What fuel pumps were installed on VAZ 2108/2109 cars

Most VAZ 2108/2109 cars were equipped with gasoline engines with carburetor injection of a combustible mixture into the combustion chambers. Only their latest modifications were equipped with fuel injection systems.

Table: serial engines of VAZ 2108/2109 cars

| Engine modification | Volume, cm3 | Number of valves, pcs | Injection type | Years of manufacture |

| VAZ 2108 | ||||

| 2108 | 1289 | 8 | Carburetor | 1984–1997 |

| 21083 | 1499 | 8 | 1986–2005 | |

| 21081 | 1099 | 8 | 1987–1997 | |

| 2111–80 | 1499 | 8 | Injection | 1994–2005 |

| VAZ 2109 | ||||

| 2108 | 1289 | 8 | Carburetor | 1987–1997 |

| 21081 | 1099 | 8 | 1988–1997 | |

| 21083 | 1499 | 8 | 1988–2004 | |

| 2111–80 | 1499 | 8 | Injection | 1994–2004 |

| 11183–20 | 1596 | 8 | 1994–2004 | |

Absolutely all carburetor “eights” and “nines” were equipped with DAAZ mechanical fuel pumps produced by the Dimitrovgrad Automotive Accessory Plant. They were and are now produced under catalog number 2108–1106010.

Mechanical fuel pump DAAZ 2108–1106010

VAZ 2108/2109 injection engines were equipped with electric submersible gasoline pumps produced by Russian enterprises Pekar, Utes, SAAZ, as well as pumps of joint and foreign production. Fuel pumps were installed on the latest modifications. The catalog number of the submersible electric fuel pump VAZ 2108/2109 is 2112–1139009.

Electric pump "Bosch" 2112–1139009

Cause of malfunction

A common malfunction of a mechanical gasoline pump is mechanical wear of its rod. When the fuel pump rod becomes shorter than necessary, it stops supplying fuel to the carburetor in the required quantity.

Worn suction valve or brass valve and sealing gasket on a mechanical fuel pump can be another cause of fuel pump malfunction.

The main sudden malfunction of the fuel pump on a car with an injection engine is low-quality fuel. Of course, the question of cleaning lies behind the fuel filter, but the fact is that the fuel injection system of a modern car is made in such a way that the finest filter element is installed after the fuel pump, and in front of it there is only a coarse filter mesh (by the way, it has to be changed or clean more often to avoid fuel pump malfunction). The strainer cannot ensure proper cleaning of the fuel available at our gas stations, and the accumulated dirt on the filter forces the pump to strain to overcome resistance. Which subsequently leads to a reduction in the service life of the part.

For car owners abroad, the fuel pump is more likely to fail due to wear on the manifold assembly in the electric motor than due to a dirty filter. But for our drivers, a typical cause of failure is severe wear and tear of the working surfaces of the fuel pump. This problem may be indicated by loud noise during operation, which will be accompanied by a drop in pressure in the fuel system and increased fuel consumption.

Also, if the issue concerns a malfunction of the electric fuel pump, worn wiring or oxidized terminals can play an insidious role. And when checking the pump shows that everything should work without failures, the electrical wiring will be baffled over and over again.

From all of the above, you can draw several conclusions for yourself:

Here are the basic recommendations to extend the service life and protect yourself from fuel pump malfunctions.

Features of the design and location of fuel pumps VAZ 2108/2109

The DAAZ gasoline pump has a simple mechanical design. It includes:

- a body consisting of an upper and lower part;

- lid;

- mesh filter;

- valves (inlet and outlet);

- diaphragms (3 pcs) with spacers;

- the rod to which the diaphragms are attached;

- return spring;

- manual pumping lever.

Design of the DAAZ fuel pump

The VAZ 2108/2108 mechanical fuel pump is located in the engine compartment of the car and is installed on the auxiliary drive housing (in front of the ignition distributor). It is driven by the camshaft through a cam mechanism and a rod (pushrod). The camshaft rotates an eccentric, which transmits force through a pusher to a balancer at the bottom of the pump housing. The latter raises and lowers the rod with the diaphragms. Thus, a vacuum is formed at the pump inlet, and pressure is formed at the outlet. Valves located in the device body are responsible for its maintenance.

The VAZ 2108/2109 mechanical fuel pump is located on the auxiliary drive housing

On injection VAZ 2108/2109, the fuel pump is not a separate device, but an element of the fuel module. It also includes:

- plastic storage cup;

- coarse mesh filter;

- fuel level sensor.

Fuel module assembly

The module is located in the car tank. Its lid (base) is located at the top of the container. You will find it by removing the back seat and peeling back the carpet.

The electric fuel pump in the injection VAZ 2108/2109 is located in the car tank

Structurally, the fuel injection pump VAZ 2108/2109 is an electric motor with an impeller on the shaft, which, rotating, pumps gasoline, creating a vacuum at the inlet fitting and pressure at the outlet. The pump is powered from the machine’s on-board network, protected by separate relays and a fuse.

Design of the electric fuel pump VAZ 2108/2109

An article dedicated to self-repair and replacement of the gas tank on a VAZ 2109 is located here:

The fuel pump does not pump: causes and diagnostics

Let's start with the fact that if the gas tank is full, the battery is charged, the spark plugs are dry and there is a spark, the starter turns the engine normally, but the engine does not seize, then you should pay attention to the gas pump. A common problem is that there is no power to the fuel pump after the ignition is turned on. In a similar way, the malfunction manifests itself in motion, when the power to the fuel pump is lost and the engine suddenly stalls.

An equally important point is how much the fuel pump pumps. In other words, the pump may hum and buzz (power is being supplied), but not create the required pressure in the fuel line. The pressure in the fuel system with a working fuel pump must be more than 3 bar (which depends on the specific car model). The indicated pressure is accumulated in the fuel rail and has an indicator of 300 kPa and above.

To check, you need to measure the pressure in the fuel rail with a pressure gauge, taking into account the indicators that are the norm for a specific car model. Using the example of injection VAZs, the pressure when the ignition is turned on is 3 atmospheres, at idle the figure is 2.5 atmospheres, when you press the gas 2.5-3 atmospheres. This method will help you accurately determine:

- malfunction of the fuel pressure regulator in the rail;

- breakdown of the fuel pump or a noticeable decrease in its performance due to wear;

- severe contamination of filters (fuel filter and/or fuel pump mesh);

In the second case, when you press the gas, the pressure does not increase; in the latter case, the pressure gauge needle rises, but very slowly or jerkily.

We also recommend reading the article on how to check the fuel pressure in the fuel rail yourself. From this article you will learn how to correctly measure gasoline pressure with a pressure gauge in the process of diagnosing a gasoline pump with your own hands.

A decrease in pressure below the norm will lead to the fact that the engine may not start or start with difficulty, stall, jerk, operate unstably and with failures. If this happens due to the fault of the pump and not the fuel filter, then there is a high probability that the coarse filter screen of the fuel pump is clogged. In this case, there is no need to change the fuel pump itself, since it will be enough to replace or even clean the mesh.

We also recommend reading the article on how to clean the fuel pump stack yourself. From this article you will learn how and what means you can clean the fuel pump filter with your own hands.

If you suspect that there is no voltage to the fuel pump, there is a quick way to check. It is enough to turn the ignition key and listen, as when you turn the key you should hear a slight hum from the fuel pump. If such a buzzing noise is not heard, it means there is no power to the fuel pump, there are problems with the wiring, etc.

We add that this method of determining the operation of the pump by sound is not suitable for all cars. On some models (especially premium ones), sound insulation is at a high level and the fuel pump turns on immediately after opening the driver's door, and not when turning the key in the lock. In this case, it may seem that the fuel pump does not work when the ignition is turned on, and the sound of the pump may simply not be heard.

Also in the general list of possible reasons why the fuel pump does not pump, the following are noted:

- failure of the fuel pump fuse;

- fuel pump relay failure;

- problems with the ground of the fuel pump;

- malfunction of the electric motor of the fuel pump;

- oxidation or damage to fuel pump contacts and terminals;

- the fuel pump itself is faulty;

Wiring to the fuel pump

On most cars, the wiring to the fuel pump consists of three wires: “plus”, “minus”, and also a wire for indicating the amount of fuel in the gas tank. If the fuel pump does not pump, then the cause may be a lack of power.

To check the power to the fuel pump, just take a 12-volt light bulb and supply it with power from the external connector of the fuel pump. After turning the ignition, the control lamp should light up. If this does not happen, then the problem is in the external circuits. If the lamp comes on, it will indicate the need to check the internal contacts of the fuel pump.

To check the external wiring, you should alternately connect the positive and negative contacts, which are removed from the fuel pump power connector, to the ground of the pump. The contacts must also be connected to the fuel pump relay. If you place the negative contact on ground, after which the ignition is turned on and the light comes on, then this means that this contact is faulty. If the light bulb does not light up, then problems with the “plus” are obvious. If you place a contact on the relay and the light comes on, there is probably damage to the wire on the section that connects the relay and the fuel pump itself.

Fuel pump electric motor

If checking the pressure in the fuel rail and the external wiring to the fuel pump gives positive results, then you should check the fuel pump motor. This electric motor is responsible for circulating gasoline inside the fuel pump.

When checking, you need to take into account that the terminals on the fuel pump themselves tend to oxidize, as a result of which power is not supplied and the pump does not pump. In this case, the motor is working, but the terminals need to be cleaned or re-soldered.

To check the fuel pump motor, you will need to attach the test lamp wires to a cleaned and serviceable terminal of the electric motor, after which you should turn on the ignition. If the light comes on, this will indicate that the fuel pump motor is not working.

Fuel pump ground contact

Problems with the fuel pump mass may be indicated by a fuel level sensor that is not working correctly. The mass may be poorly secured; in this case, the fuel pump does not pump fuel. The ground wire is usually located under the dashboard and runs through the cabin. It is necessary to find the specified wire, check and clean all contacts, then securely fasten the ground to the fuel pump.

Fuel pump relay

The fuel pump relay is often mounted next to the fuel pump ground, that is, under the dashboard.

A normally operating relay after turning on the ignition for a couple of seconds allows the pump to create pressure in the system and immediately turns off. When the ignition key is turned, the driver hears a characteristic click (the relay is turned on), then a similar click will indicate that the fuel pump relay is turned off. If such clicks are not heard, this indicates a malfunction of the relay or its contacts. The optimal solution would be to replace the fuel pump relay with a new or known-good device. Let us add that the cost of spare parts is quite affordable.

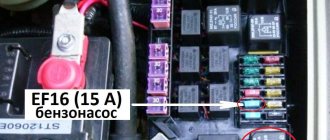

Fuel pump fuse

During diagnostics, be sure to check the fuel pump fuse. The specified 15 A fuse is usually located in the fuse box in the engine compartment and is marked FUEL PUMP, which means fuel pump.

The fuel pump fuse needs to be pulled out and its contact inspected. The integrity of the contact will indicate that the device is normal. A damaged contact will indicate that the fuel pump fuse has blown. In this case, you need to install a new fuse, which has a very low cost (as in the situation with the fuel pump relay).

Replacing an electric fuel pump on a VAZ

- Reduce pressure in the fuel supply system.

- Using the fuel supply hose tip clamp, disconnect 2 hoses in turn.

- Unscrew the 8 nuts around the circumference of the clamping ring and remove it.

- A wire with negative polarity is attached to one of the nuts; it must be removed carefully.

- We take the electric pump block out of the fuel tank, tilting it slightly, to keep the fuel level indicator sensor lever intact, otherwise it will produce incorrect parameters.

- Remove the sealing rubber ring of the fuel block. If its properties are lost, the product must be replaced.

- Install the pump in reverse order.

When installing fuel hoses, focus on the direction of fuel supply indicated by the arrows, and the installation arrow on the electric pump cover should point towards the rear of the car!

CORRECT DISASSEMBLY AND REPLACEMENT PROCEDURE

In order to properly remove the fuel pump, you must perform the following sequence of actions:

- Buy a repair kit right away.

- Remove the air filter and its housing.

- Disconnect the gasoline supply and return hoses from the fuel pump fittings.

- Unscrew the nuts that secure it.

- Remove it carefully so as not to damage the gaskets.

- After this, inspect each part for cracks, check all its valves for leaks.

- Make sure that the discharge and suction fittings remain motionless in their sockets.

- The diaphragms must be free of peeling and ruptures.

- The filter must be absolutely clean and undamaged.

- Wash all filter parts with gasoline and then rinse with a compressor.

- Replace all damaged parts, it is also recommended to install a new pump gasket.

- When installing the gasket, apply Litol-24 type lubricant to its surface.

- If the housing is damaged or there is other irreparable damage to important parts, the pump will have to be completely replaced.

- Then you need to move on to installing the pump in place.

- In this case, you should immediately adjust its supply using spacers.

- To do this, you need to measure the protrusions of the pusher.

- If the protrusion is too strong, the gasoline pressure will be increased, which will easily break the carburetor shut-off valve.

- If the distance is lower than required, when the load increases and the vehicle speed increases, insufficient gasoline will flow into the carburetor.

- Install the gasoline pump in reverse order.

- Make sure that the arrow located on the body points towards the carburetor.

- When installing the diaphragm unit, the holes in its gasket should be located away from the muffler pipe.

Thus, you have outlined detailed instructions for removing and disassembling the fuel pump, which will help you carry out this operation yourself. You can finish here, you shouldn’t have any difficulties.

When should you check your fuel pump?

It is necessary to check all potentially faulty components one by one, and the fuel pump first.

Problems when starting and running the engine are not always associated with the fuel pump. Sometimes the signs of a fuel pump breakdown are the same as those of a faulty fuel pressure regulator , injectors or jets, spark plugs and high-voltage wiring. Even experienced specialists who know by heart all the signs of a “dying” pump cannot unambiguously determine the type and cause of the breakdown the first time, and it is necessary to check all potentially faulty components one by one. In this case, the fuel pump is usually checked first. In this case, there are two types of malfunction - the fuel pump does not work at all or does not produce the required pressure. In the first case, the malfunction can be recognized by ear, since it should start when the ignition is turned on. In the second case, you need to know how to check the pressure of the fuel pump. Here you need to use a special pressure gauge. We list the main symptoms of a fuel pump malfunction: