Due to the low quality of fuel at domestic gas stations, changing cleaning systems is an everyday procedure that can increase the service life of engine systems. You can understand that the screens are clogged and the fuel filter on Kalina (11173) needs to be replaced by the following signs:

- power failures during acceleration;

- difficult supply of fuel;

- the engine does not gain momentum;

- the pressure in the ramp drops below 2.3 atmospheres;

- The mileage on the old element is more than 30,000 km.

Service is carried out in 2 steps.

- Removing the coarse mesh.

- Changing the fuel fine cleaning tank.

At the same time, for the 1117 model there is no difference in the configurations; the 8-valve designs are repaired in the same way as 16-valve blocks.

Where is the gasoline filter of Kalina 1

Each part of the unit is located in its place, calculated to achieve maximum effect and the possibility of normal maintenance.

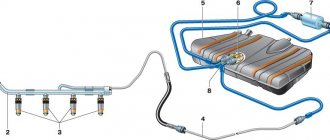

- The first line of defense is located directly at the gas pump. A coarse mesh traps large particles and debris that can damage the pump impeller.

- The main filter is located under the fuel tank on the right side. The device is a metal flask with a drawn arrow.

- The last line of defense is located in the engine compartment and is mounted directly in front of the injector yourself. The cleaning module looks like a transparent plastic flask to which hoses fit.

Let's summarize.

- It is necessary to change the mesh on the fuel pump when installing (repairing) the fuel filter.

- Fill your tank only with high-quality fuel from reliable gas stations.

- Buy original spare parts from trusted manufacturers.

And most importantly, do not delay replacing a dirty filter. Otherwise, there is a high risk of serious consequences for the car.

Did you like the article? Follow our channel for new ideas of useful car tips. Subscribe to us in Yandex.Zen. Subscribe.

The main task of a fuel filter device is to clean the fuel from unnecessary particles that have entered it. The presence of water in the fuel system causes rusting of the injectors, leads to the development of corrosion, and this leads to engine dysfunction and clogs the fuel system. This element of the car helps clean low-quality fuel from particles of resins and all kinds of additives that are added to fuel by unscrupulous manufacturers.

The fuel filter can become dirty as a result of:

- accumulation of dust and dirt due to a possible chemical combination of gasoline with air and metal;

- corrosion caused by water condensation;

- accumulation of tarry sediment;

- clogging of fuel equipment pipes with frozen water crystals at low temperatures.

- using low quality fuel.

Signs of a blockage

When the filters are clogged, the machine becomes unstable. Vivid signs of a TF malfunction:

- engine speed fluctuates;

- acceleration drops;

- in severe cases, the internal combustion engine stalls while driving or does not start.

Recommendations for self-diagnosis. It is possible to determine that the filter has failed by external factors.

- At idle, the engine speed fluctuates.

- When you press the gas pedal, the car refuses to accelerate, or the acceleration is excessively slow.

Many modifications of gasoline filters are made for Kalina. Each brand offers its own system and device.

Comparison of filters from different brands

Among the popular store offerings, there are certain brands that are trusted by customers.

- Kolbenschmidt is a German company that manufactures fuel filtration systems for cars and light equipment. Expensive devices work well for their price and last longer than factory ones.

- Mann - the next German manufacturer is trusted among motorists in the European part of the country. Quite expensive consumables fully justify their price, providing high-quality fuel filtration. The company's product range includes many modifications of filters for different machines and stationary units.

- Salut - a domestic brand supplies filters to the Lada conveyor. Consequently, the car manufacturer recommends the Salyut elements. Among car enthusiasts, the brand is not trusted, which provokes a quick replacement of equipment. The main advantage of the stock version is its reasonable price.

- Bosch - Bosch filters are often bought in sets of 2-3 pieces, with a reserve. Quite expensive equipment filters fuel efficiently and is capable of working with heavily contaminated gasoline. The only caveat is the relatively short service life.

Finally, about precautions when replacing

Compliance with the rules to ensure safety in this procedure is exceptional. Even following the utmost care during work, the release of flammable compounds and fuel spillage cannot be completely excluded. Otherwise, replacing the fuel filter on a LADA Kalina car is not a complicated procedure.

To prevent the risk of ignition of fuel vapors, you must:

- carry out the entire list of manipulations in a well-ventilated room or in an open area;

- Immediately clean up spilled fuel using a rag or filling it with sand;

- follow the rules for using portable lighting devices;

- stock up on a fire extinguisher;

- do not smoke during this repair process;

Remember to use gloves and goggles to avoid the risk of getting fuel on your hands or eyes.

How often should you install a new one?

According to the manufacturer's service documentation, the fine filter element is replaced every 20,000 km.

For the grid, the service interval is 70,000 kilometers, driven by the tidy. However, in real operation, when it is necessary to change an element, the internal combustion engine itself will tell you. If problems arise, the power plant displays the following symptoms:

- loses power;

- periodically the engine does not start;

- the check light on the dashboard lights up;

- The speed fluctuates or dips occur during acceleration.

All these signs indicate a critical blockage of the mesh. In some cases, maintenance is required after filling with surrogate fuel. Some gas stations mix gasoline with unacceptable substances, which negatively affects the sensitive mesh.

What is a fuel pump

The gasoline pump is a key component of the power system; its job is to ensure an uninterrupted, timely supply of fuel to the system.

In each model, the design and location of the fuel pump is unique; for the Lada Kalina, this device is located on the opposite side of the power unit.

On the one hand, this arrangement allows you to benefit from the technical capabilities of the machine, but on the other hand, the device requires more powerful operation than models in which the fuel pump is located closer to the engine.

In order for Kalina’s fuel pump to cope with its job, it is presented in an electric version. Its advantages are:

- simplicity of design;

- good fuel supply;

- safety.

But, as one might expect, Kalina’s electrics are not yet a strong point; they often break down, which is the main disadvantage.

In addition, the disadvantages of the Lada Kalina gas pump include increased noise levels, sensitivity to the quality of gasoline, and the fact that it requires cooling.

The issue of high-quality gasoline in our country, unfortunately, still remains unresolved; this is one of the reasons why the fuel system of the Lada Kalina fails.

Filters become clogged, which disrupts the operation of the entire mechanism and ultimately leads to pump failure.

This is why filters, or meshes as they are also called, need to be changed regularly.

We’ll talk about this, but first, let’s figure out what malfunctions happen with the Kalina fuel pump?

Types of faults:

- One of the most common pump malfunctions is a rapid decrease in pressure after the engine starts. This fact indicates serious violations that can be caused either by a valve defect or a breakdown of the pressure level regulator; it is quite possible that the injectors are also clogged. A sharp drop in pressure leads to problems in starting the engine, which, if the breakdown is not corrected, can even lead to engine failure.

- It also happens that the engine loses power, or the engine does not start at all, even when cold or hot. All this happens when a membrane or spring breaks, a rod wears out, or filters become clogged, and the latter happens more often than anything else.

- In any case, having discovered that there is something wrong with the fuel system, you should first check the condition of the filters, because, due to low-quality gasoline, they become clogged quite quickly, and it is better to change them in a timely manner, without waiting for problems. Now let’s talk about how to change the mesh from the pump yourself.

We recommend: Antifreeze or antifreeze, which is better to fill and what is the difference?

Is it important to change the filter?

According to the maintenance regulations, it needs to be changed every 30,000 kilometers. The figure is calculated taking into account the filling of high-quality, clean gasoline. If the quality factor of the fuel is in doubt, it is recommended to reduce the service interval by 2-3 times.

If you don’t change the consumables at all, the engine will act up and the load on the fuel pump will increase. Naturally with all the ensuing consequences.

The most popular filter brands:

- MANN – 820 rub;

- BOSCH – 450 RUR;

- HOLA – 400 rub;

- UFI – 250 RUR;

- PECAR – 310 rub.

If you go to a service station, the car owner will need to pay at least 1,000 rubles for everything. The final cost may vary in different regions.

Why are they even needed?

Forced fuel cleaning is a necessity to ensure the performance of any engine running on liquid fuel. Filling the filter cavity, gasoline passes through a layer (there may be several of them) of filter material, leaving on its surface particles of dust, dirt and other solid inclusions that adversely affect engine parts.

Its operating principle is based on the fact that water is heavier than diesel fuel, and centrifugal force helps separate them from each other. Due to the specific operation of separators, most of them are heated.

What are they, fuel filters?

There are three main groups:

- fuel pre-cleaning filters;

- fine fuel filters;

- fuel separators.

The first group is not very popular for passenger car engines. In them, the removal of large and small particles of impurities from the fuel is entrusted to one filter.

The second group is the most common. Filters of this type can be either case-mounted with threaded fastening, or in the form of filter elements that do not contain metal.

The difference between coarse and fine filters is mainly in the paper. If preliminary cleaning involves retaining particles measuring 75-100 microns, then final cleaning in the best filters allows you to retain particles up to 3-5 microns in size.

Filter elements can be designed with metal covers (for reliable fastening of the filter material) and can be designed with or without reinforcing mesh. Both are always installed in housings made of heat-resistant material.

This design provides for the presence of repair kits, since re-installation of sealing rubber bands and copper washers is not recommended.

Having been born more than a hundred years ago due to a technological error, it is still firmly in the lead among all filter materials.

To extend the service life of the filter, increase the filtration area and thereby improve the quality of the process itself, the paper is installed in the form of corrugations. The density of the folds in it is such that a “curtain” more than one meter long can fit in an “accordion” with a diameter of 100 mm.

By the way, in the cost of a fuel filter, the cost of filter paper is more than 60%, which means that the manufacturer can reduce its price only by losing quality!

Recently, filter materials based on propylene have been increasingly used and have already earned the approval of motorists. A small sector among filter elements is occupied by those made of fine-pored metal mesh.