Replacing the clutch disc on a VAZ-2104-2107

The clutch is the most important component of a car, without which it is impossible to imagine the operation of the gearbox mechanism, as well as the car’s performance of such operations as starting and braking to a final stop. In other words, the clutch is a necessary mechanism of any car, which is a kind of transfer point between the engine and the drive axles. This unit includes:

- driven clutch disc;

- clutch basket and release bearing with clutch.

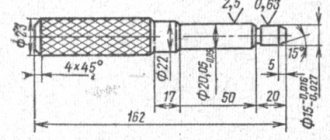

So what is this component of the clutch mechanism? This is a disc with spring plates and friction linings that are not connected to each other and are made of a material comparable to the material of the brake pads, i.e. abrasion resistant. In the center of the disk there is a hub with a splined connection.

Malfunctions

As a result of vehicle operation, the clutch disc, like any consumable material, can become unusable - the springs weaken, the friction linings wear out and become thinner. Manufacturers do not indicate a specific service life of the disk, because it depends only on the driver: one “clutch” can last only 5,000 km, while another can last 100,000. Increased clutch wear can result from:

- sudden starting at high speeds;

- slip;

- incorrect adjustment;

- participation in racing events;

- leakage of foreign liquids.

Usually there are two faults for which it is worth considering repairs:

- the clutch “slips”;

- the clutch “drives”.

When slipping, the driven disk is not pressed completely against the flywheel. What does this mean? If you sharply press the gas pedal while the car is moving, you may notice an increase in engine speed, but there will be no increase in speed. In the end, the car will someday just stand up and only towing or muscle power can set it in motion. Therefore, the issue of replacing the driven disk should not be shelved.

When the clutch “drives”, uncharacteristic sounds and noises are observed when changing gears, gears are difficult to engage. In this case, the driven disk, on the contrary, does not completely “separate” from the flywheel. In this case, pumping the hydraulics and adjusting the free play of the clutch helps, which can be easily done by anyone in a garage. If you ignore this malfunction, you can run into expensive gearbox repairs.

Clutch kit price

Now, in the era of the development of the Internet, there is no need to run to stores and look for the necessary spare part. It is enough to have access to the World Wide Web and you will have any detail in a couple of clicks. Prices for clutch discs for the VAZ-2107 vary from 470 to 2000 rubles. The cost of replacement work in Moscow and the Moscow region is 2–2.5 thousand rubles.

What advice can you give when choosing a disk? First, rummage through the forums and read reviews. Secondly, when purchasing a disc, do not be lazy to inspect it. Examine the splines especially carefully - there should be no nicks or burrs there, otherwise there is a risk that the disk simply will not fit on the shaft or will not be removed during the next replacement.

Take a look at the friction linings: they should all be uniform in composition and free of cracks. Another point is the quality of the riveting. The key to quality here is the identical dimensions of the flange. Try to swing the damper springs; if there is play, then you should refuse the purchase. And the last thing worth paying attention to is the presence of markings on the damper plate.

Typical clutch faults

Often, a basket malfunction is a curvature or breakage of its petals, or loss of elasticity of the pressure springs. In some cases, the basket can be repaired. The VAZ 2107 clutch disc requires repair or replacement if it is deformed, worn, broken or significantly scuffed the friction linings, weakened or broken damper springs. A failed release bearing is replaced with a new one; it cannot be repaired.

Associated malfunctions that can be detected during repair or replacement of the clutch are oil leakage through the crankshaft seal or gearbox input shaft, wear of the drive fork or clutch slave cylinder. Oil leakage through the seals causes oiling of the driven disk, which can cause it to slip. Signs that the VAZ 2107 clutch is slipping are a decrease in traction and dynamics during acceleration, as well as the appearance of a specific smell.

Replacement

So, having purchased a new clutch disc, we proceed to install it. In order to slightly reduce the labor intensity, we will perform the replacement without removing the box. We carry out the work on an overpass or inspection pit.

Getting started with labor feats, we will carry out the preparatory stage:

- Disconnect the negative terminal of the battery.

- Remove the clutch slave cylinder.

- We unhook the cardan from the gearbox.

- Unscrew the speedometer cable.

- Disconnect the wires of the reversing lights from the contact group on the gearbox.

- We disconnect the clutch housing from the cylinder block and the cross member of the rear engine mount from the body.

Now we move directly to the main stage of our work - replacing the clutch disc:

- We unscrew the nuts securing the gearbox support, move it back so that the gearshift lever rests against the back of the floor hole. The front part of the box will be held by the muffler, and a reliable support must be placed under the rear part.

- Holding the flywheel with a mounting tool, unscrew the clutch housing mounting bolts, turning the crankshaft to gain access to them.

- We move the clutch basket and remove the used driven disc, replacing it with a new one. Before installation, wipe the new disk and flywheel with a rag soaked in gasoline.

- The installed disk must be adjusted relative to the center of the bearing at the end of the crankshaft.

We carry out further assembly in the reverse order, not forgetting to adjust the free play of the clutch pedal afterwards.

With simple manipulations, you can make the replacement yourself and save some money from visiting a service station. The main thing is not to miss the moment when the disk fails. No nail, no rod!

Source

Clutch installation

After repairing or replacing the clutch, installation is carried out as follows:

- We lightly lubricate the gearbox input shaft, as well as the ball joint of the fork, with CV joint-4.

- We apply the driven disk to the flywheel with the side with the smaller protrusion, and to the basket with the larger one.

- In the center of the disk we insert a mandrel that fits into the inner race of the crankshaft bearing and will hold the hub.

- We mount the basket on the flywheel, placing the centering holes of the casing on the flywheel pins.

- Tighten the fasteners with a torque of 19.1–30.9 Nm. After tightening, the mandrel should come out of the mechanism freely.

- We install the gearbox in the reverse order of dismantling, after which we carry out the adjustment.

Replacing the clutch disc on a VAZ-2104-2107

The clutch is the most important component of a car, without which it is impossible to imagine the operation of the gearbox mechanism, as well as the car’s performance of such operations as starting and braking to a final stop.

In other words, the clutch is a necessary mechanism of any car, which is a kind of transfer point between the engine and the drive axles. This unit includes:

- driven clutch disc;

- clutch basket and release bearing with clutch.

So what is this component of the clutch mechanism? This is a disc with spring plates and friction linings that are not connected to each other and are made of a material comparable to the material of the brake pads, i.e. abrasion resistant. In the center of the disk there is a hub with a splined connection.

Malfunctions

As a result of vehicle operation, the clutch disc, like any consumable material, can become unusable - the springs weaken, the friction linings wear out and become thinner. Manufacturers do not indicate a specific service life of the disk, because it depends only on the driver: one “clutch” can last only 5,000 km, while another can last 100,000. Increased clutch wear can result from:

- sudden starting at high speeds;

- slip;

- incorrect adjustment;

- participation in racing events;

- leakage of foreign liquids.

Usually there are two faults for which it is worth considering repairs:

- the clutch “slips”;

- the clutch “drives”.

When slipping, the driven disk is not pressed completely against the flywheel. What does this mean? If you sharply press the gas pedal while the car is moving, you may notice an increase in engine speed, but there will be no increase in speed. In the end, the car will someday just stand up and only towing or muscle power can set it in motion. Therefore, the issue of replacing the driven disk should not be shelved.

When the clutch “drives”, uncharacteristic sounds and noises are observed when changing gears, gears are difficult to engage. In this case, the driven disk, on the contrary, does not completely “separate” from the flywheel. In this case, pumping the hydraulics and adjusting the free play of the clutch helps, which can be easily done by anyone in a garage. If you ignore this malfunction, you can run into expensive gearbox repairs.

Clutch kit price

Now, in the era of the development of the Internet, there is no need to run to stores and look for the necessary spare part. It is enough to have access to the World Wide Web and you will have any detail in a couple of clicks. Prices for clutch discs for the VAZ-2107 vary from 470 to 2000 rubles. The cost of replacement work in Moscow and the Moscow region is 2–2.5 thousand rubles.

What advice can you give when choosing a disk? First, rummage through the forums and read reviews. Secondly, when purchasing a disc, do not be lazy to inspect it. Examine the splines especially carefully - there should be no nicks or burrs there, otherwise there is a risk that the disk simply will not fit on the shaft or will not be removed during the next replacement.

Replacing the VAZ 2107 clutch with your own hands is easy and simple

If the car starts to slip under load, most likely the problem is in the clutch. It is dangerous to move with a faulty unit, so it should be changed as quickly as possible. The article provides detailed instructions on how to replace a VAZ 2107 clutch, which device to choose, and also includes a video demonstrating the process.

When is it necessary to change?

The clutch system allows the car to move off smoothly, removing the load from the engine, which reduces wear on its parts and extends its service life. Overloads are caused by an inertial moment formed during the rotation of parts of the power unit if the crankshaft speed has sharply decreased.

VAZ 2107 assembly diagram

There is no specific time frame for replacing the unit, since the service life of this device mainly depends on operating conditions and the driver’s driving style. It is recommended to diagnose the device after 80 thousand km.

Symptoms of a problem

The need to repair the clutch assembly is determined by the following criteria:

- extraneous noise occurs when changing speeds;

- the device slips, especially under load;

- the clutch does not disengage completely;

- rattling;

- jerking when starting to move;

- The clutch pedal falls out.

If the described signs appear, it is better not to delay repairs in order to avoid unpleasant surprises along the way.

This video shows the process of replacing a unit on a VAZ classic.

Causes of VAZ 2107 clutch failure

Driven and driven discs are subject to the greatest wear.

Clutch failure can be caused by the following reasons:

- wear, oiling, defects on the surface of friction linings;

- too large gaps or lack thereof in the clutch release drive;

- air entering the hydraulic drive system;

- fluid leakage from the master cylinder and hydraulic drive system;

- loosening rivets;

- disc deformation;

- jamming, wear of the driven disk hub splines, clutch drive mechanism;

- bearing wear;

- malfunction of the driven disc damper springs;

- breakdown of the release fork or its release spring;

- wear of the sealing rings, which impairs the seal.

To eliminate these problems, in each individual case you need to change worn parts; it is better to replace the clutch system assembly.

Visual inspection of the disk

What's the best way to change?

It is best to replace the device by placing the car on a lift, overpass or inspection groove. If this is not possible, then you can raise the car using a jack to get to the unit from below. For safety, you need to fix the wheels so that the car does not roll or put on the hand brake.

Tools

To carry out repairs, you need to prepare the appropriate tools:

- set of keys;

- screwdrivers;

- pliers;

- clean rags;

- jack;

- new consumables.

When choosing a new replacement kit, you need to buy original parts, preferably assembled.

Stages

The replacement procedure consists of the following steps:

- Having opened the hood, first of all you need to turn off the power to the car. To do this, you need to remove the negative terminal from the battery.

Engine compartment of VAZ 2107

- Then you need to dismantle the air filter housing and unscrew the starter mounting nuts.

- Next in the cabin, you should remove the covers from the gearshift knob, floor mats and sound insulation. Then the gearshift lever must be disconnected from the gearbox. To do this, you need to press on it and use a screwdriver to pull out the white plastic sleeve.

- To perform further repairs, you need to move under the car.

- When removing parts, you should carefully inspect them for wear and defects. Change them if necessary.

- At the next stage, we disconnect the exhaust pipe, the working cylinder, the universal joint, from which the wires should be disconnected.

- Then we dismantle the starter, which we unscrewed, and remove the gearbox. The gearbox could simply be moved to the side, but it is better to remove it to check the condition of the oil seal. If necessary, the oil seal should be replaced. It is better to remove the gearbox with an assistant, as this is a labor-intensive process. It is advisable to wash the gearbox after removal.

- Next, you can remove the basket and clutch disc. In this case, you need to remember how the disk was installed in order to install it correctly when reassembling.

Removing disks from a node - Now you can evaluate the state of the components of the node. The anthers and driven disk are subject to the most wear. The master cylinder and clutch fork should be replaced.

- You can only change worn parts, or you can change the entire assembly. It is advisable to replace the clutch assembly, since, having replaced the old parts, there is no guarantee that after a short period of time you will not have to reassemble and disassemble to replace broken parts.

Installing a new drive - Further assembly is carried out in the same order as disassembly.

After the repair is completed, the vehicle system should be checked for functionality.

Cost of clutch assembly

As mentioned above, it is better to change the clutch assembly. The question arises, which device is better.

We can offer four options for assembled units with approximate costs:

- Sachs – 4200 rub.;

- VazInterService (VIS) – from 2400 rubles;

- Valeo – 4200 rub.;

- KraftTech – from 2400 rub.

How to replace the release bearing on a Lada Kalina with your own hands

The Lada Kalina car gained well-deserved popularity among the people, which only strengthened over time, because this car showed truly high performance characteristics with minimal maintenance costs.

In the process of replacing the clutch

Replacing the clutch on a Lada Kalina yourself is quite difficult, although it is doable. Below, in our article, we will describe in detail how to carry out such work from beginning to end without making mistakes.

Two different types of clutch are installed on VAZ 1117, 1118 and 1119 cars: 190 and 220 millimeters

Determining your diameter is very simple, just pay attention to the number of starter mounting bolts. At 190 mm there are 3 of them, and at 200 mm there are 2 of them

Regardless of the manufacturer, you will almost always find the clutch disc, basket and release bearing in the assembly.

It is no secret that clutch replacement work involves dismantling the gearbox, therefore, it is necessary to take care in advance of the presence of an inspection hole or overpass. We will also need the following tools and materials:

- New clutch kit.

- Set with tools.

- Hex key.

- Jack.

- Rags.

- Screwdriver.

- Container for draining oil.

- New gear oil (if necessary).

- Lamp for illuminating hard-to-reach places.

The first step is to carry out work under the hood of the car.

- Disconnect the power and negative cables from the battery and then remove it.

- Then we remove the air filter housing along with the corrugation.

- Remove all wires from the starter.

- We dismantle all the wires coming from the gearbox and the power unit.

Let's move on to working under the car

- If there is crankcase protection, unscrew all the bolts and remove it.

We remove the gearbox and move on to working with the clutch.

- First of all, we need to unscrew the release disk housing, which is attached to the flywheel with 6 bolts. When performing this work, the flywheel must not be allowed to rotate and must be held in place with a pre-prepared screwdriver. Unscrew the bolts slowly, one at a time, allowing one turn per circle for each bolt.

Unscrew 2 bolts on three sides

Remove the basket and driven disk

The driven disc is covered in oil - one of the reasons why the clutch does not work well

Development on the “petals” of the basket

Attention!

In order to avoid new clutch problems, you should follow these simple rules:

- Press the clutch pedal smoothly, but release it more sharply, but without throwing it.

- When parking on an incline, it is better to release the clutch pedal and engage the handbrake (handbrake - approx.). The handbrake must be adjusted and keep the machine on the slope.

- Shift gears as quickly as possible, avoiding “throwing” of the gearbox.

- In the cold season, when many people press the clutch pedal to make it easier to start the engine, the clutch experiences increased load. The clutch system does not suffer wear only when the oil warms up.

- While driving, do not keep your foot on the clutch pedal, but slightly further away from it.

Replacing the VAZ 2107 clutch disc.

Good afternoon, visitors to my site. This article will discuss replacing the clutch disc on VAZ models such as 2101-2107. On classic VAZ models, the clutch is almost the same, which means the method for replacing it is also the same.

I will try to explain everything in detail and show it in photographs. I made this replacement on a VAZ 2105 car.

And so, let's look at the methods and specific order of replacing the clutch disc. In life, almost every motorist has encountered such a mechanism as a clutch. There can be many reasons, the study and understanding of the operation of this mechanism or, as in most cases, it is repair and maintenance. There are two ways to replace the clutch disc: remove the engine from the car and calmly carry out repairs, or use the inspection pit and replace the disc by removing the gearbox. The first method requires the use of special devices, for example, such as a small lifting device, to remove the engine from the engine compartment; you will also need to drain the coolant and disconnect the pipes from the radiator, and this makes many motorists nervous. Therefore, I think the second method will suit us better, and it will be discussed in our article. I once saw how the clutch disc of a VAZ 2107 was replaced without removing the gearbox; it was simply moved back a little so that the input shaft came out, and the disc was replaced. I will say on my own behalf that this is such a hemorrhoid that it is better to remove the gearbox.

Replacing the clutch on a VAZ 2107 car

Any VAZ 2107 car owner, when driving his car, must be sure that it is in full working order. Problems with such an important mechanism as the clutch will primarily affect the quality of the braking system. That is why if you notice that the gears suddenly begin to shift with force, immediately check the condition of the clutch. If necessary, it must be urgently replaced.

Preparatory work

In order to replace the clutch on a VAZ 2107, you will need access to the gearbox and engine from below, so you need to use a special lift or a so-called inspection hole. Before starting work, be sure to remove the negative terminal from the battery and you can proceed.

First remove the air filter and unscrew the starter.

Now we can work on the gearbox on the VAZ 2107. We will need to dismantle its lever. We will not remove the box itself. Press it with a screwdriver and pull out the locking sleeve located in the groove of the lever rod. You can take it out, unscrew the bolts and dismantle the front floor.

Clutch replacement rules

Let's move on to work “under” the car.

Disconnect the driveshaft and axle gearbox. But before that, we advise you to perform one tricky trick. Draw marks on the flange of each part with a marker so that you can later install them exactly in the position in which they were.

Unscrew the nuts securing the safety bracket, as well as the receiving pipe from the gearbox. There is no need to disconnect the cardan from it, because we will not remove the box.

Unscrew the nuts that secure the box to the bottom of the car. A part such as the cross member of the rear support will also have to be removed.

Disconnect the wiring from the reverse light sensor.

Dismantle the tension spring of the fork, which is responsible for disengaging the clutch, disconnect the two bolts from the working cylinder that releases the clutch.

Unscrew then remove the clutch pan. Now all that remains is to remove the four bolts securing the crankcase.

Using a pry bar, move the box as far back as possible. That way she won't bother you.

In the place where the box was located, there is a distance that will allow you to reach the clutch basket and disc. It is connected to the flywheel with six bolts.

Unscrew them and you can easily remove the clutch along with the release bearing located on the transmission input shaft.

Pull out the basket and pressure plate and inspect them. If they are in good condition, then there is no need to change them.

The necessary elements must be replaced, which may even include both disks, and reassembled.

Before you begin assembly, we recommend lubricating the splines of the gearbox input shaft and polishing the clutch disc with a simple rag.

On a VAZ 2107, the location of the clutch disc to the crankshaft bearing must be adjusted. This should be done using a special mandrel. It can be found at any auto store. If you do everything correctly, the mandrel will freely come out of the bearing and move back.

Thus, you have independently replaced the clutch, which will allow you to be confident in the reliable operation of your car.

Lada 2107 LADA 2107 › Logbook › No. 18 “Replacing the clutch”

Good day everyone!) It's time to replace the clutch. The clutch was worn out and slipped under load. I previously replaced the clutch disc. This disc lasted less than 30,000 km. (27,540 km) It was decided to change this assembly (clutch disc, clutch basket, release bearing) among the manufacturers ( thank you very much to my subscribers for the advice!

), I settled on (Poland). Good quality parts, included: clutch disc, clutch basket, release bearing, basket mounting bolts with lock washers, guide bushing. The seller gave a guarantee of the quality of the parts. Also, at the same time, I purchased a new clutch fork (), a new gearbox boot, a new fork stopper (apple).

Having disassembled the car, removing the gearbox and clutch basket with disc, I saw a scorched disc and minor wear on the plane of the basket (I didn’t take pictures). Next I examined the surface of the flywheel. There was also wear on the surface of the flywheel. The wear was not critical (half a millimeter), considering that the flywheel is factory and has traveled more than 140,000 km. It was possible to leave everything like that, but it was decided to replace mine and the flywheel, so as not to look at this unit for a longer time. I bought a new flywheel.

In the process of replacing the flywheel, I was helped by the recommendations of a book on repairing a VAZ-2107 car and a video by Roman Romanov

The flywheel is installed. Clutch parts were replaced. I installed a clutch disc with a basket, a release bearing, a clutch fork, and a new gearbox boot. I did not change the clutch fork stopper (apple) because it was not available at the factory. All seats are lubricated with grease (green)

In the process of reinstalling the gearbox on the car, my dear friend ImMihalk came to my aid, for which I have my sincere and huge gratitude to him!

The process of installing the gearbox was difficult for a long time due to inaccurate alignment of the clutch driven disc, although the kit included a guide bushing.

Setting it up many times, we were unable to install the gearbox into the seat. (Last time, when changing the driven disk, I used a guide sleeve carved from a wooden block and installed the gearbox without problems). Perhaps everything was caused by the fact that we worked on a Great Orthodox holiday, on which it is forbidden to work. But this was due to necessity, I needed a car for the evening, and my Moskvich 2140

also suffered from a malfunction and is currently not drivable. My friend Sergei, a service station employee at my GSK, came to our aid and provided us with a section of the input shaft of a VAZ car. Having accurately centered the clutch disc with the input shaft (blank), we still managed to install the gearbox and assemble the car) I am very pleased with the result of the work! The clutch works smoothly and clearly) We’ll see how long it lasts during operation)

Clutch replacement and repair

Our company carries out clutch replacement in Krasnoyarsk at a professional level. Modern tools and diagnostic methods are used to accurately determine the nature of the malfunction.

| Repair | Foreign cars, rub. | VAZ, rub. |

| Clutch replacement | from 3500 | from 1500 |

| Replacing the release bearing | from 3500 | from 2000 |

| Replacing the clutch cylinder | from 550 | from 450 |

| Replacing the clutch cable with adjustment | from 500 | from 500 |

| Replacing clutch brake fluid | from 650 | from 550 |

| Replacing the clutch fork | from 3000 | from 2000 |

| Bleeding the clutch | from 250 | from 150 |

Finding and eliminating defects during clutch repairs

If such defects are observed, then you need to contact the service to carry out diagnostics to identify the following malfunctions:

If a disc distortion with the threat of partial or total destruction is detected, then another unit is installed and the units are debugged. Very often you have to replace the clutch cylinder.

It is possible to replace the entire clutch kit, which includes the following components:

Our experts recommend installing the rear oil seal of the engine crankshaft at the same time as installing the new system. The entire process of replacing a clutch in Krasnoyarsk does not take very much time.

Symptoms of malfunction

There are several main defects that indicate the need to contact Service Motors:

- slippage – lack of disk clamping, which causes slipping during the torque process;

- driving – complete relaxation of the disk by the basket is not ensured, preventing gear shifting;

- breakdown of the release bearing - characterized by a high noise level and the ability to switch.

Clutch replacement

When a new system is installed, activities are carried out in a strictly defined sequence:

- dismantling elements in the cabin - the box handle, center console are removed, wires, thermal insulation, air duct and pistons are disconnected. The plate is disassembled, the cover is unscrewed and the switching mechanism is eliminated;

- dismantling components under the car body - the cylinder fastenings are disconnected, the cardan is unscrewed, the muffler fastenings and the transfer mechanism with the crankcase are unscrewed;

- elimination of the cross member with the transfer case;

- Troubleshooting and replacement of the set or individual elements is carried out. In particular, the clutch disc is being replaced.

Call the manager of our company from whom you can find out the estimated price for replacing the clutch and place an order, indicating the time of arrival. Our specialists will quickly replace the clutch in Krasnoyarsk on any car.

Replacing the VAZ 2107 clutch

If the car begins to slip under load, noises are heard when switching gears, rattling appears, the movement begins jerkily or the pedal falls, the VAZ 2107 clutch needs to be replaced. It is more effective and easier to install a new assembly. But if you have practical knowledge and skills, you can repair individual parts and devices yourself. To understand how to fix it, you need to study the design of the unit.

Required spare parts

Depending on the type of repair - replacement of the VAZ 2107 clutch master cylinder, release bearing or the entire assembly, you will need the following spare parts:

- disk (article Y00200B or 2101-1601130);

- cylinder (article 2101-1602610-15);

- release bearing (article CT 319);

- spring (article - 2108-1601-188);

- bolt (article 13825821);

- clutch (article 2101-1600010, 3000240001 or 2103-1601085);

- rivet (article - 2108-1601-295);

- friction lining (article: 2109-1601-138-02 or 2109-1601-138);

- coupling assembly (article - 2110-1601-180).

Tools you will need for your work

It is advisable to immediately prepare all the necessary tools so as not to be distracted from the process:

- jack;

- set of keys;

- pliers;

- hub key;

- screwdrivers;

- mandrel for removing the basket;

- set of heads;

- rags.

The running time depends on what you decide to do. Usually it is about 4 hours. Beginner takes longer. But the efforts will not be in vain, since in car services the usual price for replacing a VAZ 2107 clutch as of December 15, 2018 is 3 thousand rubles.

Order of Operations

For ease of operation, the machine must be placed on a lift, on an inspection hole or on an overpass. If such equipment is not available, you need to jack up the car. To be on the safe side, two. Don't forget about safety and lock the wheels, you can use the hand brake.

Next, we perform the following steps sequentially:

- We de-energize the car by disconnecting the batteries with the minus terminals.

- Disconnect the speedometer cable from the gearbox, disconnect the clutch cable, and turn off the drive. Experts believe that it is necessary to dismantle the gearbox; this will make it easier to change oil seals, repair the crankcase, and replace the VAZ 2107 clutch slave cylinder. The gearbox has significant weight, and you will need an assistant to remove it.

- You need to loosen the starter fasteners; to do this, remove the air filter housing and the starter nuts.

- In the cabin, we completely free access to the gearshift knob, disconnect the knob from the gearbox, to do this you need to pry it off and remove the bushing.

If a leak is detected, repair of the VAZ 2107 clutch master cylinder is required, mainly it consists of replacing the rubber seals. This is a very difficult job that requires skills and experience.

We install the basket on the flywheel and perform assembly in the reverse order.

Watch the VAZ 2107 clutch repair yourself in the video

:

Let's summarize

Practice shows that to replace the VAZ 2107 clutch cylinder, you can successfully use not only the original, but also its analogues (article 2101-1602615-17, MB01-1602610, A11.1602610, S1939 S3.1). The work often uses French spare parts from the Valeo brand, and German brands Luk, Kraft and Sachs. It is important that your efforts will be justified in any case, since you should not hit the road with a faulty car, and the price of urgently replacing a VAZ 2107 clutch at a car service reaches 5 thousand rubles.

Instructions for dismantling the starter on a VAZ 2107

Disconnecting the battery

- The first step is to de-energize the machine's electrical network by disconnecting the battery.

- Next, you should remove the mudguard, which will be present if the “seven” has an injection-type engine installed.

- The fastening bolt, located at the bottom of the starter shield, is unscrewed using a socket wrench (the throat size of which is 10 mm) with an extension.

Unscrew the nuts

- At the next stage, the three mounting bolts securing the starter with the clutch housing are unscrewed. To do this, use a 13mm socket wrench.

- If the car is equipped with a carburetor-type engine, then the air duct and air filter must be dismantled. If the engine is of an injection type, then the intake manifold extensions must be removed.

Removing the starter

- Using a 13mm socket wrench, the fastening nut located on the starter shield is unscrewed, after which the shield itself is pulled out.

- At the final stage, you should unscrew the fastening nut connecting the electrical wires of the starter and the battery, after which you can remove the starter.

Installation of the starter is carried out strictly in the reverse order.