It often happens that the gearbox on a VAZ-2110 begins to work incorrectly. Some motorists are beginning to panic, believing that the gearbox will soon fail. In fact, often the culprit of all extraneous squeaks, noises and crackling noises when changing gears is the gearbox linkage . As practice says, in most cases this part does not need to be changed; it is enough to simply adjust it correctly.

But there are times when adjustment does not lead to the desired results. In this case, the part will have to be replaced.

How to identify signs of a broken rocker on a VAZ-2110

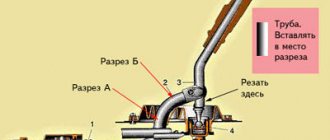

Gear shift drive diagram.

It is enough for an experienced owner of a VAZ-2110 to easily determine if the link is broken. This is indicated by a number of the following signs:

- Unable to engage first gear.

- The gearbox does not want to turn off first gear.

- It happens that the first gear is engaged without problems, but then the transmission itself switches to reverse gear.

- First and fifth gears do not engage, but other modes engage normally.

To avoid expensive gearbox repairs, if even one of the above symptoms is detected, you need to immediately go for diagnostics to a car service center or to a garage to independently determine and repair the breakdown.

What should I change?

Most types of breakdowns can be diagnosed independently, after which they should be promptly eliminated:

- If the gearbox lever has a lot of play, this is the result of wear on the rocker . In this situation, adjustment will not help. The backlash can only be eliminated by replacing the backstage.

- The rocker makes a characteristic ringing sound when changing gears . One of the most difficult cases. Replacing the slide may not help. This defect is usually related to the gearbox. It is possible that this is a manufacturing defect, or the result of unqualified intervention in the gearbox.

- The gear is engaged with great difficulty, it can “get knocked out” . In this case, you can try adjusting the scenes. If this does not help, it will have to be replaced.

- When trying to engage first gear, it always shifts into reverse . In this case, you need to change the backstage. In some cases, a repair kit may help.

- When the engine is running, there is strong vibration of the gear shift lever . In this case, it is possible that there is play in the hinges of the box.

All detected breakdowns must be promptly repaired, otherwise serious gearbox repairs cannot be avoided.

Gearbox control drive Lada Priora Lada Priora

Adjustment may be required after removing and reinstalling the VAZ 2170 gearbox, as well as in case of unclear gear shifting during operation of the Lada Priora. You will need two “13” keys.

1. From below the car, loosen and unscrew the nut of the clamp bolt on the transmission control rod by 3–5 turns.

2. Use a screwdriver to slightly widen the groove of the clamp and the groove at the end of the rod to ensure free movement of the rod relative to the gear selection rod, and set the rod to the neutral position.

Scheme for adjusting the position of the Lada Priora gear shift lever: 1 – reverse lock bracket; 2 – axis stop; 3 – gear shift lever axis; 4 – axle bushings; 5 – gear shift lever; 6 – spacer sleeve; 7 – spherical washer of the ball joint; 8 – spherical pin of the gear shift lever; 9 – body floor; 10 – ball joint; 11 – buffer; 12 – spring; 13 – template 67.7834.9527; 14 – bracket cover

3. Inside the car, remove the gear shift lever cover from the handle, lower the cover down along the lever and install the lever so that its lower (non-bent) end is approximately vertical. If you have template 67.7834.9527, position the gear shift lever as follows: with the lever cover removed, install the template in the window of the lining 14 of the reverse locking bracket. Insert the stop 2 of the axis of the lever 5 into the groove of the template 13 and press it against the template in the transverse direction without causing elastic deformation of the bracket 1. Fix the lever 5 in this position.

4. From the bottom of the VAZ 2171 car, with light hand movements (so as not to move the levers of the VAZ 2172 gear selection mechanism), select the axial play of the rod in the rearward direction and its angular play in the counterclockwise direction.

5. Tighten the nut of the clamp bolt, placing the clamp at a distance of 1–3 mm from the end of the rod.

Gearbox and gearbox Lada Priora

Gearbox Lada Priora |

Lada Priora gearbox malfunctions, their causes and solutions |

| Removal and installation of the Lada Priora gearbox |

Disassembly and assembly of the Lada Priora gearbox |

| Disassembly and assembly of the secondary shaft Lada Priora (Lada Priora) |

Disassembly and assembly of the input shaft Lada Priora (Lada Priora) |

Dismantling and assembling the Lada Priora gearbox synchronizer (Lada Priora) |

Assembly and disassembly of differential Lada Priora (Lada Priora) |

Selection of differential bearing adjusting ring for Lada Priora |

Assembly and disassembly of the gear selection mechanism Lada Priora (Lada Priora) |

Removal and installation of gearbox seals Lada Priora (Lada Priora) |

Replacing gear shift lever axle bushings for Lada Priora |

Assembling and disassembling the gear shift lever Lada Priora (Lada Priora) |

| Gearbox control drive Lada Priora |

Modification by installing a different type of backstage

In the photo above there is a short-throw rocker, below is a standard one from a VAZ-2110.

Currently, VAZ-2110 owners have the opportunity to install an improved gearbox linkage on their car. This tuning includes replacing a standard part with a short-stroke rocker. Thanks to this procedure, gear shifts begin to shift much more clearly. Installation of the modernized backstage occurs according to the following algorithm:

- First, you need to disassemble the ball from the outside.

- You need to unclench the iron ring of the support and spread the plastic legs. After this the ball will come out.

- The thrust from the support is switched off. A piece of pipe and a piece of sheet metal need to be welded to the rod itself.

A car's transmission is one of the key components when driving. Since it transmits torque and power directly from the engine to the wheels and serves as the necessary transmission link.

The transmission structure is heterogeneous and includes many additional components and assemblies, among which the linkage (jet thrust) plays a special role. Such a detail also plays an important role in the correct operation of not only transmission systems, but also the correct operation of the engine (albeit indirectly).

Video “Replacing the VAZ backstage”

This video shows the process of removing and installing a new transmission element on a VAZ 2110 car.

Many inexperienced drivers begin to panic and talk about a breakdown of the gearbox, although in fact the culprit of the problem is the rocker.

Practice shows that replacement and repair are rare and not very common measures. Much more often, the current situation forces you to simply adjust the scenes.

But today we will talk not only about adjustment, but also talk about the features of modification, repair and replacement of this element.

Element location

Possible signs of malfunction

A typical malfunction of the rocker for the VAZ 2110 model is:

- Some looseness in the shift lever.

- A very large free play of the handle also indicates a breakdown of the transmission thrust.

- The most typical example is the ability to change gears without squeezing the clutch. Some may decide that in this case it is even easier to drive the car - there is no need to use the third pedal, but this situation does not last forever and leads to major damage to the gearbox.

On video, the repair kit for the VAZ 2110 wings:

Malfunctions of the backstage also include:

- Difficulty engaging first or fifth gear . This condition is caused by mechanical failure of the components of the slide, which do not allow the lever to move in the required direction;

- Independently changing gears without selecting them . If the driver has chosen first gear, and it suddenly turns out that it is now reverse gear, there is an obvious malfunction of the rocker.

Diagnosis of the problem

The gearbox linkage in a car is necessary so that the unit cannot independently change gears as a result of the simultaneous movement of the sliders. This mechanism requires careful care, as well as periodic and high-quality adjustments. If the adjustment is performed poorly or some time has passed, this may manifest itself while the car is moving and the driver will feel discomfort.

VAZ 2110 car

In practice, as a result of constant use of a car with a rocker drive that requires adjustment, the vehicle may be at risk of breaking the entire transmission system. Therefore, attention should be paid to the quality of the unit’s operation and problems that arise during operation should not be neglected.

To understand that in your VAZ 2110 you need to adjust the rocker shaft, you just need to pay attention to the operation of the gearbox unit. Symptoms of the malfunction will be as follows:

- There were problems with engaging first gear. In particular, it will be impossible to turn on the gearshift lever, and sometimes it will be impossible to switch from first speed to second.

- Instead of first gear, reverse gear is engaged. Imagine: you are about to start moving and engage first gear, but instead your vehicle starts moving backwards. Perhaps after switching to “neutral” the problem will disappear, but over time it may happen again. In this case, in 98% of cases the problem lies precisely in the rocker shaft, that is, this has nothing to do with the speed lever.

- There may be problems with engaging first and fifth speeds. At the same time, all transmissions will work normally.

New component of the VAZ 2110 transmission system

- A large amount of play has appeared in the gearbox selector, that is, when switching the lever, you noticed that a gap has appeared. Apparently, the rocker in your vehicle is out of order and adjusting it will no longer help: you will have to repair the mechanism.

- A new extraneous noise has appeared, uncharacteristic of the gearbox of your VAZ 2110. In particular, the rocker began to ring, that is, you feel a distinct ringing from under the unit. This problem can be called the VAZ 2110 disease, since many car enthusiasts have encountered it. In this case, the cause of the breakdown may be an inaccuracy made during the assembly of the car at the enterprise or errors made by the car owner or a mechanic at a service station when adjusting the mechanism. It is also worth noting that the ringing often appears after repair work has been carried out on the chassis.

- The speed may simply jump out. That is, you have engaged a gear, but when accelerating, the car immediately loses power because the gearshift lever automatically engages neutral speed. This will require some fine adjustments.

- Vibrations of the gearshift lever. If the linkage is faulty, the driver may feel increased vibration of the gearbox selector. Often this indicates the appearance of a small gap in the hinges of the gearbox unit.

Troubleshooting, cost

To eliminate these breakdowns, there are both new rocker panels on the market and repair kits for selective repairs of a specific part. Such kits are an order of magnitude cheaper than a new unit and allow you to maintain a condition suitable for driving for quite a long time.

The average cost of a repair kit for the VAZ 2110 model varies depending on the manufacturer (mostly domestic) and is about 300 rubles.

Repair of certain parts occurs by dismantling the structure and replacing individual elements:

- In the engine compartment, it is necessary to remove the protective cover and fastening coupling from the nut connecting the transmission torque rod and the gear shift knob;

- Then, inside the car, it follows in the space behind the protective cover of the gear shift knob, it is also necessary to remove part of the plastic of the floor tunnel;

- After this, you need to use a wrench to remove the bolts (there are four of them) that hold the lever;

- Then you should insert a sleeve into the inside of the lever;

- Then remove the body and take out the main shaft of the rocker;

- After disassembling the entire system, you should carefully inspect it for defects and damage, in the event of which the failed parts must be replaced;

- After replacing parts, assembly of drive a is carried out in the reverse order.

When noise comes from the gearbox, vibrations and other unpleasant properties appear, many car owners begin to seriously panic. Although often a breakdown of the gearbox is a premature, incorrect “diagnosis”, since often the problem is in the shifter.

Many years of experience clearly demonstrates that replacing the rocker is a rather rare occurrence, because it is easier to adjust it. However, this article is aimed not only at covering this topic, but in addition will tell you how to carry out repair work correctly, what modification features should be taken into account, as well as how to change the rocker on a VAZ 2110 , following all the rules.

Repair

Regardless of what exactly you do with the rocker - repair, adjust or change, you will still need to disassemble this unit.

Disassembly is performed as follows.

- Remove the cover from your gear shift knob.

- Place the car on a pit, or raise the front end with a jack.

- Remove the front console. It is held in place by mounting bolts.

- Now remove the curtain itself. To fix it, AvtoVAZ used 6 bolts in the case of the VAZ 2110 model.

- When carrying out dismantling work, be sure to examine the condition of all elements.

- By bending the boot, you will gain access to the support, oil seal and cardan shaft.

Changing the boot

Now regarding the repairs. There may be several recommendations in this regard, depending on the current state of the node and its components.

- At best, repairs will require the use of a repair kit for the backstage. It doesn't cost much.

- If the bushing is deformed, it will need to be replaced with a new one.

- Check the lever shaft bore for wear.

- Make sure there is no play in the driveshaft. Otherwise, a regular repair kit will no longer be enough, that is, a complete replacement of the entire backstage will be required.

- Often the culprit of extraneous noise and rattling when shifting gears in gearboxes is the rocker pad. Changing it is quite simple, and even a beginner can perform the operation.

Signs indicating a malfunction

Fortunately, it’s quite easy to identify the fact that the rocker is the culprit of the breakdown! Indeed, this is directly indicated by many factors, including:

- Inability to engage first and/or fifth gear, while the others shift without any problems.

- The first gear categorically does not want to engage, move to a different position or disengage.

- When first gear is engaged, the handle behaves quite naturally, but then it begins to “jump” into reverse gear on its own.

If your car is characterized by at least one of the above points, then you should immediately send it to a service station or carry out repair and restoration work yourself (if you have the necessary experience, knowledge and skills).

Adjustment

If the slide shows the very first signs indicating a deterioration in its working condition, then it should be adjusted. Almost everyone can do this correctly if you follow the algorithm below:

- At the very beginning, you need to make every effort to activate first gear.

- To ensure maximum safety, the car should be secured on the overpass, and then put on the hand brake and place additional supports under the wheels. This will ensure that the vehicle is insured against involuntary movement.

- We do not turn off first gear.

- You need to get under the hood of the vehicle to find a special clamp at the bottom that simultaneously holds and secures the rocker. Finding the gearbox will not take extra effort, after which you need to try to loosen the clamp.

- If all manipulations were carried out as correctly as possible, you should return to the salon to move the lever to the left all the way. If you move it in any other direction, the slide will definitely come off. This is undesirable, so extreme care should be taken.

- We return to the starting position and tighten the clamp back.

- It should be noted that it is often enough to move the rocker in relation to the cardan by just a couple of millimeters.

During this process, the condition of the driveshaft should not be neglected; on the contrary, it is advisable to evaluate its current condition, since it may require replacement if it is severely worn.

Finalization

At the moment, a situation has arisen where the happy owners of a VAZ 2110, in order to refine and modify the gearbox, are discussing replacing the standard rocker with a so-called “short-throw” one.

The latter is a product (consequence) of tuning done with your own hands. How justified such an event is, each owner must decide individually.

If we evaluate it objectively, then the installation of a gearbox is exclusively for the benefit of the gearbox, since it makes gear shifting clearer and more responsive.

There is no need to dismantle the standard version if you decide to install a short walker. To do this you need to perform the following manipulations:

- disassemble the ball joint from the outside;

- after this, you should unclench the metal ring of the support, and also spread the plastic legs;

- in this way the ball will come out;

- then the rod is disconnected from the support, and then a sheet piece of metal having high strength and a small piece of pipe are welded to it;

- In order to avoid spontaneous inclusion of speeds, you need to lift up the hinge with the hook.

It should be clearly understood that this type of installation will require great effort when switching stages. The positive thing is that such switching will become more pronounced and smooth, which in itself is convenient.

Repair and restoration work

Regardless of the repair, adjustment or replacement of the link, the need to disassemble this unit does not disappear.

The parsing process includes the following procedure:

- First, you need to remove the casing from the gearshift lever, or, more precisely, from its handle.

- The front of the car needs to be raised with a jack or placed on a pit.

- Unscrew the mounting bolts that hold the front console, and then remove it.

- Now you need to unscrew the six bolts that hold the rocker and also remove it.

- When dismantling, you should be extremely careful, paying attention to the condition of each part and element, so that if their condition is unsatisfactory, replace it with a working analogue.

- To gain direct access to the cardan shaft, oil seal and support, you need to bend the boot.

What is a backstage

The term appeared along with the first multi-speed gearboxes. It meant some kind of hidden mechanism connecting the driver and the transmission, with the help of which the driver gave a signal to the manual transmission about the need to change to the next or previous speed.

The term “scene” is not specified in any regulatory documents. This is the popular name for a mechanism or a specific part. Even drivers with many years of experience often use it differently. Some call this the gear selection mechanism located under the bottom of the car and connected to the gearbox by a lever (sometimes two levers) or cables. Others are the rod connecting the gearbox lever and the gearbox.

We propose to call the entire mechanism connecting the gear lever and transmission a “slide”. This makes it somewhat difficult to divide mechanical transmissions from AvtoVAZ into rocker and cable ones, but it allows us to perceive the gear shift mechanism as a single unit.