On any passenger car with a gasoline engine, the gas pump serves to supply fuel under pressure from the fuel tank to the metering device - depending on the modification of the engine on VAZ cars, the fuel system can be carburetor or injection.

The fuel pump (BN) on carburetor internal combustion engines of the 2110 car is located behind the valve cover, next to the distributor-distributor; on a car with an injection engine, it is located in the fuel tank (submersible type). If the BN begins to malfunction, the engine does not pull or develop speed, and in many cases the engine cannot be started at all.

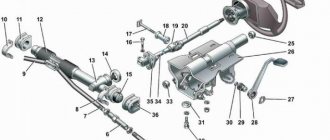

Fuel pump circuit (electric)

The design of the electric fuel pump 2110 itself is quite simple - the unit is an electric motor, which is supplied with 12 Volt power. The BN is mounted in a housing, and a mesh is installed at its inlet - a coarse filter. The filter element prevents dirt particles from penetrating into the pump housing, thereby protecting the device from clogging and possible breakdown.

The electrical circuit of the VAZ fuel pump contains the following elements:

- ignition;

- fuse;

- relay;

- wiring;

- the engine control unit.

When you turn the ignition key, power is supplied through the relay to the BN terminals, and the pump begins to pump gasoline. After the input line of the fuel line is filled with gasoline, the ECU (control unit) through a relay gives a command to turn off the voltage - the fuel system is ready to start the engine, all that remains is to crank the engine with the starter.

Common mistakes

You can use our instructions in one case: when the fuel pump does not work, but other systems are working properly.

Sometimes the engine does not start for several reasons at once. And then you need to reduce the pressure like this: wait 5-6 hours, and do not turn on the ignition. Be careful! Actually, the ramp is under pressure

You can find out about the presence of pressure in the standard way:

Open the hood; There is a fitting on the fuel rail, closed with a plastic cap. It is turned away (photo 1); Using the nipple cap (photo 2) you can unscrew the fitting plug

This action is performed carefully: the residual pressure has not disappeared anywhere.

Even if gasoline starts to gush out, do not try to tighten the fitting right away. Let the pressure drop a little.

Diagnostic connection and plug

Trying to fix a fuel pump is commendable. It will be possible to change its mesh. But the cause of the problem may also be a clogged fine filter.

The replacement filter (“can” 2112-1117010) gradually fails. On all fuel-injected cars, including the VAZ-2112, the fuel pump will not stop working even if the filter is completely clogged. Fuel is not pumped, but the engine does not burn out.

Fuel pump relay VAZ 2110

A relay in any electrical circuit is designed to close and open a circuit; its main role is to protect the elements of the electrical circuit from high inrush current. When starting an internal combustion engine, the current required to crank the starter reaches 80-300 Amps, and if the relay is not installed, any element of the electrical circuit may be damaged.

The VAZ 2110 fuel pump relay is a standard type; inside the plastic case there is an electromagnetic coil with a core; when voltage is applied, the contacts are closed due to the electromagnetic field. Relay 2110 is a four-pin relay, rated for a current of 30 Amps.

Where is the fuel pump relay for VAZ 2110 injector?

Often, due to a relay failure, the engine stops starting; to fix the problem, it is necessary to replace the faulty part. The fuel pump relay (RB) of the VAZ 2110 injector is located in the car interior, under the instrument panel, next to the center console. To get to the pump, you need to unscrew the two screws of the protective plastic casing and dismantle it - of the three elements located here, the “relay” responsible for the operation of the pump will be located in the center (in the figure below, number 5).

Gasoline pump VAZ 2110 injector price

Electric fuel pumps 2110 are produced by various manufacturers; they can be sold either assembled with a housing, or the electric motors themselves can be sold separately. It makes sense to change the BN assembly only when the bulb (body) of the device is damaged; more often than not, only the fuel pump motor itself requires replacement, since it basically stops working.

Main manufacturers of fuel pumps 2110-2112:

For VAZ 2110 injector fuel pumps, the cost may vary; on average, BN can be purchased at a price from 700 to 4500 rubles. The most inexpensive products are produced by Hofer and Pekar; the average price of an electric fuel pump (motor) complete with a Pekar mesh filter is about 800 rubles. The most expensive are Bosch BNs; the cost of the assembled device is 4300-4600 rubles.

A little about the design of the fuel pump

The VAZ 2101 fuel pump housing consists of two halves. On the bottom there is a diaphragm drive lever. There are two small valves in the top cover - inlet and outlet. By the way, they are included in the repair kit. But it is better not to use it, since the effectiveness of replacing several components and gaskets is extremely low. As practice shows, even highly professional repairs will not give good results.

The fuel pump will still not work as it should. And if you think that the electric fuel pump on the VAZ 2101 can save the situation, then you are mistaken. These are unnecessary problems that you simply don't need. Such a fuel pump must be installed if an engine with a two- or seven-wheel drive (injection) is being installed. In all other cases, it is useless to do this - there are a lot of costs, there is no effect.

Therefore, the only right solution is to completely replace the VAZ 2101 fuel pump. Its price in stores is 450-500 rubles, no more. The repair kit is cheaper, but the guarantee that it will pump the pump is small. But if you install a new one, the problem will disappear for several years. According to reviews from car owners, the most reliable fuel pumps for the VAZ 2101 are those produced by DAAZ. But it is worth noting that Pekar and Weber are also praised by drivers. True, it doesn’t happen every once in a while, sometimes a true G (marriage, in the sense) comes across. With repair kits the situation is even worse.

And if there is a chance to purchase a low-quality fuel pump, but it is small, then you can buy a repair kit of a very low grade. From my own experience, I will say that I personally purchased kits in which the valves either did not fit into their grooves at all, or fell into them like a spoon in a mug. I don’t know, it’s quite possible that fate doesn’t like me very much, but this happened not only to me. Therefore, I decided that the best way to repair the VAZ 2101 fuel pump is to purchase a new one. And install a new rod. And gaskets.

Replacing the fuel pump mesh for VAZ 2110 injector

Russian fuel does not always meet quality requirements, and over time, due to poor gasoline, dirt accumulates in the gas tank in the form of sediment. The debris also clogs the filter screen of the electric fuel pump; due to the accumulated dirt, the fuel does not fully enter the fuel line, causing interruptions in the operation of the internal combustion engine. To eliminate the malfunction, it is necessary to clean or replace the coarse filter, but to get to the mesh, you need to remove the BN.

Before starting disassembly, you should reduce the pressure in the fuel system, otherwise, when unscrewing the fuel line fittings, gasoline may escape in a stream and flood the entire interior of the car. To relieve the pressure, remove the fuse responsible for the operation of the BN, start the engine and wait until it stalls. We replace the VAZ 2110 injector fuel pump mesh as follows:

- turn off the ignition;

- in the back seat in the cabin we find hinges, and by pulling them, we fold the lower “seats” forward (right and left);

- there is a hatch on the bottom under the seat, it is secured with two self-tapping screws;

- unscrew the screws and dismantle the hatch;

- disconnect the plug from the wires that supply power to the electric fuel pump; to do this, bend the latch and forcefully pull the parts of the connector away from each other;

- unscrew the fittings of the fuel pipes - main supply and return (17 mm wrench);

- unscrew the nuts of the pressure plate of the used pump (there are 8 fasteners here, 7 mm wrench);

- The nuts are small, it is better to put them in some kind of jar so as not to lose them. Remove the plate and remove the pump assembly from the gas tank. You need to remove the fuel pump together with the rubber sealing ring and lift the pump carefully so as not to damage the fuel level sensor. When removing the BN housing, it is necessary to tilt it, otherwise it will not come out of the tank;

- remove the screen from the fuel pump and install a new part;

- We install the electric fuel pump in place. Here it is important to put the housing in the old places - if you move the used pump, it will be impossible to tighten the fuel line fittings.

Description of the work

The location of the VAZ 2110 injector fuel pump is in the gas tank located under the bottom of the car, in the area of the rear seat. It is accessible from the cabin, so no inspection holes or other additional devices are required. Only tools needed:

- open-end wrench 13 and 17 mm;

- Phillips screwdriver;

- 7 mm tubular socket wrench.

Instead of a long 7 mm tubular wrench, you can use a small open-end wrench, but this will be inconvenient and take more time. Before starting repairs, you should completely remove and pull out the rear seat to gain access to the gas tank. Two more preliminary operations that are done in the engine compartment.

- Loosen the nut securing it to the negative terminal of the battery, remove the clamp along with the wire.

- Relieve pressure from the fuel line. At the end of the ramp, near the outer nozzles, there is a bleed valve with a rubber cap on it. Having removed it and substituted a plastic cup, you need to press the valve stem. Fuel will leak out from there and the pressure in the system will drop.

Under the bottom of the rear seat there is a square hatch that provides access to the gas tank; it will need to be removed. The subsequent disassembly diagram looks like this.

- Using a Phillips screwdriver, unscrew the 2 screws securing the hatch cover, remove it and put it aside.

- Disconnect the fuel pump electric drive connector and move it out of the way.

- Using an open-end wrench, loosen and unscrew the 2 nuts that secure the fuel line pipes to the fuel pump fittings.

- Pull the tubes out of their sockets. The round rubber rings attached to their ends must be removed and replaced with new ones, since they are designed for one-time use.

- Using a long tubular wrench, unscrew the 8 nuts that hold the flat flange that presses the VAZ 2110 fuel pump to the bottom surface. Remove the flange from the studs.

- There is a rubber gasket on the mounting studs under the clamping part of the body. The latter must be removed from the studs, otherwise it will not make it possible to pull out the fuel supply device. Then carefully remove the fuel pump from the tank cavity along with the float. If the rubber gasket is worn out, then it is better to replace it too.

When removing the unit, gasoline will flow out of it, so you should place a rag underneath and quickly move the fuel pump out, placing it above a wide pan. The mesh is located at the end of the suction tube and is secured with a plastic ring. You can remove it manually.

If the ring is strongly stuck to the tube, it is recommended to pry it off, for example, with a flat screwdriver. Next, a new mesh is placed and fixed by pressing the hand all the way. Now you can reassemble, which is done in reverse order. There is an arrow stamped on the top of the unit; it should point to the rear of the car.

If it is necessary to replace the fuel pump on a VAZ tenth model or repair it, then the system is disassembled as described. When replacing, you need to remove the float and level sensor from the unit and move them to the new pump. The entire procedure, if performed in conjunction with replacing other consumables, will take you no more than half an hour.

Malfunctions of the electric fuel pump 2110

If the pump stops working, there may be several reasons for the malfunction:

- electrical wiring is damaged;

- fuse burned out;

- the relay stopped working;

- BN motor burned out;

- The engine control unit has failed.

When a driver in a car with a VAZ 2110-12 injection engine turns on the ignition, the electric motor starts working - a characteristic buzzing sound is heard. If no sounds are noted, it means that the BN is not pumping fuel.

The easiest way is to check the electric fuel pump fuse, which is located almost in the same place as the relay, located to the left of the RB.

If the fuse is blown, it must be replaced. It often happens that when replacing a fuse, it immediately blows. The main reasons for the malfunction of this phenomenon:

- the fuel pump itself “shorts”;

- There is a short circuit in the electrical wiring.

Another characteristic malfunction of the electric fuel pump is that fuel is pumped, but the operation is accompanied by loud noise. A noisy fuel pump is a sure sign that this device will not “live” for long and will soon fail.

Checking the electrical circuit

Unlike a carburetor engine, where the fuel pump is mechanically driven, on the injection VAZ 2110/2112 a special relay and fuse are responsible for the operation of this device. Therefore, before moving on to diagnosing the pump itself, it is necessary to check the indicated elements. If any one of them is faulty, the pump will not work at all.

Turn on the ignition without starting the engine and listen. When the fuel pump is running, it emits a characteristic “whistle” when started. If it is not there, it means that either the pump itself has failed, or one of the elements of its power supply circuit has failed.

The pump relay and fuse are located in an additional mounting block located inside the vehicle's center console. It can be accessed by removing the plastic trim (near the front passenger's left foot). It is secured with several screws. Under the cover you will find three relays and three fuses. Typically, the fuel pump circuit protection elements are located centrally.

The relay and fuse are located in an additional mounting block under the cladding

To check the fuse, remove it from its socket and “ring” it with a tester. If necessary, replace it, observing the rating (15 A). It is unlikely that it will be possible to check the relay for functionality without special equipment. But you can take another relay, for example, the radiator fan (far left), and install it in place of the one being diagnosed. Turn on the ignition and listen to see if the fuel pump starts working. If yes, buy and install a new relay. If the problem persists, continue diagnostics.

Article on the topic: Replacing brake pads: step-by-step diagram

To check the fuel pump relay, you can install the radiator cooling fan relay in its place.

How to test a relay

If the electric fuel pump does not show any signs of life when the ignition is turned on, this does not mean that it has burned out. The cause of the malfunction may also be a relay. The easiest way to check the RB by ear is that when you turn on the ignition, the relay should click. If you don’t hear a click, there is a high probability that the “relay” is faulty.

But not everything is so simple - the problem can be “tricky”, for example, the car does not start the first time. The cause of the malfunction may be hidden in burnt relay contacts. It’s quite simple to check the functionality of the pump itself; proceed as follows:

- remove the protective casing, under which there is a block with relays and fuses;

- we unscrew the fastenings of the block, remove it, it remains attached to the wires;

- we pull the RB out of the block, place a jumper between two opposite contacts, thus directly supplying power to the BN;

- If, with such a connection, the electric motor of the pump begins to make noise, it means that the BN itself is working, most likely, the malfunction is hidden in the relay.

If there is no voltage on any of the contacts on the RB block, you should look for a break in the wiring; there may also be poor contact at the place where the wire is attached to the terminal.

Connectors under the hatch, disconnecting them

You need to remove the hatch under the rear seat: two screws are unscrewed with a Phillips screwdriver. Next you need to disconnect the connector on the module, and then move on to the block under the dashboard. First, turn off the fuel pump!

Replace the fuse. Let's move on to the fuel pump: connect the probe (zero cord) to any of the mounting studs. Voltage should appear on the “gray” wire when the ignition is turned on.

And also check the potential difference between the “gray” and “black” wires - it should be equal to 12 volts, and also at the moment the ignition is turned on. Wiring:

- The two outer cords are the FLS sensor;

- “Black” – minus power supply;

- "Grey" is a plus.

The "black wire" sometimes loses contact with ground.

There are reviews from owners that say: the fuel pump on a VAZ-2112 does not work if the electric motor is working properly and there is voltage in the connector. This happens when the contacts of the internal terminal block oxidize (see photo). Internal connector - yellow It is not easy to get to the connector on the motor - you need to remove the fuel pump module by unscrewing 8 nuts around the perimeter.

Fuel check valve

The electric fuel pump of the VAZ “Ten” has good performance, but it creates too much pressure in the fuel system. In order to bring the pressure back to normal, a VAZ 2110 fuel pump valve is built into the fuel line; it is located in the “outlet” fitting of the BN housing. On the “tens”, a pressure regulator is also installed, which is located behind the fuel rail.

A valve malfunction involves a ball sticking in the open position, and the fuel pressure in the system may drop to zero. If such a problem occurs, the car is very difficult to start, since all the gasoline from the fuel lines goes back into the gas tank when the ignition is turned off. Is it possible to somehow repair the valve?

Drivers of 2110 cars claim that you can try knocking on the fitting in the BN flask so that the shut-off ball falls into place. If the malfunction cannot be eliminated in this way, the electric fuel pump bulb must be replaced, since this housing itself is non-separable.

What is a fuel pump and how it works

The purpose of the fuel pump is to supply fuel to the car engine from the fuel tank. Since the engine and gas tank are located on opposite sides of each other, fuel supply is impossible without a gas pump.

There are two types of fuel pumps: mechanical and electric. A mechanical fuel pump can be found in a carburetor type car. Fuel must be supplied to the carburetor at low pressure. Electric fuel pumps are specially designed for fuel systems with injection type fuel supply (injectors).

The mechanical fuel pump is attached to the outside of the fuel tank, and the electric one is attached to the inside. Some engines have two fuel pumps at once: one of them operates at large volumes and at low pressure inside the fuel tank, and the other operates at small volumes and at high pressure, located near or on the engine.

Mechanical fuel pumps suck fuel from the tank into the engine. The distance between the pump and the carburetor is small. Thanks to this they can work under low pressure. The operating principle of electric fuel pumps is based on pushing fuel into the engine. The operation of such a pump is controlled by the vehicle's electronic system.

This control takes into account throttle position, fuel/air ratio and exhaust gas content. Electric fuel pumps heat up quickly and make a lot of noise due to the fact that they operate under pressure. Because of this, they are placed in the fuel tank as it muffles the noise and cools the pump.

The fuel pump is started by an electric motor. After turning the ignition switch to switch on, a signal is sent from the on-board computer to start the fuel pump. An electric charge enters the fuel pump. The engine rotates for several seconds, during which time the necessary pressure is created in the fuel system. If a signal is not sent to the on-board computer within two seconds, the fuel pump automatically turns off.

If an emergency shutdown does not occur, fuel enters the fuel pump through a tube and exits through a one-way valve. Next, it enters the fuel filter, which traps particles of debris and dirt, and only after that the purified fuel enters the engine. The fuel pump stops working simultaneously with the engine.

Pressure is the most important parameter for a fuel pump, affecting the amount of fuel injected into the engine. The gearbox is responsible for the stability of the fuel supply.

Mechanical fuel pump "tens" VAZ

The VAZ 2110 (Lada-110) car has been produced at AvtoVAZ since 1995, and the first engines on this model came with carburetors. Eight-valve VAZ 2110 engines with a power of 72 hp. With. were set to “tens” until 2000, and the fuel pumps on these internal combustion engines, accordingly, were mechanical.

The 2110 mechanical fuel pump consists of parts:

- metal case (two halves);

- top cover;

- pusher with diaphragm;

- two valves;

- return spring.

Gasoline is pumped from the fuel tank by oscillating the diaphragm and opening and closing valves. The diaphragm with a pusher is driven by the camshaft eccentric; on the lower BN housing there is a manual pumping lever for gasoline.

What fuel pumps were installed on VAZ 2108/2109 cars

Most VAZ 2108/2109 cars were equipped with gasoline engines with carburetor injection of a combustible mixture into the combustion chambers. Only their latest modifications were equipped with fuel injection systems.

Table: serial engines of VAZ 2108/2109 cars

| Engine modification | Volume, cm3 | Number of valves, pcs | Injection type | Years of manufacture |

| VAZ 2108 | ||||

| 2108 | 1289 | 8 | Carburetor | 1984–1997 |

| 21083 | 1499 | 8 | 1986–2005 | |

| 21081 | 1099 | 8 | 1987–1997 | |

| 2111–80 | 1499 | 8 | Injection | 1994–2005 |

| VAZ 2109 | ||||

| 2108 | 1289 | 8 | Carburetor | 1987–1997 |

| 21081 | 1099 | 8 | 1988–1997 | |

| 21083 | 1499 | 8 | 1988–2004 | |

| 2111–80 | 1499 | 8 | Injection | 1994–2004 |

| 11183–20 | 1596 | 8 | 1994–2004 | |

Absolutely all carburetor “eights” and “nines” were equipped with DAAZ mechanical fuel pumps produced by the Dimitrovgrad Automotive Accessory Plant. They were and are now produced under catalog number 2108–1106010.

Mechanical fuel pump DAAZ 2108–1106010

VAZ 2108/2109 injection engines were equipped with electric submersible gasoline pumps produced by Russian enterprises Pekar, Utes, SAAZ, as well as pumps of joint and foreign production. Fuel pumps were installed on the latest modifications. The catalog number of the submersible electric fuel pump VAZ 2108/2109 is 2112–1139009.

Electric pump "Bosch" 2112–1139009

Mechanical fuel pump malfunctions

All parts of a car engine are subject to wear and aging, and the life of a mechanical fuel pump also depletes over time. Main malfunctions of the mechanical device:

- warping of hulls;

- cracking of the diaphragm;

- valve failures.

If the diaphragm allows air to pass through, the pump may stop pumping gasoline into the carburetor; through the torn diaphragm, fuel enters the crankcase and mixes with the engine oil. When gasoline gets into the oil, fuel consumption increases sharply, and the engine itself starts poorly, especially when warm. Checking the presence of gasoline in the crankcase is quite simple - if you light the oil dipstick with a lighter, a fire will occur, and a gasoline smell will come from the oil crankcase.

A common defect that occurs in mechanical gasoline pumps is warping of the surface at the point where the pump is attached to the body of the auxiliary units. If the surface is deformed, engine oil begins to leak at the joint between the planes.

Choosing motor oil for manual transmission

Transmission oil is designed to lubricate mechanical parts. High-quality oils with high performance during the operation of the gearbox pass through all parts, creating a special film on them. Thanks to this, the wear resistance of spare parts increases and they become stronger. In view of this, oil for a manual transmission is considered a significant consumable.

According to the manufacturers' recommendations, it is possible to pour motor lubricant into a manual transmission if the car has front-wheel drive. Engine and gearbox oils differ in viscosity index. Engine lubricant is thinner. You can verify this by shaking bottles of engine and transmission oil.

When choosing which oil to pour into the unit, be sure to take into account the viscosity index and operating indicators. Transmission oils are divided into the following categories:

- GL-1 – mineral water without additives;

- GL-2 – contains fatty foods;

- GL-3 – resists scuffing well;

- GL-4 – is resistant to scuffing and wear;

- GL-5 – resistant to corrosion, wear, and scuffing.

Oils included in the first three categories are used in the mechanics of machines produced a long time ago. Lubricants of the 4th and 5th categories are used in transmissions of passenger cars of various models. GL-4 is only available in cars with front-wheel drive. GL-5 is suitable for gearboxes of rear-wheel drive vehicles and drive axles.

Today, the most common are universal petroleum products, that is, those that can be used at any time of the year. Seasonal replacement of consumables is not very profitable for the motorist; it takes money and time.

https://youtube.com/watch?v=jpzO7iyGtpk%3F

Fuel pump VAZ 2110 carburetor price

Unlike electric fuel pumps, mechanical fuel pumps are generally cheaper; the price largely depends on the manufacturer. The most famous companies producing gasoline pumps:

The cost of the device ranges from 350 to 850 rubles; repair kits are also sold for used mechanical pumps; the kit contains a diaphragm, rod, and valves. The repair kit is quite cheap - from 70 to 200 rubles, but it does not always make sense to carry out repairs, since the pump assembly itself is inexpensive.

An interesting fact is that the fuel pump for carburetor engines for the VAZ “ten” is suitable for the VAZ 2108-09-099 models, as well as for the Zhiguli VAZ-classic 2101-07. The “Classic” BN differs only in a slightly different arrangement of fuel fittings, and in order to install the pump from the “Classic” on a car 2110, it is necessary to use longer fuel hoses.

Symptoms that clearly indicate a faulty pump and rod

The main sign of a faulty fuel pump is that the engine begins to stall at high temperatures, and after stopping it does not start. It sits for a while, cools down, and only then is it possible to start the engine. Of course, another breakdown has a similar symptom - a violation of valve adjustment. Only in this case does it feel as if the engine is trying with all its might to pull the car, but cannot, it is beyond its capabilities. And when the fuel pump starts to malfunction, the engine simply stalls.

The reason for this is excessive heating. As we said, the VAZ 2101 fuel pump consists of two valves. Well, one or both became warped due to heating and stopped opening. Cool them slightly and you can continue moving. Remember how often you saw a wet rag thrown over a gas pump? Now you know what purpose this is for.

But there is also a VAZ 2101 fuel pump rod, a truly wonderful contraption. It is made of steel. And if in the Soviet years it was hardened, now no one needs it. The price of the stock is at least 25 rubles. Well, who will spend kilowatts of energy on a part whose final cost is 25 rubles? Nobody! What happens then? But an unpleasant picture emerges - the fuel pump lever simply erases the rod, reducing its length.

And if you have gaskets under the fuel pump housing, then you are just lucky! When you pull one out, the rod will protrude from the insert more. And that’s it, the pump will continue to pump gasoline normally. But what if there are no gaskets? Who knows what could happen, for example, they forgot to put them on? And that’s why the rod was worn out. What to do then? Try taking it out and inserting it the other way. You know, this action helped several times.

A sign that the fuel pump rod has worn out is that the car accelerates to a certain speed. I had such a thing that I drove around the city normally, but as soon as I got on the highway, my maximum speed was 90 km/h, and that’s all. You step on the gas, but the engine stalls, it doesn’t have enough gasoline. I released the pedal a little - it drives calmly and shows no signs of breakdown. Moreover, a pump rod malfunction cannot always be detected when driving around the city or at idle speed. A short-term increase in engine speed will not give the same effect as long-term driving at high speed.

VAZ 2110 fuel pump injector: signs of malfunction

So, fuel pump 2110, fuel pump 2112 and similar models are no different in their purpose from analogues on other cars. The device is electric, the main task is to supply fuel from the tank through the fuel lines, as well as maintain the required pressure in the fuel supply system.

As a rule, if the fuel pump of a VAZ 2110 fails, in this case there is no supply of gasoline to the engine, the running engine will simply stall, and when you try to start it will not be possible to start the internal combustion engine. However, it also happens that the pump on the “ten” or the fuel pump on the VAZ 2112 works, but there are interruptions in its operation. In this case, the following symptoms may appear:

- the engine jerks during operation, the “check” on the instrument panel lights up;

- during active acceleration, jerks and dips occur;

- at speeds above average and with the gas pedal fully pressed, there is not enough power, etc.

At the initial stage, insert the key into the ignition and turn it to the start position. The pump should make a characteristic hum. If you can hear it, it means all the wires are connected, that is, power is going to the pump.

It turns out that there is a high probability that everything is in order with the wiring and in-depth diagnostics need to be carried out. In this case, you first need to check the pressure in the fuel rail, which will determine whether the pump is pumping or not. If the pressure is not enough, then you need to get to the pump itself.

Design features of fuel pumps for carburetor and injection fuel injection systems

Mechanical fuel pumps, which were installed on the first modifications of the VAZ 2110/2112, have a simple design. It is based on a set of membranes made of special rubberized fabric that is resistant to the chemical action of gasoline. The pump body has two valves: inlet and outlet. The membranes are driven by a rod (pusher). It is driven by a cam mechanism rotated by a camshaft.

Such a mechanical fuel pump can serve for decades until the drive rod wears out or one of the membranes breaks. And even then, if this happens, you can replace these elements in half an hour.

The first modifications of the VAZ 2110 with a carburetor injection system were equipped with mechanical fuel pumps

With an electric fuel pump, things are much more complicated. Its design is based on a small electric motor. It is no different from a regular one, although it works completely immersed in gasoline. The pressure in the system here is created not by a membrane (although there are such pumps), but by a specially shaped impeller mounted on the electric motor shaft.

The service life of the electric fuel pump is 150–200 thousand km. But it can fail much earlier. The main cause of breakdowns when the resource is not used up is additives added to gasoline, as well as various kinds of mechanical impurities. The former destroy the brushes and commutator, while the latter clog the valve mechanisms.

In the injection VAZ 2110/2112, the fuel pump has an electrical design and is part of the submersible fuel module

Model VAZ 2110 fuel pump: check and replacement

Once you are convinced that the cause of the problem is the VAZ fuel pump, and not the wiring and fuel filter, you need to check this element. It often happens that the fuel pump mesh becomes clogged.

The fact is that the pump itself takes fuel from the tank, and from its lower part, where debris inevitably settles. To prevent dirt from the tank from getting into the engine power system and into the motor itself, the pump has a special mesh filter, which becomes dirty over time.

To remove or replace the fuel pump, you will need to prepare:

- screwdrivers, socket head and extension;

- spanners and spanners;

- It is also advisable to have a fire extinguisher, rags, etc. on hand;

All work must be carried out outdoors or in well-ventilated areas. Before starting work on removing the pump, the terminals from the battery must be removed! The main reason is that the pump is located directly in the gas tank, which means you have to deal with fuel and its vapors.

First of all, some nuances may occur on different engines, but the general procedure is the same regardless of the internal combustion engine:

- To make it clearer where the fuel pump is located on a VAZ with an injector, you need to remove the rear sofa, then remove the carpet, under which there is a protective cover for the fuel pump;

- Next, you will need to unscrew the screws securing the cover and move the cover to the side. Below it you can see the pump itself. Before removing the pump, remove dirt and dust that usually accumulates in this area. This is necessary to prevent contamination from entering the tank;

- By removing the protective cover and removing the dirt, you can see two fuel pipes and a wiring harness. First you need to disconnect the block of wires from the fuel pump connector (the block is secured with a latch that needs to be snapped off);

- Now you need to lower the pressure in the system so that gasoline does not spill out. To do this, just turn the engine with the starter. If the engine starts, let it run until it stalls. Next, you should crank the engine with the starter again. If the engine does not start, it means the pressure has dropped;

- Now the battery terminals are removed! By the way, some gasoline still remains in the fuel lines; this must be taken into account when removing them;

- On cars with different internal combustion engines, the fuel pump itself and the mountings of the fuel pipes, connector and wiring block may be different. On some motors the tubes are secured with clamps, on others there are nuts. It is important to consider that there are rubber rings at the ends of the tubes, which are replaced if they become unusable.

How is cleaning carried out?

The fuel pump is located at the rear of the car, usually on the right side.

It can only be accessed from the passenger compartment by removing or reclining the rear seat. You must first remove flammable objects and be careful to avoid sparks, as

When removing the pump, drops of fuel may spill.

The device must be removed from the vehicle and disassembled into its component parts. Removing and cleaning the fuel pump screen:

- The cover under which the fuel pump is located is removed.

- The negative terminal from the battery is removed, the tubes are disconnected from the unit.

- The pressure ring is unscrewed using a special puller.

- The pump is removed. The remaining fuel is first drained, the sealing ring is dismantled, and the dust is vacuumed out.

- Removing the lower part of the device, where dirt and deposits in the form of a brown slurry usually accumulate.

- The filter mesh is removed by simply prying it off with a screwdriver.

- The mesh is replaced or cleaned, avoiding even minor damage: rinse with carburetor cleaning fluid and clean with a soft brush.

- After cleaning, the bottom part of the body and the mesh are “washed” with gasoline.

- The unit is assembled in the reverse order and installed in the fuel tank.

- The fuel supply and return pipes are connected, and the fastening of the clamps is checked.

- The electrical power connector is being connected.

Tips and tricks

If it is necessary to replace the VAZ 2110 pump or after removing the pump for preventative replacement/cleaning of the mesh, after completing the reassembly and installation of the pump, do not immediately install the rear sofa and the pump cover.

Additional verification will be required before doing this. To do this, you need to turn on the ignition and determine whether gasoline is leaking from the fuel pipes. Also, the smell of gasoline in the car interior, etc. is not allowed. If this is the case, then you need to determine the cause of the leak and replace the problematic elements, tighten the tube nuts, etc.

To make the selection accurate, the existing module must be removed from the car and purchased a similar one. Also, when choosing, you need to take into account the type of engine, since the pumps are different. Before purchasing, the fuel pump itself should also be inspected, its housing should be checked (cracks, dents, and defects are not allowed).

When to replace

Such minor repairs are carried out as the grid becomes dirty, which happens quite quickly, given the quality of domestic fuel. The correct approach is to change all consumables at the same time, guided by the frequency of pouring new oil into the engine.

During this procedure, you can replace the air and oil filters, as well as the fuel pump mesh. If you make it a habit to change this mesh only after it is completely clogged, the pump will constantly work with increased load, as a result of which repair or even replacement of the VAZ 2110 fuel pump will quickly be required.

If after this the car engine does not start or even the sound of the VAZ 2110 pump cannot be heard, then you need to check the presence of gasoline pressure in the line. This is done using the bleed valve on the ramp. The verification procedure will be discussed below. If there is no fuel, it becomes clear that the fuel pump is not working or its screen is clogged.