The question of how to set the ignition on a VAZ 2109 worries many car enthusiasts. Indeed, owners of these car brands from time to time encounter problems associated with unstable operation of the power unit.

A common symptom is normal engine starting and incorrect idle speed.

What is the reason for this phenomenon? Are there ways to solve it?

According to experienced craftsmen, you need to pay attention to the ignition system - it is the main cause of such a malfunction.

Moreover, in 90% of cases the problem can be solved independently.

Setting the ignition timing (ignition timing) on VAZ-2108, 2109, 21099 cars

Setting the ignition timing

(ignition timing)

on VAZ-2108, 2109, 21099 cars

(second slide)

Setting the ignition timing is one of the main settings of a car engine. Incorrectly set ignition (both in the direction of increasing the advance angle and in the direction of decreasing) immediately affects its operation for the worse.

Signs of incorrectly set ignition timing

overheating, detonation, shots into the muffler or carburetor, this is not a complete list of such malfunctions.

It should be borne in mind that similar symptoms occur with an incorrectly adjusted or faulty carburetor, faulty valve mechanism, etc.

Purpose of setting ignition timing

Set the optimal ignition timing at which the main characteristics of the car engine - power, throttle response, idle speed, fuel consumption - will be normal.

Tools for work

— Tachometer

(you can use the built-in one in the instrument panel, you can connect an external one (for example, an auto tester, a multimeter in tachometer mode), you can use your ear, if you have experience).

strobe and autotester -

Socket or open-end wrench.

Either a matching ratchet socket or an L-shaped wrench. Size 10.

— We warm up the car engine to operating temperature (85-90)

.

— Set the minimum idle speed (750-800 rpm)

. To do this, turn the “amount” screw of the fuel mixture on the carburetor. You can set the minimum speed using the tachometer or by ear. If they correspond to the norm, then we skip this point.

location of the adjusting screw for the “amount” of the fuel mixture on the carburetor 2108, 21081, 21083 Solex - Remove from the fitting on the housing of the vacuum ignition timing regulator

,on the distributor-distributor, a silicone vacuum supply tube coming from the carburetor.

—

We check by placing a finger on its hole to see if there is a vacuum in it.

It shouldn’t be there, since in theory it should start working at speeds above 800. If it is, slightly reduce the idle speed (by rotating the “amount” screw of the fuel mixture on the carburetor) until it disappears.

— We plug the hole in the silicone tube with a small bolt or simply bend it in half (tie it in a knot).

— Using a 10mm wrench, loosen the three nuts securing the breaker-distributor housing.

— We are looking for a hatch on the gearbox housing with a scale and a visible part of the flywheel. It is usually closed with a rubber stopper.

We remove the plug.

location of the inspection hatch in the clutch housing on VAZ 2108, 2109, 21099 cars -

Wipe the scale in the hatch with a rag so that the installation marks are clearly visible on it.

— Use a screwdriver to turn the flywheel by the teeth of its crown and find a long transverse alignment mark on it.

When it stands opposite the triangular cutout on the scale in the hatch, it means that the ignition timing is 0 0, and the pistons of the first and fourth cylinders have risen to top dead center. If it is poorly visible due to oiling or contamination, we wipe the edge of the flywheel through the hatch until we find it. You can highlight the mark with chalk.

mark for setting the ignition timing on the flywheel and a scale with degrees

— We check whether this is a risk (what if your flywheel is installed incorrectly).

We check using the following marks - the long mark on the flywheel should be opposite the triangular cutout on the scale, the mark on the camshaft pulley should be opposite the protrusion on the rear timing belt cover (to see them, remove the plastic timing belt cover).

Engine workflow through cylinders

The cylinders are activated as follows:

- In the first there is an upward movement. The gases expand and the mixture of air and fuel burns.

- In the third, to carry out the compression procedure, the piston rises.

- In the fourth, “injection” occurs - the piston moves down and at the same time a mixture of air and gasoline enters the cylinder.

- In the second cylinder, the piston rises and takes the upper position so that gases escape through the valve system. After which the exhaust gases are removed from the power unit.

Based on the principle of operation of the cylinders, their activation diagram looks like this: 1-3-4-2. It is important to connect them correctly so that the cylinders work in that order.

How to set the ignition on VAZ 2109 injection models

The VAZ 2109 with an injector is equipped with an electronic ignition system module. Those. configuration occurs by programming and flashing the control unit. It is impossible to adjust the system without specialized equipment.

Setting up ignition using a strobe light

The ignition angle is adjusted and checked at idle speed. The number of crankshaft revolutions should be in the range of 800 - 900 rpm.

- The engine is warmed up to 90 C.

- Crankshaft rotation speed 800 – 900 rpm. If the frequency becomes higher, check the carburetor fuel assembly.

- The vacuum tube is disconnected from the fitting and the engine is turned off.

- The tube is bent in the middle with a screw, then the securing nuts of the distributor-breaker are unscrewed.

- The rubber plug is removed from the gearbox housing. This is where the flywheel inspection hole is located.

- The cylinder wire is disconnected from the shaft cover, and a strobe light is attached in its place.

- They start the car. The device (strobe) will send signals to the flywheel.

- The distributor shaft is rotated until the mark on the mark coincides with the mark on the flywheel.

- The mark is marked. If the mark on the flywheel matches the mark on the crankshaft pulley, then the setting is correct.

How to set the ignition on a VAZ 2109 using an incandescent lamp

To debug the ignition using an incandescent lamp, you will need a 10 mm key and a 12 Volt light bulb. Ignition adjustment occurs by loosening the fastenings of the spark system sensor.

The procedure for setting up the light bulb is as follows:

1) Turn the crankshaft with a wrench until the marks match. If there is no key, then you can set the fourth speed at idle and push the car until the marks coincide.

2) A lamp is connected to the cable that connects the breaker and the ignition coil.

3) Using the other two wires, the light bulb is connected to the ground of the VAZ 2109.

4) Loosen the bolts on the distributor and start the car. The incandescent lamp should light up.

5) The distributor body is turned to the right until the lamp goes out. Afterwards, the body is smoothly rotated to the left. After the lights come on, they stop.

6) Tighten the housing mounting nuts.

This method is most suitable for self-tuning the spark generation system.

Setting up tachometer markers

In order to set up the ignition using this method, two people are needed. One will be in the pit and rotate the distributor, the second will be located in the car interior.

The tachometer setting is done as follows:

- Turn on the ignition and watch the arrow of the device.

- A person in the pit cushions the mounting nuts and bolts of the distributor and turns it.

- The ignition key is turned, the tachometer indicator jumps and returns to 0.

- If the distributor remained in the location to which it was turned when the instrument needle deviated, it means that the adjustment of the ignition structure was correct.

How to regulate OZ?

Aurally? By spark? By a light bulb? By strobe? Let's figure it out now.

Let’s say right away that we won’t talk about the strobe light. Firstly, the average driver simply does not have it at hand. And, secondly, it’s better not to mess with him. The fact is that the strobe light shows the ignition timing only when the engine is running, but at the same time, due to the centrifugal regulator, the OZ is shifted towards advance even at minimum idle speed. Therefore, generally speaking, there is no point in waiting for precise adjustment.

The correct adjustment recommendations are always contained in the specialized literature for a specific car model - they should be followed. Let's take for example the AZLK-2141 car with a UZAM engine and a contact ignition system. Please note that the slider on Ufa engines rotates COUNTERclockwise.

The sequence of operations for a Moskvich engine should be as follows.

- Loosen the distributor fastening.

- We determine the beginning of the compression stroke in the first cylinder. To do this, we turn out the spark plug of this cylinder, plug the hole with a suitable plug (even from crumpled paper) and turn the crankshaft with the starting handle until the plug pops out.

- We continue to turn the crankshaft until the first mark on its pulley aligns with the tip of the ignition installation pin pressed into the lower crankcase cover.

- We make sure that the slider is looking with its current-carrying plate at the contact of the distributor cover, corresponding to the wire of the first cylinder.

- We connect any low-power light bulb (for example, in a test screwdriver) with one end to ground and the other to the low voltage terminal of the coil connected to the breaker.

- Turn on the ignition and turn the distributor body counterclockwise until the breaker contacts close. The lamp shorted by the breaker should go out.

- Holding the slider, apply a small force clockwise to eliminate gaps in the drive mechanism, then slowly turn the distributor clockwise until the light comes on.

- Tighten the distributor fastening. Don't forget to return the candle to its place!

On cars like the VAZ-2108, which switched to electronic ignition, but at the same time retained both centrifugal and vacuum regulators, the procedure is completely similar - up to a different location of the standard marks. The slider rotates counterclockwise. However, the probe lamp must be connected between the switch and the ignition coil, and in no case to the Hall sensor.

What does the expression “set by spark” mean? Roughly speaking, the same as with a light bulb. In this case, instead of a light bulb, use a spark plug that has been unscrewed in advance, the threaded part of which must be connected to the engine ground. Instead of the light bulb lighting up, we catch the moment the spark jumps - that’s all.

What about adjustment by ear? It is carried out like this: when driving on a warm engine at a speed of approximately 50 km/h in 4th gear, sharply press the right pedal. If the OZ is set correctly, then a short-term disappearing detonation should be heard. If the detonation is too strong, you should turn the distributor in the direction of rotation of the slider. If there is no detonation at all - against the rotation of the runner. You still remember that in the domestic automobile industry the runners rotated both back and forth?

Purpose of the distributor cover

The design of the ignition distributor cap (aka distributor) has remained and remains virtually unchanged throughout the entire history of the use of this device as part of the ignition system of gasoline engines:

- On most ignition caps, the contacts for the spark plug wires are marked with numbers that correspond to the serial numbers of the corresponding cylinders

- In addition to protecting the distributor mechanism itself from moisture and dirt, it also serves the purpose of alternating the supply of high-voltage current from the ignition coil winding through high-voltage wires to the spark plugs

- It is because of this narrow specialization that the distributor cap has undergone almost minimal changes along the evolution of all car systems

Let's look at the design and operating principle of this much-needed part.

The distributor cap is a molded part made of non-electrically conductive material (insulator) that has the following device:

- Metal contacts are pressed into this part - these are the side and central electrodes

- The number of side electrodes strictly corresponds to the number of engine spark plugs (but not cylinders, do not forget that there are engines in which there is more than one spark plug for each individual cylinder); the distributor cover on the VAZ 2109 in our case has four side electrodes

- A high-voltage (armor) wire coming from the ignition coil is connected to the central electrode from the outside

- To the side electrodes - high-voltage (armor) wires going to the spark plugs

- Inside the cover itself there is a central contact equipped with a terminal that has a spring-loaded contact element (“carbon”), which transmits voltage to the central (main) contact of the distributor rotor (ignition distributor)

Schematic design of the lid

When installing the cover on the distributor body, it is important to take into account not only the order of connecting the armored wires, the orientation of the cover in relation to the “nose” of the runner is also important. The ignition distributor cover is attached to the distributor body using latches or screws (the distributor cover on the VAZ 2109 is secured with screws) To prevent the formation of condensation under the lid, it has a special ventilation hole

Incendiary physics - advance, distributor and UOZ

How to set the ignition? What is UOZ? Where did the runners rotate in domestic cars? What does the expression “set by spark” mean? - there are many interesting questions to which owners of modern cars may not give the correct answers.

What is ignition timing - also known as ignition timing? Is this some kind of attribute of ancient cars or something unshakable, akin to universal gravity? Most modern car owners are unaware of this. All car systems are controlled by numerous controllers, and therefore timely sparking in the engine cylinders is entirely their responsibility. Meanwhile, a huge number of ancient machines are running around the country, unfamiliar with processors and other chips. Therefore, questions like “How to regulate the SOP?” still sound today.

It's always a pleasure to answer technical questions. But first you have to remember some “incendiary” terms.

Do-it-yourself ignition system repair

So, if problems with the engine indicate problems with the ignition system, you should proceed with immediate repairs. The essence of the work being carried out comes down to installing or setting the correct ignition timing. The engine will only run stably when you adjust the ignition system. To begin repairing this mechanism, you need to stock up on some tools:

- strobe;

- tachometer;

- flat screwdriver;

- key to 10.

Having a strobe light on hand will greatly facilitate the process of setting up the ignition, so we recommend purchasing one for personal use.

Before you start setting the ignition timing and angle, do some preparatory work. The first thing you need to do is start the engine. Then either wait or rev the engine until the engine temperature is 90 degrees Celsius and the idle speed should be around 800 rpm (use a tachometer to determine this parameter). To obtain the required values, use the fuel regulator located on the carburetor body.

As the engine operating temperature reaches 90 degrees, remove the silicone tube through which the discharge occurs from the fitting. The lever for adjusting the fuel supply is located on the ignition timing distributor panel or distributor. The distributor is attached to the carburetor itself. Place your finger on the other edge of the tube and check if there is a vacuum effect. It can be checked very simply: if your finger is stuck to the tube, it is there; if not, then there is no effect either. Now you need to reduce the number of revolutions until the vacuum completely disappears.

Then turn off the engine. Bend the silicone tube so that there is no gap. Take a 10mm wrench and unscrew the distributor nuts. The photo above clearly shows the flywheel and crankcase hatch. The gearbox housing contains a hatch with a flywheel scale. Remove the plug and, if there is dirt, wipe it off the inspection hatch. On the scale you will see stripes responsible for correct ignition setting. Next we focus on them.

Using a flathead screwdriver, rotate the flywheel to the long line on the scale. Before setting the ignition, you need to align the long strip exactly opposite the triangular cutout on the scale. The fact is that this position means a zero ignition angle. At the moment when the long strip is in this position, the first and fourth cylinders remain in a fixed position.

If, due to poor visibility, you doubt that the selected strip is the longest, it is worth re-evaluating its location relative to the camshaft. To do this, you need to remove the timing belt cover and see if the mark you are interested in matches the mark on the rear cover.

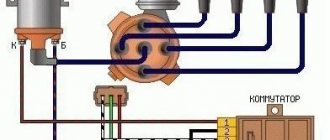

Next you need to use a strobe light. To connect it, you need to perform several simple manipulations:

- first connect the red wire to the positive on the coil;

- then place the dark wire anywhere on the body;

- and secure the mount to the fourth cylinder along with the wires.

Before connecting the device, it is better to read the instructions for use.

Dismantling

After dismantling the distributor, you can disassemble the device in order to repair its components, or completely replace the distributor with a new unit.

- De-energize the car by removing the negative from the battery;

- Disconnect the high-voltage components and the vacuum ignition corrector hose from the distributor;

- Remove the drive cable responsible for the throttle valves from the bracket. Next, the fastening nuts are unscrewed and the bracket is dismantled;

- Before removing the ignition distributor, apply a mark to the housing of the distributor and drive of auxiliary elements. This way you can simplify your task of setting the ignition timing for its precise setting. The mark is applied to the metal by scratching;

- Press the latch holding the block with the power wires and disconnect it from the distributor;

- Place the piston from the first cylinder to the top dead center position by moving the engine flywheel clockwise;

- Unscrew the remaining ignition distributor screws. The first fastener was removed when removing the damper cable sheath bracket;

- Remove your damaged distributor.

Disassembly and repair

Quite often, repair work with the distributor is associated with wear and the need to change the seals (coupling). To change the oil seal, as well as other failed components of the distributor, we bring to your attention the appropriate instructions, as well as video tips.

- Remove the ignition distributor cap by releasing the locking clip.

- Remove the slider. It is wiped with a clean rag and checked for mechanical damage. If there are chips or cracks, the element must be replaced.

- The runner must fit tightly on the shaft, which is achieved due to the presence of a plate spring with a pressing action. If it stretches or breaks, replace it.

- There is a resistor in the slider housing. The normal reading of its resistance is 1 kOhm. By measuring the data with an ohmmeter, you can draw conclusions regarding the performance of the component.

- Remove the low voltage wiring terminal. To do this, unscrew the mounting screw from the housing.

- Remove the plastic screen that serves as dust protection.

- A power wire comes from the Hall sensor and is held by the holder's claws. Using a screwdriver, the claws are opened and the wire is removed. Next, you need to unscrew the pair of mounting screws securing the Hall sensor support plate.

- Remove the vacuum corrector. Just be sure to disconnect it from the support plate lever before doing this. To perform this operation, carefully remove the retaining ring from the pin.

- The next step is to remove the pair of screws that hold the corrector to the distributor body.

instructions and purpose

Let's first consider the general purpose, design and types of distributors:

- The distributor is part of the ignition system, and is designed to regulate, transmit and control the electrical signal to the distribution coil switch, igniting the spark along the spark plugs in the required accordance (in sequence with the ignition stroke)

- There are two types of ignition systems - non-contact and contact (of course, there are others, but they are not very common), accordingly, distributors are also used of two types

- friend They differ from each other only in design: the presence of contacts (in a contact system there is a breaker), a sensor distributor (in a contactless ignition sensor system there is a distributor)

- According to the main characteristics, both systems are almost identical

On VAZ-2109 cars, as well as 2108 models-2199, a distributor with a built-in Hall sensor, four spark, with built-in centrifugal (regulators and vacuum) ignition timing is standardly installed. You can see the main details in the photo above:

- 1 - sealing ring

- 2 - special

- 3 – coupling adjusting washers

- 4 - roller with a centrifugal regulator located on it

- 5 — support plate

- 6 – screen, protecting from dust

- 7 - the so-called “runner”

- 8 - Hall sensor itself

- 9 — lock washer

- 10 - thrust washer

- 11 — distributor, ignition housing

- 12 — vacuum corrector

Description and modifications

As such, a “nine” engine does not exist in nature. At least, the AvtoVAZ plant did not produce it. All 2109 models were equipped with a figure-eight power unit and its modifications. Of course, in many documents you can find the VAZ 2109 engine, but this is deception or ignorance.

But in the technical documentation of the manufacturer you cannot find information about the 2109 engine, since such an engine does not exist. During the entire period of their production, all “nines” were equipped with engines with the following markings: VAZ-21081 (1.1 8V), VAZ-2108 (1.3 8V), VAZ-21083 (1.5 8V), VAZ-2111 -80 (1.5i 8V) and VAZ-11183-20 (1.6i 8V).

Adjusting the ignition timing

Ignition timing is the moment a spark occurs at the spark plug electrodes. It is determined by the angle of rotation of the crankshaft journal relative to the top dead center (TDC) of the piston. The ignition angle has a noticeable effect on engine performance. If its value is too high, ignition of the fuel in the combustion chamber will begin much earlier than the piston reaches TDC (pre-ignition), which can lead to detonation of the fuel-air mixture. If sparking is delayed, this will lead to a decrease in power, engine overheating and increased fuel consumption (delayed ignition).

The ignition timing on the VAZ 2106 is usually set using a car strobe light. If there is no such device, you can use a test lamp.

Setting the ignition timing using a strobe light

To adjust the ignition timing you will need:

- car strobe light;

- key to 13;

- a piece of chalk or a correction pencil for printed text.

The installation process itself is carried out in the following order:

- We start the car engine and warm it up to operating temperature.

- Disconnect the hose from the vacuum corrector located on the distributor body.

- We find three marks (low tide) on the right engine cover. We are looking for the middle mark. To make it better visible in the strobe beam, mark it with chalk or a correction pencil.

Video: adjusting the ignition using a strobe light

Setting the ignition timing using a warning light

To adjust the ignition using a lamp you will need:

- the warning lamp itself;

- 36 head with handle;

- key to 13;

- 16mm spark plug wrench with wrench.

The work order is as follows:

- Using a 36mm socket, placed on the crankshaft pulley ratchet, we rotate the shaft until the mark on the pulley aligns with the casting on the cover. When using gasoline with an octane rating of 92 and higher, the mark on the pulley should be aligned with the middle ebb. If the octane number is less than 92, the mark is placed opposite the last (long) ebb.

- We check whether the distributor is installed correctly in this position. Unfasten the latches and remove the distributor cover. The outer contact of the distributor slider should be directed towards the spark plug of the first cylinder.

Video: adjusting the ignition using a light bulb

Installing the ignition by ear

If the valve timing is set correctly, you can try to set the ignition by ear. This is done as follows.

- Warm up the engine.

- We drive out onto a flat section of the highway and accelerate to 50–60 km/h.

- We switch to fourth gear.

- We sharply press the accelerator pedal all the way and listen.

- With the ignition set correctly, when the pedal is pressed, a short-term (up to 3 s) detonation should occur, accompanied by the ringing of the piston pins.

If detonation lasts more than three seconds, ignition is early. In this case, the distributor body is rotated several degrees counterclockwise, and the verification procedure is repeated. If there is no detonation at all, the ignition is late, and the distributor body must be turned clockwise before repeating the test.

When and why do you need to adjust the ignition?

First, a little theory. If the working mixture in the cylinders burned instantly, then there would be no problems with advance in principle. Set it on fire at top dead center and everything is fine. But the mixture does not burn instantly: it takes milliseconds. In this case, the actual rotation speed of the crankshaft is, of course, not constant. Therefore, you cannot stupidly ignite the mixture at the same time under different engine operating modes: it will burn either too early or too late. The result will always be disappointing - the engine pulls poorly, overheats, runs unstably, detonates, etc.

In particular, if you start “sparking” too early ( large

), then the gas pressure will increase sharply until the piston reaches top dead center, preventing its movement.

Because of this, the power will decrease and the efficiency of the engine will deteriorate, it will lose throttle response and will jerk at low speeds. With late sparking ( low CV

), the mixture will burn for a long time with an expanding volume, and therefore the gas pressure will be significantly lower than the calculated one. Power and efficiency will decrease, and the engine will overheat greatly, since the mixture will burn out throughout the entire expansion stroke.

There is only one treatment method - ignite the working mixture according to the speed and load on the engine. In addition, adjustment of the OZ may be required when switching to gasoline with a different octane number. By the way, on very ancient cars (at the beginning of the last century), the ignition timing was regulated by the driver: a special handle was provided. But it soon disappeared, because the engine acquired a distributor with a centrifugal mechanism inside.

What do ignition malfunctions promise?

Difficulties in starting the power unit, strange color of exhaust gases, incorrect operation of the engine at idle speed - all this can be the cause of incorrectly adjusted ignition timing.

At the same time, many car enthusiasts blame the carburetor and spend a lot of time cleaning or repairing it. As a result, money and time are wasted, but there is no result.

On the other hand, if the ignition system does not produce a spark, and the spark plugs are regularly filled, then the problem may lie elsewhere.

An incorrectly set angle manifests itself as follows:

Currently reading

Lada Largus FL 2022 in a new body or everything new, not yet forgotten old

1.1k

Chevrolet Niva: a good purchase or a headache, is it worth buying on the secondary market?

23.2k

1. Powerful detonation appears during operation of the power unit.

It is not difficult to recognize the problem. The main symptom is an uncharacteristic ringing sound that is heard when you press the accelerator pedal.

This malfunction is a common occurrence among motorists who do not properly monitor the condition of their vehicle.

The cause of detonation is early ignition timing, which not only reduces the comfort of driving a car, but can also lead to deformation of the pistons.

Alternatively, the rings may be defective, which in this case will inevitably have to be replaced.

2. The appearance of smoke from the exhaust pipe.

— after starting the power unit, black smoke comes out of the exhaust pipe. This problem is a clear indication of pre-ignition.

3. Motor power decreases.

This is especially noticeable when the vehicle picks up speed.

There may be a delay of several seconds between pressing the gas pedal and the car starting to accelerate. If the car starts to accelerate, it happens jerkily.

4. Fuel consumption increases.

One of the main consequences of incorrect system configuration. This and the problem described above are evidence of late ignition.

This is explained by the fact that when the piston reaches the top point, the fuel mixture does not burn completely and continues to burn even when the piston moves back.

5. Uneven idle.

An incorrectly set ignition immediately manifests itself as engine malfunctions at idle.

In such a situation, experts recommend setting up the system first, and only then starting to check other systems.

Basic technical concepts

The ignition system is a variety of interconnected instruments and devices that guarantee the appearance of an electrical discharge, which in turn ignites the mixture of fuel and air in the internal combustion engine system. This system plays a huge role in the vehicle’s technical equipment and electrical equipment.

We are not interested in the entire ignition system, but only in the moment the spark appears, which determines the correct operation of the entire system. This moment is called the ignition moment, because. determines the time for ignition of the working mixture in compressed form. Incorrectly set ignition timing entails many problems in the operation of the car. With the help of this article you will learn how to identify the problem, what it means and how to fix it.

VAZ-21099: under the hood

Methods for adjusting the ignition of a VAZ 2109 carburetor and injector with your own hands

Adjusting the electronic ignition on the injector

If you have an injector and find signs of early ignition, then keep in mind that all injectors are equipped with an electronic module. Accordingly, on the injector, the procedure for adjusting and setting the desired spark moment on the spark plugs is carried out by programming the control unit. To implement a scheme for adjusting the spark timing of the electronic module on the injector, you will need special software. Therefore, owners of “nines” with an injector need to contact a service station to adjust the module.

Placing marks on the VAZ 2109

Adjustment with strobe light

You can adjust the module malfunction using another scheme, using a strobe light - in this case, the adjustment process is carried out at idle speed of the engine with a carburetor. It should be noted that the crankshaft speed in this case should be from 820 to 900 rpm. Many experts consider this method the most accurate!

How to set the ignition on a VAZ 2109 carburetor using a strobe light:

- As stated above, the rpm should be no more than 900. If this parameter on the carburetor is outside the limits, it is necessary to adjust the volume of the fuel-air mixture.

- Then it is necessary to disconnect the vacuum pipe from the fitting, after which the vehicle engine is turned off. In this case, it is necessary to remove the gap in the vacuum pipe.

- If there is no clearance, the next step is to unscrew the three nuts securing the distributor-breaker device.

- Next, you need to remove the rubber plug from the gearbox housing. Behind it there is an inspection hole for the flywheel. It is also necessary to disconnect the cable for the first cylinder from the camshaft cover.

- Now the strobe light is turned on in operation - it is connected instead of the disconnected cable, as well as to the battery. When you start the engine, the device will send signals in time with the flywheel. You need to rotate the camshaft until the mark matches the one on the flywheel. When setting a mark after connecting the strobe, it must be fixed. To check the mark in accordance with the diagram, diagnose its position. If the marks on the flywheel and crankshaft coincide, this indicates that the ignition adjustment on the carburetor was successful (video author - Dmitry).

Adjusting the ignition by light bulb

If the strobe light does not turn on or you simply do not have one, then a malfunction of the switch or other element that led to the need for adjustment can be solved using a light bulb. By the way, switch malfunction is a problem for many. So, to set the spark moment on the module you will need a regular 12 volt lamp. The procedure itself consists of setting the module torque by loosening the spark regulator lock.

The procedure is carried out as follows:

- To correctly set the spark torque on an internal combustion engine module with a carburetor, using a special key, you need to turn the crankshaft until the marks match. If you don’t have such a key (you need a special key), then put the car in fourth gear and move it until these marks coincide.

- You need to connect the prepared lamp to the wire that connects the distributor to the coil. Using the second wire, you need to connect the lamp to ground.

- Now you can connect the central cable to the vehicle ground, that is, to the car body. You should loosen the fixing screws on the distributor body, and then activate the ignition - if there are no problems, the lamp will light up.

- Next, in order to correctly set the spark on the module, you should rotate the housing to the right until the lamp goes out. When the lamp goes out, start turning the distributor to the left. You only need to stop when the light comes on. Try not to move the devices anymore, just tighten the case screws. The spark adjustment circuit on the carburetor using a lamp allows you to solve the problem of adjustment yourself, and you will not need to spend money on a device. In principle, any motorist can cope with such a task (the author of the video is Nail Poroshin).

How to connect wires correctly

When replacing high-voltage conductors, they are first connected to the ignition distributor. The distributor cover is convenient in that it is always installed in one position. There is a special mark on it, thanks to which it will not be difficult to place the part in place. Before connecting the wires, inspect the cover. It must be intact, since if cracks appear, the performance of this unit is not guaranteed.

The mark on the distributor cover is located next to the wire socket of the first cylinder. The firing order of the cylinders is slightly out of order (1-3-4-2) due to the ignition slider. It moves around the circle (distributor) counterclockwise. It is precisely by this principle of movement of the slider that it is easy to remember the order of the wires. They need to be connected to carburetor and injection VAZ-2109 according to the same principle. On the distributor cover, connect the wires according to the principle of movement of the slider, this is the only way you can set the ignition correctly:

- the socket of the first cylinder is located at the mark;

- the third one is connected at the very bottom;

- on the same line with the socket of the first, there is a place for the wire to the 4th cylinder;

- at the top point the second cylinder is connected.

On the engine itself, the cylinder numbering goes from the location of the timing belt to the starter, that is, from left to right. The fourth cylinder is closest to the starter, and the first is closest to the timing belt. When connecting, it is important to look at which socket of the distributor cover the wire comes from, if you confuse their location, the car will not start.

If you have connected the wires correctly, but the car still does not start, then the problem may be in them. Check high-voltage conductors for integrity. If you haven't changed them in a while, it's worth buying a new set. The peculiarity of these wires is that over time microcracks can form on their surface. They lead to a lack of spark when the ignition distribution system is working. Moisture and dust get into these cracks, which damages the wire from the inside, although it appears intact from the outside.

Car enthusiasts recommend purchasing sets of high-voltage wires from foreign manufacturers, as they last much longer than stock or domestic ones. It is advisable to replace the spark plugs along with the wires, especially if cracks or carbon deposits appear on their surface. This is necessary so that after repair you definitely do not have problems with ignition.

Source

Verifying that the settings are correct

After we have dealt with the question of how to install the ignition on a VAZ 2109, we will consider the process of checking whether the adjustment work has been carried out correctly.

So, if configured correctly:

- during the process of rapid acceleration of the power plant (when the car is warm), there is no violation of the stability of its operation;

- When the car is moving at a speed of about 50 km/h in fourth speed and during sharp acceleration, there should be a short detonation of the engine. If there is no detonation, ignition is later; if it is present, but does not go through, it is earlier. We make the adjustment by turning the distributor in one direction or another.

Remember that it is often impossible to achieve stable operation of the power unit due to improper operation of the fuel system or even due to low quality gasoline. In this kind of situation, the best way out of it would be to set the carburetor to the most optimal operating mode and then adjust the ignition timing.

Incorrectly set ignition does not have the best effect on the operation of the engine, worsening its performance characteristics. Many car owners, as soon as the first problems with the engine appear, due to lack of experience, decide that the cause of everything is a carburetor failure. In reality, the problem often lies in incorrectly adjusted ignition timing and can be eliminated if you know how to set the ignition on a VAZ-2109 (carburetor) using a simple set of tools.

- Difficulty starting the engine;

- unstable idling and uneven operation of the power unit as a whole;

- a noticeable decrease in engine power, as well as its throttle response;

- increased fuel consumption;

- the appearance of dips in speed when accelerating the car;

- the presence of thick black smoke in the exhaust gases when starting the engine and while driving (indicates that the timing is too early and, as a result, poor fuel combustion).

Each of these signs is the reason that the engine begins to work less efficiently, and this, in turn, affects the operating comfort of the car as a whole. Therefore, we recommend that you read the guide on how to set the ignition on a VAZ-2109 car with a carburetor engine in order to apply this knowledge in practice, if necessary.

In garage conditions, even a driver who has no experience in car repairs can adjust the advance angle. To do this, you will need a 10" wrench and a strobe light or light bulb. Naturally, with the help of a strobe, setting the ignition of the VAZ-2109 (carburetor) will be more convenient and accurate, but with the help of a light bulb you can also achieve a satisfactory result. Next, we will look at how adjustment work is carried out using both options.

Preparatory activities and necessary tools

Installing the ignition of a VAZ 2109 carburetor begins with preparatory activities. In particular, you need:

- Warm up the car engine;

- Set the parking brake and install wheel chocks under the rear wheels.

Remember that you cannot ignore safety rules, because a car is a highly dangerous vehicle, and failure to comply with safety rules when driving, servicing and repairing it can cost you dearly.

An important point: before you start work, you should make sure that the carburetor is correctly configured on the car. It would not be superfluous to carry out a visual inspection of all elements of the system. If we are talking about a carburetor car, special attention should be paid to inspecting the condition of the distributor.

If you have a car with an injection engine, it is worth checking the ignition module for serviceability. The thing is that, as practice shows, it is this module that fails most often and is the reason for the inoperability of the entire system.

To complete the work we need:

- strobe;

- a set of keys.

Adjusting the ignition timing

For subsequent actions, use a 13 key to loosen the fastening nut of the distributor (ignition distributor). Connect one wire from the light bulb (it will act as a voltmeter, that is, indicate the presence of voltage) to the low-voltage terminal that the coil has, the second to ground.

Now turn on the ignition

Slowly and carefully rotate the distributor body clockwise, stopping immediately when the light goes out. The sparks that appear will indicate the moment of ignition

Move the distributor counterclockwise until the contacts are disconnected and the lamp lights up again. Everything is in order, you can safely tighten the distributor, the setup is complete.

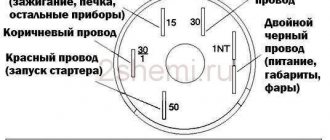

The procedure for connecting high-voltage wires to the ignition module of VAZ 21083, 21093, 21099

In order to connect previously completely removed high-voltage wires in the correct order to the ignition module (coil) of the ignition system of the injection engine (2111) of VAZ 21083, 21093, 21099 vehicles, you need to know some features.

— On the injection engine of VAZ 21083, 21093, 21099 cars, cylinder counting is carried out from the timing drive to the gearbox.

— On some types of high-voltage wires near the tips there are white rings with markings (or markings on the wires themselves).

— On the ignition module, near each terminal there is a cast number of the cylinder to which it corresponds.

Often, due to contamination and inaccessibility, it is impossible to determine which numbers are printed on the ignition module. Using the diagram below: “Ignition module of the ignition system of engine 2111 of VAZ 21083, 21093, 21099”, it is enough to simply connect the high-voltage wires from each spark plug to a specific terminal of the ignition module.

Ignition module of the engine ignition system 2111 of VAZ 21083, 21093, 21099 cars, diagram, front view

Notes and additions

— High-voltage wires running from the module to the spark plugs are of different lengths: the longest for the spark plug of the first cylinder, then in descending order.

— When replacing high-voltage wires, you should change them one at a time so as not to confuse the leads.

Source

Distributor in a contactless ignition system

The contact ignition system, which is installed on the antediluvian classic VAZ models, is an example of Italian reliability, stability and maintainability. This system (not the ignition system in principle, namely the VAZ one) was developed by the Fiat concern in 1963 and remained practically unchanged throughout the entire era of the reign of the classic Lada, right up to the moment when the last VAZ 2107 was rolled out of the gates of the Izhevsk plant. the last seven already had a contactless ignition system; it did not undergo any significant changes.

On cars of the Samara family - 2108, 2109, 2114, the ignition system is contactless. What does this mean and what are the differences between it and the contact system? Here they are:

- there is no contact group in the VAZ 2109 distributor;

- the operation of the contactless ignition system is controlled electronically, and not by single-cell electromagnetic relays;

- adjustment of the ignition timing is carried out using other methods;

- The VAZ 2109 contactless distributor is more compact than classic VAZ distributors.

The operating principle of the ignition system and its main tasks have not changed with the use of a contactless system. It has become easier to maintain and has become less dependent on mechanical wear of the contact group, but more on the quality of electronic semiconductor components. Electronic control units of old 2109 require mandatory testing before purchase, since the quality of domestic radio components may not always be stable.

Purpose of distributor VAZ 2109

In any ignition system, contactless or contact, there are two circuits - high voltage and low voltage. The distributor, the ignition distributor, is exactly the device that deals with both high-voltage and low-voltage wiring. Its main task is to distribute high voltage between the spark plugs at the right moment and in a certain order.

The distributor works as follows: High-voltage voltage is generated in the ignition coil by electromagnetic induction. It is supplied via a high-voltage wire to the central contact of the distributor cap. The contact is in constant interaction with the slider, which distributes the current across four contacts corresponding to the spark plug in the cylinder. The slider is in constant rotation and alternately closes the central contact with the spark plug contacts. Current is supplied to the spark plugs through high voltage wires in the order determined by the order of operation of the cylinders - 1-3-4-2. The slider is driven by a drive shaft, which is connected to the camshaft.

Operation of the hall sensor and centrifugal mechanism

The VAZ 2109 distributor device allows you to adjust the ignition timing while the engine is running. This is achieved through a centrifugal device, which is capable of moving the slider with a sharp increase in the number of revolutions. The design of the centrifugal mechanism is similar to those installed on distributors with a contact ignition system.

The VAZ 2109 distributor also has a vacuum corrector. It works as follows: when a vacuum is created in the intake manifold, to which the corrector is connected, the vacuum is transmitted through a tube to a chamber with a rubber diaphragm. The diaphragm is connected to a rod, which is hinged to the plate on which the hall sensor is located. It was this sensor that replaced the contact group in the distributor and made the ignition system more stable. Together with the plate, the sensor can move, adjusting the ignition timing, increasing or decreasing the angle, depending on the intensity of the set of revolutions and the vacuum in the manifold.

Malfunctions in the distributor

Since the 2109 distributor has a minimum of mechanical parts, it is not as susceptible to wear as a distributor with a contact group. However, they exist and you need to be prepared for them.

- The hole for ventilation and pressure compensation on the distributor shank often gets clogged. This leads to the fact that crater gases, having no other outlet, break through the distributor shaft seal and oil the slider.

- Breakdowns to ground occur in the distributor cap due to microcracks.

- Due to poor quality elements, the hall sensor fails;

- The distributor shaft bearing becomes loose.

All these troubles can be solved quite simply, if you don’t mind the time, everything can be eliminated with your own hands. The VAZ 2109 distributor, the price of which is not much more than 1000 rubles, is, in principle, a consumable unit, so making a decision to repair it may be unprofitable in terms of time spent. I wish you the right spark distribution, and good luck on the roads.

Terminology

Ignition distributor

- an electromechanical device that ensures timely supply of high voltage pulses to the spark plugs.

It is often called a distributor

.

Ignition advance

- ignition of the working mixture in the cylinder before the compression stroke ends.

Ignition timing (IDA)

— the angle of rotation of the engine crankshaft from the position corresponding to the appearance of a spark on the spark plug until the piston reaches top dead center.

Contact ignition system

- a system in which switching of the ignition coil is provided by a mechanical interrupter.

Contactless ignition system

- a system in which switching of the ignition coil is provided by an electronic module controlled by an electronic crankshaft position sensor - for example, a Hall sensor (VAZ-2108) or magnetoelectric (GAZ-2410).

Breaker

ignition system - a mechanical switch in the distributor, directly connected to the primary circuit of the ignition coil.

Runner

- a distributor element that alternately transmits high voltage from the ignition coil to high-voltage wires connected to the engine spark plugs.

Angle of closed state of contacts (UZSK)

- a value indicating how long the contacts of a mechanical breaker should remain closed. For classic Zhiguli cars, the UZSK is approximately 55 degrees. A correctly selected UZSK gives the ignition coil the opportunity to gain the necessary energy and completely transfer it to the spark plugs.