Purpose, principle of operation

A fuel filter (or fine filter) is designed to remove dust, solid particles, sediment from the bottom of the gas tank, water, paraffins and, in general, everything unnecessary that hangs around in the fuel mixture and can damage the engine from the gasoline (diesel fuel, gas) entering the engine. The better the filter, the better the fuel will be cleaned, which means the engine will run longer without problems.

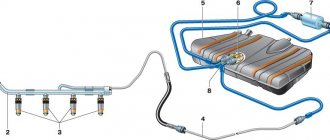

Schematic diagram of a direct-flow injection filter

The location of the filter is between the gas tank and the engine in front of the pump (or in front of the carburetor in older cars). Gasoline (diesel fuel) passes through the filter material under pressure, purifying it of impurities before further use. Filters for diesel engines also have a membrane for separating water, as well as a heating system that ensures the fluidity of diesel fuel at sub-zero temperatures.

It is impossible to clean the smallest pores of the filter from contaminants either at home or in an industrial environment, therefore, when the resource is exhausted (or earlier, if it is critically contaminated), the filter is simply replaced with a new one, and the old one is handed over for recycling.

Fine filters

The main purpose of the FTO is to clean fuel from small foreign particles that were not caught by the coarse filter.

Its design is practically no different from the FGO, and the mesh consists of smaller cells.

Types of fine filters

There are non-separable (disposable) and collapsible (reusable) fine filters.

The former are made of fabric or paper that is folded into a spiral or star shape to form a filter curtain.

The spiral shape provides better cleaning due to the increased surface of the filter material by 1.8 times - the contact of the fuel with the filter becomes longer.

Non-removable filters last quite a long time

Non-removable filters are usually installed on the fuel line section in front of the fuel pump.

There is no pressure in this place, and the likelihood of leakage is reduced.

The basis of the dismountable FTO device is a brass or ceramic mesh filter element.

These filters can be removed, washed and cleaned.

The most convenient are filters with a transparent body, as they allow you to visually assess the degree of contamination of the filter material.

The transparent housing allows you to visually assess the degree of filter contamination

Is a filter really necessary? What does it affect?

First of all, the purity of gasoline is important for the injectors of an injection engine: their thinnest holes become clogged with deposits of paraffins, sulfur, dust, dirt and other “goodies.” This is followed by deterioration in engine performance (after all, the required amount of fuel does not enter the cylinder and is not dissipated properly), loss of power, “triple”, when an injector in one of the cylinders fails, and after that - expensive repairs. For systems with a fuel injection pump (high pressure fuel pump), cleaning is carried out before fuel enters the pump: the fine fitting of the parts does not withstand foreign impurities. Buying a new pump also costs a considerable amount.

Clogged injectors

If we compare the quality of European and Ukrainian fuel, the latter will be far from winning: the purity of our gasoline is such that the service life of good imported filters is exhausted almost 2 times faster than the manufacturer expected. Impurities in gasoline appear both at the manufacturing stage (manganese to increase the octane number, sulfur and paraffins due to insufficient purification) and at the transportation stage (dust, dirt). The level of the plant itself will also be an important factor: gasoline purification is a delicate matter and requires modern, expensive equipment. You can evaluate the quality of the fuel yourself by disassembling the old filter after replacing it, as many car owners like to do. All the dirt that has collected in the filter could end up on the pistons, injectors and engine walls.

But, be that as it may, fuel filters are installed on absolutely all cars all over the world: no matter how clean the gasoline is, additional protection will not hurt. We have a good filter - not a precaution, but a vital necessity.

About internal combustion engine power systems

Let’s return to the motor triad “clean oil, clean air, clean fuel.” We have already talked about filtering engine oil and air, now it’s the turn of fuel.

Fuel filters are the most important components of the engine power system. But first, let's remember what these systems are. Let's start with the gasoline engine.

Good old carburetor. This is, of course, history. But history is alive - just look at the old Zhiguli and Volga cars on our roads. And a lot of carburetor foreign cars were imported at one time. But one way or another, there is a demand for carburetor filters, both here and abroad.

Gasoline injection into the intake manifold. Sometimes it is called distributed injection. Fuel is supplied by injectors at a main pressure of 3–4 bar. The pressure in the system is created by the central fuel pump and maintained by the pressure reducing valve. The pump is located in the fuel tank, under the bottom or under the hood.

Injection of gasoline into the combustion chamber. Another name is direct injection. Here, two circuits are involved in the fuel line - low and high pressure. The pressure in the first reaches 3–4 bar and is created by the same central pump. But another electric pump is built into the low-pressure circuit, feeding the second circuit. From it, fuel under a pressure of 120 bar is supplied to a hydraulic accumulator connected to the injectors.

In both cases, the fuel filters are in the lines under a pressure of 3-4 bar. But with direct injection, the filter requires more subtle cleaning, and we will talk about this later.

Single-point injection can be considered a transitional option from the carburetor to the injectors. The requirements for it are less stringent than for distributed injection and, as a rule, are not considered separately.

Let's move on to diesel systems. Here the fuel can be injected into the prechamber or directly into the cylinder. To achieve efficient combustion, almost all modern diesel engines have fuel injected into the cylinder.

High pressure fuel pumps (HPFP) are the oldest, if you like, classic diesel system. There are also more modern solutions - pump injectors and Common Rail.

An injector pump is a unit that combines a pump, a magnetic valve to control injection and a sprayer for each individual cylinder. This system allows injection pressures of up to 2000 bar to be achieved.

The Common Rail system has a common accumulator - a pipe, often called a rail or fuel rail. From the pipeline, fuel is injected into the cylinders by injectors. Thanks to radial piston pumps, rail pressure can reach 1600 bar or more. The latest systems develop pressures of up to 2500 bar.

With the advent of modern gasoline and diesel injection systems, the requirements for fuel purity have increased significantly. Moreover, they are constantly becoming tougher. How many foreign inclusions need to be detained? This is what the author was told at the leading Russian institute FSUE NAMI.

Gasoline filtration requirements:

• 5–25% – for outdated carburetor systems (polluting particles 3–5 microns);

• 25–65% – for distributed injection systems (particles 3–5 microns);

• 48–70% – for traditional direct injection systems (particles 3–5 μm);

• 85–95% – for the latest direct injection systems (particles 3–5 microns);

Requirements for diesel fuel filtration:

• 25–65% – for old-style motors (pollutant particles 3–5 microns);

• 85–95% – for new Common Rail systems (particles 3–5 microns);

• 98% – for the latest Common Rail systems (2 micron particles).

In this case, the material must separate at least 95% of water from the fuel.

For today's automotive practice, some of the figures look exaggerated. In fact, they are promising and should be strived for. But in any case, these data correlate well with the infographics of MS Motorservice International and KOLBENSCHMIDT, presented in the figure below. And the listed problems are successfully solved through the use of the latest single-layer and multi-layer filter materials.

Types of fuel filters

The first step in the filter system is coarse cleaning: a regular dense mesh installed inside the gas tank, designed to filter out particularly large particles.

Next is the fine filter, which, in fact, is what we are talking about: it retains fine particles, which, nevertheless, can clog the injectors of an injection or diesel engine.

Different filters are made for different types of fuel: there are varieties for gasoline, diesel fuel, and gas.

The following fuel filters are distinguished by location:

- Submersible filters located in the fuel tank. This is a one-piece structure into which a fuel pump, a coarse filter and a fuel level sensor are connected.

Submersible filters

- Main filters that are included in the fuel line in the area from the gas tank to the pump. If a main filter is provided in the design of the car, then preliminary fuel purification is carried out directly in the gas tank (a fine-mesh mesh that retains large particles before they enter the fine filter)

Depending on the type of engine, there are:

- Filters for carburetor systems that are not demanding on the quality of gasoline. Such filters have the simplest design, allowing them to retain 60 percent or more of particles up to 15 microns in size.

- Filters for injection engines sensitive to gasoline purity. They have a more complex design, a durable body and can trap contaminants up to 10 microns in size.

- Filters for diesel engines requiring high-quality fuel, capable of retaining not only the smallest particles, but also water and paraffins. The best modern filters are capable of removing up to 95% of contaminants up to 5 microns in size!

- Filters for cars with LPG, since liquefied gas is also not particularly clean.

Coarse filters

FGOs trap only large particles of impurities in fuel. They are usually made in the form of a metal (brass) mesh, which can be removed, washed and returned to its place.

In carburetor systems, several coarse meshes with cells of different sizes are used.

- A mesh with large cells is installed on the neck of the gas tank.

- A mesh with smaller cells is installed on the fuel intake.

- The inlet fitting is equipped with a mesh with the smallest cells.

Coarse filters are made of brass mesh

In the case of an injection engine, the FGO with a mesh is built into the fuel pump of the gas tank.

Diesel units are usually equipped with a sediment filter. This, however, does not exclude the use of grids.

The diesel fuel coarse filter has a number of advantages over screens, reliably protecting the engine from condensate drops getting into it.

Diesel FGO is not disposable. It can be washed and reinstalled.

Design and principle of operation of the coarse settling filter

The settling filter consists of the following elements:

- housing with lid;

- a filter element made of aluminum plates 0.15 mm thick with protrusions of 0.05 mm - located on a sleeve in a glass attached to the body;

- threaded bushing screwed into the body;

- distributor pressed by bushing;

- sealing paronite gasket between the glass and the body;

- damper located in the lower part of the body.

Diesel engines are usually equipped with a sediment filter

The settling filter works according to the following scheme:

- Through holes in the distributor, diesel fuel enters the filter.

- The fuel moves lower into the damper - large particles of mechanical impurities and condensate remain here.

- Then the fuel goes up to the mesh of the filter part, on which small particles of impurities remain.

- Fuel enters the engine through the fuel outlet.

Subtlety of elimination

Screening fineness is an indicator of the number (as a percentage) of particles of a certain size that the filter retains.

The level distinguishes between average, nominal and absolute screening fineness with specification of particle size.

- Medium means that the filter captures 50% of particles of a certain size;

- Nominal – screening out 95% of particles;

- Absolute – complete screening, the filter retains 100% of particles.

In the characteristics of the filter, this indicator is indicated as follows: “Nominal screening fineness 15 microns,” and this means that the filter retains up to 95% of particles up to 15 microns in size.

Modern filters are developed in accordance with strict environmental standards, and their nominal screening fineness can be 6 microns, 4 microns or less. Such filtration is important primarily for diesel engines, which are more sensitive to fuel purity, and at the same time more hazardous to the environment than gasoline engines. The better the fuel purification, the less harmful emissions.

Replacement Regulations

Signs that you need to replace fuel filters are as follows:

- difficulty stopping the engine,

- spontaneous engine stop,

- reduced power,

- noisy engine operation,

- copious black smoke from the exhaust pipe.

Waiting for the listed symptoms to appear is dangerous. The diesel engine does not tolerate inattention. Delay in replacing fuel filters reduces the life of the engine and provokes premature failure. To avoid trouble, change filters at least as often as recommended by your vehicle's owner's manual.

Already in 1960, the Belgian importer of Volgas began installing several varieties of atmospheric diesel engines on the “twenty-first”, of course, foreign-made. True, the car “stopped driving” at the same time, but in Western Europe already 50 years ago, economy was much more important than dynamics.

Manufacturers are constantly improving fuel filters for diesel engines. The estimated service life of modern replaceable filter elements reaches 90 thousand kilometers. The practical recommendations of car manufacturers are much more modest, which is probably explained by two factors. Firstly, the service life is greatly influenced by low quality fuel. The filters do not have clogging indicators, so it is impossible to check the condition of the filter elements without disassembling them, and it is better to be safe than to cause significant damage to the engine. Secondly, branded service brings significant profits, which brand rights holders are in no hurry to give up.

There are no uniform recommendations for replacing filters for all diesel cars. Typically they range from 25 to 40 thousand kilometers. The cleaner, if present, is coarse, and there is no special recommendation in the car manual; it should be changed along with the main fine cleaning element.

The figures given are only generalized data and are not intended for practical use. Look into the "primer" of your car. It is possible that its manufacturer considers it advisable to change filters more often. For example, for Renault Duster diesel cars in 2015, the filter life was set at 20 thousand km; before this date it was only 10 thousand km.

Low quality fuel significantly reduces filter life. Sometimes one refueling is enough to harm the engine. If you notice something wrong after visiting a gas station, drain the suspicious fuel and fill the tank with a known quality one. Replace the fuel filter as soon as possible, even if the signs of unstable operation have disappeared.

Filter design

The simplest filters are made for old carburetor engines: a filter element is installed inside the housing (often transparent to visually control the degree of filling) - special paper folded into a star-shaped curtain. Through the inlet pipe, gasoline enters the filter housing, passes through the paper and enters the outlet pipe. Such a system is quite sufficient for cars that are not demanding on the quality of gasoline.

Injection engines are much more sensitive to the quality of cleaning, and the fuel pressure in the system is an order of magnitude higher. They consist of a durable body (metal or high-quality plastic) and good filter material (paper is folded in a star shape or wound in a spiral, the second option is better in terms of filtration quality).

Diagram of a direct-flow injection filter

Diesel engines are the most demanding on fuel quality, which means that filters for them have the most complex design: not only separating solid particles, but also removing water, paraffins, sulfur and other impurities.

Diagram of a diesel filter with water separation

To achieve high filtration rates, a special material is used, the cells of which are not evenly spaced, but with a decrease in size from the surface to depth: larger particles are retained in the upper layers, smaller ones in the deeper ones. This internal structure greatly extends the life of the filter, because it clogs less and can pass fuel in the required volume for longer.

Gasoline injection filters

As already mentioned, injectors are very demanding regarding the purity of gasoline. Another feature of injection engines is the relatively high pressure in the power system. Naturally, the filter installed after the electric fuel pump must have a safety margin. Therefore, during testing, such filters are exposed to pressure up to 1.5–2 MPa (15–20 atmospheres).

The gasoline injection filter is installed in the tank, under the bottom or under the hood. The environment under the hood is aggressive. High temperatures and vapors of operating fluids reign here. This means that filter designers must take care of the corrosion resistance of its “body”. If the filter serves under the bottom, the issue of corrosion becomes especially relevant. Therefore, its body is made of galvanized steel, aluminum alloy or especially durable plastic.

And another interesting detail. A metal fuel filter housing is not easy to make. This is not just stamping, but so-called deep drawing, which requires the strictest technological discipline. And the greater the ratio of body length to diameter, the more difficult it is to ensure uniform wall thickness. When picking up a branded product, it’s useful to remember this.

A filter curtain is placed in the filter housing. Sometimes it is laid in a star pattern - in the KOLBENSCHMIDT documentation such filters are called radial (see illustration above). Indeed, the fuel passes along the radius of the curtain to the inner reinforcing tube. Along the way, dirt particles settle on the surface of the paper and deep in the pores, and the purified fuel rushes through the holes in the inner tube to the outlet of the filter.

But there is another way to style curtains - spiral-fold. KOLBENSCHMIDT specialists call such filters axial (axial). The filtration principle here is somewhat different than in radial filters.

Look at the picture on the previous page. Filter paper, thinner than a radial filter, is wound around the inner amplifier tube. But it is wound in a very clever way - so that V-shaped pockets are formed along the axis of the filter, capable of collecting dirt particles. The fuel is also fed along the axis, cleaned in the pockets and exits the filter through the central tube.

Spiral-fold laying allows you to place 1.5–1.7 times more material in the same volume than when laying with a star. At the same time, the paper for axial filtration differs from the paper used for the star - it is not smooth, but creped, “crumpled”. Experiments have shown that crepe retains more dense mechanical impurities.

Surprisingly, crepe paper is cheaper than regular paper. The explanation is simple - its impregnation is carried out at the stage of preparing the “mass” in the mixer, in contrast to the impregnation of the finished paper web. This means that manufacturers of such filters can pursue a more flexible pricing policy - an important opportunity during a crisis.

Features of execution

According to the method of execution, they are distinguished between direct-flow, screw-on and cartridge filters.

Direct-flow filters are used in carburetor and injection gasoline systems. There are pipes installed at the inlet and outlet through which the filter is connected to the fuel system. Gasoline enters the housing, passes from the outer walls to the center through the filter element and is sent for further use. The pipes can be located either on one side of the filter (in the cover) or on opposite sides.

Screw-on filters have a threaded connection with which they are connected to the fuel line. Fuel enters through a larger diameter with holes around the circumference, and exits through a smaller central one. Such filters are designed for high pressure and are made in a durable metal case or plastic case with a metal lid.

The filter cartridge consists of a metal casing (glass) and a replaceable core with a filter part. The filter element can be purchased separately, and thus save money on regular fuel filter replacements.

Filters for injection engines have a fuel pressure regulation system: an additional outlet pipe into the gas tank, through which excess gasoline is removed from the system. In diesel engines, filters also remove air bubbles and are designed with a bleeder valve to release excess air.

In diesel filters, the container (often transparent) for collecting water has a drain valve through which accumulated water can be drained from the filter.

Thus, the modern fuel filter has evolved from a simple device to a self-regulating system necessary for long and high-quality engine operation.

Diesel fuel filters

According to statistics from FSUE NAMI, from 30 to 45% of diesel engine failures occur due to malfunctions of fuel equipment. This is truly a precision system - it is not without reason that the highest requirements for fuel purification are placed on it.

The classic FS diesel filter from KOLBENSCHMIDT is shown in the figure on this page. Much of what was said in the previous sections is also true for diesel filtration: power system diagrams, filter types, curtain design. Therefore, we will not repeat ourselves. Let’s just add that spiral-pleated installation is increasingly being used in diesel filters. This design is the last word in modern fuel purification systems.

In addition, sensors for the presence of water, pressure and temperature control, heating and water separation systems, faucets for draining sludge and other combinations of useful devices are built into the design of diesel filters.

By the way, about water in fuel, this headache for diesel drivers. How is moisture separation carried out? There's no secret. We just haven’t told you everything about crepe filter paper. A curtain made from this material helps combat water contained in the fuel. In a situation where ordinary paper is clogged with moisture, crepe paper allows this moisture to pass through, but not immediately, but as local pressure increases. At the exit from the pores, moisture flows in large drops onto the inner wall of the housing or into a sump, if one is provided for in the filter design. The driver opens a special tap and lets the water drain. In a word, a simple operation, especially since in some cars the water level is determined by a special sensor.

Since Common Rail diesel injection systems are precision and high-tech, at the time of the first (attention - the very first!) engine start, no dirt that got into the filter during assembly should penetrate into the fuel equipment. Therefore, this assembly takes place in a special Clean Room workshop. Here the filters are packaged, sealed and delivered to distributors in this form.

The author had the opportunity to visit such workshops. The Clean Room employs specially trained staff. Special shoes, a white uniform, sterile caps and gloves are required. The room itself is certified in accordance with the International Standard EN ISO 14644. Dust simply does not have a chance to survive in the “white zone” of a clean room.

Operating the fuel filter

Actually, operation does not require special attention from the car owner: all requirements boil down to purchasing a high-quality filter, correct installation and timely replacement. For diesel cars, filters with a water sump can be installed; then, from time to time, accumulated condensate must be drained from them through a special valve.

Since the filter model depends on the engine model (cars of the same brand can have different engines, which means they need different filters) and its volume (the larger the engine volume, the larger the filter volume), the replacement schedule is indicated in the service book. When undergoing maintenance, the fuel filter is changed as one of the consumables.

On average, a filter for gasoline injection engines has a service life of up to 40 thousand km. For diesel filters, the resource depends on the method of laying the filter element: a radially folded “star” will last approximately 24 thousand km, and a spiral winding has a much longer resource - up to 40 thousand km.

The filter life is affected by several factors:

- The quality of gasoline, the purer the gasoline, the longer the filter will work fully.

- The quality of the filter itself. The filter element (special paper) is produced by just a few large specialized factories, which receive orders from filter manufacturers. The totality of the design of all parts (body, cover, filter core, pipes, etc.) also determines the service life of the filter itself, because in addition to clogging, it can leak, crack and present other unpleasant surprises.

- Changing summer diesel fuel to winter and vice versa. Paraffins that accumulate in the filter clog it tightly, rendering it unusable, so switching to winter fuel is one of the conditions for the uninterrupted operation of the fuel system.

Paraffins in the fuel filter

- Emergency situations that arise during vehicle operation. For example, water condensate may freeze in the filter and thus damage the porous filler.

- Poor quality gasoline. Impurities that are sometimes added to fuel corrode the filter element, rendering it completely unusable in a very short time. That is why most drivers prefer to refuel at gas stations of large companies that monitor the quality of fuel.

On diesel cars, an additional heater for the filter can be installed: in winter, the fuel thickens during parking until a dense gel is formed, and to facilitate engine starting, pre-heaters are installed on the filter, heating diesel fuel to a temperature above the freezing point of paraffins.

Diesel filter with heater

What to remember for those who want to change the fuel filter with their own hands

“Replacing a fuel filter is a rather labor-intensive procedure, plus it is unsafe, because it involves working with fuel - it is not recommended for an untrained person to change the fuel filter with their own hands,” says Konstantin Epaneshnikov . — As a rule, after replacing the filter, fuel leaves the fuel line, and starting problems arise. This is especially pronounced on diesel cars - it is difficult to start a diesel car after replacing the fuel filter. This is another argument in favor of not changing the fuel filter yourself, especially if a person is not prepared and does not know how to do it correctly.

However, if you decide to change the fuel filter yourself, you will need to wait until the fuel runs out. After this, turn the ignition again for three seconds to release the pressure.

You will find detailed instructions for replacing the fuel filter in this article.

Instructions

How to change the fuel filter correctly

show more

Signs of a clogged or failing fuel filter

A filter malfunction is manifested, at best, by a decrease in fuel supply:

- Gasoline consumption increases;

- “Trippling” - one of the engine cylinders does not work;

- The engine power decreases, which becomes noticeable during acceleration or driving uphill. This is a rather dangerous situation on the highway when, instead of overtaking the car in front, you end up with “synchronized skating” due to the inability to pick up speed;

- The car suddenly stalls while driving or at a traffic light;

- The engine does not start at all.

If the cause is a clogged fuel filter, these faults can be easily eliminated by simple maintenance. There are also worse options: if the filter turns out to be of poor quality or the internal structure is damaged, unrefined gasoline will flow into the fuel injection pump and engine, leading to more serious problems. This will be heard from the operation of the pump (noise during movement) and the engine (the same “triple movement”, vibration and loss of power).

PROBLEMS ARISING

Unfortunately, the quality of fuel today is far from ideal and unpleasant situations have become common when jerks and dips appear during the movement, first at high speeds, then at low speeds. So:

- When the car begins to start poorly or does not start at all, there can be many and very different reasons; the owner cannot always guess that it is necessary to replace the VAZ 2115 fuel filter

- Since the driver’s opinion is that there seemed to be no problems before leaving, so only over time will the owner perhaps understand the real cause of the problem, which is hidden in the contamination of the fuel filter

- Some try to correct the situation by changing the oil in the engine or gearbox, others hope that their problem will be solved by flushing the injector or computer firmware

- The real cause of problems is dirt, which is present in large quantities in the fuel.

- It is natural that the dirtier the gasoline, the faster it clogs the filter, and this will more often cause dips and jerks to bother you while driving.

- The only correct way out of the situation is to replace the fuel filter on a VAZ 2115

- At the first such symptoms, the filter element should be replaced, regardless of the mileage of the car, at the time of trouble, even if it is much less than thirty thousand

- The procedure should be carried out in a designated place on an inspection ditch or overpass, do not dump fuel on the ground, place a container, remember about the environment

Attention: When repairing a car, do not forget that gasoline is highly flammable, so smoking or using a lighter when replacing fuel filters or any repairs related to the fuel system is life-threatening! In addition, fold rags soaked in gasoline separately and then the likelihood of a fire or explosion during repairs will be minimal. Always keep a powder or carbon dioxide fire extinguisher nearby.

- You must first find out what brand and type of filter you have, so as not to make a mistake when purchasing a replacement one.

- When installing a new filter with your own hands, replace the O-rings on the tubes

- You should also pay attention that the arrow drawn on the filter is in the direction of the movement of fuel in the line, otherwise your problem will return very soon

- Next, we will describe replacing the fuel filter on a VAZ 21154 in its technological sequence

- This sequence practically coincides with replacing fuel filters VAZ 2110-2115

Selecting a fuel filter

The filter installed on the car is only the one that strictly corresponds to the engine parameters, neither better nor worse. Injection filters are not suitable for carburetor systems, and if you really want to get high-quality filtration, you need to choose a filter of higher quality, but of the appropriate type.

When choosing, you need to focus on the engine brand and technical parameters: external and internal diameters, diameters of the inlet and outlet pipes, overall dimensions of the housing. When purchasing, you should also pay attention to the complete set of the filter: many manufacturers add spare o-rings, which will come in handy when replacing the filter.

On average, the larger the engine size, the larger the filter volume and its throughput will be.

How not to buy a fake

It has long been no secret to anyone that there are many surrogate products for most well-known manufacturers of consumables. In addition, counterfeits are found not only for expensive products, but also for the middle and inexpensive price segment. More often, counterfeit products are manufactured in China, and sometimes even in the Russian Federation. To avoid purchasing low-quality fuel filters when choosing, it is important to pay attention to the following parameters:

- Appearance of the product. A good manufacturer cares about the quality of the housing and filter element. Therefore, before purchasing, you should carefully inspect the fuel filter itself. The body must be free of dents, nicks, cracks and other defects. It is desirable that it contains technical information, engravings or stamping, a company logo, etc.

- Exterior of the box. A good manufacturer will never skimp on the packaging of its products. Accordingly, the box on the original product will have high-quality printing with clear edges of the drawings and clear, non-blurry text. The presence of grammatical errors or unclear symbols or hieroglyphs in the description indicates that this is a surrogate product. The manufacturer's logo on the box must match.

- Presence of gaskets in the box. Original products always contain gaskets in the packaging that are necessary during installation to ensure the tightness of the fuel line. They are made from a special material that is resistant to aggressive environments. Although this depends more on the specific manufacturer, you should check the equipment specified in the documentation attached to the product.

- Fuel filter cost. You should not give preference to the cheapest possible product; such filters can be either of very low quality or simply counterfeit. It is worth choosing products from the middle or high price segment. This is especially important for business-class injection cars or diesel engine types, since a high degree of fuel purification is required here. By saving on a fuel filter, you may later face costly repairs to engine components or the fuel system.

- A store. To protect yourself from purchasing low-quality goods, it is better to make purchases in trusted stores that have all the documents giving them the right to conduct trading activities. Ideally, it would be if this outlet is the official representative of a particular company engaged in the production and distribution of auto components.

Most modern manufacturers of fuel filters try to protect their products using modern technologies. There are many ways to determine the originality of a product, from sending an SMS message with the number indicated on the box to identifying the product via a QR code. Such protection measures reduce the purchase of counterfeits to almost zero.

Inspection of the used filter

The condition of the removed filter can tell the car owner a lot:

- There is a lot of black dust in the filter pleat - the presence of manganese additives in gasoline;

- The filter is all clogged with dirt - the fuel contains a large percentage of resins and asphaltenes;

- Black mucus on the filter element – there is fungus or bacteria in the fuel;

- Wave-like curvature of the corrugated element - there is a large amount of water in the fuel.

But the condition of the outside is not as important as the type of filter inside the central channel: if there are no deposits on the inside and the paper is clean from the inside, then the filter coped with its task.

How does the fuel filter of the VAZ 2114 work?

The hero of this article, the “fourteenth” VAZ model, also has it in the fuel system.

Structurally, the VAZ 2114 fuel filter is the same as other creations of this domestic automaker. It looks like a plastic (or metal) cylinder, inside of which there are several filter elements:

- rough cleaning;

- fine cleaning.

The first is responsible for ensuring that large pieces of dirt do not get into the car’s engine, and the second cleans gasoline from smaller particles and impurities.

But, unfortunately, this part does not last forever and sooner or later it will become clogged, especially if you constantly fill the “fourteen” with gasoline at dubious gas stations. We will tell you further how to find out that the VAZ 2114 fuel filter is clogged.

Using a dirty fuel filter shortens the life of the engine several times.

Filter location

Now that all readers understand how important and necessary fuel filters for diesel engines are, we can consider the procedure for replacing them. First of all, it is worth carefully studying the location of this node. In this regard, diesel cars are also different. Diesel fuel filters are installed in two different ways. Let's look at each possible option:

- First. The unit is built into the fuel pump and located in the gas tank. To get to it, you will have to gain access to the tank in any possible way. As a rule, it is necessary to remove the rear seat in the car. After this, you can begin repairing the unit. A similar organization of fuel filtration is often used on newer diesel cars (Ford Mondeo 4, Mitsubishi Pajero 4, KIA Soul, etc.).

- Second. The diesel fuel filter is located in a separate unit. In this case, it is also difficult to find the unit - just open the hood, or look under the gas tank and find the characteristic “barrel” behind it - this will be the fuel filter. This type of arrangement of the unit is not uncommon for both old diesel models and new ones (UAZ Patriot, Ford Kuga, etc.).

The location of the diesel fuel filter largely determines how it will be replaced, how difficult this procedure will be and what will have to be done during the process. In any case, repairs of this kind are not complicated, so if necessary, a trip to a service station can be avoided without any problems.