For the normal operation of the chassis and the entire vehicle, high-quality shock absorber struts are required. If you have a need to replace such a unit, then you will be faced with a fairly significant problem: the modern market is simply overflowing with similar components for vehicles, so it will be quite difficult for an inexperienced car owner to make the final choice. We’ll talk now about how to select rear and front shock absorber struts.

What is such an element?

First of all, it should be said that car struts are one of the most important suspension components, which includes such elements as:

- shock absorber;

- bumpers;

- supports;

- spring;

- silent blocks, etc.

If the racks break, the chassis will not be able to work normally. At the same time, natural wear and tear, mechanical damage, aggressive driving, etc. lead to failure of the element.

Naturally, it is best to take original racks from an official dealer - this will ensure stable functioning of the chassis. On the other hand, some car enthusiasts want to change the parameters of their car. It is for such a case that our article is intended.

Why you can't ignore problems with racks. Counting money

Due to a faulty shock absorber or worn struts, the contact of the wheels with the road surface worsens, which negatively affects stability and controllability. This is especially noticeable during sharp maneuvers at speed. Unpredictable vehicle behavior increases the risk of an accident.

Those for whom this sounds unconvincing should look at the problem from a financial point of view.

As the struts wear out, all vibrations begin to be transmitted to the body, the load on the chassis components, as well as steering parts, increases, contributing to their accelerated wear. Brake pads and discs may be damaged.

A faulty shock absorber, even with a slight imbalance of the wheels, leads to intense and uneven wear of the tires, greatly reducing their service life.

It is not difficult to calculate and make sure that timely replacement of worn-out racks will allow you to avoid more serious expenses in the future.

Shock absorbers

The most important element of the racks, which most often needs to be replaced. The service life of such a device can reach 120-150 thousand kilometers, but everything greatly depends on the quality of the road surface, the general condition of the suspension and driving style.

Shock absorbers are divided into three types:

- oil Oil is used as the working fluid. The most budget option. Very effective, but the handling of a car with such devices will not be the most effective. On the other hand, they completely cope with their task in case of leisurely driving. And the comfort indicators here are simply excellent;

- gas-oil. Additionally, they run out of gas. The cost of such products is, on average, 30 percent more expensive. At the same time, they are characterized by increased efficiency, especially when driving on roads with slight transverse irregularities. This is especially noticeable when cornering and when driving fast. True, the comfort indicators here are not the highest;

- gas. They are characterized by increased rigidity, which allows you to effectively drive through any unevenness. Comfort in them is the lowest.

The first option is intended for daily use. They are the perfect complement to family vehicles and compact cars. But gas-oil ones are well suited for tuning a vehicle.

Shock absorbers that run entirely on gas are the worst in terms of comfort. At the same time, the handling here is simply excellent. No rolls are dangerous for a vehicle with such shock absorbers.

When choosing rear and front shock absorber struts for yourself, it is worth remembering that some models may have remote reservoirs, thanks to which the energy capacity of the equipment increases, which maintains the stability of the car in any situation.

Such devices are most often installed on SUVs and SUVs, as well as any other cars that are often driven on poor road surfaces.

Models with magnetorheological fluid also perform well. With its help, the shock absorber settings change while driving. True, their cost is very high, so you can only see such racks on premium vehicles.

You may also be interested in: Replacing the clutch in a car with a DSG robot

Rack arrangement

The part connects the wheels of the car to the frame and body. And it transmits the driving moment and direction to the structure of the car.

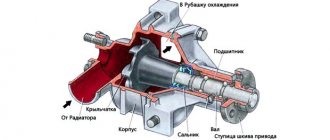

Car racks consist of the following elements:

- A hollow cylinder with a piston inside. Filled with material with a low compression ratio.

- A hydraulic mixture that transmits force to the piston. May consist of liquids and gases.

- A push rod connected to the car body.

- The piston, which is located in the cylinder, is equipped with a valve and fits tightly to the walls.

- Sealing seals and seals to prevent liquid leakage.

- A housing that combines all parts into a single structure

- Connecting elements for mounting the device.

Car struts are needed for smooth movement on uneven roads. This design improves the vehicle's traction and maneuverability on dry asphalt and unpaved surfaces. Hydraulic fluid or gases reduce the amplitude of vibrations during sudden shocks. The stiffness of the car's suspension depends on the type of working mixture.

Springs

The second most important element of the racks. As a rule, the coils on classic springs have the same thickness. As a result, a very good level of comfort is provided while driving, in addition, this design feature allows you to neutralize strong shocks when driving on bad roads.

At the same time, springs with identical coils do not always lead to proper vehicle stability - often in this case, when turning and braking, the car begins to roll to one side.

Reinforced springs look more preferable here (they can be identified by the Heavy Duty or HD markings).

For production, high-strength metal alloys are used, while the coils are characterized by increased thickness, due to which the reliability of the elements increases. As a rule, such models are installed on SUVs, as well as other cars that are used in harsh conditions.

There are also models in which the thickness increases towards the center, while the diameter at the edges is relatively small.

Such a solution leads to an optimal balance between the comfort of people in the cabin, as well as the vehicle’s handling characteristics. At the moment, this option is the most popular for cars in the mid-price range.

In addition, other elements may be used instead of a spring, including:

- cylinders;

- springs;

- torsion bars, etc.

At the same time, here we are talking about a special suspension, and not about a stand assembly, since the elements are installed separately.

What types of MacPherson suspensions are there?

This scheme is used primarily in the front suspension of front-wheel drive cars. I would like to note that the classic type is considered to be a shock-absorbing strut with one lower wishbone.

The lower lever itself can consist of two levers or one massive “burdock”. There are designs where the anti-roll bar is attached to the lever. This design does not have a stabilizer link, which simplifies maintenance.

On more expensive car models, MacPherson strut suspension can be installed in the rear chassis. This improves the car's handling in corners and sharp turns at high speed. In this case, additional levers can be added to the circuit. Usually there are up to three of them: two transverse and one longitudinal.

Kayaba

The Japanese manufacturer supplies our market with very high-quality spare parts for the chassis, and their cost is very low. The assortment is large.

Shock absorbers are available in gas, oil and combined types. The main advantage is the durability of such devices, as well as their full compliance with the declared parameters.

The disadvantage comes down to the presence of a huge number of fakes of this brand on the market. Therefore, you should be very careful when choosing products with the KYB logo. It is best to make purchases in specialized auto stores with a good reputation.

Which shock absorber struts have the highest PR rating?

When choosing among analogues of a given spare part, buyers want to know which manufacturers are recommended by car owners. In January 2022, the TOP 5 shock absorber struts with the highest ratings on PartReview looked like this:

- MARSHALL - 100% positive votes. Average rating: 4.9

- Japanparts - 93% positive votes. Average rating: 4

- Demfi - 90% positive votes. Average rating: 4.4

- Patron - 88% positive votes. Average rating: 4.1

- Stellox - 86% positive votes. Average rating: 4.3

Fenox

The Belarusian manufacturer specializes in the production of inexpensive components for most modern vehicles. Among other things, we are pleased with the wide range of cars from the VAZ brand.

First of all, oil struts are highly valued, as they demonstrate very good performance characteristics. In addition, such equipment is suitable for use even in cold winter conditions.

The production controls are very tight, so the parts will last for a long time, especially if aggressive driving is avoided.

Delphi

Probably, the DELPHI car rack is the best option among the budget offers available on our market. At the same time, the quality is quite good. As confirmation, it should be noted that this English brand supplies its products to the famous General Motors concern.

You may also be interested in: How to troubleshoot and repair a vacuum brake booster yourself

There are also models for our VAZs. A distinctive feature of such oil shock absorbers is their increased rigidity, which allows the driver to enjoy a sporty ride without fear of flying into a ditch.

The use of high-quality production technologies and modern materials guarantees a long service life of the elements.

On average, such struts are replaced no more often than every 200 thousand kilometers. If you use the devices not in the north of Russia, but in a more suitable climatic zone, then the service life increases even more.

Next video about racks:

Repair or replacement

The shock absorbers themselves are practically beyond repair. If we are talking about racks, then some service stations can offer such a service. But it must be borne in mind that used parts will most likely be used for repairs, and changes will likely be made to the design that may affect safety. 50 thousand kilometers is the maximum that they can guarantee you after this repair.

It makes more sense to purchase and install new racks. Firstly, you will immediately feel the difference, and secondly, during normal use you will forget about the problem for several years.

Koni

The products of the Dutch brand are supplied to the assembly lines of such famous automakers as Lamborghini and Bentley. At the same time, there are also models for less prestigious vehicles. A distinctive feature is the increased requirement for the quality of oil and gas-oil shock absorbers.

As a result, when using such components, the stability of the vehicle increases significantly. On the other hand, this has virtually no effect on comfort parameters.

Another achievement of the manufacturer is the long service life of the elements. The main disadvantage is the high price (for Koni products you will have to pay 2-3 times more than for most analogues).

What is the difference between a strut and a shock absorber, and how can we stop confusing them?

Good afternoon. From this article you will learn how a strut differs from a shock absorber, and you will be able to conduct an educational program for salespeople in auto parts stores (by an interesting coincidence, they are the ones who often get confused in their names).

Let's agree on terms.

A shock absorber is a device designed to dampen vibrations and absorb shocks and impacts of moving elements (suspension, wheels), as well as the vehicle body itself, by converting the mechanical energy of movement into thermal energy.

The simplest shock absorbers were mechanical (friction) and served only to dampen vibrations (damping). They looked like this:

Over time, oil tube shock absorbers were developed. They resist the movement of the rod due to the flow of fluid between the cylinders.

Unlike mechanical shock absorbers, with hydraulic shock absorbers the force changes in proportion to the speed of movement (the faster the rod moves, the more force is needed to move it).

Hydraulic shock absorbers look like this:

And here is their animated principle of operation:

It is important to understand that any shock absorber (oil, gas, gas-oil) works on this principle, and differs only in the working fluid; their design remains similar in any case. those. or gas or oil passes through narrow valves and due to this there is resistance to the rod, naturally the liquid heats up and the heat is transferred to the atmosphere.

A strut is an entire suspension unit designed to orient the wheel in space, dampen vibrations and cushion the body. If the shock absorber was essentially an oil pump, then the strut combines a shock absorber, a spring, a steering knuckle and a suspension arm.

This is what the racks look like:

It is possible that the strut is not rotatable (for example, in a rear suspension), then it looks like this:

What is the difference between a strut and a shock absorber?

The strut replaces the upper control arm, upper ball joint, and steering knuckle. The strut axis has a larger diameter, as it determines the geometry of the suspension and the position of the wheel. If the car is equipped with air suspension, the strut also acts as a spring!

A shock absorber, unlike a strut, does not determine the geometry of the wheel and does not replace the suspension arm and ball joint. It simply dampens vibrations directed along its axis.

Thus, the shock absorber is a small part of the strut.

If you are too lazy to read, here is the difference between a strut and a shock absorber in the abstract.

That's all I have for today. I hope that now you will not confuse the strut and shock absorber. If you have questions about how a strut differs from a shock absorber, or if you would like to add to the article, please do so via the comment form.

Source

Bilstein

Such devices are not inferior in quality to original car racks. It is worth noting that they are supplied to BMW, Mercedes, Toyota and Honda factories. This is already the best evidence of the reliability of the elements.

Models for sports cars, which are perfect for tuning your car, have even more improved parameters.

A wide range of settings allows you to ensure the stability of the car in any situation. The cost is quite high, but slightly lower than in the case of the Koni brand.

Principle of operation

The main parts of a machine strut are a spring and a shock absorber. The combined action of these elements provides good road stability, maneuverability and comfort:

- The spring is located on the axis of the strut, where it receives shocks when the car hits bumps and irregularities. Hard metal reduces the range of vertical movement. Dampenes the vibration impact of the road surface on the car body.

- The shock absorber of the machine strut, located on the longitudinal axis, reduces the return amplitude. And it stops the car from swinging in the vertical and horizontal directions. Working together with the spring has the desired effect on reducing vibrations that occur when hitting uneven road surfaces.

The functions of a car rack are:

- machine support;

- transmission of driving force from the wheels;

- stabilization of the body along the main axis;

- warning of dangerous tilt angle;

- Damping side impacts.

The design of the devices differs for different wheel axles. The front side pillars of the car are thin, long and with a support bearing. They can rotate freely around a vertical axis together with the wheel.

Pilenga

An Italian concern that makes components for various cars, including VAZs. It is difficult to find a better combination between price and quality.

The range is very wide, it includes more than 8 hundred different products. The models comply with all current international quality standards, which is evidence of their durability and reliability.

True, you shouldn’t expect increased durability on our roads. Even in gentle mode, the service life reaches about 30 thousand km. But when used in difficult conditions, the period of use can be reduced to 10-15 thousand km.

What is the difference between a Monotube and a Twin Tube Shock Absorber?

In a monotube shock absorber

the piston works both on compression and rebound, which allows you to instantly dampen spring vibrations; in

a two-pipe

absorber, the piston works only on rebound, and the compression is regulated by a bottom valve; hence, the efficiency of damping spring vibrations is much less in a

double-tube shock absorber

.

Interesting materials:

How to properly place speakers in a room? How to speak to a waiter correctly? How to propagate bamboo correctly? How to properly dilute an antibiotic for a sample? How to plant bamboo correctly? How to eat coconut correctly? What is the correct way to ask your spouse? How to put have or has correctly? How to make plans for the day? How to dry almonds in the oven?

BelMag

A domestically produced product that occupies a leading position in our country. The brand stands out for its affordable pricing policy, as well as a very wide range.

By the way, in the BelMag catalog you can see not only struts, but also other components for cars, including suspension, steering rack, brake system, etc.

The goods are delivered directly to the VAZ and GAZ factories, and they are also exported to other countries of the world. The dealer network is very different in its level of development, so you can see products from this brand in almost any auto store.

According to owner reviews, such shock absorbers demonstrate excellent performance when driving even on dirt roads, as well as on uneven roads.

At the same time, a slight sway is felt on the asphalt at speeds of more than 90 kilometers per hour, so the BelMag model range will not be the most relevant option for tuning sports cars.

You may also be interested in: Wheel alignment stand - basic equipment for your service station

Diagnostics

During normal vehicle use, shock absorber struts usually last 3-4 years, often even longer. But this period can be significantly reduced if you decide to save money and purchase a cheap low-quality part. The service life of the racks also depends on the correct installation, driving style and road conditions.

There is no point in trying to manually rock the car to determine the health of the shock absorbers. The actual amplitude of the vehicle's sway while in motion is much higher, so this method can only identify completely damaged shock absorbers.

The behavior of the car in motion will tell much more about the condition of the struts. The following signs may indicate problems:

- knocking or creaking while driving;

- significant shaking and long attenuation of vibrations of the machine body;

- deterioration of road grip, especially noticeable when entering a turn at speed;

- increase in braking distance in the absence of problems with the brakes;

- when accelerating, the rear of the car noticeably squats, and when braking, it nods;

- obvious traces of hydraulic fluid leakage due to a worn shock absorber seal;

- uneven tire wear;

- shock absorber cylinder deformation, spring corrosion or other obvious damage to strut elements.

More accurate diagnostics can be made at a service station that has a special stand. The car is rocked on it, and sensors record the amplitude of the vibrations. As a result, the system determines the remaining service life of the racks as a percentage, and service specialists give an opinion on the possibility of their further operation.

Sachs

This company is a division of the world-famous ZF brand, which cooperates with most of the most popular automakers. Among the assortment you can find oil, gas and other products. A very wide selection of sports racks.

At the same time, the models are easy to customize if you decide to get serious about car tuning. It is worth noting that the price here is quite reasonable, especially considering the use of innovative technologies during the production process.

The materials used to make the stands are also of very high quality. All this has a positive effect on the durability of the units.

How does a shock absorber strut work?

The shock absorber strut is part of the wishbone suspension design. It acts as a limitedly rigid connecting element between the body and the wheel. The rigidity of the rack, in combination with the holding force of the levers connected to it, is sufficient to prevent the wheels from moving relative to the body in the horizontal plane. At the same time, the stand, which has a telescopic design, allows the wheel to move up and down within the required limits, which makes it possible to absorb the impacts that the wheel receives.

Finwhale

This is probably the most versatile option. The German model is perfect for most modern cars.

The main partners of this brand are the world's largest brands, such as Volkswagen and General Motors. At the same time, the brand’s range also includes products for domestic cars.

Shock absorbers are oil and gas. At the same time, setting up the units is very simple, which is the main advantage of the model range. Additional advantages include reliability and durability. There are no downsides as such.

Interesting facts about shock absorber struts

Earl McPherson's original design was intended for use on both the front and rear axles of a vehicle. Cars with MacPherson struts did exist (for example, the Starion coupe of the Japanese concern Mistubishi), but much more often the suspension on struts is installed only on the front axle of the car, since one of its main advantages is the attachment of the lower part to the steering knuckle, which allows you to organize simple and reliable steering.

Soon after the appearance of the shock absorber strut, employees of the plant that produced the Ford Vedette model in the French city of Poissy complained about the difficulties that arose in the process of mastering the new design and even tried to abandon its use.

SAAZ

Our list ends with the best Russian manufacturer of car racks. SAAZ products are widely known to most car owners of domestic vehicles.

Struts and shock absorbers are distinguished by their increased reliability, while they are excellent for the climatic conditions of any region of Russia.

The products meet international standards, while production equipment is constantly updated, which allows the brand to compete with famous foreign companies.

The most popular are gas-filled models, which guarantee excellent stability of the machine.

At the same time, turns are easily taken even on large turns. But the durability here leaves much to be desired, which is the main disadvantage of the brand.

Bottom line

So, after reading this article, you can find out the structure of car racks and how they work. Every car enthusiast will draw the appropriate conclusions for himself. Before choosing a stand, you need to approach this matter with all seriousness. Because you will then drive this car for a long time. And the safety of other car owners and pedestrians also depends on your choice in favor of one stand or another. The average service life of a part on good roads is 100 thousand kilometers. On bad roads, the resource drops significantly. The stand may not last even 30 thousand kilometers. Also, the resource significantly depends on driving style.