Here we will talk about independently replacing the timing chain drive on a Niva 21214. The timing belt affects the operation of the entire car, so the importance of this unit should not be underestimated. Replacing a chain drive is a rather complicated process, which, however, can be done by any car enthusiast, provided that he follows the instructions and shows a little diligence.

A chain has significant advantages over a belt drive. These include, first of all, its reliability. While a belt can break, this rarely happens with a chain. Usually it just stretches. It lasts much longer than the belt, which means it needs to be changed less often. But still, the chain does not last forever, and after a while it also has to be replaced with a new one. When replacing the chain yourself, it is very important to set the marks correctly and follow safety precautions.

Replacing timing chain and sprockets (injection engine)

Remove the cylinder head cover (see here).

Rotate the crankshaft until the mark (hole) on the camshaft sprocket coincides with the mark on the camshaft bearing housing.

Remove the crankshaft pulley (see here). Disconnect the camshaft sprocket with the chain from the camshaft (see here). Remove the chain from the sprocket.

For clarity, we show the chain removal operations on a dismantled engine.

We unscrew the three bolts securing the oil pan to the camshaft drive cover (see here).

Using a 10mm socket, unscrew the three nuts and six bolts securing the camshaft drive cover to the cylinder block.

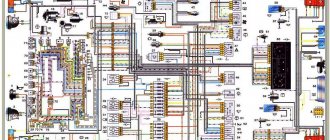

A “ground” wire is secured under one nut (on the left side).

Remove the camshaft drive cover.

. and a sealing gasket. |

Using the “17” head, unscrew the axis of the hydraulic chain tensioner shoe. |

We take out the tensioner shoe. |

Remove the chain from the crankshaft sprockets and the oil pump drive shaft.

We take out the camshaft drive chain.

Using a puller, press the sprocket from the toe of the crankshaft. |

The sprocket is fixed on the crankshaft with a segment key. To remove the key. . Carefully, trying not to damage the key and shaft, use a chisel to knock it out of the groove of the crankshaft. |

Using a chisel, loosen the bolt securing the oil pump drive shaft sprocket. |

Using a 17mm spanner, unscrew the sprocket mounting bolt. We hold the sprocket from turning with a screwdriver resting through the hole in the sprocket on the head of the bolt securing the thrust flange of the roller. |

. and the oil pump drive shaft sprocket. |

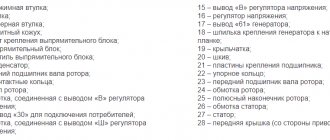

Location of camshaft drive and oil pump parts. |

Install the drive mechanism parts in reverse order. Having installed the key in the groove of the crankshaft, we put on the sprocket.

. and press it onto the crankshaft, tightening the pulley mounting nut with a wrench.

Having unscrewed the nut, we press the sprocket with a tool head of a suitable size (a piece of pipe). |

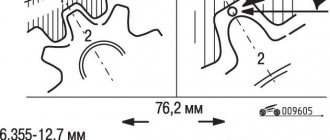

Before installing the chain, align the mark (mark above the keyway) on the crankshaft sprocket with the mark (protrusion) on the cylinder block. |

. and the mark on the camshaft sprocket with the mark on the shaft bearing housing.

Having installed the chain and hydraulic tensioner, turn the crankshaft clockwise two turns and check that the alignment marks match.

We install the removed parts in reverse order.

Video

Source

Build process

- The front cylinder head cover is installed and a layer of sealant is applied.

- The bolts are tightened.

- The air filter is installed, sealant is applied and the pan is screwed on.

The fitting is unscrewed to bleed air from the block before filling with coolant. Pour liquid into the radiator. After it leaks out of the fitting, the lamb is screwed into place. Filling the engine oil. The hose and crankcase ventilation tube are connected to the fittings, and the copper wires are connected to the ignition coils.

The tips of the high-voltage wires are connected to the spark plugs. It is possible that after unscrewing the spark plugs, the remaining water in the wells penetrates the cylinders. Using a long knitting needle and a clean rag, it is easy to remove moisture from them.

Important! Adjusting the chain improves timing mechanism retention and pulley operation. It is important to ensure regular monitoring of its location.

How to set timing marks on a VAZ 21214

Today I was doing some minor engine repairs; it was necessary to align the TDC marks on the RV and KV. I decided to leave a note here so as not to forget)), and maybe it will be useful to someone else. There is a mark on the RV, there is only one of its kind.

There is also a mount for the phase sensor marker, we don’t need this.

On the HF damper it is a little more difficult, due to its inaccessibility (if the radiator is not removed). But looking at the removed pulley, everything becomes clear. You can find the missing tooth spot by touch, count 20 teeth counterclockwise, and look for the mark there.

And so in a real situation. Opposite the mark you can put a mark with a marker, it will be clearly visible.

To find it, you don’t need to remove anything additional, your hand can go through freely, turn the pulley to a position where you can comfortably draw a line. Well, in conclusion, it’s easier to first set a mark on the RV sprocket and then look for the mark on the damper, it will be somewhere near the crankshaft sensor (DPKV). Since the crankshaft makes two revolutions during one revolution of the RV, you need to look in the area of +- 5 teeth.

on how correctly the timing marks are set on the Chevrolet Niva . Regular diagnostics and monitoring of its tension helps to prevent breakdowns in time and increase the life of the engine.

- During scheduled maintenance (if the mileage is 100 thousand km). If the marks on the camshaft sprocket do not match the mark on the bearing housing identified during phase diagnostics. When the pump that drives the “water pump” fails. If the chain is damaged (wear, stretching or cracking), requiring urgent replacement and adjustment according to the marks.

Marks are marks and notches located on the gears of the gas distributor. For clarity, below is an example of installing a notch on a drive gear disk. It coincides with the center of the DPKV (crankshaft position sensor).

The marks on the camshaft pulley are fixed against the ebb on the bearing housing, which fixes the main shaft on the platform.

Prepare a screwdriver and wrenches for “8”, “13” and “10” , devices for turning the crankshaft and additional parts:

- Oil seal (front) New cylinder head gasket Pump gasket Tensioner Damper bar, limiter and chain guide Sealant Engine oil and oil filters Coolant Crankshaft seal Gears

- Installation of the risk on the VAZ-2123 (according to the standard) is carried out in the inspection hole. Put the car on the parking brake. Shoes are placed under the front wheels. You need to wash the engine and fender liners. The air filter is removed. Drain the engine oil, unscrew the oil filter. Drain the coolant. The valve cover fastenings are unscrewed. To prevent engine oil from leaking into the cylinder head area, it is recommended to replace the cylinder head gaskets. By rotating the crankshaft pulley, marks are set on the camshaft gear and bearings.

If the notches do not match, work continues:

- The “whiskers” of the lock washer are bent. The fixing bolt is unscrewed using a key set to “13”, and the position of the camshaft sprocket is loosened. The first gear on the gearbox is engaged, allowing you to avoid spinning when unscrewing the crankshaft gear bolt. The fastener is removed with a lock washer. To prevent the bolts from falling into the engine sump, use a deep-head wrench or unscrew the bolt by hand. Remove the chain tensioner using a screwdriver. It should be replaced if it is stretched or strained, during scheduled maintenance, after 60-80 thousand kilometers.

- The camshaft sprocket is removed. If you pull it towards yourself (a distance of 5-10 cm), it will be removed along with the chain. Check for wear on the sprocket teeth, which form an inverted “V” shape. The part must be replaced if there are grooves on the leading part of the teeth. On a working mechanism, the chain moves on the teeth. The scrolling step is one tooth. The sprocket with chain is placed on the camshaft flange. When the chain moves on the sprocket, its holes will not line up with the pin. The crankshaft should be rotated in the specified direction until the mark and pin match. It is important to secure the part with a bolt and washer (without tightening it all the way). After turning the crankshaft twice with a special wrench, check the placement of marks on the camshaft gear and bearings. If the marks correspond, their adjustment has been successfully completed. The fastenings of the crankshaft and camshaft sprockets are tightened tightly.

If there is a discrepancy, you must repeat the steps.

For clarity of the obtained result, it is suggested to look at the example in the photo .

In the upper corner is an overview of the notch placed against the DPKV core. Below is an asterisk on the flange. The dot is visible opposite the bed in the aluminum cylinder block.

Timing marks on Niva Chevrolet

The Chevrolet Niva from the jeep family is equipped with a chain drive in the timing mechanism. The performance characteristics of a chain are even greater than those of a belt drive. The chain also has the best technical performance, which affects the transmission torque. If a loose belt causes the pulley teeth to slip, a weakened chain does not allow this to happen. But with the operation of the car, the gas distribution chain also tends to wear out, stretch, explode and become unusable, which requires its replacement. At the step of replacing the chain, it is important to carry out the installation observing the marks. This article will tell you what tags are, their purpose and how to place them on a VAZ-2123.

How is the replacement made?

If chain stretching is detected and the decision is made to replace only the hydraulic tensioner, then this is an incorrect assumption. It is necessary to replace all parts: chain, hydraulic tensioner, seals, gaskets. Replacement is done in the following sequence, using all the necessary tools:

Use a spanner wrench to unscrew the tube fitting, which has a “10” head. The tube is designed to supply oil to the hydraulic tensioner.

Having loosened the fitting, the tube is removed and moved upward so that it does not interfere with further work. The two nuts securing the device itself are also unscrewed using a “10” wrench.

The device is ready to be removed from its mounting location. We grab the protruding part with our hands and pull out the device. There is a gasket on it, which also needs to be removed to replace it with a new one.

A used device cannot be repaired and requires the installation of a new one. Before installation, it is necessary to coat the gasket with a layer of sealant to prevent oil leakage.

Replacing an old device does not require serious mental and especially physical effort. Installation of a new one is carried out in the following steps:

- The device is inserted into the new seat, having first checked that the structure is identical to the old tensioner.

- Screwed in with two fastening nuts.

- The tube is inserted and secured.

It is simply impossible to make a wrong replacement. After installation, the operation of the motor and the tension of the new chain are checked. An important point is to replace the timing chain in order to 100% protect the car and your health from unexpected breakdowns on the road. This article will tell you how to replace the chain.

Now the owners of the Chevrolet Niva can, without doubt and without errors, correct the existing problem with weakening the chain tension. Remember that if your car has traveled more than 100 thousand km, and there are no characteristic sounds from under the hood, then do not neglect the situation, but disassemble and check the looseness of the chain and the functionality of the tensioner. Happy renovation work!

Recently, an old friend of mine came to see me in his old Chevrolet Niva with the characteristic sound of an extended chain.

In addition to the timing kit, I had the foresight to purchase even a front cover gasket, a crankshaft oil seal and a kilo of marinated meat. I could not refuse such an offer. So, Niva Chevrolet replaced the timing chain and front crankshaft oil seal.

First, let the engine cool to an acceptable temperature. Remove the pipe by unscrewing the bolt by 10 and loosening the clamps.

Next, we unscrew the eight nuts by 10 and move aside the throttle cable and all the pipes that will interfere with us, remove the valve cover.

Remove the air conditioner belt by unscrewing the bolt 13 of the tension roller.

Then loosen three 13mm nuts and one bolt of the generator belt tension roller and remove it.

Now comes the fun part. To unscrew the pulley nut, we need a 38mm socket. Since the elongated head does not fit under a regular wrench (the radiator is in the way, but we don’t want to remove it), we use a pry bar, carefully sawed off from the hub key of some large car.

Everything fits perfectly. Unscrew the nut and remove the crankshaft pulley.

Unscrew the deflection roller.

We dismantle the reinforcing plate.

We unscrew the six nuts securing the front timing chain cover to the block and the three bolts securing it to the pan and remove it.

Set the top dead center. The key on the crankshaft should align against the mark on the block.

The mark for the camshaft sprockets is against the ebb of the camshaft housing.

Next, unscrew the oil supply pipe and two nuts 10 of the chain tensioner.

Next, unscrew the tensioner shoe, damper and remove the timing chain.

Compare the new and old timing chain. It could be worse.

New timing kit.

Reinstall the chain, guide and tensioner shoe. We tighten the chain by hand and check that the marks match.

To make it convenient for us to check the marks after installing the front timing cover, we find the factory mark on the crankshaft pulley and mark it with a white marker. This mark at TDC should be opposite the center of the crankshaft sensor.

We install the front cover, crankshaft pulley and tensioner. Let's check the marks again. We install all the removed parts in the reverse order of removal. Fill with fluids, start the engine and enjoy.

>

Useful post?

Yes

No

What are tags and their purpose in the Shnivy mechanism

Marks in the timing system on a Chevrolet Niva car are special types of notches and holes that are located on the gas distributor pulleys. The photo shows pulleys with marks along which the timing chain is aligned.

See:

Aligning the chain with marks is done so that it is better fixed and holds the gas distribution mechanism itself. If you install the chain without following the marks, then the operation of the pulleys will be uncoordinated and will then lead to their rapid wear. Therefore, it is important, whenever replacing a chain or parts of a gas distribution mechanism, to install them in accordance with the marks. There may be a malfunction of the timing system when the chain tension is loosened or it is stretched. In order to correctly set the timing mechanism according to special marks, we will look at the procedure for installing the gas distributor phases on the VAZ-2123.

Setting the timing of the gas distribution mechanism using special marks

So, setting the phases in the timing system according to special marks on a Chevrolet Niva car includes the following sequence of actions:

Timing marks VAZ(LADA) 21214 NIVA

Installing timing marks

for VAZ(LADA) 21214

NIVA

. Sorry about the quality. The camera died.

Part 2. Valve piston = repair Niva Chevrolet NIVA Chevrolet 44

Overhaul of the Chevrolet NIVA engine.

After repair work, it is recommended to replace the cover gasket.

After the cover was removed, the following view is observed, shown in the photo below.

Under the valve cover

See:

Important! When unscrewing the bolt, it is necessary to control its position, because it is not fixed by anything and can freely fall into the engine sump. It is recommended that when loosening the tightening, unscrew it by hand or with a deep-head wrench.

When assembling, do not forget to replace the gasket on the cover!

The work carried out does not require much time, but is the key to the successful operation of the parts of the gas distribution mechanism of the Niva Chevrolet car. Drawing a conclusion, I would like to note the importance of setting the timing chain according to special marks. If for some reason you forgot to align the pulleys with the marks, then it is better not to start this process and make the adjustment again. This will extend the life of the timing system and all its components.

Do you still think that diagnosing a car is difficult?

If you are reading these lines, it means you are interested in doing something yourself in the car and really saving money , because you already know that:

And of course you are tired of throwing money down the drain, and driving around the service station all the time is out of the question, then you need a simple CAR SCANNER ELM327, which connects to any car and through a regular smartphone you will always find the problem, turn off CHECK and save a lot of money.

We ourselves tested this scanner on different machines and it showed excellent results, now we recommend it to EVERYONE! To prevent you from falling for a Chinese counterfeit, we publish here a link to the official website of Autoscanner.

Source

Consequences of incorrect installation and adjustment

- Characteristic extraneous clicks appear in the engine, which become louder as the vehicle speed increases.

- The engine is unstable even at idle speed.

- The car's acceleration time increases significantly because the engine does not respond well to pressing the gas pedal.

- Acceleration occurs in jerks, during which clouds of black smoke may fly out of the exhaust pipe.

- Valve wear accelerates many times over, and if the shafts are out of synchronization too much, the valves become deformed and their seats break.

- Incorrect adjustment can also lead to a broken timing chain. This, in turn, can puncture the radiator, break the fan and other engine parts.

- The engine constantly overheats, and the consumption of engine oil and antifreeze can increase significantly.

As can be seen from this article, correctly set timing marks are the key to long and uninterrupted engine operation. There is nothing complicated about this; even a novice car enthusiast can do it. It is important to take your time, follow the above sequence of actions, and also try not to drop the sprocket lock washers into the engine sump. Because it will be very difficult to get them from there.

The huge advantages of VAZ cars, even the latest models, are that repairs are quite simple. Almost all components can be replaced or repaired by a car enthusiast himself following the instructions with a little diligence. At the same time, the cost of repairs will be an order of magnitude lower than in the service, although without a guarantee from the master.

How to tension a chain on a VAZ 2121, replacing the chain tensioner, when it needs to be replaced

Chain tensioner - as is already clear from its name, it is needed only to tension the chain so that it does not loosen while the engine is running, and so over time this part breaks for various reasons, this happens, sometimes the tensioner simply cannot withstand very heavy loads breaks, for example, if you keep the engine speed in the red zone for a long time, the tensioner cannot withstand and breaks, but it can also break because it is not very durable, for example, there are a lot of very bad tensioners on the market at the moment qualities that really fail very quickly and after that they will need to be replaced with a new one, and you will learn how to do this from this article.

Design and symptoms of timing chain malfunction on Niva

Structurally, the VAZ 21214 engine installed on the Chevrolet Niva is similar to any engine of a classic Zhiguli . The differences lie in the use of a hydraulic tensioner in the timing mechanism, hydraulic valve compensators and a single-row chain instead of a double-row. In addition, the engine of a modern car is equipped with fuel injection, air conditioning, and hydraulic booster, which somewhat complicates repairs.

The chain in the timing mechanism is considered more reliable than a timing belt . It does not tear and has an additional margin of safety. The factory instructions require replacement at 100 thousand km, or at the first sign of malfunction. In this case, not only the chain is subject to wear, but also the camshaft and crankshaft sprockets. The development and natural stretching of the chain leads to a shift in valve timing and deterioration of engine performance.

Symptoms of Chevrolet Niva timing faults:

Important! The simplest and most reliable way to determine a malfunction is to evaluate its operation by ear. A thin metallic ringing from under the cover indicates a weakening of the chain tension. With severe wear, the sound becomes similar to the rattling of a diesel engine.

The main reasons for accelerated wear of the chain and sprockets in the timing mechanism are low-quality oil and its irregular replacement, engine operation in extreme conditions, and defective replacement parts.

What you need to know about the gas distribution mechanism (GRM) of the Chevrolet Niva

The Chevrolet Niva engine has one camshaft, which alternately opens 8 valves. It is driven by the crankshaft through a chain that rotates on their pulleys. The stable operation of this element is ensured by the tensioner and damper.

In order for the intake and exhaust valves to open at the required stroke, the crankshaft and camshaft must move synchronously - the camshaft rotates twice for one revolution of the crankshaft. You can evaluate the coordinated operation of both units by the marks that are installed on the pulleys.

(Timing) Chevrolet Niva

How to replace the chain tensioner on a VAZ 21213-VAZ 2131

Cars of the Niva family are very old models, in my opinion the very first cars went back to 1977 if memory serves, but these are new times and the car is still being produced and refined, so here are the chain tensioners that AvtoVAZ installed on its cars in Depending on the year of production, they may differ from each other, so for example, somewhere before 2000 or even higher, these cars of the Niva family came with the most common spring chain tensioners, these tensioners are very easy to remove, but one of their drawbacks (Or maybe an advantage) is the fact that they do not tension themselves, that is, from time to time you have to tighten them yourself, which is very inconvenient, but this is for someone, because it only takes 1-2 minutes to tighten the chain tensioner!

Now let’s look at a new type of tensioner that came on cars that were produced much later, so to speak, during Russia and not during the USSR, and so in new times, the so-called hydraulic chain tensioner was installed on this family of cars, its whole advantage is that you won’t need to constantly tighten it, that is, it was installed at the factory, and you, as they say, forgot about it, but it’s not so simple, if this tensioner suddenly jams or something else happens to it, then you will have to change it to a new one , and today you will learn how to replace this type of chain tensioner in this article. (By the way, you can see what a hydraulic chain tensioner looks like in the photo below)

By the way, if you have a regular tensioner of an old model, but it looks like it is shown in the photo, then read more about how to replace this unit in the article entitled

Removing the chain tensioner

1) At the very beginning of the operation, use a wrench to unscrew the tube that is connected to the hydraulic chain tensioner itself, and after this tube is unscrewed, disconnect it and move it aside.

2) Then, using a wrench or a socket with a universal joint (If it is difficult to get to), unscrew the two nuts that secure the hydraulic tensioner to the car engine (One of the nuts is not visible in the photo, but when you look at this tensioner on the car, then you will immediately understand where the second nut is, since it is located nearby) and then carefully remove it from the hole in which it is located.

Installing a new

Installing a new tensioner occurs in the reverse order of removal, and by the way, after installation, close the hood and sit behind the wheel of your car, then try to start the car and if that chain rattle disappears, then you did everything correctly and that’s why the chain rattled the tensioner itself.

Checking the tensioner for wear

Timing belt 21213, specifics

single-row timing belt 21213

The photo shows a single-row timing belt 21213, which has already been checked and run-in. Set contents:

- Single row chain 21214

- Set of Rusmash stars

- Tensioner shoe, tensioner shoe shaft, short chain guide

- Front crankshaft cuff (Rezinotekhnika)

I'll try to explain why the new kit is better. The difference in losses between the SAME single-row and double-row circuits in terms of efficiency (efficiency) is relatively small. According to theory, about 4-5%. But we have an “ace of trumps” in our pocket. The double-row chain in timing belt 21213 is bush-type, that is, the roller does not rotate, the so-called “heavy chains”. The single-row chain that goes to this timing belt is a bush-roller chain, the rollers rotate, these are “light chains”. But in this case, the difference in friction losses is no longer a few percent, but tens of percent. There is a separate article about this bushing-roller chain. And of course, friction losses on the rubber and plastic shoe of the tensioner are clearly not in favor of the old design. Now about the chain tensioner for this unit. I recommend installing “Rusmash”. The point is this: the tensioner shoe 21213 has an iron base, and the shoe 21214 is plastic, and the TZA tensioner, with its sharp nose, will slowly break it. Mechanical tensioners were discussed in more detail earlier.

Selecting tools and spare parts for replacement

Replacing the timing chain on a Chevy Niva is impossible without an inspection hole or a lift . Therefore, before you decide to carry out such repairs yourself, you need to find a suitable place. Convenient access from below is necessary to remove the engine protection and conveniently unscrew the auxiliary pulleys. You will have to remove the radiator with fans and drain the coolant. On average, the entire replacement operation will take from 3 to 5 hours.

Necessary tools for repair:

With spare parts for repairs everything is also simple . Buy them only from trusted stores and well-known brands. The abundance of spare parts for VAZ engines in stores does not always mean a quality product. Timing units from factory manufacturers and official conveyor suppliers have proven themselves to be the best.

Important! Parts for different VAZ engines may differ in design. The Chevrolet Niva has the VAZ 21214 engine model, while the classic Niva may have the VAZ 2106, 21213, 21214, 21218 engine and their modifications.

We will need:

Advice. It is convenient to combine such a labor-intensive operation of replacing the chain with other work on the engine. For example, replacing the pump, radiator, leaking oil seal, drive belts of mounted units and other minor repairs.

Adjusting the chain according to the marks.

When replacing a chain, installing a new one should be done in several stages:

- collecting the necessary tools: screwdriver, set of keys for 8, 10 and 13. Wrench for rotating the crankshaft

- The car is placed on a viewing hole or raised using a jack. The wheels are fixed with shoes or a stop.

- Before starting work, you must turn off the fan and unscrew the radiator mounts. All pipes, except the air duct, remain in place; the antifreeze does not drain.

- After this, the valve cover is dismantled. After all the fasteners have been unscrewed, you must carefully remove it, preventing dirt from getting inside.

Cause and investigation

We received a lot of questions by email: why was the double-row adjustable gear removed from sale, why don’t you offer a good double-row timing kit? The reason is simple: I don’t see the point. The double-row timing chain and the rubber coating on the tensioner shoe “ate” all the fine adjustments. Since I don’t like criticism and loudmouthing, without offering an alternative, I picked up and tested a single-row kit for a carburetor engine. Now you can put a good split gear on it, a tuning camshaft, and you will really feel the nuances when adjusting.

Step-by-step instructions for replacing the timing belt yourself

Repairs begin by preparing the car for partial engine disassembly . To do this, the machine is placed on a pit or a lift. Remove the engine protection, drain the antifreeze from the radiator, dismantle the main radiator with cooling fans. Loosen the fastening of the power steering pump and generator, remove the drive belts.

With an air conditioner, there are 2 options : drain the refrigerant and dismantle the radiator, or carefully move it to the side and hang it so as not to break the hoses. We disconnect all the cooling system hoses that interfere with the repair area. Remove the air filter, throttle cable, air pipe. In this semi-disassembled form, you can proceed directly to replacing the timing chain.

Replacing the chain drive

- Place the car on a level surface. Open the hood. Disconnect the battery. Remove the air filter.

- The choke cable should be disconnected and moved away. It is also necessary to disconnect all electrical drives and pipes.

- Remove the fan, generator belt and pump roller. The belt should be thoroughly examined. If deep cracks or other damage is found on it, it must be replaced with a new one. Remove the tray protection and thoroughly clean its cover.

- Remove the valve plug. Unscrew the camshaft sprocket screw.

- Take a wrench and unscrew the ratchet nut.

- Now we begin to rotate the crankshaft until the marks on it and on the engine casing completely coincide. Make sure that the marks also match on the bearing housing and camshaft sprockets.

7. Then remove the casing covering the motor. To do this you will have to remove several bolts. We remove the sedative. Unscrew the screw securing the oil supply pump. There is no need to remove the screw. It should only be loosened and left in place.

Now let's check the operation of the mechanism. To do this, start the engine and listen to how the engine operates. By hearing it is quite possible to determine whether everything was done correctly or something went wrong. If the sound is familiar, rustling, then everything is done correctly. If there is a characteristic grinding sound, the procedure must be repeated.

Installing timing marks VAZ 21214

There is a standard 21213 NIVA, the engine of which has tractor traction at the bottom and lacks traction at speeds above 3000. Replacing the chain, all the sprockets, the camshaft with the bed did not solve the problem. Rearranging the chain on a tooth back and forth, too. It was noticed that the mark on the camshaft sprocket is not installed strictly opposite the protrusion; it can be placed half a tooth forward or backward. It was decided to check the valve timing. A device for adjusting valves with an indicator is welcome, but not at all required. However, I have it. The valve clearances must be properly adjusted!

When replacing the lower sprocket, check that the marks on the small sprocket and the pulley match. They correspond to TDC.

For example, we got 15 degrees.

By simple calculations (in our head) we find the valve overlap point (15 + 12.5)/2 = 13.75 degrees. This point, located at TDC, is considered optimal. In our example, the overlap point moved 1.5 degrees after TDC. You can check the pie chart of the valve timing and compare the result:

On my car, the mark, with new sprockets and chain, turned out to be shifted forward by 5 (!) degrees. This is where the tractor came from. Perhaps VAZ specifically places this mark with an offset in order to increase the torque at the bottom, or maybe during assembly they use sprockets from Lada cars. In NIV, the block is slightly higher, which is why the mark shifts. Don't know. To correct the situation, a split (adjustable) sprocket was purchased and installed:

With its help, you can smoothly adjust the position of the camshaft relative to the crankshaft + - 1 tooth.

If we set it so that the overlap point does not reach TDC, we get earlier opening of the intake, an increase in power at high speeds and a drop in traction at low speeds, and vice versa, the overlap point after TDC - we have tractor traction at low speeds, and stupidity at high speeds. Exact recommendations like “how many degrees should I turn?” no one will give it to you. It all depends on the condition of the engine and personal feelings. However, you should not go more than half a tooth away from the point of zero overlap. It must be remembered that at large angles the pistons may collide with the valves. I made it so that the overlap point was shifted by 2.5 degrees before TDC, I got a good pick-up after 3000 rpm, and at low speeds the thrust remained almost unchanged. After all the manipulations, it is necessary to re-set the ignition timing, and it may be necessary to adjust the idle speed.

Consequences of untimely replacement

Often the cause of repairs is an imperfect design of the hydraulic tensioner. To avoid this, many people replace the Chevrolet Niva chain tensioner from hydraulic to mechanical. Otherwise, operating the timing chain longer than expected can lead to disruption of the normal operation of the engine , and in advanced cases, to its overhaul.

The increased functional life of the components and simple replacement allow you to regularly replace the timing mechanism yourself. In combination with high-quality oil, this will significantly extend the life of the engine, and will save the car owner money and nerves.

Chain 21214, operation

This is the most important part in the revised article. Operators and mechanics have a slang expression about the operation of mechanisms and engines - “in operating or normal mode.” Let me explain with a comparison, like the son of a doctor. A person has blood pressure and pulse, which are considered normal. Let it be 120/80 and 60-70 beats per minute. And suddenly there was a pounding in my temples, my pulse quickened - hello high blood pressure. In both the first and second cases, you will walk, think, eat. But in the first case, your body and heart in particular are working “in working mode,” and in the second, the situation needs to be corrected. The doctor has a tonometer and a stethoscope in his hands, and the control unit has a knock sensor that listens to the noise level in the engine. In fact, its purpose is to measure detonation in the cylinders, but if there are still extraneous loud sounds in the engine, then it will add them to the overall picture. In professional diagnostic programs, it is possible to look at the data before entering the ADC (analog-to-digital converter). For this circuit, the knock sensor readings are lower than on Ditton, from 3% and higher. The service life of this chain is also higher than that of the Baltic one; operation “in operating mode” is more than 100 thousand km. Just install chain 21214, not on factory stamped sprockets, but on turned sprockets, with teeth made on a gear-cutting machine, otherwise there will be no fun. It is for this reason that I do not recommend purchasing a chain separately. Or at least with a set of sprockets, or better yet a complete timing belt set.