Oxygen sensor for VAZ 2112

The oxygen sensor (hereinafter referred to as OS) is designed to measure the amount of oxygen in the exhaust gases of a car for the purpose of subsequent adjustment of the enrichment of the fuel mixture.

A rich and lean mixture is equally “bad” for a car engine. The engine “loses” power, fuel consumption increases, and the unit operates unstable at idle.

Domestic car brands, VAZ and Lada, among others, have one oxygen sensor preinstalled. European and American technical means are equipped with two controllers:

They are no different from each other in design and size, but perform different functions.

Catalytic Converter Malfunctions

The catalyst (also known as a catalytic converter) is designed to purify exhaust gases from harmful impurities and plays the role of a kind of filter. Inside the catalyst can there are ceramic or metal honeycombs coated with a catalytic layer of precious metal. Over time, soot from the exhaust gases accumulates, clogs the honeycombs, and the exhaust gases pass through the catalyst with difficulty.

It is not always possible to clean the catalytic converter; in many cases it must be replaced. But since the catalyst is quite expensive and clogs quite quickly (premature failure often occurs due to low-quality gasoline), many car owners try to get rid of this part in various ways:

- remove the catalytic element by knocking out the honeycomb from the can;

- Instead of a catalyst, a flame arrester is installed;

- If the catalytic converter is an integral part of the manifold, it is replaced with a special insert (stinger).

Where is the oxygen sensor located on the VAZ 2112

In cars of the Lada (VAZ) family, the oxygen controller is located on the section of the exhaust pipe between the exhaust manifold and the resonator. Access to the mechanism for the purpose of prevention and replacement from under the bottom of the car.

For convenience, use an inspection channel, a roadside overpass, or a hydraulic lifting mechanism.

The average service life of the controller is 85 – 115 thousand km. If refueled with high-quality fuel, the service life of the equipment increases by 10 - 15%.

Oxygen sensor for VAZ 2112: original, analogues, price, articles

| Catalog article/marking | Price in rubles |

| BOSCH 0258005133 (original) 8 and 16 valves | From 2400 |

| 0258005247 (analog) | From 1900-2100 |

| 21120385001030 (analog) | From 1900-2100 |

| *prices are as of May 2022 | |

Mass-produced VAZ 2112 cars are equipped with German Bosch brand oxygen controllers. Despite the low cost of the original, not many car enthusiasts buy factory parts, preferring analogues.

Note to the driver. Service station mechanics strongly recommend purchasing parts with factory catalog numbers in order to prevent unstable operation of the power unit.

Signs of malfunction, unstable operation of the oxygen sensor on a VAZ 2112 car

- Difficulty starting the engine when cold or hot;

- System error indication on the dashboard (P0137, P0578, P1457, P4630, P7215);

- Increased fuel consumption;

- Engine detonation;

- A copious amount of blue, gray, black smoke (exhaust) comes out of the exhaust pipe. Which indicates an unbalanced fuel mixture;

- During the startup process, the engine “sneezes” and “chokes.”

Reasons for reducing the service life of equipment

- A natural factor due to the duration of operation without intermediate prevention;

- Mechanical damage;

- Manufacturing defect;

- Loose contact on the end switches;

- Unstable operation of the firmware of the electronic control unit as a result of which the input data is interpreted incorrectly.

Installation and replacement of an oxygen sensor on a VAZ 2112

- Key to "17";

- New controller;

- Rags;

- Multimeter;

- Additional lighting (optional).

Do-it-yourself diagnostics of the controller on a VAZ 2112:

- We turn off the engine, open the hood;

- Disconnect the terminal from the DC;

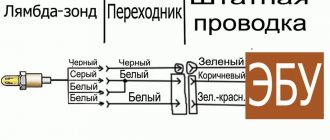

- We connect the limit switches of the multimeter (pinout);

- We switch the equipment to the “Resistance” mode;

- We read the scale readings.

If the arrow tends to infinity, the controller is working properly. If the readings go to “zero” - there is a short circuit, a malfunction, the lambda probe dies. Since the controller is not dismountable, it cannot be repaired; it must be replaced with a new one.

The process of self-replacement is not at all difficult, but requires care on the part of the repairman.

- We install the machine on the inspection channel for ease of work. If there is no inspection hole, then use a roadside overpass or a hydraulic lift;

- We turn off the engine, open the hood, wait until the exhaust system cools down to a safe temperature, so as not to get burns to the skin of the hands;

- Near the resonator (coupling) we find the oxygen controller. Remove the block with wires;

- Using a key set to “17”, unscrew the sensor from its seat;

- We carry out preventive maintenance, clean the threads from deposits, rust, and corrosion;

- We screw in the new controller;

- We put on the block with wires.

We start the engine, it idles. It remains to check the serviceability, functionality, and stability of the engine stroke. We look at the dashboard, error indication of the electronic control unit.

Source

Correct probe replacement

Replacing a lambda probe on a VAZ 2112 requires the following actions:

- First, disconnect the probe wire from the electrical wiring. The procedure is carried out with the engine completely cooled and the ignition off. To replace an old device, you should purchase a sensor with the same markings as the previous one

- Then, using the key we need, we unscrew the old sensor. From a dead point, it is best to rip the device off with the ignition on, and, of course, the hot sensor and exhaust pipe, otherwise there is a risk of damaging, pulling or stripping the threads; in a cold state, any metal shrinks, and you will have to unscrew it with considerable effort. When you've pulled it off, you can turn off the engine. It will be much easier to unscrew further

Attention: when the engine is hot there is a danger of getting burned, so you should use thick cloth gloves and be careful

- The new probe is screwed in until it stops in order to create a tight seal.

- Connecting the electrical wiring

- We check the performance of the new oxygen sensor using an oscilloscope, and a voltmeter, as well as an ohmmeter, the engine temperature is not lower than 350 degrees, at this point the replacement of the VAZ 2112 lambda probe is completed

That's all, good luck in replacing and checking your sensor, and in addition we recommend video material on replacing it.

All VAZ-2112 sensors 16 valves and their location: diagram and description

The efficient operation of the injection engine is ensured by a set of sensors. They all connect to the ECU. Lada hatchbacks of the 2112 family were produced only with injection engines, and two varieties of these internal combustion engines are 16-valve. We will talk about them further. All VAZ-2112 sensors, their location and appearance will be shown in the photo.

The excess oil pressure sensor, which is not connected to the ECU, is shown in the video.

Understanding the oxygen sensor

It is necessary to determine the sensor articles not by the engine model or even by Euro standards, but only by the ECU unit.

Types of oxygen concentration sensors (OCC)

The number of oxygen sensors can be two or one - it all depends on environmental standards. AvtoVAZ also used two types of sensors - 0 258 005 133, 0 258 006 537 (BOSCH part numbers). The first of them are compatible with BOSCH M1.5.4, MP7.0 and January 5.1 controllers. Newer sensors were connected to the BOSCH M7.9.7 ECU (January 7.2). The two different types of sensors differ even in appearance.

The ECU unit in “Dozens of VAZs” is located under a plastic cover. It is located near the front passenger's foot.

The red arrow marks the first, that is, the main sensor. The top photo corresponds to engine 21124 (1.6 l).

Sensor locations (21124 and 21120)

VAZ-21120 engines (1.5 l) could meet the Euro-3 standard, and then an “extended” catalyst was welded behind the main sensor. The second sensor was located behind it, that is, behind the “can”. Let's clarify:

- The Euro-2 standard corresponds to a design with one sensor (main);

- During the transition to Euro-3 standards, a second sensor was added (blue arrow).

By the way, the 24th engine can meet Euro-4 standards.

0171 (fuel mixture too lean) - Community “Lada 2110, 2111, 2112, 112, Bogdan” on DRIVE2

Hi all. This is the situation, I bought a 2110 with a jammed engine, a 1.5 16-valve engine, they did a major overhaul, everything was as it should be. After the capital, there are failures at the lower levels, twitching. Error 0171 pops up (fuel mixture too lean), fuel pressure at idle is 3 atmospheres. If you remove the hose from the pressure regulator, then 4 somewhere rises. The fuel pump, mesh, fine filter are all new. The fuel is fine. For air leaks, I also checked the corrugation, which I changed from the air flow sensor to the throttle, and I also changed the idle speed sensor. I also swapped the ignition module from another car and it remained the same. When I unscrew the spark plugs, there is a white coating on them, which means a lean mixture. Before the renovation, there was also such a deposit on the candles. I cleaned the injectors with ultrasound, installed new rubber seals when assembling them, but air cannot be sucked in there either. I talked to the owner and he said that he had installed a new lambda probe and was also looking for the cause. When we assembled the engine, the air pressure sensor was faulty, it worked at idle at all, replaced it and it started working. What I’m thinking is that maybe the old owner changed the lambda and drove with a faulty air flow sensor and because of this he ruined the new lambda probe, could this be the case? Or advise what else I can try. Everything I thought about, I searched everything. Brains January 5.1 I still have thoughts that it might be a matter of firmware

vote

Article rating

Main set of sensors for 16-valve VAZ-2112 engines

The ECU must control many parameters at once. The most important information will be the position of the crankshaft. You can turn off all sensors except the DPKV, and this will not lead to the engine stopping.

Sensors connected to the ECU

Let's list all the elements one by one:

- 15 – DTOZH. A resistor screwed into the thermostat housing. The temperature of the antifreeze is determined;

- 17 – DPRV, also known as DF (phase sensor). The operating principle is the Hall effect. The position of the camshaft is controlled. Check it out here.;

- 20 – TPS. Resistor fixed to the throttle assembly 19. The angle of deflection of the throttle valve is measured;

- 21 – Mass air flow sensor. Sensor connected to the filter housing. Controls air flow; the main signs of its malfunction are discussed here;

- 22 – IAC. Not a sensor, but a regulator (electromagnet). Used in idle mode. About its testing and diagnostics here. About replacing the IAC here.;

- 24 – lambda probe or oxygen sensor (see above);

- 25 – speed sensor. Fixed in the gearbox slot. Operating principle – Hall effect;

- 26 – DPKV. Electromagnetic sensor. The position of the crankshaft is controlled;

- 27 – DD (knock sensor). A piezoelectric element mounted on the outer wall of the cylinder block.

Let's take a look at how all the elements look in real life. Shown are pictures of VAZ-2112 sensors (16-valve internal combustion engine).

Each element will be easy to find under the hood

Everything said above is true for two engines at once - for units 21124 and 21120 (1.6 and 1.5 l).

You cannot unscrew the DTOZH sensor without draining the coolant. And to disconnect the sensor means to disconnect the connector, but not to dismantle the sensor itself.

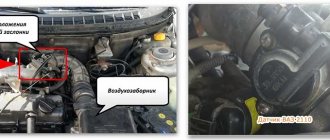

Where is which sensor located - engine compartment diagram

Let's look at another picture.

Engine compartment and engine 21124

It is important to understand where the following elements are located:

The location of the phase sensor is indicated in the previous chapter.

Never unscrew the speed sensor. It will be difficult to install it in a way that maintains a seal.

Device and symptoms of malfunction

To completely burn 1 kilogram of fuel mixture, about 14.7 kilograms of air are needed. Therefore, the lambda probe data is very important in the fuel supply system, since its performance directly affects the smooth and stable operation of your car’s engine. Periodic checking of its performance is very important, however, before checking the lambda probe, we need to study the device, as well as the principle of operation. The oxygen concentration meter sensor, otherwise called a lambda probe, (in our case, VAZ 2112 lambda probe) contains the following elements:

- Metal body with threads for mounting

- Sealing ring

- Ceramic insulator

- Electrical signal current collector

- Wires

- Cuff that seals wires

- Live contact for heating circuit

- Protective shell (outer) with ventilation hole

- Ceramic tip

- A special tank with an incandescent coil in it

- Protective screen, with a hole for the passage of exhaust gases

All parts of the lambda probe are made of materials resistant to high temperatures, since the sensor itself has a fairly high operating temperature, so it is not afraid of overheating, while overheating, for example, a motor will have dire consequences (and this is possible if the probe faulty). Probe sensors can have from one to four wires in the device, respectively, the name comes from them: one and so on up to four wire sensors. By the way, some “craftsmen” claim that the VAZ 2112 works well without a lambda probe, but they are mistaken, it’s just that until the engine is warmed up, the readings of the sensor are not taken into account during injection, since it has not reached its operating temperature, therefore, you can trust such advice drive without it, only on a cold engine. Failure of the oxygen sensor is often caused by violations in the maintenance and care of internal engine parts and some other factors, such as:

- Cleaning the body (washing) with products that are not intended for this purpose

- Accidental contact with coolant or brake fluid on its body

- Increased content of lead (metal additives) in fuel

- Severe overheating (red hot) of the sensor housing, which is caused by an unrefined combustible mixture

- In addition, the ingress of highly contaminated gasoline may occur due to a malfunction of the gasoline pressure regulator, or the DTOZh (coolant) temperature sensor, or a clogged fuel filter.

Articles

For oxygen sensors, the designation 21120-3850010 was first used. Then an article appeared with the numbers 1118 (see photo). It appears to be a new type of sensor. It will be easier to use BOSCH articles.

Exhaust system of VAZ-21120 engine

We list the article numbers of the remaining sensors:

- Mass air flow sensor (21124 or 21120): 21083-1130010-01, -10, -20;

- Mass air flow sensor (motor 21120 with ECU January 4.1): 2112-1130010, -01;

- TPDZ : 2112-1148200;

- RXX: 2112-1148300-02;

- DPKV : 2112-3847010, -01, -03, -04;

- DTOZH : 2112-3851010, -01, -02, -05;

- Speed sensor : 2110-3843010-13, -18;

- DPRV : 2112-3706040, -02, -03;

- DD: 2112-3855020, -01, -02, -03;

- Oil pressure sensor: 2106-3829010, -01, -02;

- Antifreeze level sensor : 2110-3839310-10, -11, -12, -13, -14;

- Coolant temperature gauge sensor: 2101-3808600, -02, 2106-3828010.

The last three sensors are not connected to the ECU. However, a rough road sensor (2123-1413130) can be connected. It affects the operation of the engine, although it is attached to the body.

Engines with ECU January 4.1 do not have oxygen sensors.

In general, on VAZ-2112 hatchbacks, sensors may be different from those indicated in the list. But then we are talking about an 8-valve engine. And everything that we indicated applies to 16 valves, here is a diagram of this engine.

Source

Why does the lambda probe die?

We have already clarified above that the service life of the oxygen sensor is 80-160 t.km. You probably have a question: why is there such a variation in the resource, as much as 80 t.km? In fact, the life of the sensor depends on the conditions in which the car was operated:

- bad gasoline, the exhaust of which contains a lot of lead and iron, clogs the sensor electrodes after several fill-ups;

- poor condition of oil scraper rings and caps. Because of them, oil can get into the mixture, and with it into the exhaust system;

- due to clamped valves, pops are released into the exhaust system, which destroy the working surface of the sensor;

- due to an incorrect mixture, ignition timing, as a result of which the sensor overheats, crackling from the high temperature of the converter or catalyst.

Oxygen sensor for VAZ 2112

The oxygen sensor on the VAZ-2112 is designed to measure oxygen in the exhaust gases of a vehicle. Thanks to the results obtained, it is possible to control the level of enrichment of the fuel mixture. It is worth noting that for the VAZ-2112 engine, both a too rich mixture and a lean one are critical. The engine may lose power or begin to consume a lot of fuel. In turn, when the engine is idling, unstable speed will be observed.

Description of the oxygen sensor

Let's start with a description of the device. We invite you to familiarize yourself with its purpose, structure, and operating principle.

Purpose and location

The VAZ 2110 lambda probe largely influences the stable functioning of the engine, ensuring the normal operation of its parameters. This controller is an electronic device used to determine the amount of oxygen present in the exhaust gases. This is necessary in order to reduce the volume of harmful impurities and elements contained in exhaust gases. In order to ensure the required proportion of the air-fuel mixture, which affects the reduction in the concentration of impurities, air must be supplied to the engine in the required quantity.

This is not always achieved, and the reasons may be different. If the controller fails, the carbon monoxide content in the exhaust gases will be about 3-7%, while the standard value is 0.3%. As for the location, this sensor on a VAZ is installed on the exhaust pipe of the muffler, from below. The readings recorded by the lambda probe are transmitted to the motor control unit. And the ECU, focusing on them, adjusts the composition of the combustible mixture, thus setting the required time for the injection phase.

Location and service life of the controller

On a VAZ-2112 with engines with 16 valves, the measuring device is located at the exhaust pipe, between the exhaust manifold and the coupling. To replace the device, you must gain access to the underbody of the vehicle body. For the best convenience, you need to drive the car into a garage with a pit or drive onto an overpass located near the highway.

The service life of the oxygen sensor may vary. If a motorist uses a high-quality fuel mixture, the service life will be up to 110 thousand kilometers. In the case when a low-quality mixture is used, the service life is reduced to 85 thousand kilometers.

Types of sensors and operating principle

The lambda probe is installed in the exhaust system. Sensors are divided into two types: two-point and broadband.

The two-point sensor consists of ceramics, the elements of which are coated with zirconium dioxide on both sides. Installed in front of or behind the catalytic converter.

The principle of operation is to measure the level of oxygen concentration in the environment and exhaust gases. If the level changes and becomes different, a voltage is created at the ends of the sensor elements, from low to high. Low voltage is created if there is excess oxygen in the system.

Otherwise, if the system does not have the required level of oxygen, high voltage will be created. These signals are sent to the engine control unit, which distinguishes them by current strength.

The wideband sensor is a more modern design. It also has two ceramic elements. One of them can be called “pumping”. It is responsible for activating the process of pumping or removing air from the system.

The second element can be conventionally called “two-point”. The principle of operation is based on the fact that as long as there is the required amount of oxygen in the mixture, the current strength on the “pumping” element does not change and is transferred to the “two-point” element.

It, in turn, receiving a constant current from the “pumping” element, maintains a constant voltage between its elements and is inactive.

As soon as the oxygen level changes, the "pumping" element supplies the changed voltage to the "two-point". This, in turn, ensures either pumping air into the system or pumping it back.

How to determine that the DC is faulty

Motorists often ask what symptoms of failure may occur with a faulty oxygen sensor. Here are the most common of them:

- Unstable starting of a cold and hot engine.

- Errors appeared on the dashboard. Signs of DC malfunction are failures P0137 and P0578. They also often occur when the DTOZH malfunctions, so a check is needed.

- There is too much fuel consumption at short distances.

- Ignition of the working mixture in the cylinders.

- Exhaust gases that are black or bluish-black are also signs of a DC malfunction. This may also indicate a poor quality fuel mixture.

- The engine begins to "trouble". Extraneous sounds are observed. Which indicates that the driver has been using a low-quality fuel mixture for a long time.

Types of lambda probes on different cars

Now let's look at the malfunctions of this sensor on different brands of cars.

The first will be VAZ cars from 2110-212. Until 2004, these cars with injection engines were equipped with Bosch lambda probes with identification number 0 258 005 133.

On newer models of this family, as well as on VAZ 2114-2115, Priora, Kalina, Bosch sensors also began to be used, but with the number 0 258 006 537.

The elements installed before 2004 did not have heaters, so they only started working after the engine had warmed up.

Now these cars are equipped with heated lambda probes, which allow the sensor to reach operating temperature much faster.

In addition to the main signs of a malfunctioning lambda probe on these cars, there are two more:

- after stopping the engine, crackling sounds may be heard from under the car;

- Car exhaust gases change in smell due to the large amount of unburned fuel.

On a model such as the Ford Focus 2, the marking and number of lambda probes depends on the power plant.

For example, on engines with 1.8 and 2.0 liters of volume, two sensors are used.

The installed sensor before the catalyst has the original marking 3М519F472FF, and the lambda probe behind the catalyst is 3М519G444FF.

The 1.4 and 1.6 liter engines also had two sensors: the first was 3M519F472VA, and the second was 3M519G444VA.

Some 1.6-liter engines have two catalysts installed, so they have 4 sensors.

Two lambda probes located before the catalysts are marked 3M519F472DA and 3M519F472BC, and the sensors after the catalysts are marked 3M519G444DA and 3M519G444CA.

And these are just some of the sensor markings used on Focus 2.

It is worth noting that these sensors differ from the same VAZ sensors produced by Bosch with the marking 0 258 006 537 only in the connector for connecting the wiring, and the devices themselves are identical.

Therefore, special signs of malfunction, in addition to the generally accepted ones, are indicated above.

On the Skoda Octavia, the VAG concern installs its oxygen sensors with catalog numbers 06A906262BR, 06A906262AJ, etc.

It all depends on the power plant and year of production of the car.

But structurally, their differences from the same Bosch boil down again only to the wiring connector. The rest of the design is identical and there are also signs of malfunction.

The Honda CR-V also comes with original lambda probes with catalog number 36531RNAJ01 installed from the factory, but Bosch ones are also suitable instead, which indicates that all devices are almost identical in design, and the only difference is in the connectors.

On Renault Logan, the factory lambda probe has catalog numbers 8200052063, 7700109844 and 8200495791. They differ from each other in the color of the wire braid.

It is noteworthy that these sensors are also used on the VAZ Lada Largus.

But the design, as well as the signs of malfunction of these sensors, do not differ from those described above.

In order not to encounter a faulty lambda probe at the wrong time, periodic checking of its performance is required.

Diagnostics of the probe should be carried out using special equipment - an oscilloscope, but some are content with checking with a multimeter.

This sensor can fail at any time, but it is worth considering that many original devices can be replaced with non-original ones, the main thing is that their characteristics are identical.

With the right approach, identifying a faulty lambda probe is not so difficult, and there is nothing difficult in replacing it.

Another sign of a faulty oxygen sensor is that the engine begins to heat up, which entails disastrous consequences and expensive repairs.

Hello! I have such a problem, up to 60-70 degrees when warming up the engine runs stably, then the internal combustion engine starts to fluctuate, the speed starts to fluctuate, when checked with a scanner, the correction coefficient freezes and the voltage on the DC becomes a stopper. Could this be the cause of a faulty DC? I forgot to write it shows the error “poor mixture” P0171. VAZ 2115

Hello. Please tell me. I have a VAZ 2211 124 doors. 16th grade I put a new cylinder head on the hundred. After the replacement, when I picked up the car, I noticed that the engine began to work with some kind of vibration. And the revolutions fluctuated, it was noticeable by ear, but according to the tachometer everything seemed to be normal, the needle stayed straight. Two months passed and the engine began to start poorly. It happened that you set it to warm up at 220. You turn the starter and turn it, but it just slowly grabs. grabs it, the hop starts up. Then it started doing the same thing when it was cold. A warm engine starts well. But as soon as it sits for about 20 minutes, it cools down, and again the same bad start. In short, I replaced all the sensors except the lambda sensor. detonation and air flow sensor. I also changed and cleaned everything in the fuel system. New used pump, replacement filter reg. A day or two is fine. then everything is the same. Yesterday I started it without warming up and it started normally. But the engine still worked with some kind of incomprehensible vibration, small and with floating speed. It was freezing today. I set it to warm up. In the meantime, I changed the camshaft timing sensor. I started trying to start the engine. the same thing is useless. At first I was spinning around completely empty. Then a little later it seemed to start to catch on. In short, I suffered, I suffered, it seemed to buzz, but not for long. For about a second or two it starts to stall, the revs drop and it stalls. Well, the next attempts are the same. And the check light came on, but before that the error did not pop up. Now I would like to go for diagnostics, but now it doesn’t want to start at all. What could be the reason, tell me if you know.

Hello. Yes, this is your situation:((You should have gone for diagnostics even earlier. There could be a million reasons. You’ve already done the best you could. Therefore, you can’t do without diagnostics. You can, of course, check everything for air leaks, but that’s not 100% option. I think you have already checked the spark plugs. Have you checked the camshaft sensor? Is the timing belt installed correctly?

Functionality check

Many VAZ-2112 owners ask how to check the lambda probe (oxygen sensor) themselves. To do this you will need to do the following:

- It is necessary to turn off the engine and allow it to cool.

- After this, open the hood of the car and disconnect all contacts leading to the oxygen sensor.

- Take a multimeter and connect the end probes to the lambda probe.

- Then use the “Resistance” mode on the multimeter. If the arrow goes to infinity, then the device is working correctly and the readings are being transmitted correctly.

- In a situation where the arrow shows a value near zero, the measuring device is faulty and needs to be replaced.

How to independently replace the device on a VAZ-2112

To replace a faulty controller, you will need to perform the following algorithm:

- Drive the car into a garage with a pit or onto a roadside overpass for ease of work.

- Turn off the engine and give it time to cool.

- Then you need to look under the bottom and find the oxygen sensor near the clutch.

- Next you need to disconnect the block with wires.

- Use a wrench to remove the oxygen sensor.

- Clean the threads and contacts using cleaning fluid.

- After this, use a wrench to secure the new measuring controller.

- Place the block with wires.

To check, you need to start the engine at idle speed. If there is no error on the dashboard and the readings are determined correctly, then everything was done correctly.

How to extend the service life of a recreation center

To extend the service life of the sensor, you will need to follow the following recommendations:

- Conduct a technical inspection of the vehicle on time;

- use only original spare parts for the car;

- do not allow the use of low-quality fuel mixture;

- Contact a car service if you find problems with engine operation.

You can change the oxygen sensor on a VAZ-2112 yourself without going to a car service center. Only original components must be used. If there are problems starting the engine, you should check the correct operation of the lambda probe.

Signs and causes of lambda probe malfunction

According to statistics, oxygen sensors fail gradually, so you can identify its malfunction if you pay attention to the following “symptoms” in time:

- The idle speed began to drop or “float”.

- The car jerks, and after starting the engine, popping noises uncharacteristic of the engine are heard.

- The engine power has decreased and when you press the gas pedal there is a slow response.

- The engine overheats greatly and fuel consumption has increased.

- The smell in the exhaust pipe has changed (exhaust gases have become more toxic).

As a result of a failed sensor, the quality of the fuel mixture entering the combustion chamber deteriorates, which disrupts the smooth operation of the engine. There can be many reasons for this:

- Incorrect operation of the filament circuit or reduced sensitivity of the sensor tip.

- Low-quality fuel with a high content of iron, lead, oil decay particles and other harmful inclusions. All these substances stick to the platinum electrodes, causing the sensor to malfunction.

- Problems with the lambda probe heating system. If the heating stops functioning as it should, the oxygen sensor will produce inaccurate data.

- Overheating of the regulator housing. This happens if the ignition timing is incorrectly set.

- Worn oil scraper rings. In this case, engine fluid enters the exhaust pipe, which affects the lambda probe.

- If the engine is started repeatedly.

- Using sealants (especially silicone) to install lambda probes.

- The compression level in the engine cylinders is impaired. In this case, the combustible mixture burns unevenly.

- Clogged engine petrol injectors.

If you notice that the lambda probe is not working, you should not ignore the symptoms, as otherwise you will cause yourself a lot of problems with your car. The fact is that most modern cars are equipped with an emergency locking unit, which can work at the most unfortunate moment. However, the impossibility of further movement is not the worst thing. If the sensor becomes depressurized, the injection system will fail and you will have to pay for expensive repairs to a more serious unit.

Therefore, it is recommended to periodically check the condition of the lambda probe. You can do this yourself.