The importance of carburetor modifications

Carburetors produced from the factory are designed to operate the engine on a forced lean mixture, which ensures maximum efficiency and environmental concern.

Because of this, the standard carburetor does not allow the engine's power to be fully realized, and the car does not realize all its dynamic characteristics. Carburetor tuning is especially important when boosting the engine, since the need for a sufficient amount of prepared air-fuel mixture increases even more. Standard carburetor adjustments can affect idle speed, but set it up for optimal performance in the midrange. and even more so at high speeds it is not possible. At speeds above 4500, engine starvation occurs, since an unfinished carburetor is not able to cope with an air flow at a speed of about 120 m/s. As a result, a situation arises that an untuned carburetor strangles both forced and conventional engines.

Impact of modifications on engine life and fuel consumption

Theoretically, after all these modifications to the carburetor, fuel consumption should only increase and engine life should decrease. But all the numbers on paper and in theory often differ from practice. In fact, as the car’s power increases, the need to constantly press the gas pedal goes away in order to somehow stay in the flow. Accordingly, the secondary chamber opens much less often and due to this, fuel consumption, if not reduced, then remains at the same level.

If we talk about the service life of the motor, there are a lot of disputes and rumors surrounding this topic. If we turn again to practice, it shows that operating a “classic” engine at moderately high speeds not only does not harm it, but also increases the service life of many parts. There are, of course, some disadvantages, but they are outweighed by many noticeable advantages.

To sum it up, we can say that carburetor tuning is the best budget option for increasing car power. You can achieve decent results with minimal costs.

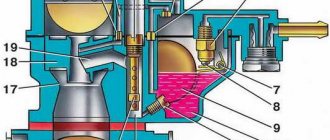

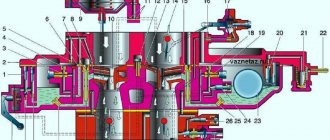

Design of the carburetor DAAZ 2107-1107010-20

Advertisement for the sale of LADA VAZ 2114 2012

DAAZ 2107-1107010-20 is a rather technically complex device. The carburetor is replete with a huge number of details, but, fortunately for the car enthusiast, it is not necessary to remember all of them.

The main components that directly affect the quality of the mixture:

- air and throttle valves;

- float chamber. A certain amount of gasoline comes here;

plastic float with needle valve. When there is a sufficient level of gasoline in the chamber, it rises and the valve shuts off the fuel supply;

- mixing chamber where gasoline is mixed with air;

- all kinds of channels;

- Air and fuel jets for proper mixture preparation;

- spray;

- air flow configurators, in other words - 25 diffusers;

- accelerator pump.

Main components of the DAAZ 2107-1107010-20 carburetor

The engine does not idle the main reason

Announcement of sale of VAZ LADA 2115 Samara 2008

The first thing you need to pay attention to is the solenoid valve. It is installed, however, not on all VAZ 2106 carburetors

It is this small device that most often falls into disrepair. Its operating principle is similar to a solenoid relay - there are windings, an armature, and a return spring, but the dimensions are somewhat smaller.

The function of the solenoid valve is to open the path for gasoline to flow (with the throttle valve closed) when the ignition is turned on. And close when disconnected, respectively.

The most common breakdowns of the solenoid valve, as a result of which the idle speed disappears:

- The winding is destroyed, the armature with the needle does not move, fuel is not supplied.

- The fuel nozzle located on the edge of the valve is clogged.

- The valve armature is jammed due to deformation.

You can check this device very quickly; you will need a small piece of wire, stripped from both edges. Connect one end to the positive side of the battery, and connect the other end to the terminal of the solenoid valve. There should be a fairly loud click, but if it doesn’t, then most likely the winding is damaged.

If there is a click, remove the wire connected earlier and turn on the ignition. Place the power connector onto the valve. If there is no click, then the wiring is damaged. In the event of a breakdown, there can be three exits, you can use any:

- If the solenoid valve is completely destroyed, it would be wise to unscrew it and remove the tip (fuel nozzle). And thus get to the nearest store without much difficulty. The price of a new VAZ 2106 solenoid valve is about 100 rubles, so repairs will not be expensive.

- Temporarily connect the output of the solenoid valve to the positive terminal of the battery - if the wiring is damaged. But in this case you will have to remove the wire during each stop.

- It would be much more efficient to run a wire from the solenoid valve output to the “+B” ignition coil contact. The fact is that voltage appears on it only after the ignition is turned on.

Options for tuning the “Seven” carburetor

So, if you decide to try your hand at improving the performance of your car, it is advisable for you to start by improving the performance of the carburetor.

First of all, this will allow you to fill your hand, and also make sure that all actions were not carried out in vain. The maneuverability of the vehicle is significantly improved, and fuel consumption is reduced.

How could this not impress some car enthusiast? Probably, every owner of not only a “Seven”, but any car, only dreams of increased performance, and the need to spend money on refueling less and less often.

Although you should set yourself up for this option, when the performance characteristics of the car improve along with a slight increase in fuel resources.

There are several options based on which you can tune the VAZ-2107 carburetor with your own hands. The first is to refine the carburetor design, and the second is to improve the mechanism by introducing a new repair kit.

Finalization of the design

The structural modification of the VAZ-2107 factory carburetor is aimed at eliminating the problem, as a result of which it is not possible to fully provide full power at which it could reach the engine speed declared directly by the manufacturer.

So, first find and release the spring, which is located between the pump and the damper. Now feel free to remove it, you won’t need it anymore. Unfortunately, fuel consumption may increase slightly for this reason, by approximately half a liter for every hundred kilometers.

Grinding the diffuser

Kia Spectra 2008 sale announcement

It is recommended to start tuning a Solex carburetor by reducing the resistance to air flow in the intake tract. The factory-made diffuser has a lot of sagging and protrusions caused by poor casting quality and subsequent surface treatment. Because of this, parasitic air flows and turbulence arise, which interfere with the flow of the mixture into the combustion chamber.

To correct the situation, you should disassemble the carburetor and visually inspect the diffuser. It usually looks like the one shown in the figure below.

Solex carburetor diffuser with obvious casting defects

Initially, it is necessary to sand all seams and protrusions that have arisen due to imperfect production technology. As a result of the modification, you should get a result as in the figure below.

Diffuser with polished surface

At this stage, it is possible to complete the improvement of the passage of the fuel-air mixture, but as you know, there is no limit to perfection. Experienced car enthusiasts recommend not stopping only at polishing manufacturing defects, but giving the diffuser maximum aerodynamic characteristics. You can achieve good streamlining of the surface by giving it a shape similar to an oval or wing, as shown below.

Diffuser with maximum streamlining

How can you solve the problem of upgrading an Ozone carburetor?

Let's try to look step by step at the carburetor improvement complex using the example of the VAZ-2105.

Modifying the Ozone carburetor is not such a difficult task; you can completely cope with it yourself if you have some experience and knowledge.

From all of the above, it is clear that it is necessary to ensure that the carburetor operates in such a way that it produces a universal working mixture for all operating modes. Most models have 2 screws that regulate the composition and size of the incoming mixture. They can only adjust the idle and high speed modes.

For other modes, deeper tuning of the carburetor engine is required.

What you need to know to adjust the carburetor

The main thing is to do everything in the correct sequence so that you don’t have to do the work again; first you need to go through these steps:

- clean the radiator housing;

- adjust the throttle and air damper drives;

- adjust the starting device;

- on the throttle valve of the 2nd chamber, adjust the pneumatic drive;

- adjust idle speed;

- reduce the toxicity of exhaust gases.

And so on in order, to clean the carburetor body, you need to use mixtures in aerosol cans, you can also just take white spirit or kerosene. To ensure that nothing interferes with thorough cleaning, you need to remove the air filter.

Adjusting the float mechanism

The operation is carried out in three stages. First, the float is checked to ensure its correct location in relation to the walls of the chamber and its lid. This procedure makes it possible to achieve “ideal” immersion of the float by eliminating the phenomena of deformation of the bracket on which it is mounted. Deformation can be eliminated simply by straightening the fastening element with your fingers.

Secondly, close the needle valve and begin to adjust the 2107 carburetor: put the lid in a vertical position, move the float to the side, and bend the bracket tongue (using a screwdriver). All these operations are performed in order to achieve a gap between the float and the cover at a level of 6–7 mm. Thirdly, open the valve, move the float to the side, and achieve a gap of 15 mm between the needle seat and the float.

How does this system work?

In order to correctly determine in the future why you are using a lot of fuel, you need to know how the engine power system works. With this knowledge, you will already know how to reduce the fuel consumption of your UAZ.

After air enters the intake manifold, the volume will be measured by a certain sensor. All this information will then go to the ECU. The process will receive the task of injecting fuel through an injector, or, to be precise, through injectors. Everything that is released into the atmosphere is detected by the exhaust measurement sensor. The data obtained helps determine the actual fuel consumption.

Already with knowledge about the operation of the entire system, it is easier to find the exact reason for the unreasonably high consumption of gasoline.

Checking Solex carburetors

Before adjusting the carburetor, you should check to see if any foreign objects have gotten onto the throttle valves. If a foreign object gets into the carburetor, this will inevitably lead to the need to overhaul the engine.

After the settings have been completed, you should check the operation of the accelerator pump. When you open the throttle, streams of gasoline should appear from the nozzle. If they do not appear immediately, the car will slow down strongly when starting to move.

In order to clean the carburetor, it must be disassembled. First, unscrew the air and fuel jets and emulsion tubes

The location of each element must be remembered, as this is important for the subsequent assembly of the carburetor

To check the integrity of the diaphragm, you need to unscrew the cover of the power mode economizer. You can tell that the diaphragm is broken by the following signs:

- The engine does not stall completely even with the screw tightened.

- When the ignition is turned off, spontaneous combustion may occur.

- Unstable engine operation.

- Excessive fuel consumption when driving.

After checking the diaphragm, the carburetor should be cleaned. This must be done carefully, using only air or, if the contamination is very serious, using soft copper wire. It is best to clean a Solex carburetor using the blowing method, in which you should blow through all its parts, trying to direct the contamination far out. Next, close the lid and lubricate all the rubbing surfaces of the carburetor. This should be done after you have washed its outer part.

Features of the selection of jets

When doing carburetor tuning with your own hands, the car enthusiast should modify the existing jets or purchase new ones of the appropriate size. To refine the jets, metal drills with a diameter of 1 mm to 2.5 mm are used. With their help, a standard jet is drilled out to the required size. In this case, the throughput increases. To reduce it, instead of drilling, soldering with tin is used. Next, a hole of the required size is made in the solder.

Location of jets in a Solex carburetor

Tuning the Ozone and Solex carburetors is not fundamentally different, since they are structurally similar, which can be seen in the images.

Jets in the Ozone carburetor

We remake the carburetor according to plan:

- Initially, you need to decide on the size of the jets. Depending on the goals pursued, a jet of increased or decreased size is installed;

- It is recommended to check the carburetor settings. If necessary, they should be adjusted;

- The vehicle is being tested. At the same time, dynamic characteristics and fuel consumption are controlled;

- We gradually increase or decrease the size of the jets until we achieve failures in engine operation and unstable operation;

- We return to the penultimate installed jet;

- If desired, you can replace the jets in both chambers;

- Check the result. An increase in diameter should lead to an increase of 5-10% power, and a decrease should lead to a reduction in fuel consumption to 1 liter per 100 km.

This is interesting: The location of the camshaft in the engine

Disassemble and modify

Removing the springs

Initially, it is necessary to remove the springs from the vacuum drive - they are located in the throttle valve of the primary chamber of the carburetor. After removing the springs, the process of accelerating the car will become easier and faster. The original purpose of these springs was to save fuel, but in practice this turned out to be completely different: without springs, gasoline consumption per 100 km will increase by 0.5 liters.

Wire to the rescue

The next step is to replace the throttle valve vacuum actuator. The vacuum drive should be replaced with a mechanical one.

This can be done as follows: take a small, even metal wire and bend one edge into a ring. We look for the nut that holds the throttle valve and put a wire ring on it. The result will be a protrusion, which on the outside of the lever will now be located between the wire and the other drive lever.

We fasten the nut and test the car while sharply pressing the gas during acceleration.

The purpose of this method is to simultaneously operate both chambers of the carburetor.

Air in the carburetor

With proper air flow into the carburetor, its operating efficiency increases. Diffusers marked 3.5 are usually installed on stock VAZ carburetors. They can be replaced with an analogue 4.5 and, thus, improve the acceleration of the car. At the same time, you can also replace the pump atomizer accelerator.

Such modernization does not affect fuel consumption in any way, which is why many tuners modify Ozone carburetors in this way.

Changing jets

The procedure is not easy. After such a replacement, it is possible to significantly improve the quality characteristics of the mixture and achieve higher productivity.

But you shouldn’t do the replacement yourself; it’s better to contact professional workshops that specialize in tuning and repairing carburetors. It is almost impossible to select the necessary jets without experience and knowledge on your own.

Tuning the thermal filter

Domestic tuning involves another way to modernize the carburetor. This time we will talk about replacing the hose in the carburetor injection system. This hose supplies air to the heat filter.

The entire modernization process consists only of replacing the existing hose with a longer one and connecting it directly to the fan, thereby providing direct air supply and removing air turbulence in the filter. This method can significantly improve the acceleration performance of the machine.

Important! If you overdo it, you can spoil the engine and eventually damage the carburetor itself. The air, bypassing the filter, carries with it particles of dirt, water and dust, directly entering the carburetor and engine

Tuning the Ozone carburetor does not end there; there are still a huge number of ways to make your car faster and more powerful. In the article, we tried to present only those that are most common among owners of carburetor cars, and which you can safely try on your car without much risk.

Content

The VAZ 2107 car is a classic of Soviet engineering. It was created on the basis of the 2105, which, in turn, was developed on the basis of the Fiat 124. The “seven” was conceived as a family car. Therefore, there are no special characteristics in the car.

But modern car enthusiasts do not agree with this state of affairs and strive to add some of their own unique touches to the “Seven”. This applies not only to styling, but also to hardware tuning. In this article we will talk about how to improve the dynamic characteristics of a car by working with its carburetor. You can achieve the desired result in various ways. Some experts recommend working on the engine. Installing lightweight components (pistons and connecting rods), along with grinding the manifolds, allows you to improve the acceleration dynamics of the VAZ 2107.

All this work requires the participation of professionals and specialized equipment. But often, the owners of the “Seven” prefer to do everything with their own hands. This allows you to avoid unnecessary costs. Therefore, it is worth considering the option of modifying the carburetor. This path is not so expensive and does not require special qualifications. And best of all, you don't even need a garage. As a result, you can significantly improve the performance characteristics of the VAZ 2107 and spend less money on modifications. In addition, the positive effect will appear immediately.