Replacing the gear shift rod oil seal for Lada Priora

We replace the gear selector rod oil seal when we detect an oil leak through it from the gearbox.

Remove the power unit mudguard (see “Removing the power unit mudguard”).

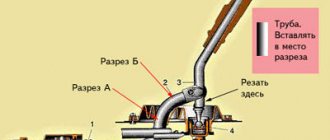

Having unscrewed the locking screw of the gear selector rod hinge with a wrench “10”, we move the joint assembly with the control rod off the rod and remove the protective cover of the gear selector rod hinge (see “Replacing the cover of the gear selector rod hinge”).

Using a powerful slotted screwdriver, evenly (from different sides) pry the oil seal race by the collar... ...and press the race with the oil seal out of the clutch housing socket.

With a suitable size mandrel...

...press the oil seal out of the cage. We clean the race and the seat under it in the clutch housing from the old sealant. We especially carefully inspect the surface of the hole in the gearbox. In case of large scuffing of this surface or a malfunction of the holder, the holder should be installed on a preparation of the “cold welding” type.

Having selected a mandrel (for example, a tool head) with a diameter close to the outer diameter of the oil seal...

...press the oil seal into the cage until it stops (the working edge of the oil seal must face the clutch housing). We apply a thin layer of sealant to the outer surface of the oil seal race, and transmission oil to the working edge of the oil seal.

We put the clip on the switch rod and insert it into the hole in the clutch housing. Leaning a mandrel of a suitable size on the collar of the oil seal...

...press the clip into the clutch housing socket. We carry out further assembly in reverse order.

Video on the topic “Lada Priora. Replacing the gear shift rod oil seal"

Lada Priora (LadaPriora) Changing the oil in the gearbox, replacing the rocker seal, replacing the rocker shaft, Replacing the oil seal and gearbox rod boot (glass) VAZ 2110, replacing the shift rod seal 2108 (all front-wheel drive VAZ)

Source

Main malfunctions of the scenes

All malfunctions of the Lada Priora gearbox and how to eliminate them:

| Symptom | Malfunction | Gearbox model | Way to solve the problem |

| Unclear gear shifting | Worn bushings | 2170–2181 | Replace all bushings |

| Damaged pillow | 2170–2180 | Replace pillow | |

| Cables stretched | 2181 | Replace cables | |

| The tension of the traction clamps is loose | 2170–2180 | Adjust then tighten | |

| The lever has failed | The pillow tore | 2170–2180 | Replace pillow |

| Lever travel too long | Worn bushings | 2170–2181 | Replace all bushings |

| Cables stretched | 2181 | Replace cables | |

| The tension of the traction clamps is loose | 2170–2180 | Adjust then tighten | |

| One or more speeds do not turn on the first time | Forks are deformed | 2170–2181 | Replace plugs |

| The tension of the traction clamps is loose | 2170–2180 | Adjust then tighten | |

| Cables stretched | 2181 | Replace cables |

The main malfunctions of the Priora gearbox are the same for any transmission and are determined by their design. The lever and rigid drive are made of steel, so they do not break. The remaining parts, all kinds of plastic bushings and cables, clamps that secure the rods, often fail (their nuts have a bad habit of becoming loose). In addition, on the so-called rocker boxes, that is, gearboxes 2170–2180, the rubber band (the rubber support of the lever) often fails, which also leads to problems with switching on the required speeds.

One of the rare defects is the rattling of the 2014 Priora gearbox, although it also occurs on cars of other years, but always with a rocker transmission. It is caused by contact between the torque rod and the gear shift rod. Due to the running engine, the contact becomes vibrating, and the collision of parts generates ringing. To eliminate it, just slightly move both rods away from each other.

How to change the oil seal on the backstage of a Priora?

Many car owners have encountered this problem when the top of the gearbox and the gearshift rod are in oil. This occurs against the background of the fact that the rod seal has become unusable. It is clear that this is not an extreme measure, but still such an oil leak cannot be called the norm. Along with the oil seal, you will also have to change the rod, which is interconnected with the gear shift mechanism, as well as the axis of the rod, which has a spring lock. You can purchase a gasket in advance that is installed under the gear shift cover. Replacing the rod and oil seal of the mechanism can be done in parallel, along with repairing the gear shift drive

Leaking oil seals is not the most pleasant thing. This problem is the same for both the engine and the gearbox. In this article we will analyze a situation that is standard for front-wheel drive cars - leakage of the gear selector rod oil seal. First, you need to understand what a gear selector rod is, and only then understand how to replace the gear selector rod oil seal.

Repair or replacement

Before deciding whether repair, adjustment or replacement of the link is necessary, it will have to be disassembled.

- Remove the cover on the gear shift knob;

- The machine must be installed on a jack or on an overpass (pit);

- Remove the front console, which is bolted on;

- Remove the rocker by unscrewing 6 bolts.

During this procedure, carefully inspect all parts. You definitely need to bend the boot and inspect the condition of the support, cardan shaft, and oil seal.

It may be necessary to use a rem. kit, and perhaps a more complex repair is needed.

If the bushing is deformed, it needs replacement. If the cardan has play, as well as if the hole in the lever axis is worn, a complete replacement of the link and repair belt is necessary. the kit clearly won't help.

It happens that the rocker pad is to blame for the rattling noise when changing gears. Replacing a pillow is a simple operation, but can be beneficial.

What is a gear selector rod and why is it needed?

Older cars had a classic layout, with the rear wheels driving and the gearbox located under the car's interior. The gearshift knob was brought into the cabin and made it possible to control the transmission directly. In front-wheel drive cars, there is an urgent need for a special mechanism that would allow control of the gearbox located under the hood, while sitting in the car's interior. This device is called the gear selector rod, or, as drivers are accustomed to calling it, the rocker.

This part is inserted into the gearbox and connected to the gear shift handle mechanism. Using special levers, the gearbox handle acts on the rod and changes its position, which leads to a gear change.

The rod is connected to the gearbox through an oil seal, since there is oil inside the box that is under constant pressure. To prevent pressure from squeezing the oil out, a system of seals is provided in all parts of the gearbox connecting to external mechanisms.

The oil seal is a round rubber product, inside of which there is a hole for the rod. The material used may vary. It all depends on the make and model of the car, although many manufacturers make oil seals of the same size but from different materials. They all differ in their properties, but they have the same function - to prevent oil leakage from the car transmission by increasing the tightness of the moving parts of the unit.

Backstage repair and adjustment

In this section we will describe the replacement of all consumables, as well as all the adjustments to the Priora gearbox that can be carried out on a particular transmission.

Backstage repair kit

To repair a Priora gearbox of any type, you will need:

- pit;

- overpass;

- lift;

- jack with safety stands.

In addition, you will need the following tools:

- a set of spanners and open-end wrenches;

- flat and Phillips screwdrivers;

- ratchet with extension and set of bits.

If you work from a jack, be sure to use safety stands. And after installing the car on them, shake it strongly in all directions. If it falls off the stands, it means you installed them incorrectly. But it’s better if the car falls while you’re not under it.

Installation of a short-stroke rocker on a Lada Priora

Installing a short-stroke rocker on the Lada Priora makes gear shifts clearer, and besides, the rocker stroke itself will be less, therefore making shifting more convenient.

How to install a short-throw rocker with your own hands:

Remove the gearshift lever cover and knob. The knob on the lever is not attached in any way, it is pulled together, just apply some force.

We remove the gearshift lever rod from the cardan, having first loosened the clamp (you will need a key to “13”).

In order to release the lever, it is necessary to release the ball from the spring mechanism (necessary for engaging reverse gear with locking). To do this, remove the locking ring.

Under no circumstances should you pull up on the lever in an attempt to release it.

A little patience and the locking ring is removed.

We take out the locking ring, the lever with the ball inserted into the plastic frame and the spring.

The plastic mandrel consists of two parts: the upper cylindrical part (left) and the lower (right). The upper part has a slit and fits onto the lever. The lever ball is inserted into the lower part and clasped around the upper part so that the grooves coincide, and the entire assembly rests entirely on the lever.

We take out the lever along with the rod through the interior. If you prefer, you can disconnect the lever from the rod, but from my point of view it is not at all necessary to disconnect it.

In the photo there is a short-stroke link at the bottom and a standard link at the top.

We remove the cardan. First, pull off the rubber boot and use a “10” key to unscrew the bolt on the left on the cardan.

Cardan from Priora (above) and Viburnum (below). It is immediately noticeable that the cardan rods are different in length. It is necessary to shorten the stem from the viburnum, depending on the type of short-stroke link, because The slides come from different companies, but the rod may not fit completely, as a result of which the gearbox lever will be shifted towards the handbrake lever.

How is the rod seal replaced?

First of all, the malfunction must be diagnosed. To do this, check the oil level in the gearbox. If it has become noticeably lower, drive the car onto an inspection hole or overpass. Pay attention to the junction of the rocker and the gearbox; if traces of oil are found there, the oil seal must be replaced.

First you need to purchase all the components. These include: the oil seal itself (you choose the material of manufacture yourself; there is no significant difference between them, but the difference in price is noticeable) and the boot of a small cardan. In most cases, this boot is either torn or will be damaged during dismantling. That is why it is necessary to purchase additional spare parts in advance so as not to open the hood again.

Replacing the cylinder head gasket on a VAZ 2170 2171 2172 Lada Priora[edit]

If an external leak of engine oil or coolant is detected at the junction of the head and cylinder block, remove the head and replace its gasket. A leak can also occur due to warping of the block head due to overheating. In the absence of sealing on the cylinder head gasket into the internal cavities, antifreeze can get into the oil which begins to foam (foam can be seen especially clearly on the filler neck and in the cavity of the valve cover), in addition, an oil film may appear in the antifreeze. In case of this malfunction, it is necessary to replace the gasket as soon as possible, since this malfunction can lead to engine failure due to the incorrect operation of two systems at once - lubrication and cooling.

How to change the rod seal - Video instructions

- Make a mark of the position of the rod and cardan so that after assembling the parts you do not have to adjust the gear shift. Then use a 13mm wrench to loosen the tie rod clamp.

- After this, pull the boot off the cardan. Unscrew the 10mm bolt used to secure the cardan to the gear selector rod. The cardan must be dismantled along with the boot.

- Now drain the oil from the gearbox. This is done so that after removing the oil seal, oil does not pour on you. Screw screws of sufficient length directly into the oil seal. After that, grab them and pull them towards you with all your strength. The seal should come out. As soon as it comes off, take a new oil seal and lubricate it with a special sealant.

- Let the sealant sit on the part for a while. After this, take a tube of the same diameter and use it to press the new oil seal into the gearbox. Oil can only be refilled after 24 hours, depending on the type of sealant chosen.

- Now change the boot on the cardan and install it. Reassemble the parts in the reverse order according to the marks made. After assembly, do not forget to fill the gearbox with oil.

Replacement of wheel drive seals and gearbox rod seal of Lada Priora

The front wheel drive seals can be replaced without removing the gearbox.

We carry out the work on an inspection ditch or overpass.

Draining the oil from the gearbox

Remove the left and right front wheel drives (see “Removing the front wheel drives”).

Use an impact puller to press out the right drive oil seal.

Press out the left drive oil seal in the same way.

If there is no impact puller, you can press it out with a mounting spatula or a powerful screwdriver

The gearbox can be equipped with two types of oil seals: both with and without oil drainage notches.

Oil seals without notches are interchangeable for left and right drives.

Seals with notches differ:

at the left drive oil seal, the arrow on the housing points counterclockwise, at the right drive it points clockwise.

Using a mandrel of a suitable diameter, press in a new right wheel drive oil seal.

You can use the old oil seal as a mandrel when pressing. Similarly, press in the left wheel drive oil seal.

Apply a thin layer of transmission oil to the working edges of the oil seals.

Reinstall the drives of both wheels. Pour oil into the gearbox.

Replacing the gear shift rod hinge boot and rod seal

Move the protective cover off the gear shift rod hinge

Using a 10 mm spanner, unscrew the hinge locking screw.

We move the joint assembly with the control rod from the gear selector rod

Remove the protective cover of the hinge from the switch rod

Using a powerful slotted screwdriver, pry the oil seal holder by the collar evenly from different sides.

Press the race with the oil seal out of the clutch housing socket

Using a mandrel of a suitable size, press the oil seal out of the holder (Fig.

We clean the race and the seat under it in the clutch housing from the old sealant.

Select a mandrel (for example, a tool head) with a diameter close to the outer diameter of the oil seal.

We press the oil seal into the cage until it stops (the working edge of the oil seal should face the clutch housing).

We apply transmission oil to the working edge of the oil seal, and sealant to the outer surface of the race.

We put the cage on the switch rod and press it into the clutch housing socket, resting it with a mandrel of a suitable size on the collar of the oil seal cage.

We carry out further assembly in reverse order. We replace the damaged hinge cover.

Before assembly, clean and degrease the threads of the hinge locking screw and apply sealant to the threads.

Before tightening the screw, we ensure that the holes in the hinge and the gear selector rod match.

The bolt securing the hinge to the rod differs in length and color. This bolt is cadmium plated (gold colored finish). Cannot be replaced with other bolts.

If the shank taper or thread is damaged, the bolt must be replaced with the same one. The bolt is fixed with TB-1324 glue.

If there is no such glue, then you can use another similar thread locker.

Two ways to replace the gearbox seal on a VAZ-2110

It is easier to change the oil seal with the gearbox removed.

Replacing an element that has become unusable can be done in two ways.

- The first of them is very labor-intensive , since it will be necessary to remove the gearbox. But replacing the oil seal will be much easier.

- The second method seems less time-consuming and labor-intensive , but in practice it is very difficult to carry out this procedure. Only experienced motorists who have repeatedly had to repair their cars can replace the oil seal directly on the car without removing the gearbox.

Troubleshooting

Experienced car owners know the visual reasons why they can determine the failure of the rocker seal. Naturally, for such reasons it is impossible to accurately determine the cause of the leak, but this gives a signal to carry out diagnostics, in which the cause of the oil leak can be accurately identified.

The most important sign is oil stains under the car, especially in the gearbox area.

An oily rubber boot indicates a malfunction of the rocker seal.

But these spots do not always indicate oil seal failure. It happens that this is due to the oil filter, which sometimes does not tighten properly. In any case, the driver is obliged to monitor for any oil leaks in the checkpoint area . To do this, you need to monitor the oil level. This is the only way to save the box from damage, which will certainly happen if it operates with a minimum amount of oil.

Another way that indicates the oil seal is worn out is a characteristic crunch that is heard when changing gears . But only an experienced VAZ-2110 owner can diagnose this crunch. In any case, if you hear unusual sounds when shifting into gear, it is better to diagnose the gearbox.

Set of tools required for replacement

A minimum set of tools for replacing the oil seal without removing the gearbox.

In order for the replacement of a part to take place without problems, you need to prepare the place and the necessary set of tools in advance. You will need:

- A set of keys and sockets, and for 13 you need two keys and there must be a key for 10. There must also be a socket head for 22.

- A chisel or screwdriver will be needed to knock out the oil seal.

- The hammer is small so you can get under it.

- Silicone sealant.

- Awl and hook.

Additional accessories

A regular self-tapping screw will allow you to do without a special puller.

For those who decide to replace the gearbox seal without removing it from the car, you will need additional equipment:

It should be noted that the replacement process without removing the gearbox is much more complicated. In addition, there is a possibility of damaging the part being replaced during pressing.

Pulley, or damper, generator drive, its purpose

The multi-belt drive of the generator and other additional units, when installed on the Priora, in addition to transmitting torque from the crankshaft, performs another important job. To understand its meaning, it is worth making a short digression into the ECM.

The principle of operation of an engine with an “injector”

Cars equipped with an ECM are radically different from conventional carburetor cars. The fact is that the ECU (Electronic Control Unit) is responsible for all the actions of the ignition and fuel supply systems. It is he who gives the signals for the formation of a spark in the cylinder chambers. And it sends signals for fuel injection by opening the fuel rail injectors. The question naturally arises, how does the computer know that it is time to issue commands to turn on the necessary nodes?

The crankshaft sensor informs him of this. It is worth considering this process in more detail. This sensor operates on the long and well-known Hall effect. That is, the signal is interrupted when a special technological clearance on the disc being read coincides with the sensor. On “injection” cars, this signal coincides with TDC (Top Dead Center) of the compression stroke of the first cylinder. So, you need to know that on Russian cars it is the pulley that does the work of the information disk.

Features of the pulley (damper)

The generator drive of the Priora, like other domestic cars, is called a damper. This is a Disk with streams, along the edge of which there is a series of teeth. In one place two teeth are missing. This is the desired position of the crankshaft, and it is from this that the computer starts counting. So, from the moment this opening enters the sensor’s coverage area, the Priora ECU sends signals to open the injectors and generate a spark in the cylinders, according to the usual scheme.

The engine operates according to tables stored in the ECU memory. From this it should be clear that the pulley not only powers the generator, but also gives the command to start the engine!