Photo: AVTOVAZ

Almost half a century ago , on September 9, 1970, the first production VAZ-2101 Zhiguli rolled off the main assembly line of the Volzhsky Automobile Plant. “Kopeyka,” as the car was popularly nicknamed, quickly became one of the most common passenger cars in the country. Over the years of production, the Volzhsky Automobile Plant produced about five million VAZ-2101. Other interesting facts about the legendary “penny” are in our material.

“Russification” of Fiat: the prototype of the VAZ-2101 was an Italian car

In the 1960s, the demand for cars in the USSR increased sharply - the country needed a truly “people's car.” As a result, the government proposed building a new automobile plant that could produce over half a million cars a year.

To speed up the creation of such an enterprise, it was decided to attract foreign specialists - the Italian concern FIAT. In May 1966, in Turin, the USSR Minister of Automotive Industry signed a cooperation agreement with the management of FIAT. In August of the same year, it was decided that the prototype of the new Soviet sedan would be the Fiat 124 - at that time one of the most successful models, “car of the year in Europe.” In April 1970, the first samples of the Soviet VAZ-2101 sedan rolled off the assembly line of the Volzhsky Automobile Plant, built in Togliatti.

The new car was not at all a copy of the Fiat 124. To adapt to Soviet roads and difficult climatic conditions, the “Italian” underwent thorough training - in total, more than 800 changes were made. As a result, the VAZ-2101 even surpassed the Fiat 124 in a number of indicators.

Among the innovations are a reinforced body and an improved engine. The rear suspension was also completely replaced, the ground clearance was increased, and full heating appeared in the cabin. The latter was especially appreciated by Soviet car enthusiasts, who learned that in cold weather the car can be warm, and starting the engine in winter may not require much effort.

In addition, the rear disc brakes were replaced with drum brakes. This design is more suitable for domestic roads. By the way, during the tests 35 samples were used, which covered more than 2 million kilometers of Soviet roads. So the “Russification” of the Italian Fiat 124 turned out to be useful for the Fiat concern itself. The Italians received unique information about the reliability of their cars.

VAZ-2101. Drom claims: in 1970, the first serial “penny” was collected not on April 19, but in August

Last spring, large celebrations were supposed to take place in Tolyatti dedicated to the 50th anniversary of the Volzhsky Automobile Plant - even a visit by Vladimir Putin was agreed upon. In connection with the coronavirus epidemic, they decided not to risk the health of the national leader - the president made do with a telegram that contains one notable error, specifically concerning the 50th anniversary of the plant. With the onset of summer, the “expiration date” of the anniversary occasion had not expired at all, because the assembly line at VAZ was launched not in April 1970, but only in August. Let's talk about this today and remember what else the plant lived with in that important first year of the start of assembling the VAZ-2101.

When to celebrate an anniversary

The Volzhsky Automobile Plant (VAZ) became a full-fledged subject of the Soviet automobile industry of the USSR long before the launch of the assembly line - back in 1966, when construction work was just gaining momentum. The production of cars was established in 1970, and the following summer, by the will of the Ministry of Automotive Industry, the AvtoVAZ automobile production association was formed on the basis of VAZ, which, along with the parent plant, also included related enterprises. The process of forming such associations was going on everywhere at that time - the ministry was trying to improve the mechanisms for managing the industry under the conditions of a planned economy. Simultaneously with AvtoVAZ, AvtoGAZ and MosavtoZIL appeared, and a little later - AvtoUAZ, AvtoZAZ and others.

So, the plant appeared in 1966, the conveyor was launched in 1970, the AvtoVAZ production association - in 1971. Hence the question, when should the anniversary be celebrated? The answer lies on the surface - whenever the hero of the day wishes. It’s hard to argue with this, so we are happy to congratulate AvtoVAZ on its 50th anniversary. Meanwhile, we cannot agree that the first cars rolled off the VAZ assembly line in April 1970 - and primarily because this contradicts the official documents of AvtoVAZ itself! Let's figure out how this can be?

For Ilyich's birthday!

Two months ago, AvtoVAZ sent out an “anniversary” release to journalists, where it was written in black and white that on April 19, 1970, “the first six VAZ-2101 Zhiguli sedans rolled off the assembly line of the Volzhsky Automobile Plant.” It would seem that what is unusual about this? The date that made us think about the authenticity of this fact was April 19th. Those who studied in Soviet schools remembered for the rest of their lives that Lenin’s birthday was April 22. Maybe the difference of three days is not without reason, maybe they wanted to be on time exactly by this date?

In the technical specifications prepared by the Ministry of the Automotive Industry for the Fiat concern, the make and model of the first VAZ car were not indicated anywhere - only “Car No. 1” and a set of technical characteristics. In the photo - the Italian prototype of the “penny”: FIAT-124

Already the first dive into the documents indirectly confirms our assumption. From a letter from the head of Fiat, Vittorio Valletta, sent to the “respected Soviet delegation located in Turin” in July 1966, we learn that a little earlier, in negotiations with the Italians, the USSR Minister of Automotive Industry, Alexander Mikhailovich Tarasov, set a different deadline for completing the construction of the plant: not 1970, but 1969. More precisely, we are talking about the start of “production of the base car in 1969” and the achievement of “design productivity in the shortest possible time.” It turns out that Tarasov wanted to play it safe, realizing that they were unlikely to make it in time for the anniversary? Yes, most likely, after all, they tried to “make up” all production achievements in the USSR by the next anniversary of the Great October Revolution, or by November 7 - and here is the 100th anniversary of the founder of the Soviet state, how can such an opportunity be missed!

The front page of the newspaper "Volzhsky Avtostroitel" dated January 21, 1970. The factory publication covered in detail the installation of the conveyor and the start-up of other production facilities

Now let’s arm ourselves with a file of the newspaper “Volzhsky Avtostroitel” for 1970. This is not just a factory large-circulation newspaper or a workshop wall newspaper - it is “The organ of the party committee, factory committee and directorate of the Volga Automobile Plant,” that is, each article here is agreed upon and endorsed before sending the issue to the set many times, each word passed not only the proofreader and editor, but also where a stricter ideological filter. Such newspapers were a sign of the Soviet era - they were published at all large enterprises of the USSR. We flip through the pages of “Volga Automaker”, and the first thing that catches our eye are headlines like “Symphony of Labor”, “Towards the Anniversary”, “Hard work is the best gift to the Motherland!” and so on. Meanwhile, upon careful reading, it turns out that the newspaper was made by caring people: here you can find the sincere indignation of the inspectors of the Komsomolsky Searchlight, and a note from the thread grinder of workshop 51-R Ivanov, indignant that the trade union meeting was held right in the building under construction, and not in the quiet and comfortable assembly hall of the Exhibition and Convention Center, and in general - they were torn away from work, and detailed messages from mid-level production managers in the “Alarm Signal” section.

What did these caring people write about? The fact that every day the lag behind the schedule for launching the conveyor, which was supposed to be operational by April 22, 1970, became more and more obvious and that the 100-day Lenin shift announced in January would most definitely not end with the production of the first conveyor Zhiguli. By the way, the expression “Lenin Watch” meant that each of the 100 calendar days before Ilyich’s birthday was not an ordinary “working” day, but a “shock” day. What is “percussion”? To a modern reader who is not familiar with the peculiarities of Soviet official verbiage, it is perhaps impossible to explain in a nutshell...

While the construction and commissioning of the plant was underway, Italian cars were tested at Soviet testing grounds

It was from the publications of the Volzhsky Autobuilder that an ordinary VAZ employee, not allowed into high offices, could quite freely learn that in 1970 the plant miserably failed the plan: according to the original plan, 30 thousand cars were supposed to roll off the assembly line by the end of the year. At the beginning of February, when it became clear that the assembly line would not be launched on time, the “Socialist Commitments of the Volzhsky Automobile Plant” was rewritten - the figure of 27,500 cars already appears. In fact, only 21,530 were collected, at least this figure was transferred by the plant to the planning department of the ministry. What is the reason? Firstly, the installation and debugging of the conveyor continued until the beginning of August, and secondly, the conveyor was unable to increase the average production rate per shift for a long time. In August it was only 16% of the projected value, in October - 51%, and even in December - only 69.4%.

Very remarkable illustration! It is believed that the photo is one of the first cars assembled by hand. Notice that there is a working Fiat in the foreground!

We will not retell the articles of the factory's large circulation, we will only clarify that the newspaper did not openly report about the disruption of the start-up of the conveyor, but with each new issue there was more and more material indicating an inevitable failure. On April 22, the front page featured a large portrait of the leader of the world proletariat and the headline “Lenin is with us!”, but not a word about the assembly of the first car on the assembly line. At the same time, mechanical assembly mechanic and party bureau member A. Shalashov reported: “The staff of the Main Conveyor No. 1 workshop took an active part in the construction and finishing of the assembly and body production workshops. From April 1969 to April 1970, 1,500 meters of concrete were laid in the welding, galvanizing and fittings-radiator shops. 21 foundations were made, 2,600 square meters of end blocks were laid. During the shocking days of April, we collected and installed 7,000 meters of chain on the main conveyor and about 260 pendants.” And that’s all you need to know about the “work” of the main conveyor before Lenin’s birthday. From further publications of the “Volzhsky Autobuilder” we see that the installation and adjustment of the belts actively continued until July inclusive, and that the first production car rolled off the assembly line only on August 5.

It is believed that this photo shows one of the first six cars assembled on the night of April 18-19, 1970 from foreign components. As various production facilities were commissioned, similar “technological” samples were collected in batches before the assembly line was launched

But a newspaper, even an official one, is one thing; can it be trusted? We open the “Explanatory note to the annual report on the main industrial activities for 1970”, prepared by the directorate of the “Volzhsky Automobile Plant under construction”. In Soviet times, every automobile plant (and not just an automobile plant, any organization in general) annually sent such a document to the relevant central administration or ministry along with the “Annual Report” itself. So, in this report it is written in black and white: “Since August, the production of VAZ-2101 Zhiguli cars has begun on the first production line, working in one shift.”

But this is a staged photograph. It says “April” on the hood, but it’s the end of summer...

However, where did the legend about the release of cars on April 19 come from? Realizing that the conveyor would not be launched by April 22, at the direction of the management, “on the night of April 18-19, 1970,” several crews from workshop No. 45-3 of the main conveyor “began the trial assembly of cars from Italian parts and assemblies. <…> The main task was set: during the trial assembly process, identify equipment shortcomings and eliminate them.” An attentive reader will ask the question: why do such an important task at night? The answer is provided by the calendar for 1970. The fact is that April 18 and 19 fell on... Saturday and Sunday! Simply put, the team was called not at all in order to “identify equipment shortcomings”, but in order to urgently assemble several machines by hand. Why at night - so as not to interfere with the assemblers assembling conveyors during the day!

So, we repeat, we do not deny that cars were assembled at VAZ for Lenin’s birthday - they were indeed assembled, but only by hand, mostly from foreign parts (essentially it was a FIAT-124), and not on an assembly line. Later, when the tape was launched, several cars were covered with the words “April 1970” and photographed. Why they did this back in the 70s is understandable. But why now, in the 21st century, when the plant, generally speaking, has become an integral part of the Renault concern, continue to talk about the launch in April?.. We cannot answer this question, but we note that unreliable information is like water flowing through capillaries , went up - from Tolyatti to Moscow, or rather, to the Kremlin. The congratulatory telegram, which was sent to AvtoVAZ on behalf of Vladimir Putin, contained the following lines: “I congratulate you on a great, festive event - 50 years ago, on April 19, 1970, the first car of the legendary VAZ-2101 brand rolled off the assembly line of the Volzhsky Automobile Plant.” . Well what can I say...

"Treshka", "Niva" and "Oka"

VAZ lived in 1970 not only by launching the assembly line and increasing the pace of assembly - this was the main task of the production workers, but the design service was already working, and not just working - for 1970 the Ministry of the Automotive Industry even approved a plan! What did the engineers do? Firstly, projects to modernize the “kopek” “in the direction of changing the appearance of the car” - this is exactly the phrase used in the report. The car has just entered the assembly line, and ours have already begun to improve the exterior of the Fiat 124, no less - “The Best Car of 1966” according to journalists and editors of automobile publications.

VAZ-2103 became the anniversary model, which exchanged the first million on the assembly line

The matter was not limited to the appearance of the “penny” - they also took on the interior (in terms of its design), increasing dynamic performance, reliability and durability. In addition, work began on “constructive measures to improve the safety of the machine.” Of course, in 1970, all these directions were only broadly outlined, at least as of the end of the year, the development of design documentation had not yet begun, but this did not apply to dynamics! Work was carried out on an engine with a displacement of 1300 cc. cm as of January 1971 - prototypes were in the manufacturing stage, but that's not all. You will be surprised, but the documentation for the 1600 cc engine has already been practically developed. cm, which they planned to install on the VAZ-2103. As for the “three rubles” itself, the design department was also at the finish line for it, and the volumes of supplies of components were discussed with all its might with its subcontractors. By the way, the VAZ-2103 was put into the category of promising passenger cars back in the late 60s, so this was a planned work, and not an initiative of the plant. A VAZ-2102 car, that is, a “penny” station wagon, was also on the way - they were finalizing the drawings and conducting final negotiations with component suppliers.

The station wagon was specified in the Technical Specifications. By the time of launch, such versions of the Fiat 124 (it’s the one in the photo) had been produced in Italy for several years, and their development in Togliatti went without any particular difficulties

While the installers were assembling the assembly line, the designers were thinking about two promising models, and these are not modernizations of the “penny”, but independent developments. “An all-terrain vehicle for rural areas based on VAZ-2101 units” - this is how the future VAZ-2121 Niva was then described according to the documents. It will be put on the Togliatti assembly line only in 1977, and in 1970 the designers are still developing a draft technical specification. The second promising model was the “mini-compact 4-seater passenger car VAZ-1101.” By the way, several years earlier, NAMI had already developed a technical design for the “Cornflower” car with front drive wheels, which bore the index 1101. During the discussion at the ministry, it was “turned up,” but with the launch of VAZ, front-wheel drive was again given the green light.

VAZ-E1101 prototype. This could be Oka...

By the end of 1970, the technical specifications for the future Oka had already been prepared and sent to the ministry for approval. The designers did not wait for an answer and, even before the new year of 1971, sat down to the technical project. It’s hard to believe, but VAZ’s “Explanatory Note for 1970 on Core Activities” clarifies: “Drawings have been developed for a number of components, in particular for the engine. Documentation for the remaining units is being developed.” But that’s not all - one prototype engine was allegedly manufactured and even “production of a sample car” was underway. It turns out that Oka could have appeared before Niva? Yes, she could, but that’s a different story...

“Niva” did not immediately acquire its usual features! Pictured is one of the first prototypes

From all that has been said, we can conclude that the plant already had an experimental base? Yes, it is indeed mentioned in the annual report, but from the description it still follows that it was far from a full-fledged site, and they largely worked there on their own. Judge for yourself. The experimental workshop was located on the temporary premises of the KVC (Building of Auxiliary Workshops) and occupied an area of 2000 square meters. m. meters. Is it a lot or a little? This is only a third of a football field, so there is still no need to talk about any full-fledged experimental work in 1970. By the way, at the end of the year, even according to the temporary layout, only 60% of all equipment was installed, which in units means 68 units. Not much!

When a country doesn't have enough regular production cars, is there any time to experiment?

How much did the first Zhiguli cars cost?

What else needs to be said about the first “full” year of the plant? The car was launched with difficulty, heavily, which can be judged at least from the given data on the average production rate. The labor intensity of manufacturing a “penny” at the end of the year was 136.7 standard hours, or 200% of the design labor intensity, while the actual cost of the car in December 1970 was 3,703 rubles against the plan of 4,000 rubles. It is again not possible to reconcile these two figures: if they spent twice as much time on the release of the copy as planned, why did it end up costing less than planned? This is another feature of farming in the USSR: on occasion, the accounting department could “give” the necessary figures.

But the first Zhiguli cars are already at the training ground!

The commissioning was delayed not only in the assembly line, but also in the metallurgical and mechanical assembly production. Coupled with delays at related factories, which also disrupted plans, this led to the need to purchase components from Fiat. In 1970, 378 items were purchased, or 9.4% of the total! By the way, the subcontractors are not to blame for everything - VAZ itself has not mastered 139 items.

By the time of the large-scale receipt of materials and components, the production and dispatch departments did not have time to get on schedule, and what about departments - even temporary warehouses were not ready! Because of this, cargo was stored in open areas without timely acceptance and transfer under financial responsibility. Such sloppiness led to losses, or, simply put, to theft, as noted in VAZ’s reporting documents.

And here there were no frauds - in the photo there is a conveyor car, about the 10,000th in a row, autumn 1970

Throughout the year, commissioning and conveyor work were carried out under construction conditions; this not only contributed to the theft of materials and spare parts, but also did not have the best effect on the quality of the machines. “The development of new equipment, new materials, and the insufficient level of quality of supplied components did not allow us to ensure high quality cars. In the past year, 1,030 complaints were received, which amounted to 4.8% of the output.” The main defects included: engine jamming, water pump failure, noise in the rear axle, valve knocking, faults in electrical equipment, oil leakage through engine connectors, fluid leakage from brake cylinders. It’s interesting that the VAZ management blamed only half of the faults on the subcontractors—the rest they honestly took upon themselves. By the way, Soviet factories turned out to be not the worst at all, although some have a defect rate exceeding 50%! The worst spare parts came from Yugoslavia - the defect rate was 80%! All this led to the fact that for many months VAZ carried out a 100% sorting of all incoming purchased products...

In short, the first year of VAZ’s life was filled with events, some of which were sad, for example, three people died at the plant, and in general, injuries were characterized by a “high frequency rate.” But still, the main event at VAZ in 1970 was the launch of the conveyor. And even though the first Togliatti cars had more than enough shortcomings, today we remember them with warmth and tenderness, after all, the “kopek” is the first truly mass-produced car in the USSR!

The export VAZ-2101 gave the name to the main AVTOVAZ brand – LADA

In August 1968, the magazine "Behind the Wheel" announced a reader's competition for the best name for a new car. The publication received thousands of proposals, including such original titles as “Violet”, “Memorial” or “Pervozhets”. They chose the option that, as contemporaries recall, was proposed by VAZ designer Alexei Cherny - “Zhiguli”. This is the name of the mountains near Tolyatti. People first nicknamed the VAZ-2101 “unit”, and already in the late 1980s the name “kopek” was assigned to the car.

When Zhiguli began to be exported, the question of the name arose again. The fact is that foreigners could not pronounce the word “Zhiguli” correctly. In addition, in some languages it did not have quite decent meanings. For example, in Arabic “Zhiguli” sounds like the word “thief”, and in Spain it resembles “gigolo”.

It was necessary to come up with a new name for the export cars of the Volzhsky plant. It appeared in 1973 - LADA 1200. Today LADA is the main brand of AVTOVAZ.

The Soviet car LADA 1200 was sold in many countries: East Germany, Germany, Austria, Czechoslovakia, Bulgaria, Sweden, Yugoslavia, Hungary, Finland, Switzerland, France, Egypt, Great Britain, even Australia and Japan. For export to countries with left-hand traffic, the Volzhsky Automobile Plant has mastered the production of two right-hand drive versions of the Zhiguli - VAZ-21012 and VAZ-21014. In some countries, the Soviet “kopek” acquired a local flavor. For example, in Cuba, VAZ-2101 “limousines” became popular, which were widely used as minibuses.

Deal of the century: how and by whose decision Fiat 124 turned into VAZ-2101

Zhiguli is half a century old: on April 19, 1970, the first VAZ-2101 cars rolled off the main assembly line of the Volzhsky Automobile Plant. How and by whose decision did the Fiat 124 turn into the VAZ-2101? How much of the first Zhiguli was political and how much was engineering? What is ours and what is Italian?

It is often said that by concluding the “deal of the century” with the FIAT concern, the USSR supported the Italian Communist Party. They say that politics is a concentrated expression of economics. But where is the evidence?

The head of the Italian oil and gas concern ENI, Enrico Mattei, was a staunch supporter of relations with the USSR. He was not a communist. And, going to Moscow in 1958 to conclude contracts for the supply of Volga oil, he thought only about ridding Italy of the dictates of the “seven sisters” - as he dubbed the energy syndicates BP, Exxon, Gulf Oil, Mobil, Royal Dutch Shell, Chevron and Texaco. And it started to happen: in exchange for oil, they began supplying technological equipment to the USSR, they opened credit lines for us... It was a dangerous relationship. There is no doubt that the death of Enrico Mattei in a plane crash on October 27, 1962 was the work of the CIA.

It is not for nothing that the president of the FIAT concern, Professor Vittorio Valletta, flew to US President Lyndon B. Johnson to argue that the contract with the USSR was aimed only at “improving the living standards of the Soviet population.” I met stiff resistance. Even the Vatican got involved: a deal with the Antichrists!

The head of the intermediary firm Novasider, Piero Savoretti, a confidant of Professor Valletta, the founder of the Mille Miglia race, who married the Intourist translator Nina, also walked the blade. It was he who organized a grandiose Italian exhibition in Sokolniki on May 28, 1962. The exhibition was visited by Khrushchev, an undeservedly overlooked figure. For some reason, all the credit for the creation of the Volzhsky Automobile Plant is attributed to Brezhnev and Kosygin, and Khrushchev allegedly generally believed that Soviet people did not need passenger cars. Meanwhile, it was Nikita Sergeevich who gave the go-ahead to the project. Savoretti arranged a meeting with Professor Valletta for the First Secretary of the CPSU Central Committee. The head of Fiat’s special relations department, Riccardo Chivino, conveys Khrushchev’s words: “I’m going to send Kosygin to you. Don’t deceive him, he’s a good person!”

And a month later, Kivino took the first deputy chairman of the USSR Council of Ministers, Alexei Kosygin, to FIAT factories. I recalled that the distinguished guest pronounced the surname of the actual owner of the factories, lawyer Giovanni Agnelli, as it is spelled with a r, “Agnelli.”

There is an interesting episode in the memoirs of Signor Kivino: back in 1956, FIAT was going to sell a license to the USSR for the production of the rear-engined tiny Fiat 600. What prevented it is a mystery. But it was “seichento” that became the prototype of the first Zaporozhets.

Fiat 124/540 studie 3a in Crimea, with the Ayu-Dag mountain in the background. Winter 1967, comparative tests with Autobianchi Primula, Fiat 1500, Peugeot 204, Moskvich-412 and Volga on the route Baydar Gate - Sokolinoe - Orlinoe - Yalta and near Sevastopol

But why was the Fiat 124 chosen - although even the chief designer Dante Giacosa did not consider it ideal for such a large country as the USSR? The fundamental decision to build a new large automobile plant was made in January 1965 at the Scientific and Technical Council of the Committee on Automotive and Tractor Engineering - it was held at VDNKh in Moscow in the presence of Kosygin and Brezhnev. But what to choose? Comparative tests of foreign cars at the NAMI Institute began to boil with renewed vigor. Ford Taunus 12M, Morris 1100, Peugeot 204, Skoda 1000MB were purchased, but the front-wheel drive Renault 16 hatchback, “Car of 1966” in Europe, became the favorite. By that time, the head of the NAMI passenger car bureau, Candidate of Technical Sciences Boris Fitterman, had long been the leader of the “front-wheel drive opposition” among Soviet automobile engineers.

One of the 35 Fiat 124 samples received in 1968 fell into the hands of Boris Fitterman. An ardent supporter of front-wheel drive, he created this prototype NAMI-0132 - a hybrid of a Fiat body and a Peugeot 204 power unit

Brezhnev allegedly drew the line at the protracted debate personally: “Comrade engineers, stop working on technology, we will get involved in politics! Italy is closer to us than France.” Although, they say, at the dacha in Zavidovo, where both the Renault 16 and the Fiat 124 were driven, the Secretary General also liked the French car more.

But try to separate truth from fiction! Let's get back to the facts.

By order No. 124 of the Minister of Automotive Industry of the USSR Tarasov dated May 28, 1966, the NAMI Institute was entrusted with carrying out developmental design work and road testing of the Fiat 124. It turned out that the gentle “Italians” could not withstand the special roads of the Dmitrov test site and Soviet methods. When the bodies of the Fiats began to crack, an Italian delegation rushed to the Dmitrovsky training ground: “Show your Belgian pavement!” Having thoughtfully picked the cobblestones with his finger, chief designer Dante Giacosa asked for all the documentation on the “Belgian” - and the Italians laid out the same road at home, at the Mirafiori plant.

Tests in the USSR added more than 800 changes to the car's design. They were introduced not by us, but by the Italians, according to the protocol on scientific and technical cooperation with the Ministry of Automotive Industry. The document was signed in Turin on May 4, 1966 - as Riccardo Chivino recalls, the ceremony had to be postponed for two hours because “to celebrate, Minister Tarasov overdid it with toasts.” I just got drunk.

Signing of an agreement on scientific and technical cooperation in Turin, at the Fiat Centro Storico. Professor Valletta is closely watched by a colorful group (from left to right): Deputy Chairman of the State Committee on Science and Technology (and Kosygin's son-in-law!) Germain Gvishiani, Fiat chief designer Dante Giacosa and the actual owner of Fiat Giovanni Agnelli. On the right, Riccardo Chivino, Fiat's director of special projects, came into the frame. Date: May 4, 1966

The only one who did not sign the protocol was the chief designer of the MZMA plant, Alexander Andronov. He was not satisfied with the archaic engine with a cast iron block and a lower camshaft - let's say, overhead camshaft and aluminum, like the Moskvich-412. But the Italians sincerely believed that for a la macchina of this class, a lower-mounted “cast iron” engine was just the thing. Moreover, they mastered the engine recently, in 1964. The Italians had an overhead version - but even the famous Fiat doppio asse a camme with two overhead camshafts and a belt drive was based on the same cast-iron block. It was intended for models of a higher class, and one of them was offered to us as the “Car No. 2” stipulated by the agreement - Fiat 125. If we agreed, we would have gotten an overhead engine. But our engineers refused in favor of the design, which later became the VAZ-2103.

Giving in to Andronov meant making a new engine, and in a short time: the plant was supposed to be launched in three years! Therefore, both the Italians and Minister Tarasov tried to persuade the obstinate engineer. The wrong one was attacked! As a result, a solution acceptable to everyone was born: the block was still cast iron, but with water passages, and the overhead camshaft was driven by a chain.

Engines for comparison: Fiat 124, Fiat 125 with two overhead camshafts, early VAZ-2101 (with liners). VAZ testers led by Anatoly Akoev found that the cartridges did not provide much benefit, and a year later they were abandoned

Any deal is the result of a compromise. The amount of the targeted loan ($320 million) allocated to Vneshtorgbank of the USSR by the Italian bank Istituto Mobiliare Italiano (IMI) did not cause any controversy. But the Italian side insisted on their accepted interest rate of 7%. And Kosygin, sending Minister Tarasov to Italy, set the bar at 5%.

Passions were heating up - and this was not without Renault and the KGB. The Izvestia newspaper's own correspondent in Italy, Leonid Kolosov, also an employee of the First Main Directorate of the KGB, nicknamed Kisa, received an order from the resident - to ensure a reduction in interest on the loan!

Two outstanding automobile designers, Alexander Andronov and Dante Giacosa, whiled away the time during the negotiations in the same way - they made sketches of the delegation members. This is how they signed the agreement - Minister Tarasov and Professor Valletta. A talented person is talented in everything!

Leonid Sergeevich had good connections. Once he almost seduced Claudia Cardinale. Through friends in the corridors of power, Kolosov spread false information that Minister Tarasov had some kind of agreement with Renault. Everyone knew about President de Gaulle's interest in a major project with the Russians. The Italians were getting on their nerves: FIAT was then on the verge of bankruptcy. And Kisa’s good friends did their job - IMI reduced the rate to 5.6% and promised Vneshtorgbank favorable conditions for the purchase of production equipment.

By the way, in June 1966, de Gaulle flew to the USSR - and we actually concluded a technical assistance agreement with Renault in the amount of 700 million francs ($142 million), but for the re-equipment of the MZMA plant.

Were the Italians expecting a trick from us? One day, Professor Valletta sarcastically asked Leonid Kolosov: “What, dottore, have you retrained from a businessman to a journalist?”

In August 1966, a general agreement on cooperation between the USSR and the FIAT concern for the construction of a plant with a capacity of 600 thousand passenger cars per year was finally signed in Moscow. So who outwitted whom and how much did the Volzhsky Automobile Plant cost the country as a whole? It is known, for example, that on February 19, 1968, by order of the USSR Council of Ministers, the estimated cost of industrial construction of VAZ was approved in the amount of 1 billion and 143.3 million rubles. In various sources you can come across amounts of 1.57 and even 1.85 billion rubles. According to Forbes magazine, the construction of the plant in Tolyatti cost $887 million, of which FIAT earned $322 million. Although, when evaluating deals, they often forget to take into account indirect benefits. What to do with the ban on the supply of technology to the USSR? And the Italians undertook to settle everything themselves. Forbes journalists were drooling: two thirds of the equipment received by the Russians was made in the USA or under American licenses! Among others, the companies TRW and Gleason were named.

Minister Tarasov signed the act of acceptance into operation of the first stage of VAZ with a capacity of 220 thousand cars per year only on March 24, 1971. At the beginning, the share of imported components from VAZ and its related companies reached 75%, by the end of 1970 it remained at the level of 20-25%, and by April 1971 the related companies were fully compensating for imports

Production of “Car No. 2” VAZ-2103 began on November 5, 1973, and on December 21 the commission finally accepted the plant into operation, but it reached its full capacity of 660 thousand cars per year only on October 5, 1974. Production at VAZ is not serial, but mass: the process is divided into simple operations and is carried out rhythmically. In total, from 1970 to 1984, 2,702,903 VAZ-2101 units were made. The circulation of the VAZ-2102 station wagon (1971-1986) is 666,889 units. VAZ-21011 (1974-1983) and VAZ-21013 (1977-1988) cars produced a total of 2,143,997 units, VAZ-2103 (1973-1984) - 1,304,866 units, VAZ-2106 (1976-2001) - 4,175,319 things

The agreement provided for the transfer to us of two models, “Car No. 1” and “Car No. 2”. However, in addition to the Fiat 124 sedan, we also got the Fiat 124 Familiare station wagon, which turned into the VAZ-2102. In addition, the USSR Council of Ministers decided to increase the production capacity of VAZ to 660 thousand cars per year instead of the six hundred thousand stipulated by the agreement.

Prototype VAZ-21032 with steering wheel on the right, 1970. To compensate for the increased load on the right side caused by the relocation of the controls, a stiffer spring 21012-2901 was installed in the right suspension. The required rigidity was achieved by increasing the thickness of the rod

An interesting nuance: under the terms of the agreement, FIAT undertook to purchase durable goods from the USSR for five years, an extensive list of which included, in particular, passenger hydrofoils. Is this why the Mediterranean routes were filled with our “comets” and “meteors” in the early 1970s?

They decided to give the future car a name - and the word “Zhiguli” was first suggested by VAZ designer Alexey Cherny. With this, he alarmed both Fiat and Autoexport: “gigolo” translated from Italian means “gigolo, prostitute, man living off his mistress.” A competition for the best name was announced by the magazine “Behind the Wheel” and the newspaper “Soviet Russia”. There were so many proposals: VIL-100 (100th anniversary of Vladimir Ilyich Lenin), Desina (the brainchild of the Soviet and Italian peoples), Pato (Palmiro Togliatti), Rossita, Sovital, Tatarin (!), Hundredth Spring, Ilyich, Genius... Among the favorites there were Volzhanin, Mechta and Druzhba, but Zhiguli and Lada took the lead - which Autoexport grabbed onto. True, “Lada” means “barn” in Swedish, so in the Kingdom of the Three Crowns, VAZs were sold under the VAZ brand. And the Italians at first used the abbreviation TAZ in all seriousness - until the end of 1967, the phrase “Volzhsky Automobile Plant” was not heard anywhere.

The famous rook was proposed in the summer of 1967 by Alexander Dekalenkov, a former artist-designer of the UGK AZLK. The idea was captivating with its simplicity: the letter B in the form of a Cossack boat with a sail filled with wind. At the bottom they added the name of the new city - Tolyatti. And when a test batch of emblems arrived from Turin in January 1970, the letter I was turned upside down in the Latin manner: “TOLRTI”. The defective samples were immediately sold out: a rarity even better than the famous “Red Mercury” postage stamp!

In January 1967, a more serious incident arose - if this had happened six months earlier, the “deal of the century” would not have taken place. The poetess Marietta Shaginyan, a comrade-in-arms of Lenin himself, came to Italy with an assignment from the newspaper Izvestia. Leonid “Kisa” Kolosov was appointed to take care of the old Bolshevik, who was born 11 years earlier than the FIAT company itself. He describes Marietta Sergeevna as a cantankerous old woman with a croaking voice, categorically opposed to everything Western. How suddenly she found common themes with Professor Valletta! And he had something to tell: in 1945 he could have been shot for collaborating with the Nazis. Communist partisan Luigi Longo interceded. Since then, Valletta and Comrade Longo, who headed the Italian Communist Party in 1964 after the death of Palmiro Togliatti, have developed a trusting relationship. Soon, Izvestia published enthusiastic essays by Shaginyan - “Three days in a Fiat.”

The best Soviet pop performers came to VAZ. At first, just to perform, later - to get a car as a fee. In 1970, the average salary in the USSR was 122 rubles, a VAZ-2101 cost 5,500 rubles, a two-room cooperative in Moscow - 4,000 rubles

And in Italy a general strike was planned, and the proletarians of the Fiat factories were preparing to lead it. Professor Valletta came out to the heated crowd and read out excerpts from a Soviet newspaper. And the people dispersed! An old Bolshevik broke a strike. Because of this, Leonid “Kisa” Kolosov was almost deprived of accreditation.

Meanwhile, preparations for the launch of the plant continued. The designers were allowed to work not according to GOST, but according to Fiat technical conditions - otherwise we would not have had new brands of steel, plastics, lubricants, rubber... Sometimes Italian specifications were stricter than our standards, and future related manufacturers did not always meet them. There was a real breaking down of barriers.

The whole country took up the “Lenin watch” for the 100th anniversary of the great leader of the socialist revolution. This gave reason to think that the VAZ-2101 was also prepared as an anniversary gift. Not this way! The agreement provided for the start of production of “Car No. 1” in 1969, and “Car No. 2” in 1970. However, it was not possible to complete the shock Komsomol construction on time. Italian equipment suppliers threw up their hands: “Where to put it?” And the slogan “We will provide the first car by the end of 1969!” changed to “Let’s collect for the centenary of V.I. Lenin’s first VAZ cars!”

Collected. That is why we are celebrating the anniversary of the VAZ “one” now, in April 2020.

Alexander Kuznetsov worked as an assembly fitter in the main building (workshop 45, section 3) from March 16, 1970 to 1978 and participated in the assembly of the first six commercial samples:

— Since the morning of April 18, 1970, six bodies were lowered: two cornflower blue, two white and two cherry. They were assembled in exactly 24 hours, the finished cars were driven off the assembly line at 5:00-5:30 on the 19th. Everything happened slowly. 10-12 empty conveyor hangers were left between the bodies. Until one team had completely completed work on all the cars, the conveyor was not moved further. The brigades were not yet full, sometimes two or three people each. The finished vehicles were rolled into a hangar made of shields, where they were locked from prying eyes. Something almost went wrong, the Italian technicians with the words “but bene” forced me to redo the operation - they say, it’s not good. By the way, about a thousand of the first cars had power units, transmissions, rear axles and suspensions from Italy. Sometimes you take a cardan from a box, and it’s longer, from a Fiat 125 model. You grin, throw it back into the box, and take another one. Italians!

The assembly of the first Zhiguli cars was not officially completed. And for taking photographs without permission you could easily get a triple. Thanks to an unknown daredevil, you can imagine how it all happened

Thread is the assembly conveyor line of the main building. There are three of them in total.

Taveer is a lower pushing conveyor, carts moving synchronously with the conveyor hangers. They assemble the engine with gearbox, front and rear axles for further installation under the body. Argotism from the English “tow-veyor” - towlines conveyor.

Montarsina - a post on the conveyor where the brake system was pumped. The word was clearly introduced by the Italians.

Inserts are extensions to the façade of the main building. Their rhythmic arrangement helps break the visual monotony of the world's longest assembly building. There are seven inserts in total. As a joke, VAZ workers call the eighth insert the plant management building, and the ninth is the liquor store closest to the plant.

But bene is Italian, “no bene”, “not good”.

Photo by Vladimir BELOKOPYTOV, Stanislav KAZAKOV, Denis ORLOV, Vladimir SAMOKVASOV, AVTOVAZ PJSC, FSUE NAMI, ACI, Centro Storico Fiat, Fortepan/Sándor BAUER, Registro Fiat Italiano.

Tatiana RALKA, Olga TIKHOVA, Stanislav BEREZIY, Sergey IONES, Alexey VOSKRESENSKY, Denis DEMENTYEV, Nikolay MARKOV, Alexey KHRESIN, Maxim SHELEPENKOV helped in creating the material.

Sports success: VAZ-2101 participated in auto racing

According to experts, the sporting success of the Zhiguli was rooted in the engine itself - the engine was perfectly amenable to boost. The debut of the “kopek” took place at the beginning of 1971 in Riga at the team championship of the USSR Winter Rally Championship.

“The new VAZ car, lighter and more dynamic, immediately attracted the attention of athletes and motorsport specialists. Everyone was waiting to see how he would perform on the track. Let us note that, apart from Shuvalov, Pistunovich and me, there were no experienced riders in the Togliatti team. Already in the first high-speed sections, our unknown team began to win with a decent advantage. The gap was so large that after the races many drivers approached the VAZ cars and carefully examined the tires to see if there were any studs on them. Well, it can’t be that on the very first track the Togliatti team effortlessly beats the much more experienced athletes who competed in Volgas and Moskviches! We still lost that time. But not because of the technology, but because of a lack of experience - the cars did not let us down,” VAZ tester Yakov Lukyanov later recalled.

Photo: “Behind the Wheel” magazine

In the autumn of the same year, VAZ-2101 cars took part in international competitions: three Soviet crews started in the Tour of Europe - 71 marathon. In total, they covered 14 thousand kilometers across the territory of 14 European countries. At the end of the round, the VAZ team was awarded second place. Literally two years later, at the Tour of Europe - 73, the teams driving the VAZ-2101 immediately received gold and silver cups.

After this, the “kopek” appeared on the tracks of various races for many years, and VAZ-2101 is found in amateur rallies even today. Already in the new century, in 2004, the car participated in the race of historical cars, held at the prestigious Nürburgring track. The rivals of the 1971 “penny” were such racing legends as the Jaguar E-type, BMW 2002TI, Alfa Romeo Sprint GT, Ford Mustang and Porsche. The VAZ-2101 crew finished thirtieth and was in first place in its class, ahead of the Jaguars and Porsches.

What is the significance of a “penny” for the country and for the people?

After the “penny” I exchanged one Zhiguli for another. I had a red “five”, a luxurious green “six”, in which I drove Alla Pugacheva for four years. Then there was the “seven”, sea green - in December 1987 I drove it to Stockholm to take a gift to Joseph Brodsky, who was receiving the Nobel Prize there. In those days, traveling to capitalist countries in your own cars was prohibited. I was the first such auto traveler. I went wild for this thing - I traveled to more than 30 countries, all of Europe from the Arctic Circle to Gibraltar, put my car on a ferry, took a Mediterranean cruise with stops in Turkey, Egypt, Syria, and even Africa - Morocco! “Zhiguli” opened the world for me then! And the number of girls I rode on this car is beyond description! “Zhiguli” gave me the opportunity to feel like a superman!

Dmitry Lomakov

,

director and founder of the Lomakovo Museum of Antique Cars and Motorcycles, collector of vintage cars:

Photo: Lomakovo Museum of Antique Cars and Motorcycles

— The first car I owned from the Soviet automobile industry was Moskvich 401, which belonged to Levitan. There weren't enough garages, so it stood on my street, which was common then. But in the end, someone “attached his legs”: first they robbed him for spare parts, and then completely whistled him down. I also have a “kopeck”, they gave it to me. In fact, few people need such cars now; they are only made except as gifts.

Boris Nuraliev

,

founder and director:

Photo: Grigory Sobchenko, Kommersant

— I rode the “kopek” only as a passenger. And I bought my first car relatively late, in 1988. It was a VAZ "treshka". And although it was used, I liked it: good engine, warm, reliable for that time. But the next one, VAZ-2108, didn’t like me, it broke down at the wrong time, although, of course, it was more modern. When the 1C circulation business took off and it was necessary to carry software in boxes, but there was little money, we bought a used UAZ-3303, a “tadpole” with a large shift hut - I also drove it with pleasure.

Pavel Lungin

,

director, screenwriter and producer, People's Artist of the Russian Federation:

Photo: Anatoly Zhdanov, Kommersant

— I didn’t drive a “penny”, but I had one of the first cars of the fifth model. By chance, I was lucky that a postcard arrived to receive it in the center on Warsaw Highway. My first car was new and shiny. It pleased and was remembered by the whole family, even ended up in the film and book “Interlinear” by my mother Lilianna Lungina.

Alexander Shpagin

,

film critic and actor:

Photo: Ekaterina Chesnokova / RIA Novosti

- Our society itself at that time was like this “penny”. On the one hand, there were practically no such bright phenomena, much less cars. On the other hand, it seems to work, but not particularly great. In the cinema of the 70s and 80s, every social detail, every social symbol turned into a sign, into an image, and then into a myth. And rays diverged from them in different directions, carrying some meanings, internal codes that were understandable to most viewers. If in the cinema of the 70s a “kopek” was a car for the average intelligent person, an intermediate symbol between the pitiful “Zaporozhets” and the expensive “Volga” or a foreign car, then on the screen of the 80s “new philistines” would already be driving around in them, which, in any case, has more money than an intellectual. And for the heroes of the film of the same name by Ivan Dykhovichny, a ride on a “kopek” is a joke, an easy way to go among the people. Through the “penny” passing from hand to hand, the viewer of this film is presented with a sometimes ironic, sometimes grotesque image of the average society of the 70s and 80s. The heroes of the film choose this unsightly little car, which became the symbol of that lean and homely era, as the core of their approach to this world, its symbol.

Group "Direct Speech"

Photo gallery

VAZ produced about five million “kopecks”

The VAZ-2101 was produced from 1970 to 1988 and became the most widespread and popular domestic car. 2.7 million “kopecks” rolled off the assembly line in Togliatti, and if we count all modifications together, then more than 4.85 million cars.

Even today you can see a “penny” on the roads. It is not for nothing that the first model of the Zhiguli became famous among the people for its reliability and “indestructibility”. According to factory tests, the “kopek” required major repairs after ten trips from Moscow to Vladivostok.

Another proof of its national fame was the fact that the VAZ-2101 was named the best domestic car of the 20th century according to the results of an all-Russian survey conducted by the magazine “Behind the Wheel”.

To become the proud owner of a Zhiguli, a Soviet citizen had to not only pay a fairly substantial amount, but also patiently wait in line. “To buy a Zhiguli, I had to check in every night for a month in a vacant lot near the city of Khimki. One absence and you're off the list. Zyama Gerdt, Andryusha Mironov and I created a team for duty ...,” the famous actor Alexander Shirvindt recalled in his book.

However, foreign stars also rode the legendary “penny”. For example, LADA 1200 became the first car of the famous Formula 1 pilot Kimi Raikkonen. “An excellent and reliable car - it never broke down,” he recalled in an interview.

“Zhiguli” is the most common car of Soviet, and later Russian production. Under this name, seven models are united on a common rear-wheel drive platform, which were produced at the Volzhsky Automobile Plant (VAZ) from 1970 to 2012. Today they are called “classics” to separate them from the next front-wheel drive family, the VAZ Sputnik (Lada Samara). The ancestor of the series was the VAZ-2101 - the first car produced in Tolyatti, a twin of the Italian Fiat 124 sedan. It was also the first Soviet model designated in accordance with the industry norm of 1966, which established standard indices for cars of different classes (in this case, the number " 21" meant a small class with an engine capacity of 1100-1800 cm3, "01" was the serial number of the model, and subsequent numbers indicated the modification). On the territory of the USSR, the first generation Zhiguli was sold under the official name VAZ-2101, and in the 80s. The nickname “Kopeyka” stuck with them. In other countries, the car became known as the Lada 1200/1300, since the word “Zhiguli” is difficult to pronounce in European languages and is consonant with the negative concept of gigolo. With the collapse of the Soviet Union, VAZ began to produce all its models under the Lada brand.

At the end of the 60s. The largest automobile factories of the USSR - Izhevsk and AZLK - produced no more than 200,000 cars per year. This was not enough to satisfy the need for personal transport for a rapidly growing population, and besides, Moskvich brand products by that time no longer met international standards. Another reason for the construction of a new enterprise is the need to put into circulation the funds accumulated by Soviet citizens due to the general shortage: a modern car could become a very popular product for many years to come. In 1966, Soviet Vneshtorg concluded an agreement on scientific and technical cooperation with the Italian company Fiat, according to which Fiat provided the Russian side with a plant design and a license to produce one of its small cars, modified for operation in unfavorable climatic and road conditions, and also carried out training of Soviet specialists in Italy. In 1967, in the city of Stavropol, renamed Togliatti (in honor of the Italian communist who staged a strike at the Fiat plant in the 20s), construction of the auto giant Volzhsky Automobile Plant began.

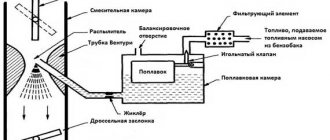

The Fiat 124, recognized as the “European Car of the Year” in 1967, was chosen as the prototype for the basic VAZ model. However, tests carried out on Russian roads showed its unreliability and poor cross-country ability, so the Italians had to significantly revise the design of the car and designate the resulting version as the Fiat 124R. The main changes affected the chassis and transmission: the car received drum brakes on the rear wheels instead of disc brakes, a reinforced front suspension on wishbones and coil springs, a new rear axle on springs and five reaction rods instead of one reaction pipe, increased clutch and improved synchronizers in 4- step manual transmission. In addition, Soviet engineers demanded that an essentially new power unit be developed for the VAZ-2101 - an in-line 4-cylinder with a camshaft in the cylinder head (OHC) and a two-chamber vertical carburetor DAAZ-2101 (Weber 32 DCR), with a volume of 1198 cm3 and a power of 64 hp The original Fiat 124 engine with the same displacement developed 60 hp, but its OHV valve design was unpromising for further development. The wheelbase remained unchanged - 2424 mm.

The VAZ-2101 was more advanced than its Italian counterpart in many respects. Its body was made of thicker sheets of metal, which increased its durability, but affected the weight of the car. Increased ground clearance and the addition of towing eyes made it easier to use on country roads. Safety has been improved by strengthening the supporting structure in some areas, installing recessed door handles and “fangs” on the front and rear bumpers. In the cabin, the VAZ-2101 was equipped with seats that could be transformed into full-fledged berths. Standard equipment included a heater, windshield washer, side window vents and a Hungarian RD-3602 radio. Early examples were equipped with floor pedals instead of outboard pedals, an auxiliary fuel pump and a handle for starting the engine in winter. It should be noted that in terms of manufacturability, dynamic characteristics, build quality and ease of maintenance, the VAZ-2101 was an order of magnitude higher than all other Soviet-made cars, which ensured high consumer demand for the entire production period.

The first VAZ-2101 rolled off the assembly line of the Tolyatti plant on April 19, 1970. By the end of the year, 21,530 units were built, in 1971 - already 172,175 units, and the planned production volume was 660,000 units. per year the enterprise reached in 1974. Sales of the car were high from the very beginning, so that most Soviet citizens were forced to sign up and wait for a car for years. In 1971, the Lada 1200 was exported to Yugoslavia, Finland, Czechoslovakia, Hungary, East Germany and Cuba, and in 1974, when the Fiat 124 was discontinued, AvtoVAZ was able to sell the model in Western Europe. In the UK the Lada 1200 cost £979. Almost immediately, the VAZ-2101 demonstrated its racing potential inherent in the design of the power unit. In 1971, the car took part in the USSR rally and circuit racing championships, as well as in the 14,000 km Tour of Europe-71 marathon, where the factory team won the silver cup. The high power density made it possible to use the VAZ-2101 as a police vehicle in the USSR and the countries of the socialist bloc.

In 1974, a modernized version of the Zhiguli appeared - VAZ-21011 (Lada 1300). It was equipped with an engine capacity of 1294 cm3 (69 hp) and was distinguished by a radiator grille with more frequent horizontal crossbars and ventilation slots above the front bumper, rubber pads on the bumpers instead of “fangs”, interior ventilation holes in the rear pillars, rear reflectors with a rear light travel, more comfortable seats and a modified location of some controls. The modification of the VAZ-21011 with a 1.2-liter engine was called VAZ-21013 (Lada 1200S), and the modification of the base VAZ-2101 with a 1.3-liter engine was called VAZ-21016. There were also right-hand drive versions of the VAZ-21012 and VAZ-21014 and experimental series of the VAZ-21018 and VAZ-21019 with rotary engines. High-performance modifications for the police and special services were called VAZ-21015 “Karat” (with a VAZ-2106 engine) and VAZ-2101-94 (with a VAZ-2103 engine). Total from 1970 to 1988 About 4.85 million VAZ-2101 sedans of all modifications were produced. In 2000, according to the results of an all-Russian survey conducted by the magazine “Behind the Wheel,” the VAZ-2101 was named the best domestic car of the 20th century.

There is a monument to the people's car in Moscow

The first Zhiguli, one can say without exaggeration, became the basis for the domestic automobile industry and a real revelation for millions of Soviet citizens. And even half a century after the start of production, there is a special attitude towards this model. Fans of VAZ's firstborn organize fan clubs and even erect monuments to the people's car. One of these appeared in Moscow. A marble pedestal on which a bronze-colored VAZ-2101 is installed “meets” you at the entrance to the capital along Volgogradsky Prospekt. At the base of the monument there are about 27.5 thousand one-kopeck coins. The organizers failed, as originally planned, to collect 2.7 million coins - that’s exactly how many “kopecks” were issued in Togliatti.