The last decade in the automotive industry has been marked by the motto “safety first.” As part of this initiative, new active/passive systems are being developed to ensure maximum safety for the driver and passengers of vehicles. But, unfortunately, most of these systems turn out to be unavailable in the basic configurations of even expensive models, not to mention budget cars of classes B and C.

In particular, heating the windshield wiper reservoir can now be found in new cars not so often, although the implementation of this function does not require significant modernization of the car design.

That is why many car owners decide to heat up the washer fluid reservoir with their own hands if it is not available. Today we will talk about how to do this.

Why do windshield washer nozzles freeze?

Quite often, at low temperatures, the windshield washer system does not work due to freezing of the nozzles.

First of all, this is relevant for fan nozzles, since the cross-sections of their holes are very small. Theoretically, if you use a special antifreeze liquid, then there should be no problems with crystallization at temperatures down to -30 °C. However, in practice, things are somewhat different; already at -10 °C the injectors stop working. Therefore, in cars that are equipped with fan-type jets, heated windshield washer nozzles are provided. There are several reasons for freezing:

- A low-quality liquid begins to crystallize at a temperature higher than that established by technological standards.

- While driving, the temperature of the injectors is greatly reduced by the oncoming air flow.

- Anti-crystallization ingredients are highly volatile and evaporate quickly. Therefore, the liquid begins to freeze at temperatures above the established norm.

- When the engine is turned off, the fluid supply to the system stops and it flows back into the tank. However, some of the liquid in the form of drops remains in the nozzles. Alcohol or another analogue quickly evaporates, turning the “anti-freeze” into ordinary water, which begins to freeze at zero temperature.

How to make your own heating of the washer reservoir from the cooling system

The coolant temperature in a fully warmed-up engine is about 80°C. This is quite enough to quickly and effectively increase the temperature of the “anti-freeze”, and, accordingly, its viscosity.

How to implement this in practice? To do this we need a copper tube with a diameter of 8-10 mm, two reinforced hoses and four clamps.

The tube must be bent in the form of a coil - this part must be in the washer reservoir, and its two ends must go out. Is it necessary to use copper pipe? No, but it is highly desirable, and here's why:

- copper is easy to process;

- the thermal conductivity of this material is higher than that of steel;

- copper is not affected by corrosion.

Using a thermistor

One of the most common homemade methods is to organize heating with a thermistor.

I can’t say what specific device characteristics are needed for a particular car.

But the point of using the device is as follows:

- you need to take a thermistor;

- cut off everything unnecessary from there;

- put heat shrink tubes on the wires;

- solder the wires to the thermistor;

- warm up the heat shrink;

- pour sealant onto the area where the thermoelement will be;

- carefully insert the thermistor there;

- add sealant as needed;

- wait until the sealant hardens completely.

Motorists note that with such re-equipment, good results can be achieved.

But the method is also recognized as an outright collective farm. A budget option, potentially effective. But it can hardly be called simple. Some people are simply afraid to make such modifications to the glass washer system. And I will understand them in many ways.

New injectors

If old sprayers do not want to work properly in winter, then it’s time to send them to the landfill. Or sell it as used spare parts.

In any case, when the washer keeps causing you problems, it needs to be replaced.

An excellent solution would be universal heated nozzles. These items fit a variety of vehicle makes and models. The assortment is impressive, that is, there should definitely not be any problems with selecting one specifically for your vehicle. The only problem is that the old system has to be dismantled and a new one installed in its place. Most kits provide detailed installation instructions. If you follow the rules and observe safety precautions, you won’t have to wait long for results.

The issue may be cost. Still, it is more expensive than buying a thermistor.

But the operating efficiency of nozzles equipped with heating is much higher. It is safer and more aesthetically pleasing. Moreover, new jets may have an attractive design that compares favorably with previous products.

It's up to you to decide anyway.

Engine heating

I think you all know how an engine works. During operation, the motor actively heats up.

And then motorists had an interesting idea. Why not use the heat generated by the internal combustion engine in the engine compartment for the benefit of the windshield washer. At the same time, this does not require any costs, plus the efficiency of this method is very high.

The only problem. This method is not suitable for all cars. This is true for cars where the jets are located directly on the hood itself. Otherwise, using this method will not give any result.

But if you are one of the lucky ones, then you have to do the following:

- take a utility knife and a piece of heat-resistant insulating material;

- lift the hood and secure it;

- mark the areas under the hood above which the injectors are located;

- draw a circle or square at these points;

- Using a stationery knife, cut two holes;

- It’s unlikely that you don’t have any insulation on the hood, but just bare metal;

- insulation is fixed around the perimeter of the holes;

- This covers the cut areas.

This creates a system for natural heating of the jets of the windshield washer unit.

The only thing left for you to do is to check the operation of your update in real test mode.

To do this, you need to close the hood, start the engine and let it warm up to operating temperature. Now get out of the car and touch the metal of the hood around the nozzles. If you feel warm, then everything works great. The injectors will definitely not freeze.

What are the advantages

Yes, when compared with the installation of new heated washers, even the option with natural heating from the engine loses in terms of aesthetics.

But the considered method has its obvious advantages. Namely:

- low cost, since you don’t have to pay anything to make a couple of holes, and the insulation can be found in the garage;

- reliability of heating, since nothing will depend on the electrics, unlike heated washers;

- there is no need to make any changes to the car's electrical system;

- absence of any external changes, since traces of modification remain on the back of the hood.

By using natural heating, you save time and money and have an effective way to combat frozen windshield washer nozzles.

Whether to use this method or not is up to each individual. How do you solve the problem of freezing injectors? Share your experience.

Subscribe, leave comments, ask questions and tell your friends about us!

Watch this video on YouTube

Why do windshield washer nozzles freeze?

There are not many main reasons for freezing of injectors without heating. Here are the main ones:

- Poor quality windshield washer fluid. This is the main and most common reason. “Anti-freeze” crystallizes at a temperature higher than that indicated on the packaging by the manufacturer. This also includes excessively diluted liquid.

- While driving, especially if it is prolonged movement at high speeds, for example, on a highway, the temperature of the windshield washer nozzles is greatly reduced by the incoming air flow. The cross-section of the injector nozzles is quite small, so it is the injectors that are the “bottleneck” and freeze first.

- If the windshield washer fluid supply system does not have a check valve, then when the pump is turned off, the fluid flows back into the reservoir. However, some of the liquid may remain in the nozzles in the form of drops. Ingredients that lower the crystallization temperature are usually volatile and therefore evaporate quickly. Windshield washer fluid begins to freeze at temperatures above the established norm.

Installing a factory heating system on a standard washer reservoir

If you don’t want to bother searching for the necessary materials, you can use ready-made kits. The auto industry always reacts very sensitively to new demand, so you can find ready-made solutions of both types, electric and flow-through, on sale.

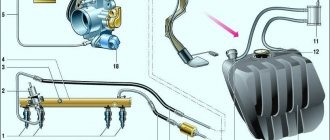

As an example of using the second option for heating the liquid coolant of the windshield washer reservoir, we can name the “Geyser” system, oriented for installation in all modifications of the VAZ. The kit includes a coil, hoses with clamps, and the plug itself. If installation is required on a car of another brand, then if the plugs and tank sizes match, no problems are expected. Otherwise, you will need to make holes in the standard plug and insert tubes from the purchased kit into them.

How it works

In winter, the windshield washer often fails. This is largely due to the fact that ordinary water or special liquids, but of low quality, are poured into the tank.

As a result, the system does not work because the water freezes, turns into ice, and clogs the nozzle tubes, as well as the nozzles themselves.

Some motorists, in order to avoid such troubles, use antifreeze for windshield washer in winter. The same antifreeze that is designed to operate the engine cooling system. Yes, the freezing threshold for this composition is higher. But globally this does not solve the problem. The liquid often freezes inside the nozzle (nozzle), which can negatively affect the operation of the washer motor and damage the entire system. We definitely don't need this.

In order for injectors to operate correctly at low temperatures, they require a heat source.

In favor of modern cars, we can say that the problem has been largely solved. This was done by installing a special heating system. That is, special sprayers are used, with a heating system already provided by the automaker.

But this heating of the liquid is not found on all cars.

I think it’s not difficult to figure out how to check whether the injectors have heating for your specific car. If they are frozen in winter and the nozzles need to be cleaned and adjusted, then there is probably no heating there.

A similar problem occurs for many cars:

- Kia Rio;

- Ford Focus;

- Lada Vesta;

- Lada Kalina;

- VAZ 2114;

- VAZ 2105;

- Daewoo Nexia;

- Renault Logan;

- Lada Priora;

- VAZ 2110, etc.

Just because there is a problem doesn't mean it can't be solved.

There are several ways. Let's consider them separately.

All models

Tired of washer fluid freezing on your windshield? Does the water in the tubes freeze? There is a simple heating method that does not involve tapping into the cooling system.

Author: [email protected] Share:

I decided to write a short report on the work done.

I spent 2 days. I did everything slowly at the dacha. I had a soldering iron and a hair dryer on hand as a heater.

The components were purchased in advance at a radio parts store: - thermostat 10A +60 degrees C - thermostat +25 degrees (converted to +5 degrees) - ceramic resistor (20w 3.9 Ohm) - imported resistor, 2 pieces (2w 75 Ohm) - wires 5 m - heat shrink tube - fuse holder, fuse 5A terminal

so in order. I refused to heat the tank with a coil from the cooling system because there were more disadvantages than advantages: - I didn’t want to interfere with the standard cooling system (you could crash into the throttle heating tube) - running the coil through the standard neck of the barrel is very difficult, the diameter is very narrow - 2-3 see, cutting the tank is not good. — you need to regulate the heating using a thermostat — again, difficulties + high power, you can heat five liters of washer fluid in 20 minutes.

I decided for myself that I would heat the liquid to 30 - 40 degrees so that the glass would not crack in the winter.

Heating was done using a large 20w 3.9 Ohm resistor. At 13V we get a power of 42W; it will take 1 hour to heat 1 liter of water by 40 degrees. A 60C thermostat was tightly pressed to the resistor with a heat-shrink tube. If the resistor starts to overheat, the thermostat turns it off. If the washer runs out, the resistor will not melt the tank. If there is a lot of washer, the resistor is well cooled. It turned out that the washer heats up by 30-35 degrees.

There are no photos of the resistor itself with the thermostat, I pushed it into the tank, but could not pull it back out

I ran the wires like this: I drilled a hole in the barrel

I did the heating of the injectors like this: I connected two 2W 75 ohm resistors in series and connected them through a thermostat converted to 5 degrees C.

I taped it here with tape.

The heating of the injectors is turned on at a temperature of +5C.

Resistors heat the plastic of the injectors, the temperature of the injectors remains positive. I filled everything with regular silicone sealant, which holds 180C.

The brown spots are remnants of old automotive high temperature sealant. It just dried out and the decision was made to replace it with a regular construction one.

This is how it turned out in the end.

I put insulation on the tubes last winter, it didn’t bring much effect then, but now I think it will be useful.

I took the plus from the accessory power connector. The right thick terminal gives out plus when the ignition is on. I don’t know whether the control is positive or power, so I put a 5A fuse in the wire break.

Operating principle of injector heating

In modern cars, trouble-free operation of injector heating is based on the use of special resistors programmed to activate electric heating elements at a certain sub-zero outside temperature. Such microscopic devices are placed inside the nozzle, and their size and shape directly depend on the model of the windshield cleaning system. Power to the heating element can also be supplied autonomously, after the driver presses a certain button in the cabin, but most often it is automated and turns on together with the heated rear-view mirrors or windows.

The only thing you will have to tinker with is installing a strong mount for new spray products, which may be slightly larger than standard products.

And in addition

- It is very important to ensure that during severe frosts the liquid supplied to the glass from the nozzles is not too hot. The temperature difference between the washer fluid and the windshield can damage the latter. Cracks may occur. Therefore, at 25–30 degree frosts, the heating system should be used with caution.

- In severe frosts, even with a heating system for the tank, it is better to use a concentrated anti-freeze agent. It will help prevent liquid from freezing on the surface of your car's windshield and your windshield wipers from freezing.

We insulate the windshield washer tubes

To insulate washer pipelines, you can use K-Flex or Flex tubes, which are usually used in air conditioning systems. You can also ensure heating of the windshield washer pipelines by running a tube, which is located behind the sound insulation under the frill, next to the steam exhaust hose of the stove. For example, by winding them together.

It should be noted right away that heating the windshield washer reservoir and tubes ensures normal operation of the washer nozzles at a temperature not lower than – 10 °C. At lower temperatures, freezing of the injectors cannot be avoided. Therefore, these heating options are recommended to be used in combination with heating the injectors.

How to make your own electric heating of the windshield washer tank

The second method of preheating the liquid liquid is to use electricity as a heat source. It is used less often, since it is believed that this method is less reliable, and its installation will require more effort.

Here, too, several options are possible. Here's one of the most common ones. We will need four 0.35 ohm resistors with a nominal value of 25 V, which are connected by soldering in a series circuit. Wires and a thermostat are soldered to this bundle. The entire structure is placed in a heat-shrinkable tube of the appropriate diameter and filled with autosealant. Such a homemade heater is placed in a tank in compliance with the safety requirements described above (no contact with the walls, pump and sensor). The wires are connected to the power system with the obligatory inclusion of a relay in the circuit and installation of a push-button switch in the cabin. As an option, you can connect such a heater to the rear window heating circuit - in this case, an additional button will not be required, but the heating of the windshield washer reservoir will work simultaneously with the heating of the rear window.

The thermostat should be selected with an operating temperature of no more than 60°C - if this indicator is exceeded, the anti-freeze heating system will automatically turn off.

How to choose heated windshield washer nozzles

Installing heated nozzles instead of conventional ones does not cause any particular difficulties, as does making a heated washer reservoir with your own hands. Most nozzles, regardless of the method of spraying liquid, are universal and suitable for any car with a round seat. If the car has a rectangular seat, then you will have to look for injectors of this type. When choosing heated windshield washer nozzles, you must carefully check their condition. Often, various fakes are sold under the brand names of popular brands, in which a low-power resistor is used instead of a wire heating element. Therefore, buy them only in trusted stores.

Some car owners buy heated injectors at auto repair yards, citing the fact that they are cheaper there. But the quality of such nozzles is unknown, so no one knows how they will work in winter. Don't skimp on the safety of your car. By spending the extra thousand on quality injectors, you will avoid serious problems in winter. The most reliable and efficient injectors are those from partner companies of well-known automakers.

At the same time, a heated injector from GAZ or AvtoVAZ and their partners is 2-3 times better and more reliable than a foreign one, the manufacturer of which is unknown. Therefore, Russian heated windshield washer nozzles often turn out to be much better than products for “modern foreign cars”, the manufacturer of which is unknown.

Inspect the packaging carefully. Uneven edges and unclear patterns are signs of a fake. Ask the seller to show you the box in which he received the injectors. The manufacturer's name on the box and individual packaging must be the same. Carefully inspect the injector body. The presence of burrs or irregularities indicates that this is a fake. Use a needle to move the jets in different directions. They should turn with little resistance. If you have to press so hard to turn them that the needle bends even a little, you have a fake. If the jets turn without effort, it's a fake.

Features of installation of heating nozzles

Nowadays, high-quality heating of washer nozzles can be installed in two current ways, including:

- Use of electric current;

- Application of the engine cooling system.

Electric heating involves the preparation of two heating elements based on 4 resistors of 200 Ohms, connected in parallel. A cut is made in the plastic structure of the nozzles with a maximum depth of 1 mm and a width of 5 mm. A heater is inserted into the hole made and filled with epoxy resin for reliable fixation. In the same way, we insert the heating element into the second nozzle, connecting it in parallel with the first product. The power consumption of this device is estimated at only 0.75 W, which is quite enough to heat the incoming liquid.

Heating of the washer elements can be done using SOD. For example, in the domestic model of the VAZ-2110 vehicle, the spray elements are installed on the frill, as a result of which the temperature in them can be increased by passing antifreeze. To do this, you will need a copper pipe, the length of which will be approximately 16 cm. Initially, we dismantle the steam exhaust pipe from the stove where it connects to the expansion tank. We attach one end of the copper product to the hose from this container, connecting the second end to the steam exhaust pipe from the stove. Neat slots are made at the bottom of the frill, where we mount the engine cooling system hose. The copper tube is located in close proximity to the nozzles that it will heat.

A similar injector heating system can be installed on any VAZ model up to the 10th series, for example, on the VAZ-2106, but with one caveat. The jets located on the hood must first be moved to the air intake grilles. To do this, you will have to make metal fixing brackets yourself, which will not take much time and effort.

Thus, heating the washer system nozzles will speed up the cleaning of the windshield in the winter, providing the driver with an excellent overview of the road situation in any weather.