Tags: no pull, jerking

Comments 26

I don't know if it will help. Due to the malfunction of two coils, two injectors did not spray. Those. the brain gives the command: no spark, no injector. I would start digging for errors in the ecu first.

I think I need to watch it anyway. Thank you

no, check them on the bench, if they work, then look at the wiring and the last option is a malfunction of the computer

No. The phase sensor could break down if two of the same injectors do not work. Or the braid itself to the injectors is acting up. And yes, a diagnostic computer costs 1000 rubles. Will save a lot of money and nerves)))

How come, a diagnostic computer costs 1000 rubles? where is it?

# I was a little mistaken in the price, it has gone up in price, but you can find it up to 1500. There are more expensive ones, but the point is only in convenience and somewhat more advanced functionality. In Krasnodar, there seems to be a State dealer www.shtat.ru/gde_kupit/krasnodar/

No. The throttle is needed to pass air. And the Throttle Position Sensor (TPS) is needed to read the opening angle of the valve itself and, accordingly, to supply the correct amount of fuel. There seems to be some kind of sensor at the injectors. It is responsible for the alternating operation of the injectors. I even changed it... but I forgot what it is called. (

A faulty injector (nozzle) has a negative impact on the operation of the vehicle engine. The sooner the car owner finds out the cause of the malfunction, the sooner he will eliminate it, saving a significant amount of time, nerves and money. Listed below are signs of an injector malfunction that indicate the need for repair and maintenance work.

Most common reasons

There are three main factors that can lead to unstable operation of the fuel injection system:

- Low quality fuel is a common problem in all post-Soviet countries.

- A long service life can equally be attributed to both advantages and disadvantages.

- Unprofessional repair work.

It should be noted that unqualified repairs are the most dangerous factor that can affect the normal operation of the injector. In the absence of certain theoretical and practical knowledge, it is not recommended to try to repair or clean the injector yourself. It is best to entrust such work to professionals who are well aware of all the nuances and features of carrying out work of this kind.

Improper cleaning of the injector can cause harm

There can be a great many reasons for a malfunctioning injector, so in this article we will analyze only the most typical signs of an injector malfunction inherent in engines of various types, and give recommendations for eliminating them.

Cleaning inside

This is one of the most important points when working with devices. Among the main devices are tubes and syringes, and delivery cartridges. Cleaning agents get inside through tubes. First, they test the composition on a small area, because it is very aggressive. Work begins if nothing happens.

After cleaning, new rings are installed. It is not recommended to put the old ones back, even if they are cleaned. The filters and fuel pump mesh are also removed and replaced with new ones. Their location is easy to find out if you study the VAZ 2114 diagram; the injector rarely changes its position.

Which indicates possible problems with the injector

Let us immediately note that there can be many reasons for unstable engine operation, ranging from a clogged fuel filter, a broken fuel pump, a failed spark plug or a faulty coil, to loss of compression, problems with the timing belt, etc. Along with this, one of the main signs of injector malfunction is difficulty starting the engine, especially when cold, as well as gasoline or diesel consumption (depending on the engine type), which increases noticeably. It is also necessary to note the unstable operation of the internal combustion engine in idle mode, similar to the so-called “triple” of the engine.

VAZ 2114 car injector system

The VAZ 2114 is equipped with an engine with a distributed fuel injection system (injector), and the stable operation of the engine of this car depends on the quality of gasoline. A low octane number of fuel leads to a drop in power and unstable operation of the power unit. As a result, any parts of the internal combustion engine (ICE) may fail. Mechanical impurities in the fuel lead to clogging of fuel filters, damage the fuel pump, and clog the injectors. You have to disassemble the fuel system (TS) and clean the injector. How the VAZ 2114 injector works, how to clean it and in what cases, how to remove and install the fuel rail, we will look at in this short article.

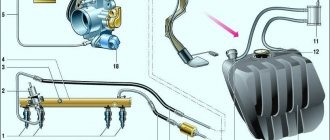

The VAZ 2115 injector is no different from the VAZ 2114, so when considering the device of the “fourteenth” model, we will also keep in mind the “15th”. The mechanical part of the injector includes:

- Intake manifold;

- Fuel rail (or rail, which is the same thing);

- Throttle assembly;

- Air filter with housing;

- Air pipe (injector corrugation);

- Injectors.

Gasoline injector device

Car enthusiasts who replace the carburetor with a distributed injection system in their “eights” and “nines” are puzzled by purchasing exactly these listed parts, not counting the electrical components.

Self-check of injectors

Let's start with the fact that automobile injectors are divided into several types, of which two types have found widespread use at different times: mechanical injectors and electromagnetic (electromechanical) injectors.

Electromagnetic injectors are based on a special valve that opens and closes the injector to supply fuel under the influence of a control pulse from the engine ECU. Mechanical injectors open as a result of increased fuel pressure in the injector. Let us add that modern cars often have electromagnetic devices installed.

To check the injectors with your own hands without removing them from the car, you can use several methods. The simplest and most affordable way to quickly check injection nozzles without removing them from the car is to analyze the noise emitted by the engine during operation.

Important information

First you need to find out exactly what kind of fuel the car is fueled with. Turning to unfamiliar gas stations is likely to interfere with stable operation. Negative consequences are associated with carbon deposits inside the combustion chambers. The service life of the injectors does not even reach 120 thousand kilometers if you regularly choose low-quality materials for refueling.

It is recommended to replace it at least every 90 thousand kilometers.

How to check the power supply to the injectors

This check is carried out if the injectors themselves are working, but any of the injectors do not work when the ignition is turned on.

- for diagnostics, the connector is disconnected from the injector, after which two wires need to be connected to the battery;

- the other ends of the wires are attached to the injector contacts;

- then you need to turn on the ignition and record the presence or absence of fuel leakage;

- if fuel flows, then this sign indicates problems in the electrical circuit;

Another diagnostic technique is to check the injector using a multimeter. This method allows you to measure the resistance on the injectors without removing them from the engine.

- Before starting work, you need to find out what impedance (resistance) the injectors installed on a particular vehicle have. The fact is that there are injection nozzles with both high and low resistance.

- The next step is to turn off the ignition and also reset the negative terminal from the battery.

- Next you will need to disconnect the electrical connector on the injector. To do this, you need to use a screwdriver with a thin tip, with which you need to unclip a special clip located on the block.

- After disconnecting the connector, switch the multimeter to the desired operating mode for measuring resistance (ohmmeter), connect the contacts of the multimeter to the corresponding contacts of the injector to measure impedance.

- The resistance between the outer and central contacts of a high-impedance injector should be between 11-12 and 15-17 ohms. If the car uses low resistance injectors, then the indicator should be from 2 to 5 Ohms.

Comprehensive diagnostics of the operation of injectors on the ramp

For such a check, the fuel rail will need to be removed from the engine along with the injectors attached to it. After this, you need to connect all electrical contacts to the ramp and injectors if they were disconnected before removal. It is also necessary to return the negative terminal of the battery to its place.

- The ramp must be placed in the engine compartment so that a measuring container with a scale can be placed under each of the injectors.

- It is necessary to connect the fuel supply pipes to the ramp and additionally check the reliability of their fastening.

- The next step is to turn on the ignition, after which you need to crank the engine a little with the starter. This operation is best performed with an assistant.

- While an assistant rotates the engine, check the efficiency of all injectors. The fuel supply must be the same on all injectors.

- The final step will be to turn off the ignition and check the fuel level in the containers. The specified level must be equal in each container.

In addition to self-checking, you can use the injector diagnostic service at a car service center. This operation is performed on a special testing stand. Testing an injector on a bench allows you to accurately determine not only the efficiency of fuel supply, but also the shape of the torch during fuel spraying.

Video: the easiest way

If the body is clean and there are no deformations or cracks on it, then repair work is allowed . To do this, you will need to remove the seal from the body and the sprayer. It is recommended to leave these parts in acetone or solvent for 1.5–2 hours. While the parts are being washed, you can use a vacuum cleaner to clean the fuel rail. Next, you need to carefully clean the place where the injectors fit into the ramp using a toothpick or a needle.

After this, you can start purging the nozzle from the inside. You will need a roll of electrical tape, an aerosol can for cleaning carburetors and a syringe. An aerosol cleaning liquid is supplied through a thin syringe into the nozzle cavity.

It is better to wrap the joint between the syringe and the tube of the canister for sealing with electrical tape. It is recommended to repeat washing the nozzle from the inside three times. Afterwards the product must dry.

A cheap product will perfectly remove dirt and deposits from the nozzle. Before installation, each nozzle is tested for resistance. The tester readings should be in the range of 11–15 ohms.

There is also a simple way to clean the injectors, without dismantling the fuel rail. However, it is only appropriate in cases where the injectors have not yet exhausted their entire service life (120–150 thousand kilometers). The use of cleaning additives in gasoline is allowed. In this case, all elements of the fuel system will be cleaned, but its closed nature does not allow removing dirt and sediment from low-quality gasoline.

A broken fuel pump can cause serious problems. You can read more about this here: https://vazweb.ru/desyatka/pitanie/zamena-toplivnogo-nasosa-vaz-2114.html

The liquid is poured into the gas tank and, together with the fuel, cleans all elements of the system.

How to clean the injectors yourself without removing them from the engine

During the diagnostic process, a common cause of unstable engine operation is that the injection nozzles are clogged. There are several ways to clean injectors, among which mechanical, ultrasonic or cleaning using special chemical compounds can be used.

In some cases, pouring a special injector cleaner additive into the fuel tank is enough to normalize the operation of the entire system. It is also recommended to rev the engine to high speeds at certain intervals and accelerate the car to 110-130 km/h. on flat sections of the path. In this mode you need to drive 10-20 kilometers. Continuous operation of the injectors under load allows for so-called self-cleaning.

Cleaning the injector should be done as a preventive measure, and not after signs of malfunction appear. If the car is operated in city driving mode on fuel of questionable quality, then the interval of preventive measures should be reduced in relation to individual operating conditions.

When and why you need to remove fuel injectors from the engine. Removing injectors on gasoline and diesel engines: features of the dismantling process.

Cleaning a car injector without removing the injectors. Methods for cleaning injectors with removal on a cavitation stand. Ultrasonic and hydrodynamic cavitation.

Malfunctions of diesel injectors, checking and self-identification of problems. Cleaning diesel engine injector nozzles, regulating injection pressure.

Common diesel engine malfunctions and diagnostics of units of this type. Checking the fuel system of a diesel engine, useful tips.

Operating principle and distinctive features of gas injectors. Basic parameters when choosing nozzles for gas equipment 4. Which gas injectors are best to buy.

Features of operation and causes of malfunctions of diesel injectors. How to independently remove, troubleshoot, disassemble and repair diesel engine injectors.