

Important!

To find the cause of the tachometer malfunction, try testing the voltage level in the wires and check the ground, since quite often this is what helps to establish the true cause of the problem.

How to repair a tachometer

Tachometer breakdowns are common, but fixing them on your own is not so difficult. To do this, let’s look at the features of disassembling the gearbox and try to answer the question: “How to fix the tachometer?”

1.

You need to remove the daily odometer reset handle from the axle.

2.

Unscrew the screws securing the gearbox visor to the body and securing the tachometer itself.

3.

All wires must be disconnected from the tachometer.

4.

The screws securing the backlight cable should also be unscrewed.

5.

Unscrew and remove the temperature indicator nuts.

6.

It is also necessary to remove the visor with the protective glass.

7.

Using a screwdriver, remove the arrow.

8.

Unscrew the screws on the gearbox scale.

9.

Remove the temperature indicator pins.

10.

Now you need to carefully bend the gearbox dial and pull out the tachometer.

After this, you should carefully examine the board for cracks and “unsoldered” places. Check the supply voltage of the microcircuit by connecting the board to a power source (it is important to observe the polarity). The voltage should be 7V.

If it differs significantly, you need to change the elements of the voltage stabilizer. Look at the output signal of the microcircuit with an oscilloscope. This should be a positive pulse with an amplitude equal to the supply voltage and a duration of 3 ms.

Check the milliammeter winding for damage - its resistance should be about 150 Ohms.

Also be sure to check the arrow. Perhaps it is jamming due to dust. Wash with alcohol and blow out the magnetic system.

After all checks and elimination of the cause of the tachometer malfunction, install it and reassemble the gearbox in the reverse order.

The tachometer in a car is used to indicate the number of revolutions of the engine crankshaft. Let's look at why the tachometer doesn't work and how to find and eliminate the cause of the breakdown. We will definitely dwell on the device and principle of operation, which will help to find out why the tachometer stopped working, the needle twitches or behaves inappropriately.

Tachometer Features

Many motorists do not use a tachometer - it is not as important as the speedometer (which is used to control speed, so as not to violate traffic rules and not earn a fine).

Using a tachometer, the engine speed is measured - and this sometimes turns out to be useful for beginners who have not learned to “feel” the engine’s operation. When carrying out tuning, beautiful devices are installed that improve the appearance of the dashboard. The sixes had four-cylinder engines. They have one feature - for each revolution of the ignition distributor shaft (distributor), four closures of the breaker contact group occur. With its help, the impulse necessary to form a spark is created. In a contactless system, the functions of a mechanical breaker are performed by a Hall sensor.

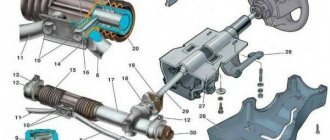

Device and purpose

The purpose of the tachometer is to visualize the crankshaft performance. The device shows how fast the crankshaft rotates per minute, these readings are also called engine speed. Structurally, the tachometer is a milliammeter connected in one housing to an electronic part; these elements are installed on a printed circuit board.

As for the principle of operation, it consists in measuring the frequency of pulse transmission in the primary circuit of the engine ignition system. With the power unit operating, during one revolution of the distributor shaft, the contacts on the breaker should close and open 4 times. Accordingly, with one revolution, 4 voltage and current pulses are formed in the electrical circuit. As the crankshaft speed increases, the pulse transmission frequency also increases, which, in turn, affects the deflection of the instrument needle.

"Seven" tidy with tachometer

Characteristics

In general, connecting the tachometer will not cause any difficulties - it has only three main wires, the rest are auxiliary. It can be used to measure the rotation speed of any engine that has electronic or contact ignition.

Using a tachometer, the number of pulses in the primary ignition circuit is measured. On four-cylinder four-stroke engines, for one revolution of the distributor shaft, 4 closings and openings of the contact group occur. In other words, each revolution initiates the formation of 4 pulses. But for each revolution of the crankshaft, only two impulses are generated. Consequently, there is a direct relationship between the rotor speeds of the distributor and the crankshaft.

Where is

There may be several options for the location of the device; the main requirement in this case is convenience for the motorist. If the tachometer is connected at home, then it is usually placed on the dashboard or on the center console, in fact, as in production. Of course, if necessary, you can install the device in any convenient place, but the two options listed above are the most convenient.

Before installing and connecting the tachometer, you need to take into account that the readings shown by the device should always be in sight. While driving, the driver must not be distracted from the road. A digital device can be installed on the “six”, although initially these models were equipped with analog devices.

Air flow

The air flow of the Niva Chevrolet is controlled using a hot-wire sensor, which is located between the hose of the intake pipe and the air filter. The magnitude of the direct current depends on the direction and amount of moving air that passes through it. In the event of a system malfunction, a code is stored in memory and the alarm is activated.

To replace, you need to prepare a 10mm wrench and a screwdriver and do the following:

- Disconnect the connector from the sensor

- Loosen the air pipe clamp

- We unscrew the bolts that secure the sensor and the o-ring

- Installing a new one

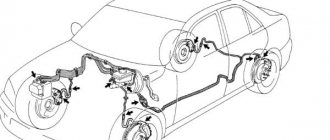

Tachometer connection diagram

The tachometer circuit depends on what ignition system is used on the car. In the case of a contact system, connections are made as follows:

- The left terminal of the tachometer (red) is connected to the positive of the ignition switch. This is the power supply to the device - it is supplied only when the ignition is on.

- The middle wire (white with a black stripe) is connected to the ground (body) of the car.

- The right terminal of the tachometer is a signal terminal; it is painted brown. It is connected to terminal “K” of the ignition coil and the contact group of the distributor.

Connecting the tachometer to the elements of the electronic ignition system is very similar:

- The red wire connects to the ignition switch. Power is supplied, as in the previous version, only when the ignition is turned on.

- The negative wire (white with a black stripe) is connected to the car body.

- The control wire (brown) is connected to terminal “K” of the coil and contact “1” of the electronic switch.

In both cases, the power wire for an incandescent lamp is connected to the tachometer, which is necessary to illuminate the scale.

Wires for connecting the tachometer

The design of the device contains not only a speed indicator, but also an oil pressure lamp.

This is interesting: Nissan X-Trail maintenance - list of works and cost

Before connecting the tachometer, you need to familiarize yourself with the purpose of all the wires:

- White - intended for connection to the part of the wiring through which voltage is supplied to illuminate devices.

- The red wire and fuse provide power to the device. Moreover, voltage is supplied to it only when the ignition is turned on.

- White with a black stripe – connection to vehicle ground.

- Brown is the signal wire through which voltage pulses are received from the coil.

- Black – designed to connect the electromagnetic relay of the charging current indicator. The relay is installed in the engine compartment, on the right side.

- The gray wire with a black stripe connects to the oil pressure sensor on the engine block.

When installing, be sure to follow the colors. Out of habit, you can perceive the black wire as negative (in fact, in most cases it is). In this case, the tachometer will not work.

Speedometer does not work on Niva Chevrolet

Chevrolet Niva SUVs are equipped with a speedometer, the needle of which is driven by a stepper electric motor.

It receives information about the speed of the vehicle from the speed sensor (DS) installed on the transfer case housing. Signs of a speedometer malfunction are manifested by the twitching of its needle, although the car is moving at the same speed. A complete failure of the speedometer is also possible, when the needle goes to zero and stops any movement on the scale. When the speedometer starts to work abnormally and the CE warning lamp lights up in the instrument cluster, you need to check what error codes have appeared in the memory of the electronic control unit (ECU). If there is an error 0500 indicating a malfunction of the speed sensor, you will have to look for a place (inspection hole, overpass, lift) where it would be convenient to get to it. The appearance of this code may be due to a malfunction of the speed sensor itself or its mechanical drive. If, due to “glitches” of the speedometer, the CE warning lamp does not light up, then you will have to do a self-diagnosis test on the dashboard. To do this, without turning on the ignition, press the button that resets the vehicle's daily mileage. Then you turn on the ignition and release this button. All arrows on the instruments, if they are working properly, must make three movements on the scale from zero to maximum and back. If the speedometer needle does not want to perform the test as expected, then we can conclude that there are faults in the speedometer itself or the instrument cluster board that do not allow the speedometer to work normally. In this case, the instrument cluster will have to be replaced, since its individual components are not available for sale.

In addition to the above-mentioned malfunctions, there may also be problems with loss of contact in the connector blocks located in the electrical circuit from the speed sensor to the instrument cluster. Particular attention should be paid to the connector on the speed sensor itself, since moisture often gets into it and then the speedometer needle begins to twitch as the car moves. Also, contact No. 9 in the red block of the instrument cluster must be checked, since it is the signal that is received from the speed sensor. There are cases, when assembling a car, that this block is installed with a slight misalignment, which can lead to a short-term loss of contact.

Types of devices

Tachometers are also divided into standard and remote ones, depending on the installation method. If everything is clear with the regular ones, then the remote ones can have several types of purposes.

First of all, the remote tachometer is intended for mounting on the instrument panel and giving the vehicle a more individual appearance. Depending on the preferences of car enthusiasts, such a device is more convenient.

Decorative stands and grips for mounting on a dashboard have been added to the design of the tachometer; it has a mainly digital signal processing principle. If it is available, there is no problem with how to check the tachometer, which is installed on the instrument panel; to do this, you need to compare the readings in different engine operating modes. Such devices are often used by professional sports racers and lovers of individuality in the design of their cars.

An external digital tachometer with a higher accuracy in determining the rotation speed is suitable for diagnosing a standard device. You can also use it to independently adjust engine operation with greater accuracy. When driving, it is more convenient to use a standard tachometer, since the eye perceives the angle of the needle well and high accuracy is not required when driving.

By installation method

There are 3 main options for this parameter:

- contactless;

- regular;

- remote

Installation of standard devices is carried out in the panel. We are talking about a shield with a VAZ 2107. Remote ones can be located anywhere. They come with a special leg for fastening. You can use either adhesive tape or double-sided tape. In a word, everything depends on the flight of fancy. Non-contact tachometers do not require connection, which means that installation is not necessary for them. It should be taken into account that such devices are not designed for constant monitoring of speed. They are better suited for checking, tuning the engine and the main tachometer.

The cost of standard devices is the lowest, remote devices are slightly more expensive, and non-contact devices are several times superior to previous types.

Type

By type, all tachometers are divided into:

- digital;

- electronic;

- analog;

- mechanical.

A mechanical tachometer is a rarity. These are the very first devices that were installed on cars. Its use today has no basis other than adherence to retro style. Analog tachometers are the main type that is found on the VAZ 2105. They have the form of a dial and a arrow, less often, a vertical or horizontal scale. These are the devices installed in panel 2107, but they can also be remote.

The electronic type is housed in a plastic box and has a display. The revolutions are indicated here in digital form. Sometimes such devices have a slight delay in readings, but their accuracy is higher than analogue ones.

And the last type is the most modern. This is a digital tachometer. It has a lot in common with the electronic one, but the display is better. Capable of displaying several different dimensions at the same time and having a nice design. This is the most expensive type.

Injector and carburetor

Many car owners have long switched to using an injector instead of a carburetor. The tachometer of the injector and carburetor has a slight difference. But it will not work correctly, without intervention in the design. You need to pay attention to this.

By connection method

The device is selected for a specific type of engine. The connection is carried out strictly according to the tachometer instructions. The colors and purpose of the wires may vary greatly.

The most common connection is 3 wires:

- "+" to "+";

- “–” to “–” or “ground”;

- "signal" for ignition.

This connection is used when replacing the tachometer on a panel from a VAZ 2107.

The second connection is more often used on remote devices. It looks like this:

- “+” to “+”, to the terminal marked “B+”;

- “–” to “–” or “ground”;

- “signal” to the coil (contact “K”).

This is interesting: Why turn signals and emergency lights do not work: possible reasons and how to eliminate them

There are all sorts of options that allow you to use the device for your own purposes. For example, the connection determines when and how the device will turn on. The choice depends on the owner’s knowledge of the car’s electrical circuits and the flight of his imagination.

Basic elements of the electrical system

The vehicle's on-board network is designed so that all components and assemblies function smoothly, and control is as comfortable as possible. According to international standards, the voltage is 12V to be compatible with most consumers.

The circuit itself is single-wire. In practice, this means that the “negative” terminal is connected to the car body, and each individual device is powered by a “positive” wire. This greatly simplifies the routing of wires along the body and reduces the number of wires required. It also reduces the likelihood of cable damage and, as a result, a short circuit.

Part selection rules

You can install this unit yourself. To do this you will need the following tools and materials:

First you need to find out the operating principle of the unit in question. The pulses read by this device enter the ignition system coil, displaying information on the screen. Auto mechanics recommend buying an electronic tachometer. When choosing this device, you should take into account the structural features of the VAZ 2105. Otherwise, the tachometer will show revolutions with a slight error. You can install a universal unit with switches. To do this, connect it to any type of engine.

In the selection process, you should also take into account the fact that there are dial and electronic tachometers. You can install the first type tachometer with a tuner. The second type includes the Balsat TX-319t model. It is a microprocessor device whose main task is to monitor the operation of the engine. If necessary, the driver can select the most suitable mode. Before you figure out how to install a tachometer, you need to consider the vehicle's capabilities:

- measurement of crankshaft revolutions of 2-6 and 8-cylinder engines,

- availability of watches,

- ability to remember maximum and minimum temperatures,

- presence of a stopwatch,

- ability to measure crankshaft acceleration.

Installing an electronic tachometer involves independently adjusting the backlight. The advantages of the Balsat TX-319t among auto mechanics include the presence of a standby mode. This feature significantly reduces energy costs.

How to connect a tachometer of this type is of interest to many car owners. First, select a mounting location. The negative wire is then connected to the vehicle body. The plus wire is connected to the corresponding ignition terminal. A voltage of 12 W appears in it.

Niva - Club / Niva - Club

The ramp is attached to the inlet pipe with two screws. Fuel under pressure is supplied to the ramp cavity, and from there through injectors into the channels of the intake pipe.

The injector is an electromagnetic valve that allows fuel to pass through when voltage is applied to it and closes under the action of a return spring when there is no power. An individual fuel filter is installed in the inlet fitting of each injector. The controller controls the operation of the injectors.

VAZ Niva injector with sealing rings The injectors are sealed in the ramp and in the intake pipe with rubber rings and fixed on the ramp with metal clips.

Typical faults

If the mechanical tachometer on a car stops working, there is mechanical damage to any of the structural elements. A broken cable of a flexible shaft, wear of the worm gear elements, the appearance of backlashes, deformations - all these reasons can cause the engine speed indicator to fail.

What to pay attention to if the electronic tachometer does not work:

- integrity of electrical wiring. In this case, it is important to check not only the signal wire, but also the ground and power supply of the instrument panel;

- quality of contacts. The presence of oxides and loose contact inside the chips may well cause the tachometer to fail;

- the integrity of the elements of the measuring unit, which are located behind the protective glass inside the dashboard. Among mechanical damage to transistors, burnout of microcircuits, tracks or swelling of resistors, the most common reason for a non-working tachometer is a violation of solder integrity. For example, on the Mitsubishi Padjero II, the appearance of microcracks in the soldering areas of the tachometer elements is a generally recognized disease.

On vehicles with an alternator connection, a non-functioning tachometer may indicate a faulty alternator. In this case, the breakdown is accompanied by the lighting of the low battery charge indicator and the sporadic lighting of a “garland” of warning lights on the dashboard.

In some types of design, changes in the linear resistance of high-voltage wires can make adjustments to the accuracy of the engine speed indication.

Why does the tachograph needle jump?

Before you figure out why the tachometer needle is jumping, or try to find the cause of incorrect indicators in a malfunction of the engine, wiring or other elements of the machine, you should check the operation of the device itself. It is worth checking the spark plugs, wiring, contacts through which it is connected, and checking its settings. If the tachograph was changed or disassembled before this, then this is the most likely factor for incorrect indicators on the device. To fix the problem, just check its settings, if necessary, adjust it from behind using the toggle switch, check the zero position and correct installation.

If all of the above descriptions have been done, but the tachograph still does not work correctly during ignition or at idle, then you already need to deal with the engine or the car’s electrical wiring.

Electrical problems are a fairly common explanation for why the VAZ (Lada) tachometer needle jumps. Owners of other car brands complain much less often about such problems. To eliminate a wiring malfunction, the first thing you need to do is assess the condition of the distributor and the capacitor located on it. If it malfunctions, no voltage is supplied to the ignition coil. Additionally, you should check the contacts, the quality of the connections, the voltage at the plus and minus. A breakdown of the coil itself also happens, which will also affect the display of data on the tachograph.

In the same way, it is necessary to test the entire ignition system. Here it is important to assess the condition of high-voltage electrical wires, their wear, and the presence of damage to the insulation. All of the above can interfere with normal sparking.

This is interesting: How to adjust the tension of a car alternator belt: ways to tension it yourself

If a problem with the electrical wiring is excluded, then it’s worth thinking about the operation of the motor itself. A common reason why the tachometer needle twitches may be problems with the quality of the fuel or its supply system. In fuel-injected cars, this may be due to an incorrect flame in the injectors. With this malfunction, you cannot do without a trip to a car mechanic. Cleaning of nozzles and atomizers and their adjustment are carried out only using special equipment (stand). But if you don’t have an injector, but a carburetor, then the likely cause is a clogged idle jet, which can be easily cleaned at home.

What does the tachometer jump at high speeds indicate?

If the tachometer needle jumps during a trip or at high speeds, then the problem is also associated, as a rule, with the car’s engine. But before contacting a car mechanic, you can independently check the presence of fuel in the tank, inspect the camshaft drive chain, the timing belt that connects the crankshaft and the camshaft; perhaps it is loose and needs to be tightened. These are the main and frivolous reasons that can cause interruptions in engines and jumps in its speed.

If no visible problems are found with these elements, then you should go to an auto mechanic. Delay and failure to respond to a signal such as unstable tachograph operation can lead to serious damage to the vehicle’s cylinder-piston system and costly repairs.

It is better not to engage in diagnostics and independent repairs if the tachometer needle is floating. You should trust specialists who, using special equipment, will identify and eliminate the causes of the failure.

Tachometer either works or not VAZ 2110 injector 8 valves

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

Guys, tell me how you can explain:

PP: AP, when the ignition is turned on - the arrows pass the test, after starting the engine the tachometer does not work

Who came across it? Where to dig?

Question about the tachometer and speedometer not working on the VAZ 2110

Question

. On the fuel-injected 10, the tachometer and speedometer stopped working, and the odometer counts. all fuses are intact.

Answer

. Most likely, the ground has disappeared on the part of the instrument cluster where the tachometer and speedometer are located. Search. The speedometer operates from the speed sensor, and the tachometer receives a signal from the injection controller. In both of these cases the CE will also light up. As far as I understand, this is not your case.

1 But my CE does not light up

(I don’t remember whether the checkbox is checked or not) 2 What mass are we talking about? Where is she? Help ::

masses and so on have nothing to do with it!

I tried the tidy from another car, it works, but mine doesn’t work on that one!

I also have this problem that appears periodically on the new Kalinov combination. Help, I'm hysterical.

PS during TO-1 they fixed the UUT problem and the seal on the gearbox was torn off for this naturally and was not restored (I saw it when I removed it myself to eliminate the creaking under it), I think now, under warranty, no one will look at this combination of mine, due to the fact that In the service book, not a word is written or noted about how the GSTO electrician fixed the problem with the fuel gauge.

Help