The end of the 90s required automobile manufacturers to introduce new power units in order to withstand competition from foreign firms. Then AvtoVAZ engineers decided to supplement their already sensational tenth family of internal combustion engines with new engine options. After this, the well-known VAZ 2110 engine appeared, which gained popularity among car enthusiasts.

The VAZ-21083 power unit, which the design engineers significantly modified, served as the base model for the production of this engine. The carburetor was still used as a power supply system in the engine design, so there was no point in talking about special innovations.

Specifications

| Engine capacity, cc | 1499 |

| Maximum power, hp | 70 — 78 |

| Maximum torque, N*m (kg*m) at rpm. | 104 (11) / 3400 115 (12) / 3000 116 (12) / 3000 |

| Fuel used | Gasoline AI-95 Gasoline AI-92 |

| Fuel consumption, l/100 km | 7.6 |

| engine's type | In-line, 4-cylinder |

| Add. engine information | distributed fuel injection |

| Maximum power, hp (kW) at rpm | 70 (51) / 5600 71 (52) / 5600 72 (53) / 5600 77 (57) / 5400 78 (57) / 5400 |

| Compression ratio | 9.9 |

| Cylinder diameter, mm | 71 |

| Piston stroke, mm | 82 |

| Valve drive | SOHC |

| Number of valves per cylinder | 2 |

Decoding of the index in the name of the AvtoVAZ engine

Firstly, the ICE index was tied to the car model on which it first appeared.

Now the concern has formed a unique system for naming its divisions:

The first two digits 11 or 21 indicate the number of the workshop where they were assembled

The third digit here acts as a separator and is always equal to one for now

The fourth digit indicates the number of valves: 1 and 8 - 8v, and 2, 7 and 9 - 16v

The fifth digit indicates the position of the internal combustion engine in the series and the higher it is, the newer the engine

You can contact the site administrator by email: [email protected]

All texts were written by me, are authored by Google, are included in the original Yandex texts and are notarized. With any loan, we will immediately write a formal letter on letterhead to support the search engines, your hosting and domain registrar.

Next we file a claim. Don’t try your luck, we have more than thirty successful Internet projects and already a dozen successful court cases.

Peculiarities

The company's engineers produced the VAZ 2110 8-valve engine from 1995 to 2000. This power unit was produced in the city of Tolyatti, and it was based on its predecessor 21083. After the production of the engine was suspended, it was replaced by the VAZ-21102 fuel-injected internal combustion engine.

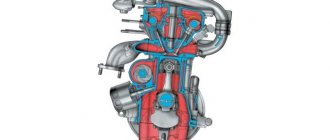

This is a classic in-line naturally aspirated engine running on gasoline for manufacturers. Its design includes four cylinders, giving a total working volume of 1.5 liters. The engine's peak power is 72 horsepower and its maximum torque reaches 104 Nm.

The engine block of the VAZ 2110 is traditionally made of cast iron with increased strength. The cylinders are machined directly into the block and it is not lined. The cylinder head is cast from aluminum. The crankshaft is made of cast iron, and it is fixed using five supports.

The material used to make the pistons was also classic - aluminum, only now they have steel inserts. The pistons are designed with two compression rings and one oil scraper ring. The connecting rods are made of steel and forged. The upper head contains a bushing made of a bronze-steel alloy.

The gas distribution mechanism is driven by a belt. If it is not replaced in time, it may break. But the VAZ 2110 1.5 engine is advantageous in that if the belt breaks, the pistons do not come into contact with the valves. The engineers managed to achieve this thanks to the fact that they made special grooves in the piston bottom.

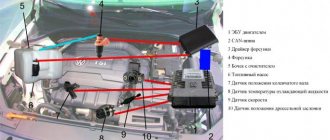

The structure of the cylinder head provides for the presence of one camshaft and 8 valves. There are no hydraulic compensators in the design, so the thermal clearance of the valves will have to be adjusted independently. A combined lubrication system is used, and the gear-type oil pump is used.

A carburetor is used as a power system, only it has a semi-automatic start function. The carburetor was installed from a partner company - Solex, only this time it was different from the others, since it had two chambers.

Most owners of cars with such engines say that the power system is completely unpretentious to the quality of the fuel used. But despite such statements, it is necessary to choose gasoline solely based on the manufacturer’s recommendations.

The design uses a contactless ignition system. The high-voltage coil is installed dry and has a magnetic circuit, but there are other versions of the motor that provide for the installation of an oil-filled coil with an open magnetic circuit.

The VAZ 2110 engine cooling system is liquid, and is characterized by forced circulation of liquid. It is designed as a closed type, which allows it to provide an optimal operating temperature range not only in severe frost, but also in fairly hot weather.

Finding the VAZ 2110 engine number is not very difficult, since to do this you only have to dismantle the air filter housing. After this, you should pay attention to the place where the block connects to the flywheel, and above it you will find an identification number.

Modifications

The standard VAZ 2110 contains new developments and some features.

The first car was completely carburetor and 8 valve. This system had a volume of 1.5 liters and made it possible to develop about 70 horsepower.

This potential was enough to get real pleasure from movement. As for the maximum speed, it varies within 160 kilometers per hour.

After the carburetor engine, the designers decided to make an injector (already 16 valve). Essentially, these are the same 1.5 liters of volume, but with slightly increased engine power to 79 horsepower. This move made it possible to improve dynamism and increase maximum speed.

A small feature is that the system has a 16 valve VAZ engine. This is very unusual for cars of this class.

Until the 90s, the vehicle had a rather sparse interior and exterior. The designers made the car as a means of transportation, not a luxury. Only after the 90s were customers able to get a spacious trunk, comfortable seats, an adjustable steering wheel, air conditioning, and so on. Over the entire production period of the VAZ 2110, a huge number of modifications of its engine were developed: both an 8-valve carburetor and a 16-valve injector.

Advantages

The internal combustion engine turned out to be quite successful, despite the fact that it was not produced for very long. This resulted in the fact that it is quite common among domestic cars and their owners note a fairly large number of significant advantages:

- An interesting fact is that the VAZ 2110 engine can be started without any problems in almost any weather. The power system was designed to ensure uninterrupted operation in extreme cold and heat.

- The valves of the VAZ 2110 engine do not bend in the event of a break in the timing belt. This was achieved thanks to the special design of the piston, so there is no need to worry about having to overhaul the engine prematurely.

- Excellent pickup. Many owners of cars with such a power unit note that its use in urban conditions does not cause problems at all, since the power is enough to keep up with the flow.

- Good resource. Like all related engines, this engine can travel about 200 thousand kilometers without serious problems and the need for major repairs. But this can only be achieved if it is serviced in a timely manner.

- Unpretentiousness to fuel quality. In our country this is a very important factor, since most gas stations cannot guarantee high quality gasoline, but for this internal combustion engine this is undoubtedly not a problem.

General information

Engines of the VAZ-21081 (1100 cc), 2108 (1300 cc) and 21083 (1500 cc) models were developed specifically for the new family. In the early years, cars were equipped with engines of 1100 and 1300 cc. See: The first 54-horsepower version was exported; Such cars were practically not sold within the USSR. Most cars for the domestic market were equipped with a 64-horsepower engine.

All engines in the family have a high degree of standardization. The only differences are in the cylinder blocks (three types, with different diameters and block heights), cylinder heads (two types, with different sections of gas channels), pistons (two types, with a diameter of 82 and 76 mm) and shafts in the knees. (two types, knees for different piston strokes).

The development of a more powerful 72-horsepower version of the 21083 engine dragged on for several years. But it was this option that was destined to become a long-liver and last in a modernized form on the assembly line to this day. The 87-horsepower 1.6-liter engine, widely used in the products of the Volga Automobile Plant, is based on the 21083 engine.

Problems

But despite a fairly large number of positive qualities, the engine is also characterized by classic malfunctions that most owners will have to face. Typically they are as follows:

- Fuel supply system. One of the most capricious parts of the engine is the carburetor. Owners of such engines no doubt know about the forced idle economizer and the main dithering system. It is also worth learning how to disassemble the carburetor in order to constantly clean the jets..

- Owners very often encounter constant fogging and leaks. Most often, the reason for this is that lubricating fluid begins to drip from the seals or around the valve cover.

- The temperature of the VAZ 2110 engine may be increased during operation. In this case, you should first pay attention to the thermostat, which may jam. If it is working properly, then you should check all the cooling system pipes for cracks.

- This engine also did not do without a lot of noise during operation. The cause of this problem may be a broken thermal gap in the valves. If this does not help, then you should start collecting money, since the pistons or main bearings of the crankshaft may start knocking.

- Often the VAZ 2110 engine troits. You shouldn’t start worrying right away, but just check the VAZ 2110 engine sensors, which often fail. All this can be eliminated literally in a garage and without additional knowledge.

Cylinder block

The cylinder block of the 21083 engine is made of cast iron and has a cylinder diameter of 82 mm. At the factory, the part was painted in a characteristic blue color. The block design allows cylinder bores to be bored and smoothed to oversized sizes. Inside the block housing there are lines for supplying lubricant to the bearings of the crankshaft and camshaft.

An oil filter and a fitting for the crankcase pumping tube are installed on the cylinder block. The fitting provides space for an additional oil level sensor. The block has eyes for mounting the generator and a front engine mount. The clutch housing is attached to the rear of the block.

For uniform cooling, the coolant channel is made along the entire height of the cylinder. There is no fluid flow between the cylinders. These channels are directly connected to a centrifugal pump mounted on the front of the unit. The top of the channels is open and mates with similar channels in the block head.

Maintenance

In order to ensure optimal engine mileage, you just need to take good care of it. Fortunately, the design is as simple as possible, so there are no problems. First you need to pay attention to adjusting the thermal clearances of the valves. This must be done after traveling 20 thousand kilometers using washers.

Do not forget also about the lubricating fluid, which must be replaced after 15 thousand kilometers, since after that it loses its properties. Many people still don’t know how much oil is in the VAZ 2110 engine, and the answer here is quite simple - 3.5 liters, but during replacement you need to use 3.2 liters. Also, if you do not know what kind of oil to pour into the VAZ 2110 engine, then it is recommended to use types 10W-40 and 5W-40.

Transmission and suspension VAZ 2110 8 valves injector

Lada 21102 has a built-in five-speed manual transmission (MT).

This box is used on all versions of the 2110 line. It has good noise insulation, the lever stroke is comfortable, and the smoothness of switching is much better than that of Zhiguli and Samara. The body (casing) of the box is made of aluminum alloy. Inside the casing there is a primary (drive) and secondary (driven) shaft. The shafts are combined with the differential and final drive. The five forward gears are equipped with synchronizers, which improve smooth shifting. Gear ratios: 1st gear - 3.636, 2nd - 1.95, 3rd - 1.357, 4th - 0.941, 5th - 0.784. For reverse gear - 3.5. The final drive ratio is 3.7. The operating instructions state that you need to change the transmission oil every 75 thousand km.

Mitigating the impact of the chassis on the body, as well as ensuring stability and smoothness, is carried out by the front and rear suspension of the Lada 2110. An independent design is used on the front axle.

Each wheel has an independent coil spring, inside of which a MacPherson strut is placed. Each strut has its own hydraulic shock absorber. The lower control arms are attached directly to the steering knuckles, and the anti-roll bar is attached to them. Levers help reduce wheel roll (rotate it around the longitudinal axis). When the car makes a turn, the wheel, which is turned “inside the body,” can move away from the axis of rotation. The stabilizer prevents this from happening by twisting. Thus, the front suspension of the Lada 2110 allows you to maintain the stability of the car when cornering. The rear suspension

is a rigid structure, the main element of which is the transverse beam. Since the rear wheels do not rotate, there is no need to provide maneuverability, but rear stability must be at a high level. Therefore, this design was used. The beam consists of trailing arms attached to each wheel and a connector that welds the arms together. The wheels on the rear axle are also equipped with hydraulic shock absorbers to soften impacts. The Lada 2110 is equipped with 175/70 radial tires. Ventilated disc brakes are used on the front wheels, and drum brakes on the rear wheels.

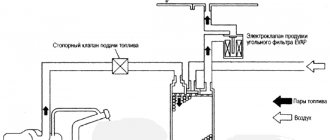

Supply system

The engine fuel system consisted of a fuel tank, pump, carburetor and connecting pipes on all Lada-Sputnik vehicles and was 43 liters. The carburetor of engine 21083 was produced under license from the French company Solex and was quite reliable in operation. The problems could only be caused by a stuck idle air valve.

Production of engines with this fuel system continued until the early 2000s, but increasing demands on fuel consumption and exhaust gas purity led to significant changes in the fuel system. Already in 1994, the first small-sized engines 21083 with an injector appeared. Injection engines reduced power to 70 hp. C. During the first years of production, most of these machines were exported.

The pre-injection system used Bosch or General Electric components. Then, under the designation “January”, the domestic fuel injection control system began to be used.”

Motor VAZ 2106

The baton of the engine, which became a real breakthrough in the Soviet market, was taken over by the VAZ 2106 engine.

It became a natural modification of the 2103 in order to increase the technical characteristics of VAZ engines in the direction of power.

The engineers achieved it:

- increasing the working volume to 1600 cm3, using the cylinder diameter, which again became 79 mm.

- The pistons for this VAZ engine were used from 21011 and it, like the donor, had two repair sizes. These VAZ engines had no other fundamental differences from the 2103, since they were equipped in the same way as their older relatives, with an “Ozone” carburetor and an ignition distributor with the same vacuum regulator.

But the 2106 engine did not find much sympathy among the owners, just as rotary engines on VAZs were once exported, since the owners of 2103, 2121, 2107 tried to select the more reliable VAZ 2103 engine.

This was due to the lower viability of the 2106 and instability of operation when using lower quality fuel. The saddest outcome was burnout of the valves and the unit required major repairs in these cases much more often than 2103.

Advantages and disadvantages

Speaking about the former dream of car enthusiasts, it is difficult not to touch upon the issues of its advantages and disadvantages. For convenience, we list them in the table:

| Advantages | Flaws |

| Economical fuel consumption during moderate driving | Low level of security. No airbags, ABS |

| Cheap spare parts, there are analogues from foreign cars | Outdated design |

| High ground clearance – 170 mm, allowing movement on light off-road conditions | Cramped interior, non-folding rear row of seats |

| Repairable engines | Rapid metal corrosion |

| Low cost on the secondary market | Sticky electric windows |

Unfortunately, the VAZ 2110 has much more disadvantages than advantages. Among them, it is also worth noting the failure of the door lock drive - this is one of the most common problems. Burnout of electrical wiring also often occurs in 10-20 year old specimens. Car shock absorbers are like a lottery - they can travel 120-150 thousand kilometers, or they can fail after 30. Practice shows that it is advisable to replace them with foreign analogues.

During active use of the vehicle, jamming or leakage of the rear brake cylinder may occur. This problem manifests itself as vibration when braking.

Among the main advantages of this model, its low cost should be highlighted. Now the most expensive copy of 2012, with one owner and 90,000 km on the secondary market costs 205,000 rubles.

Tuning

And in conclusion, I would like to say about tuning the VAZ 2110 engine.

In the VAZ 2110, engine tuning is very easy to do. To do this, you only need a tool and a room. This process can be done not only in a specialized workshop, but also in your garage.

Tuning a VAZ 2110 engine requires only a set of tools and patience:

- The first step is to simply replace the camshaft with a better one. Due to this, power will increase and engine performance will improve.

- You can also install a new crankshaft to increase the volume of the unit. If this is not done, then further tuning of the VAZ 2110 engine will be in vain.

- The installation of a compressor is quite simple. This unit allows you to increase power and get good torque.

- It is worth noting that tuning the VAZ 2110 engine can be done by anyone. This does not require special experience or skills. It is enough to know the structure of the car and have locksmith skills. Experts recommend installing a high-quality stock piston so that it can withstand about 0.5 bar.

How to determine the type of engine where the engine number is stamped

VW PASSAT CAR REPAIR SITE my new channel.

4. GAZ cars (Gorky Automobile Plant) have a slightly different placement of this engine number. On the LAWN, the marking should be on the lower left side of the cylinder block.

Toyota indicates the serial number in the series as the first digit, and the engine series as the second. For example, an engine marked 3S-FE and 4S-FE, despite the structural similarity, differs only in different amounts of work.

5. If the letter G is present in the marking, this means that the unit is gasoline, with electronic injection and, most likely, is equipped with a charger or turbine. The letter F stands for: cylinders with four valves, two camshafts and a separate drive. The letter T indicates the presence of turbines, and the Z indicates the compressor. Here is an example of such marking 4A-GZE. The presence of the letter E can mean that the car is equipped with electronic injection, S - that the engine is equipped with a direct injection system, and finally X - shows the relationship of the engine with hybrids.

6. Nissan engines have more informative readings. The first and second letters are the series, the next two are the engine size. To find out the engine volume in cubic centimeters, you need to multiply this figure by 100. 4-valve engines will be marked on the cylinder with the letter D. V - variable valve timing, E - multi-point electronic injection. The letter S is in carburetor units, the letter T is turbine, respectively, two are TT.

7. When marking engines, Mitsubishi first of all indicates information about the number of cylinders. The letters A and G (internal combustion engine) indicate the type of engine, the letter D means diesel. The designation of diesel engine models can sometimes be supplemented with the letter M, which indicates the presence of an electronically controlled injection pump (HPF). The remaining two numbers represent a series, the letter T indicates the presence of a turbine.

Well, that seems to be it! I think now you won’t get confused about the engine markings and can easily determine what’s what.

Options

The configurations of dozens today can be regarded as poor. Of course, at one time, even a minimal set of options was enough for comfortable movement, but now, with the development of technology, there are many more “wants”.

The VAZ 2110 was equipped with electric windows, heated front seats, power steering and air conditioning. The Bogdans were equipped with electric power steering. Airbags and ABS were not provided.

In the “Norma” configuration, the VAZ 2110 interior was trimmed with velor fabric and supplemented with rear headrests. The more expensive “Lux” package differed from the others in the presence of an on-board computer and heated side mirrors.