Application of gasoline additive

This procedure is best timed to coincide with replacing fuel filters and here’s why. The detergent additive is poured into the tank, so the cleaning effect extends to the entire fuel supply system.

Any foreign deposits that have been washed off rush into the filter meshes and quickly clog them. If you do not change the filter elements, you will not be able to properly clean the injectors, because dirt will reach them. So, to perform the operation you will need:

- liquid – fuel additive;

- fine and coarse mesh filters.

Before carrying out the procedure, it does not hurt to learn more about engine additives.

The method of use is simple: the chemical composition from the bottle needs to be poured into the tank and continue to operate the car. After 200-300 km, replace the filter elements. An important point: the amount of cleaner in the container is designed for a certain volume of gasoline; their ratio is always indicated on the product packaging. In order not to get a negative result and not to harm the engine, follow the prescribed dose of the composition.

Most often, car enthusiasts use injector flushing fluid from the following manufacturers:

- Hi-Gear;

- Kerry KR-315;

- Liqui Moly;

- Injector Cleaner concentrate from the American brand STP.

When washed, they will not only clog all the filters, but can also damage the fuel pressure regulator.

Using cleaning fluid

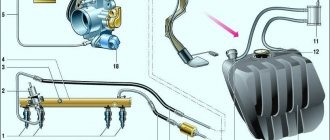

The best way to wash the injectors without removing them from the engine ramp is to connect a container with a flushing solution directly to the fuel line of the power unit. The procedure will not affect other elements of the system - filters, pump and pressure regulator. But you will need to make a simple device from the following parts:

- car gasoline hose 1 m long;

- cheap fuel filter with a paper element;

- hose clamps;

- 2 valves for tubeless tires, equipped with spool valves;

- 2 liter plastic bottle;

- manual or electric pump with pressure gauge.

It is necessary to make holes in the bottom and cap of the bottle, selecting the diameter of the drill to match the size of the valves. Then, you need to insert a valve without a spool into the hole made in the plug and attach the hose to it with a clamp. Afterwards, the hose is cut in half and a fuel filter is placed in the gap, observing the direction of flow (from the bottle). A valve with a spool is inserted into the second hole, where the pump is connected. For convenience, it is advisable to hang the bottle from the open hood with the neck down. The device is ready.

Before washing the injector directly on the car, you need to connect the homemade system to the fuel rail, for which you will have to relieve the pressure in it. Find the process fitting with a spool built into the end of the ramp, place a plastic cup under it and press the valve with a sharp object. Excess fuel will pour into the glass and the pressure will drop. Then follow this algorithm:

- Disconnect the main fuel line from the rail and connect the hose from the bottle in its place.

- Disable the car fuel pump by removing the corresponding fuse. Another option is to place a gasoline can under the disconnected line.

- Pour all the wash liquid from the bottle into the bottle.

- Connect the pump and pump the container into a pressure of 3 Bar (no more!).

- Start the engine at idle speed. Now it runs not on gasoline, but on washing liquid.

- Flushing continues until the motor has used all the fluid. During operation, you need to monitor the pressure in the plastic bottle and maintain it with a pump at 2.7-3 Bar.

The cleaning procedure is performed on a warm engine, so it must be brought to operating temperature before connecting the flushing device.

Using the technology described, cleaning the injector yourself is quite simple, and it won’t take much time. It is advisable to combine the procedure with changing the engine oil, since when flushing, some of the liquid that is not burned in the cylinders may get into the crankcase. The mileage between engine lubricant changes approximately corresponds to the frequency of preventive cleaning of injectors.

About the design of Priora injectors

It was these components that gave the common name to the type of car with an ECM. None of the drivers wants to pronounce the full name. They say simply - an injector. So what is a nozzle (injector)? This is a device that allows you to inject fuel, under pressure, directly into the working chamber of the cylinder in strictly metered portions.

The principle of operation of Priora injectors is based on the electromagnetic effect. When the circuit is closed, the coil retracts the core, which opens the channel for supplying fuel accumulated in the fuel frame under pressure. The opening signal comes from the electronic control unit (ECU). The nozzle consists of the following parts:

- Frame.

- Coil.

- Fuel cleaning mesh.

- Nozzle with holes (diffuser).

Main problems of injectors

Malfunctions of these important components of the Lada Priora car can be divided into two categories:

- Electrical part.

- Mechanical component.

The first option includes damage to the coil or connector. A break or interturn short circuit may occur in the coil. One or both contacts in the connector may break. Over time or from an impact they break off. In any case, such a nozzle requires replacement.

Mechanical malfunctions of Priora injectors include various changes in the diameter of the fuel supply channel. Most often with Priora, this is contamination caused by the settling of foreign particles on the walls of the channel and in the diffuser. Or corrosion (increase) in diameter under the influence of additives. Although this happens extremely rarely at Priora. With an increase, there are no options other than replacement. But if they become dirty, you can wash the nozzles. About replacement and flushing, about identifying a breakdown, further.

Injectors installed on Priora

The Lada Priora car is equipped with imported injectors manufactured by the German company BOSCH. These devices are highly reliable. Their service life can reach 160 thousand kilometers. However, car service specialists strongly recommend changing injectors every 120 thousand km.

Almost all Prioras are equipped with German injectors from BOSCH

Injectors for 8 and 16 valve engines

You should know that the injectors of the 8-valve Priora engine are no different in appearance from the injectors of the 16-valve engine. These are all the same devices from BOSCH, consisting of a housing, a coil, a diffuser and a fuel grid. When choosing injectors for a Priora, you need to think not about the number of valves in the engine, but about its volume. Because the markings of injectors for 1.5 liter engines are different from the markings of injectors for 1.6 liter engines. In the first case, the BOSCH injector should be marked 0-280-158-110, in the second - 0-280-158-502. You can clarify the markings in the car’s operating instructions, at the end of which there is a summary table with digital designations of all BOSCH injectors depending on engine size.

The following material is devoted to the repair and replacement of injectors in VAZ 2110-2112 cars:

Table of applicability of injectors for VAZ cars

Important nuances

There are a few things to keep in mind when cleaning your injectors. Here they are:

You cannot save on flushing fluid. The injector is a very important part of the engine. And it is extremely sensitive to the quality of the flushing fluid. The optimal choice for cleaning Priora injectors is a product from Wynns, developed specifically for injection engines.

The cost of a liter bottle is 700 rubles; Flushing fluid from Wynns is the best option for Priora injectors

You need to be very careful when removing an empty plastic bottle from the hood. It should be remembered: the pressure in it is enormous, so it can explode literally from one careless poke with a finger, and flying nipples can seriously injure the driver

The plastic bottle must be removed carefully after washing the Priora injectors.

Replacing injectors is a long procedure. Nevertheless, it is quite within the power of a novice driver if he has at least a vague understanding of the structure of an injection engine. When cleaning the injectors, the situation is much simpler: you just need to be able to use a drill and know where the main fuel hose is located.

Cleaning procedure

Cleaning injectors can provide the car owner with the following benefits:

- restoring the original functionality of the device;

- reduction of fuel consumption;

- optimization of motor operation.

That is, in case of contamination (use of low-quality fuel), it is possible to flush and clean the valves in order to restore them to functionality.

Open the hood and make sure all vehicle systems are working properly

Several cleaning methods

Experienced drivers know that there are several ways to clean injectors on a Lada Priora. Moreover, each of them has both its pros and cons.

The first option is to use a detergent additive - the liquid is added to gasoline and, after entering the gas tank, it enters the injectors. Usually one bottle of the additive (0.5 l) is enough for a whole tank of fuel. In this case, absolutely all parts of the fuel system are washed. However, the disadvantage of this method is the lack of drainage of dirt - it will remain in the system.

The second option involves using a solvent. It is considered the most effective, since flushing is carried out while the engine is running. However, it is necessary to replace the spark plugs immediately after using the solvent, as they may stop functioning.

Ultrasonic cleaning of injectors can be considered the most modern method. However, the average car owner cannot always afford to buy this type of equipment.

The Lada Priora car owner can clean and replace faulty injectors on his own - the main thing is to carefully monitor the progress of the work. The solenoid valve on the Priora is considered a fairly reliable element of the fuel system, so you will rarely have to perform any type of work with it.

Copywriter, needlewoman, traveler

Home →

Maintenance and Repair →

Car injector failure

The main reason for failure or wear of any fuel injector is contamination of the fuel system. The second aggressor is corrosion - it happens when there is moisture in the fuel. If particles as small as 0.01 mm (10 microns) are present in the fuel, this can also cause the injector to fail.

Cleaning injectors is an unavoidable task. Most often, they will need flushing by 40,000 km (in some cases this happens even earlier). Moreover, you can even do this on your own.

Replacing injectors on a 16-valve Lada Priora engine

As mentioned above, symptoms of injector malfunction include unstable engine operation, starting problems and increased gas mileage. To change the nozzle to a new element, you will have to spend a lot of time, since the replacement procedure is quite complicated.

As a working tool, it is recommended to immediately prepare:

set of open-end wrenches;

Phillips-blade screwdriver.

After the car has stood for some time and cooled down, you can start working:

The plastic retainer of the harness must be pressed to the side with your finger to pull the bundle of wires out of the injector.

After which you will need to relieve the pressure in the car’s fuel system. The average pressure is approximately 380 kPa, that is, if work is carried out without bleeding, you can get injured due to sudden fuel emissions. To do this, you will need to open the rear door of the car and remove the seat from the back row.

There is a carpet under the seat, and under it there is a hatch to the gas tank.

How to clean injectors in Lada Priora?

In order to inject liquid into a car engine, a device called an injector was created.

In technical terms, injectors are electromagnetic valves that are responsible for the metered supply of fuel to the cylinders (in systems where there is continuous injection).

Such a feed is carried out after an equal amount of time. Such strict regulation indicates the efficiency and practicality of the operation of such a part.

Purification process

Cleaning the nozzles itself should be done on a clean surface - for this you can cover the working surface with a piece of cloth.

Prepare a hose and a can for cleaning the carburetor. To flush, secure a plastic hose clamp at the inlet of the nozzle (make sure the length is at least 20 cm). The nozzle will need to be turned on, and the end of the hose itself will need to be lowered into the liquid that is used to flush the carburetor. Cleaning can be carried out by any of the proposed ones - RunWay, Liqui Moly or Hi-Gear.

You need to watch how the torch changes: it will expand or contract - it all depends on how dirty everything is. Once the jet stops changing, cleaning should also be completed.

But there is no need to add cleaning additives advertised on the market to the fuel: it very often happens that they harm the engine. The acidified dirt itself after such cleaning can create a blockage that will prevent normal access to the fuel-air mixture. Otherwise, fuel access may be blocked.

Cleaning is complete. Now do the installation in reverse order.

Despite the fact that the engine power supply system from the carburetor is a thing of the past, and its place was confidently taken by the injector, the old problems remained “thanks” to the quality of the fuel. Only now you have to clean the injectors from dirt, not the jets. If you go to a car repair shop, they will charge you a decent amount of money for the ultrasonic cleaning procedure along with disassembling the unit. To save on this service, you need to figure out how to wash the injectors with your own hands directly on the car in your own garage, without using expensive equipment.

Relevance of the procedure

How do you know if your injectors need cleaning? This is indicated by the corresponding behavior of the motor:

- engine power will drop;

- fuel consumption will increase;

- exhaust toxicity will increase;

- the engine will idle;

- There will be failures in engine operation.

If there are no such signs, then it is better not to climb into this part, even for the purpose of a routine inspection. Cleaning will definitely give a result, which will depend on the degree of contamination: the more dirty the injectors were, the greater the positive effect you can get at the output.

Cleaning Priora injectors

There are two options for washing injectors: with and without removing them from the car. The removed injectors are washed on special stands using ultrasound, under the influence of which even the oldest contaminants disappear. Ordinary drivers do not have such stands, so below we will consider a more popular option for washing injectors without removing them from the Priora. Here's what you'll need for this:

- liter of special flushing fluid;

- two automobile nipples;

- automobile fuel filter;

- a pair of metal clamps;

- a meter piece of rubber hose with a diameter of 12 mm;

- drill with 13 mm drill bit;

- electric pump;

- two liter plastic bottle.

Flushing sequence

- The bottom and cap are drilled into the plastic bottle. This is done with a “13” drill. Automotive nipples are inserted into the holes.

- The spool is unscrewed from the nipple inserted into the plug. This must be done so that the flushing liquid passes freely into the nozzles.

- Now a rubber hose is put on the nipple inserted into the plug and secured with a metal clamp. The second end of the hose is put on the fuel filter and secured with a second clamp. A piece of rope is screwed to the bottle with tape (so that the bottle can be hung on the hood).

- The car starts. You must wait until the engine warms up to 90 degrees. After warming up the car turns off. The fuel hoses are removed from the fuel pump, the car starts again and runs until it stalls. All this is done in order to completely relieve pressure in the fuel line.

- Now you need to find the fuel hose with a green button on the clamp, connected to the fuel line. To remove it, just press the green button and pull it towards you.

- The hose is put on the fuel filter (the clamp with the green button should make a characteristic click).

- The washing liquid is poured into a plastic bottle.

- An electric pump hose is connected to a nipple inserted into the bottom of the bottle, after which the bottle is suspended on the open hood of the car.

- Using a pump, a pressure of 3 atmospheres is created in the bottle (as the liquid flows out of the bottle, the pump will have to be turned on several more times to maintain this pressure).

- After the required pressure has been created in the bottle, the car starts at idle and runs for 15 minutes.

- After this time, the engine is turned off and cools down for 10 minutes.

- If there is still liquid left in the bottle, the engine starts again and runs until it stalls.

- After this, the flushing system is removed from the car, and the fuel hose is installed in its original place. Injector flushing is complete.

Cleaning methods

There are several options for cleaning the injector:

- removal of contaminants in an ultrasonic bath, which will require disassembling the injector and removing the nozzles;

- periodic flushing using special gasoline additives;

- using flushing fluid instead of fuel.

The last two methods are well suited for washing injectors with your own hands, since to implement them you do not need to disassemble and remove from the engine the elements that supply fuel to the cylinders. Another thing is that these methods are not as effective as ultrasonic treatment, and therefore are considered preventive.

Hence the conclusion: such procedures need to be done more often . The optimal interval for using a cleaning additive in fuel is 5-10 thousand km. More effective washing of injectors without removing them from the engine, which uses liquid as a fuel substitute, can be done once every 15-20 thousand kilometers.

Do not use traditional methods to service the injector, including adding kerosene, pouring solvent, or using other exotic compounds.

Instead of saving, you may end up with large costs for fuel system repairs.

5.18.Checking and replacing injectors

Signs of injector malfunction may include: – difficult engine starting; – unstable engine operation; – the engine stalls at idle; – reduced crankshaft rotation speed at idle; – the engine does not develop full power, insufficient engine response; – failures in engine operation when the vehicle is moving; – increased fuel consumption; – increased content of CH in the exhaust gases. You will need: a 5-point hex key, a flat-blade screwdriver, a 17-point key (two), an autotester.

| 1. Disconnect the connecting block of the injector wiring harness and the engine harness by pressing the lock. | 2. Perform an initial check of the injector windings. To do this, connect the ohmmeter to the contacts of the pads one by one. |

Note There are five contacts in the block: four for supplying a control signal to the injectors and one common “+12 V” (a crimson wire with a black stripe is connected to it).

3. In turn, connect the four control contacts to the common contact and measure the resistance in each case. It should be 11–15 ohms. If in one or more measurements the resistance value differs from the specified value, the tested injectors or their wiring harness may be faulty.

4. For a more accurate check and replacement of injectors, remove the fuel rail from the car (see “Removing and installing the fuel rail”).

| 5. Use a screwdriver to pry off the spring retainer of the injector... | 6. ...remove the clamp... |

| 7. ...and remove the injector from the fuel rail. Remove the remaining injectors in the same way. | 8. To identify a faulty injector, connect an ohmmeter to the injector contacts. It should show a resistance of 11-15 ohms. If the winding resistance is not normal, replace the faulty injector, as it cannot be repaired. |

Note Check the injector for the shape of the sprayed fuel spray and for leaks at specialized service stations, since such a check directly on the car is very fire hazardous. Warning The injectors of the VAZ-21126-00 engine of the VAZ-2170 Lada Priora have an original design and are not interchangeable with the injectors of VAZ injection engines of other models. Buy new injectors with exactly the same markings.

| 9. Whenever removing injectors, be sure to replace the O-rings on all injectors on the ramp side. Using a screwdriver, carefully pry the edge of the ring... | 10. ...remove the sealing ring from the injector... |

11. ...and similarly remove the ring from the sprayer side. 12. If you are installing old injectors, carefully wash their nozzles with solvent or carburetor cleaner.

Warning Install new sealing rings carefully, without using any tools, after lubricating them with engine oil. Note The sealing rings on the injectors are identical to other rings installed on early VAZ models with fuel injection systems and are interchangeable with them.

| 13. Before installing the injectors, lubricate the O-rings with engine oil or WD-40. | 14. Install the injectors in the reverse order of removal, securing them to the ramp with clamps, after tightening them a little. |

15. Having installed the fuel rail, connected the fuel line and connected the wiring harness block, secure the minus terminal on the battery, turn the ignition key 3-4 times to position “I” (ignition) at intervals of 2-3 s between turns on and check for leaks pipe connections and injector seals. 16. Install all removed parts in the reverse order of removal.

How to check for faults

The car owner can independently check the performance of the injectors on his car. The procedure is quite simple and does not require special training or expensive equipment. In garage conditions, diagnostics can be performed with a set of open-end wrenches, screwdrivers and a tester with a resistance measurement mode.

Reasons indicating problems

Diagnostics must be performed not after any period of operation or mileage has expired, but in the presence of external manifestations of injector failures. In cases where other vehicle systems are operating normally, the following indicators indicate problems with the injection solenoid valves:

- at idle there is instability in engine speed;

- starting the engine is difficult - the engine may stall;

- when overclocking it is impossible to achieve the same dynamics;

- The amount of fuel consumed has noticeably increased.

Diagnostic procedure

- Open the hood.

- Unclip the plastic clips that secure the valve's power cable. Remove the connector.

- Switch the tester to resistance measurement mode and take measurements of the windings of each of the injectors in turn. That is, you need to apply one contact of the tester to each of the five terminals, and the second one to the fifth wire for power.

- Optimal resistance values in all cases should be in the range of 11–15 ohms. If at least one pin shows deviations, it will be necessary to change the nozzle.

Payment via PayPal

After selecting payment via PayPal, the PayPal payment system will launch, where you need to select the payment method: bank card or PayPal account.

If you already have a PayPal account, then you need to log into it and make a payment.

If you do not have a PayPal account and you want to pay using a bank card via PayPal, you need to click on the “Create an Account” button - shown with an arrow in the picture.

PayPal will then prompt you to select your country and provide your credit card information.

After specifying the information required to make the payment, you must click on the “Pay Now” button.

The best injectors for VAZ 2110-12

Injector malfunctions or how to check the injectors: 1. Coking of the outlet holes.

Symptom: increased gas consumption, poor engine starting, deterioration in vehicle dynamics. Otherwise, the engine behaves normally, idle speed is stable and starts normally at positive temperatures; at negative temperatures, starting is difficult.

2. Leaky closing of the nozzle valve.

- Symptom: increased fuel consumption, poor engine starting, tripping or detonation at idle.

- Diagnostics: measure CO (on a normally running engine without a catalyst, CO should not exceed 1% in idle mode. One leaking injector increases CO by approximately 1.0-1.5%).

3. Valve stuck.

- The sign is engine tripping.

- Diagnostics: disconnecting and then connecting the injector electrical connector with the engine running. If the injector is faulty, then there will be no engine response; if the injector is working, then there will be a temporary drop in speed.

4. Unstable valve hanging.

- Symptom: floating idle (a sharp drop in idle speed followed by an increase to 1000 - 1400 revolutions or a complete stop of the engine).

- Diagnostics: as in point No. 3. If one injector hangs unstable, it is guaranteed to be diagnosed as a shutdown. If two or more, then only by replacement.

Example, injectors with a mileage of 198 thousand km. At 40 thousand km, ultrasonic washing was done, and at 170 thousand km. Lavr decarbonizer was poured.

About VAZ injectors of the tenth family: “Dozens” were equipped with Bosch and Siemens injectors. Standard injectors from the factory are mainly Bosch injectors 0 280 158 996 (or 996e).

Interchangeability of VAZ injectors: Injectors come in not only different sizes, but also different in performance. To understand which injectors are suitable for your car, just use the table:

Addition to the table: BOSCH 0 280 150 996 nozzles are no longer produced; their analogue is BOSCH 0 280 158 110 (capacity 170 cc/min). There are some differences, for example, the rubber sealing ring on the 110th is a couple of millimeters higher than on the 996th, and the “tail” (from which it splashes) is longer. But there should not be any difficulties when installing the injectors.

Flushing frequency

The atomizer for direct injection of fuel into the cylinder is a fairly reliable device and, when using high-quality gasoline, reliably serves about 100-120 thousand kilometers. But since there have always been problems with fuel quality in the post-Soviet space, signs of contamination of small holes in the injectors appear much earlier:

- Due to an insufficient amount of supplied air-fuel mixture, the engine loses power.

- The controller, seeing a lack of fuel from the lambda probe signals, increases its supply, which increases the overall fuel consumption. Moreover, the car's behavior is not getting any better.

- Popping sounds may be heard in the injector receiver or in the exhaust pipe, from which black smoke periodically pours out.

- The motor is unstable.

Replacing injectors on a Lada Priora car

Before we move on to describing the process of removing the injectors, you need to select everything you need for the job. Here is a list of tools and consumables:

- Phillips screwdriver;

- set of hex keys;

- set of open-end wrenches;

- pliers;

- wrench and set of socket heads;

- flat screwdriver.

Sequence of work

- The block to which the wires of the Priora injectors are connected is manually disconnected and removed. The block with wires on the Priora fuel rail is removed manually

- Now use a Phillips screwdriver to unscrew the screw holding the pressure plate of the fuel pipe. The mounting fuel rail on the Priora can only be unscrewed with a Phillips screwdriver

- Use a 17 wrench to unscrew the fuel pipe fitting. In this case, the tip of the tube must be held with a key at “22”, preventing it from turning. Without this, the fuel rail may break. The Priora fuel fitting should be unscrewed with only two keys

- The fuel pipe is carefully removed from the ramp, and the O-rings are removed from it. The O-rings from the Priora ramp should be removed so as not to lose them

- Use a Phillips screwdriver to loosen the clamp on the crankcase ventilation hose. The hose is then manually disconnected from the cylinder block. The Priora ventilation hose can only be removed after loosening the clamp

- The tube with lubricant level indicators is removed.

- There is a hose on the intake manifold that goes to the vacuum brake booster. The clamp on this hose is loosened with pliers. It is convenient to loosen the Priora brake hose clamp with pliers

- Use a socket head to “10” to unscrew a pair of nuts on the fastenings of the intake pipelines. The Priora intake pipeline is held on top by only two nuts

- Then, using a “13” head, unscrew all the bolts on the lower fastening of the pipelines.

- The pipeline, freed from the fasteners, is slightly lifted up and pulled towards itself. Access to the fuel rail is provided. After unscrewing the fasteners, you can simply pull the Priora pipeline towards you

- The ramp is held on the cylinder block by two screws at “5”. They can only be unscrewed using a hex wrench. Two 5-point screws on the Priora ramp can only be unscrewed with a hexagon

- After this, the ramp is removed from the cylinder block along with the injectors and wires. The Priora fuel rail is removed along with injectors and wires

- Old injectors are unscrewed from the ramp and replaced with new ones. The injector on the Priora can be unscrewed from the ramp manually

- After this, the fuel system is reassembled.

Lubrication system

General information

The lubrication system, by supplying oil to rubbing parts, reduces wear of rubbing parts, increases the mechanical efficiency of the engine, cools the engine with oil and removes wear products.

On cars, the lubrication system is combined - under pressure and by splashing. The main and connecting rod bearings of the crankshaft and camshaft bearings are lubricated under pressure. By spraying oil, the pistons, piston rings, cylinder walls, and camshaft cams are lubricated.

The lubrication system includes: an oil pump with an oil receiver, an oil filter, an oil sump, an oil filler neck with a sealing cap, an oil level indicator and oil supply channels in the cylinder head and block.

The oil pump serves to supply oil to the rubbing parts and to the oil filter for cleaning. The pump is gear-type, with internal gears and a pressure reducing valve. Installed on the front wall of the cylinder block (from the crankshaft side). The drive gear (smaller diameter) is mounted on two flats on the front end of the crankshaft.

The oil filter is designed to clean oil from mechanical impurities. The filter is full-flow, non-separable, screwed onto a fitting and pressed against the collar on the cylinder block. The filter has an anti-drainage valve that prevents oil from draining from the system when the engine is stopped. The filter is also equipped with a bypass valve that is activated when the filter element is clogged. Thus, the oil enters the oil line, bypassing the filter.

Engine crankcase ventilation is forced, closed. Ventilation ensures suction of crankcase gases from the crankcase through an oil separator (in the cylinder head cover).

Changing engine oil and filter

Attention: — It is necessary to fill in engine oil of the same brand and composition that was poured into the engine. — If you replace the engine oil with another brand of oil, after completely draining it is necessary to flush the lubrication system with special flushing oil for 10 minutes

Then replace the oil filter with a new one. — Drain engine oil only into a previously prepared container.

For this operation you will need the following tools: a 17 mm wrench, a container into which the oil will be drained.

1. Place a specially prepared container under the engine crankcase. Then unscrew the drain plug and drain the engine oil.

2. Install and tighten the drain plug.

3. Using a special wrench or by hand, unscrew the oil filter.

4. Wipe the contact surface of the cylinder block with the oil filter with a clean rag.

5. Apply a thin layer of engine oil, which will then be poured into the engine, onto the O-ring of the new oil filter.

Causes of injector contamination

When a mixture of air and fuel burns, a tar deposit is formed. It is deposited not only in the combustion chamber of the engine, but also on the surface of the nozzles. This leads to their gradual contamination. The shape and diameter of the hole in the nozzle body gradually decreases. The result is insufficient supply, a change in the spraying process. The mixture turns out to be heterogeneous. Instead of the injector delivering a mist of fuel into the engine, it sprays small streams of fuel.

The structure of the mixture changes, and an excessive amount of air or fuel appears in it. Engine performance decreases, the on-board computer tries to adapt the car to new conditions, supplying even more gasoline, which cannot burn completely.

Gasoline injectors work even worse in winter, when fuel evaporates more slowly. This leads to more intense pollution.

Injector works perfectly

Perfect combustion of fuel can only be achieved if the injector is fully operational. Translated from English, it is called a motor pump.

To understand how to properly clean, you need to know the operating principles of the mechanism itself. This part is based on one or two channels. The first will receive the sprayed liquid, the second will receive the same steam or gas, which will spray the first liquid. The torch will burn continuously and evenly if the nozzle is of high quality and clean. In gasoline engines like the Lada Priora, an electromagnetic injector is usually used. It is a simple device that operates using an electronic control unit - at the right time it is required to supply voltage to the valve excitation winding. Thus, an electromagnetic field will be created: it will retract the valve with the needle and release the nozzle. The fuel will inject, the voltage will disappear and the needle will return to the seat.