Generator VAZ 21099, VAZ 2109, VAZ 2108

Cars of the VAZ “8, 9, 99” family equipped with a carburetor, fuel injection system (injector) are equipped with generators of type 37.3701, 94.3701.

Both power supplies are AC, three-phase, with pre-installed rectifier and voltage regulator. The rotation side is right.

The first type of power source (hereinafter - IP) is driven by a V-belt, and the second - by a poly V-belt from the crankshaft pulley. Some production models of the “eight” and “nine” are equipped with IP made in Slovenia, marked AAK-5102.

If AAK-5102 fails, it can be completely or partially replaced by 94.3701. The process of self-prevention is not at all complicated, but it requires knowledge and initial experience in vehicle maintenance. Carrying out diagnostics in a non-professional manner does not guarantee the functionality of the equipment.

Why is a generator needed?

It is needed to power the on-board network when the engine is running. When stopped, the entire network is powered by a battery. If you yourself replaced the VAZ-2108 generator or any other car, you saw that it has one power terminal. Several wires are connected to it:

- The thickest one connects the generator to the positive terminal of the battery. It is through this wire that the battery is charged. Please note that there are no fuses on it. Therefore, during any manipulations with the generator, it is necessary to de-energize the on-board network.

- A thin short wire going to the voltage regulator is necessary to power the excitation winding.

- It is rare, but it happens that additional equipment is connected to this output of the generator.

The cars use a rather old but proven design of the VAZ-2108 generator. The carburetor is used in the fuel injection system. On injection cars, fuel injectors and ignition coils are powered from the power output of the generator. All other consumers take power from the positive terminal of the battery.

Technical characteristics of generator 37.3701

— The magnitude of the delivered current (at 6000 rpm-1 and voltage 13 V) – 55 A

— Voltage value – 13.6 – 14.6 V

— The direction of rotation of the rotor is right

— Maximum rotor speed – 13000 rpm-1

— Gear ratio engine/generator 1/2.04

What generator is installed on the VAZ 21099, VAZ 2109, VAZ 2108

| Specifications | 37.3701 | 94.3701 |

| Limit current strength at a voltage of 13.5 V and speeds above 5500 rpm | 56 | 81 |

| Adjustable voltage range | 13,5-14,4 | 13,3-14,6 |

| Gear ratio | 01.01.1970 | 01.01.1970 |

| Capacitor capacity | 2,3±15% | 2,1±15% |

Note to the driver!!! If the IP drive belt breaks along the way, and you don’t have a spare one at hand, cut a 25 mm wide ring from the car inner tube.

To significantly reduce current consumption when the power unit is running, it is necessary to turn off the maximum number of current consumers: radio, radio, lighting, cooler, stove heater.

Generator Modifications

On newer VAZ-2109, 21099, 2110 cars, modifications of generators with the designation 94.3701 were installed. Their power is much higher than those used on eights. But the dimensions of the VAZ-2108 generator are the same as those of more modern ones installed on dozens. Therefore, they are interchangeable, but have different characteristics. Here are the differences:

- The current strength of 94.3701 is 80 A, which is 25 A higher than that of the figure-eight unit.

- The voltage adjustment range on the 94.3701 generator is larger.

- The gear ratio between the generator rotor and the engine crankshaft is higher.

Installing a new unit is advisable if a larger capacity battery is used, and in the system of electricity consumers there are a lot of those that have greater power. And if you use standard electric cars, the battery will be discharged and will not have enough current.

Generator set price for VAZ 21099, VAZ 2109, VAZ 2108

| Catalog item | Serial number | Price | |

| A2110-80A (original) | BOSCH (9501.3801) (original) | From 3000 – 3200 | |

| 9501.3801 | FINWHALE 687-04 | 62022 / 180545 | From 3000 – 3200 |

| 9568.3749 | 922.3801 | SKL622RS | From 3000 – 3200 |

| 3701010 (HORT) | 3701024 | Contitech | From 3000 – 3200 |

| 3701971 | 3701953 | Electro 3701747 | From 3000 – 3200 |

| *prices are as of August 2022 |

The principle of operation of the power supply VAZ 21099, VAZ 2109, VAZ 2108

There are 6 coils mounted inside the generator set, the material is copper, the connection is star-shaped. The stator is a stationary structure, and the rotor rotates inside the stator. Magnetic brushes are pressed into the back of the rotor axis, and the excitation winding is wound and sealed.

After the key is turned in the ignition switch, the current from the battery creates a magnetic field, passing through the graphite brushes and copper winding. Alternating current is converted to direct current.

On the front side of the IP there are two power outputs with polarity “+” and “-”. Terminals with the appropriate polarity are connected to the battery.

To turn the generator set you will need a battery. After the battery has accumulated the spent amount of energy, the generator distributes the excess to other power sources. Thus, the size of the on-board network is maintained within an acceptable range.

How to install and connect a VAZ 2108 generator - step-by-step instructions

Installation of a new generator is carried out in the reverse order. Take a close look at the condition of the bottom bolt. If there is damage to the threads, it is better to replace it.

It will be easier for you to repair the generator later. When installing, pay special attention to belt tension. If it is not tensioned enough, your battery will not charge well. But if you tighten the belt too much, the bearing in the front cover will be destroyed. As a result, you will get an unpleasant whistle when the engine is running. And the reason for this is the appearance of play in the bearing.

The installation of the generator on the VAZ 2108 must be carried out in such a way that even the slightest distortion does not occur.

Video: Removing and installing the VAZ 2108 generator - step-by-step instructions

Replacement and repair of generator on VAZ 21099, VAZ 2109, VAZ 2108

Power supply location: engine compartment, to the right in the direction of travel of the vehicle.

Required materials and tools:

- open-end, spanner wrenches;

- knob, heads;

- torque wrench for precise clamping force;

- new drive belt as needed;

- plastic spatula for removing the belt;

- screwdrivers with a set of bits to change the brushes.

Step-by-step replacement instructions:

- We turn off the car engine.

- Open the hood.

- Loosen the terminals and remove them from the battery.

- Loosen the bolt that secures the bracket.

- We bring the generator set down.

- Remove the drive belt.

- We remove the IP from the engine compartment for further prevention.

- Upon completion of the diagnostic work, install the parts in reverse order.

After dismantling the IP, the master cleans it, performs an initial inspection, and determines possible breakdowns. The components are replaced with new ones, the terminals on the rotor are cleaned.

The part cannot be installed if cracks are found in the housing. Subsequent operation of the technical device is unsafe.

We check the integrity of the rotor winding with a multimeter. The diode bridge is also subject to prevention. Do not forget to check the integrity of the fuse, replace it with a new one as necessary, and observe the amperage.

Subject to the recommendations of specialists, subsequent maintenance of the power source after 30 - 40 thousand km.

To extend the life of electrical equipment, follow the technical inspection schedule. Purchase parts with original catalog numbers; a complete list of serial numbers is indicated in the table data.

Contact service station specialists for help if you encounter any difficulties with repairs or maintenance of electrical installations.

Removing the generator on the “eight”

To dismantle the unit for replacement or repair, you will need “17” keys and a mounting blade. Before starting work, be sure to generously treat all threaded connections to facilitate dismantling. The procedure looks like this:

- Disconnect the negative terminal from the battery.

- Unscrew the top nut securing the generator housing to the bracket.

- Unscrew the nut on the lower mounting bolt.

- Slide the generator housing towards the engine block and remove the belt.

- Unscrew the nut from the power contact and move the wires to the side.

- Remove the lower mounting bolt.

After all these manipulations, you can completely dismantle the unit. This can be done either from below, if protection is not installed on the car, or from above.

Design Features

VAZ 2109 cars can be equipped with two models of generator units. These are 37.3701 and 9402.3701.

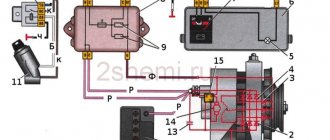

Description of the structural elements of the first:

- 1 — clamping fitting;

- 2 - bushing;

- 3 - buffer fitting;

- 4 — rear cover of the unit;

- 5 - bolt fixing the rectifier device;

- 6 - the rectifier unit itself;

- 7 - valve of this device;

- 8 - capacitor component;

- 9 — rear bearing element of the rotor shaft;

- 10 — slip rings;

- 11 — pulley of the rotor device;

- 12 - brush connected to terminal B of the regulator;

- 13 — contact 30, necessary for connecting energy consumers;

- 14 — contact element 61 of the generating set;

- 15 - brush connected to output Ш on the control mechanism;

- 16 - contact B of this element;

- 17 — the voltage regulator itself in the on-board network;

- 18 — pin for fixing the generating set to the tension bar;

- 19 — impeller;

- 20 - shaft;

- 21 — washers for fixing the bearing device;

- 22 - thrust ring;

- 23 — front bearing element of the rotor device pulley;

- 24 — rotor winding;

- 25 - pole piece of this device;

- 26 - another winding;

- 27 — stator mechanism;

- 28 — front cover of the generator unit.

Diagram of device model 37.3701

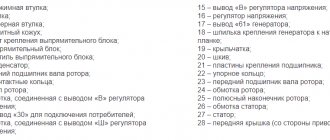

Design of unit 9402.3701:

- 1 — protective casing of the device;

- 2 — contact B+ for connecting the electrical equipment of the machine;

- 3 - capacitor device;

- 4 - common contact of additional diode elements. It connects to the D+ output on the control fixture;

- 5 — fixing device for positive diodes of the rectifying mechanism;

- 6 — clamp for negative diode elements;

- 7 - positive diode;

- 8 - negative element;

- 9 — voltage regulator in the machine’s electrical network;

- 10 — rear cover of the generating set;

- 11 — coupling bolt;

- 12 — front cover of the generating set;

- 13 - stator winding;

- 14 - thrust ring;

- 15 — front bearing element of the rotor mechanism shaft;

- 16 - shaft;

- 17 - nut;

- 18 — shaft of the rotor mechanism;

- 19 — cone-shaped washer;

- 20 - regular washer;

- 21 — pole pieces of the rotor mechanism;

- 22 — core of the stator device;

- 23 - bushing;

- 24 — winding of the rotor mechanism;

- 25 — rear bearing element of the rotor pulley;

- 26 — bushing of the bearing element;

- 27 — slip rings;

- 28 — brush assembly holder;

- 29 — contacts of the stator mechanism winding;

- 30 - additional diode element;

- 31 - common contact D.

Design of the generator 9402.3701

Carburetor power units are equipped with devices model 37.3701, and injectors - 9402.3701. These units are similar in design; they are synchronous AC motors. They are equipped with a built-in rectifier unit based on silicon diode elements. And the voltage regulator in them is electronic.

On vehicles built before 1996, 37.3701 models used separate adjusters and brush holders. In such devices, the voltage from pin 30 was supplied to pin B. In later versions, this parameter is supplied to pin B, since B is absent.

Generator bearing (front) 302 for VAZ Classic, VAZ 2108-099, Niva

The saying “the miser pays twice” has not escaped me! The generator bearings hummed quietly, unexpectedly and unexpectedly. To buy bearings you MUST know which one. Accordingly, I began to disassemble the generator. By the way, in order to disassemble it, I still need to remove it from there, and this was not at all easy for me: Difficulties arose with UNLOCKING the generator from below! Three bolts turned out to be 15. I had to go to the store to buy a key. Then, after removing the generator, I began disassembling:

NEXT: I found out which bearing was on top and started thinking about how to remove the rear one.

Don't buy these bearings! In another store we found these bearings:

changed, started EVERYTHING OK' the gene doesn't buzz, but when starting off, vibration appeared and after that I called for analysis and went and bought the same one for 1000 rubles, only almost new! This is the switch...

Worn generator bearings of VAZ 2108, 2109, 21099 cars betray themselves as a “howl” of a certain tonality. If you do not pay attention to the problem, then in the near future you may get a malfunction - a short circuit. Let's look at how to replace bearings on a 37.3701 generator, widely used on VAZ 2108, 2109, 21099 cars.

— Remove the generator from the car engine

— Remove the voltage regulator

To do this, use a screwdriver to unscrew the two screws that secure it, disconnect the tip of the wire coming from the diode bridge, and remove the regulator from the hole in the back of the generator.

Removing the generator voltage regulator 37.3701

— Remove the generator drive pulley

We unscrew the nut securing it, securing it from turning with a screwdriver.

Removing generator pulley 37.3701 for VAZ 2108, 2109, 21099 cars

— Remove the generator coupling bolts

To do this, use a 10 mm wrench to unscrew the nuts securing them and remove the bolts from the housing.

— Remove the front cover with the front bearing

We simply knock it off the armature shaft with a hammer. Before removal, mark the position of the generator housing parts relative to each other.

remove the front cover of the generator with the front bearing

— Remove the front bearing protective caps

Using an 8 mm wrench, unscrew the four nuts securing the front bearing protective cover. Remove it and the back cover with screws.

How to check for serviceability?

Before diagnosing problems with injection and carburetor cars, you must start the engine and let it run for a few minutes. Then, pressing the gas pedal, you need to increase the number of crankshaft revolutions to 3 thousand/min.

To create a simulation of driving in normal mode, enable:

- driving lights;

- rear window heating systems;

- stoves.

Diagnostics with a multimeter:

- The tester is used to measure the voltage at the battery terminals. This parameter will be 13.2 volts in model 9402.3701 and 13.6 V for 37.3701. If, during diagnostics, without removing the voltage at the battery terminals, the obtained value turns out to be different, this indicates a break or short circuit in the windings of the device. The voltage regulator and brush assembly may also fail. Sometimes the problem is oxidation of the contact components of the field winding.

- To ensure that the regulatory mechanism is working, all energy consumers are switched off. Only the high beam optics remains switched on, after which the voltage measurement procedure is repeated. This parameter should be in the range from 13.2 to 14.7 volts for model 94.3701. In the 37.3701 electric generator, the resulting value will be from 13.6 to 14.6 V.

- If the control element on model 9402.3701 is removed, it can be checked by connecting a light source to the brush mechanism. In particular, between its elements. The lamp should be rated at 1-5 watts and 12 volts. The DC power supply is connected to the D+ pins and device ground. Diagnostics is performed first by activating the voltage at 12 volts, and then at 15-16 V.

- In the first case, the light source should work, but in the second, it should not. If it is activated when 12 and 15 volts are supplied, then a breakdown must be looked for in the regulatory device. If there is no combustion, the cause should be checked for a break or broken contact between the brush elements and the terminals of the device. The regulator itself is changed to restore the generator's functionality. To test the device 37.3701, the light bulb is connected to contacts B and C, this is a plus, as well as to ground.

- Checking the valves of the rectifier device is carried out by disconnecting the cables from the battery, generator unit, and also the regulator contact. The positive terminal from the battery is connected through a light source to the B+ output on the generator device 9402.3701. If this is model 37.3701, then it must be connected to output 30. The negative contact is ground, connected to the housing. If, as a result of the actions performed, the light source started working, then the problem is a short circuit (in both blocks).

- Diagnosis of a similar problem on positive valves is carried out by connecting the positive contact of the battery to the B+ output (for model 37.3701 - contact 30). The connection is made through the light source. The negative contact goes to the output of the phase winding of the stator mechanism (you can connect to any). The inoperability of one or more positive valves will be indicated by activation of the light bulb.

- The procedure for diagnosing a short circuit on the negative contacts of the element is performed by connecting the positive terminal of the battery to the phase winding of the stator mechanism. There should be a light bulb on the electrical circuit, and the negative terminal goes to the housing of the generator set. If the lighting device lights up, this indicates damage to the negative valves or a short circuit of the stator mechanism to the body of the automobile electric generator.

- To prevent short-circuiting of the windings, the assembly is dismantled from the machine, after which the elements are disconnected from the regulator and the rectifier unit. Using a light source or an ohmmeter, parts are checked for short circuits. The valves of the generator device can be diagnosed with a tester; this does not require connecting a battery or a light bulb.

- To check additional diode elements, the positive terminal of the battery is connected to output D through a light source. In model 37.3701, the connection must be made to pin 61. The negative terminal goes to the output of one of the phase windings of the stator device; you can use a screw to secure the rectifier assembly. If the light source lights up, this indicates damage to the diode elements.

- To determine whether the valves are broken, you need to check the output current; this parameter should not fall as a result of the load. But such a problem may be caused by damage or short-circuiting of the windings of the generator unit.

- To diagnose each diode element, you will need a tester or test light. To do this, the rectifier assembly will have to be dismantled. If this device breaks down, it must be replaced as an assembly. It is possible to replace individual valves, but the main elements require re-pressing in the holding device. Performing this operation requires caution and skill from the car owner.

The windings of a stator or rotor mechanism can only be diagnosed using a flaw detector or electronic oscilloscope; the test consists of monitoring voltage curves.

The “Avto-blogger” channel described in detail the procedure for examining a car’s generator unit.

Possible faults

If the node does not work or functions incorrectly, you need to find the cause of the problem:

- When the ignition is activated, the indicator light on the dashboard does not light up. Perhaps this symptom was caused by a faulty fuse. The problem may be damaged wiring. It is necessary to check the electrical circuits and safety devices. Wiring testing is carried out using a tester.

- The LED indicator on the device does not light up, but the battery is discharged, all other control devices are working normally. A possible problem is a short circuit of the diode elements on the bridge or poor contact on the excitation winding. The cause of the problem may be a malfunction of the relay, failure of the brush mechanism, or damage to the wiring from the generator to the dashboard. All failed components can be repaired or replaced yourself.

- The battery indicator light on the dashboard lights up when the engine is running, the battery may be overcharged. It is necessary to diagnose the regulatory device; the problem may lie there.

- When the car engine is running, the battery indicator lights up too brightly or only at 50%. It is necessary to diagnose the drive belt; the problem may be that it is worn out or weakened. To eliminate the malfunction, the belt must be tightened or replaced. The reason may be a short circuit of the stator winding to ground or damage to the electrical circuit. Sometimes the reason lies in faulty diodes or disconnection of the rotor mechanism from the slip rings.

- A whistle comes from under the engine hood. The noise may appear when the power unit is started and disappear after a few minutes, or it can be heard constantly. The problem is due to wear on the drive belt. This product must be replaced.

- A strong hum-like noise may indicate a worn generator set bearing. Sometimes this symptom is associated with a short circuit of the stator winding to ground or a short circuit of one of the diodes.

- At night, when the optics are activated, you can see that the headlights burn dimly. But when you press the gas pedal, their brightness is restored to the required level. The voltage regulator device needs to be checked.

Channel “Tora 18” talked about the main malfunctions typical of automobile generator sets.

Replacing the VAZ 2110 generator

Good day, dear visitors of the site zerga.ru. In this article you will find information on how to replace a VAZ 2110 generator.

This information will also be suitable for owners of the entire line of the tenth family, and will also not ignore Priora, Kalina and other new VAZ models.

Before replacing the generator, you must make sure that it is faulty, otherwise there are cases where the generator was removed, but it is working.

In order not to remove the generator once again, you need to make sure that it is faulty. To do this, I recommend reading the corresponding article “Checking the VAZ generator”.

After we are convinced that the generator is not working, we proceed to replace it.

Since the generator is directly connected to the vehicle's electrical circuit, we need to prevent an accidental short circuit from occurring. To do this, you need to disconnect the positive terminal of the battery.

Now we are not in danger of a short circuit and we can safely disconnect the electrical wires from the generator. Everything is removed simply: a chip, two or three positive wires (under a rubber cap), which are secured with a ten-spanner nut.

Next we need to remove the alternator belt. On models of the tenth family, a flat multi-ribbed alternator belt is installed and a special mechanism is used to tension it, which we need to remove.

To remove it, you need to loosen the fixing nut of the tension mechanism.

After releasing the fixing nut, you need to completely unscrew the tension bolt and pull out the tension bracket.

Using a pry bar or a suitable piece of metal rod, we move the generator towards the engine block. At this point, the alternator belt will weaken and can be removed from the pulley without much difficulty.

How to repair it yourself?

The restoration procedure consists of several stages:

- First you need to dismantle the unit.

- Then it is disassembled, at this stage the unit needs to be repaired.

- After this the assembly is performed.

- At the final stage, the node must be installed and connected.

Required Tools

Before completing the task, you need to prepare:

- vice;

- removable tool for bearing devices;

- set of wrenches;

- screwdriver set.

Removing the generator

The dismantling procedure is performed as follows:

- The cables are disconnected from the generator set. They are usually made in red insulation and include 2 groups of conductors. One of them consists of two cables and is fixed with a nut to a bolt on the rear wall of the unit. The second group includes one cable and is connected to the terminal of the generator device via a contact element. It is also located on the back wall of the unit.

- To remove the generator unit from the power unit, you need to unscrew two nuts and a screw. First, the fastening element installed on the drive belt tensioner bar on top of the unit is unscrewed. Then the screw is unscrewed, which secures the part itself to the engine block of the machine, this element is dismantled. At the final stage, the nut is removed from the screw securing the bracket to the internal combustion engine.

- The fixation part is located at the bottom of the power unit, directly under the generator set. After the nut is removed, the drive belt must be removed from the shaft.

- The screw securing the assembly must be pushed to the left so that it comes out of the bracket. The element is pressed all the way into the vehicle body or into the mud shield of the unit.

- Then the two screws located on the right wheel side are unscrewed. They fix the dust protection of the generator set to the car body.

- If the bolt rests on the elements of the machine body, apply a little pressure to the motor. At the same time, the fastening part is removed.

User Sanya Kiselev spoke in detail about the procedure for dismantling the installation from the Nine engine.

Disassembly and repair

After the unit has been removed, all parts are dismantled and the VAZ 2109 generator is restored to functionality:

- Using a 19mm wrench, loosen and unscrew the nut on the rotor pulley. It is used to fix the impeller. To perform this task, the generator unit must be clamped in a vice. Using a screwdriver, the impeller is held from turning. Using a wrench, unscrew the nut counterclockwise.

- The impeller of the device is fixed with a pin. After dismantling it from the pulley, it is necessary to remove this element and put it aside; it cannot be lost. When unscrewing the nuts, it is recommended to sketch the location of the components.

- Then the generator unit is turned over with the back cover up. Using a size 8 wrench, unscrew the four nuts.

- The pins are removed and the front part of the device body is dismantled. The front bearing element is also located here; it is fixed using plates. To dismantle them, you need to unscrew the nuts that secure the elements.

- Using a special puller, the bearing device is removed from the landing site. If you don’t have a tool, you can use a hammer and a mandrel of the appropriate size. The use of a wooden board is allowed.

- The spacer sleeve is removed from the rotor mechanism pulley.

- This unit is removed from the rear cover of the generator device.

- The leads of the stator winding are disconnected from the rectifier. To do this, you need to unscrew the nuts that secure them. After dismantling the fastening elements, the bolts are unscrewed. They record the conclusions themselves.

- Insulating pads are located on the bolts. The stator winding must be removed from the unit housing.

The next step is to remove the diode bridge; this requires the following steps:

- Use a wrench to unscrew the nut that secures contact number 30.

- Next to this pin there is a block with a plug. This element must be dismantled. But you should first release the fastener using a small flat-head screwdriver.

- The latch is disconnected from the inside. Then the block with wires is pushed inside. The plug should remain on the cover. The diode bridge is dismantled from it.

- The next step requires a vice. The rotor mechanism must be clamped into the equipment so that the rear bearing device is located on the top.

- Using a puller, the part is dismantled. To do this, you need to put the tool on top of the assembly and pull the bearing element off the pulley.

Unscrewing the impeller of the generator unit Disconnecting contact 30, connector and dismantling the diode bridge Removing the bearing device from the pulley

After disassembling the elements of the generator unit, replacing the failed components:

- To change bearing parts, you need to check the markings of the elements. Similar spare parts are purchased at the auto store. Even if the bearings are visually intact, it is recommended to replace them. The parts are not interchangeable, so when purchasing, be sure to follow the markings.

- The same goes for the diode bridge. The markings are rewritten from the part, only after that the spare part is purchased. If there is visible damage to this device or metal oxidation has occurred, the unit must be replaced. It is fixed to the generator housing with four nuts. The diode bridge is located at the back, on the inside.

- A visual diagnosis of the front cover of the generating set is carried out. If there are cracks or other damage, the casing must be replaced. When performing visual diagnostics, it is important to pay attention to the fastening elements.

- The diameter of the seat for the bearing parts in the front cover is measured. If the socket for their installation is more than 4.2 cm in diameter, the cover must be replaced.

- Then a visual check is made of the rear of the unit. If there is damage on it in the form of cracks, it must be replaced. Wear or breakage of the seating area under the bearing element is not allowed. If such damage occurs, the cover must be replaced.

- Visual diagnostics of the internal surface of the stator device is carried out. Scratches and other defects resulting from touching the anchor are not allowed. If wear is detected, the bearing elements or the generator set cover are replaced.

The winding of the dismantled rotor mechanism is checked, the task is carried out as follows:

- It is necessary to visually inspect the slip rings. These elements must be replaced if defects are found. We are talking about signs of wear, scuffs, scratches, etc. In principle, the rings do not need to be replaced if the damage is minor. But then they will have to be sanded, for this you will need fine-grained sandpaper.

- If damage to the elements cannot be removed with sandpaper, you can try turning them on a lathe. When using the equipment, it is necessary to remove a minimum layer of metal and then sand the surface.

- Using a tester, the resistance value of the winding of the rotor mechanism is checked. To do this, the device must be connected to slip rings. If the diagnostics show that the resistance tends to infinity, this indicates a break inside the winding. To correct the problem, you will need to replace the rotor mechanism.

- Using a test lamp, a diagnosis is made of the absence of a short circuit in the winding of the anchor device on the housing. To do this, you need to activate the light source by connecting it to the battery. One contact is connected to the body of the anchor device, and the other is connected to each ring in turn. The indicator light should not light up when the rotor is operational. If it is activated, this indicates a short circuit in the winding, then the armature will need to be replaced.

Vyacheslav Lyakhov spoke in detail about performing diagnostics, as well as repairing the unit in the VAZ 2109 car.

Generator assembly

If you managed to disassemble and repair the unit, then after completing the work you will need to put it back together:

- The rear bearing device is installed at the landing site, on the shaft. A wooden board and a hammer are used to complete the task. The bearing is carefully driven in so as not to damage the part. To do this, just hit it several times.

- If the diode bridge was dismantled, it must be reinstalled. The device is located in the back cover of the case.

- The protective casing is then installed on the anchor device so that the bearing element is completely seated. To simplify the action, you can use a hammer. Light blows on the cover clog the bearing; it must be placed on the pulley. The same part installed on the front cover is replaced and fixed using plates.

- Then the generator device is dismantled from the vice. Before installing the front cover on the assembly, the spacer ring is mounted on the pulley. This part should be located between the thrust recess and the front bearing device.

- The cover is installed from the front, the stud nuts are tightened using the crosswise method. This will ensure more uniform tightening of the fastening elements.

- The stud is installed in the recess on the shaft of the anchor device. Then the impeller is installed, the element is clamped with a nut.

- At this point, the assembly procedure for the generator device can be considered complete. All that remains is to install the voltage regulator with brushes at the landing site.

Evgeny Bragin described the assembly procedures for the “nine” unit, indicating all the nuances of this process.

Installation and connection

Installation of the generator unit is carried out in the reverse order; when performing this task, it is important not to forget to connect the wire to the control device:

- A fixation bracket is screwed to the installation. A wrench is used.

- The bracket is then screwed into place with the generator set. When performing this task, you do not need to tighten the nut all the way.

- Self-tapping screws are used to secure the unit's dust protection.

- The drive belt is being installed on the generator set pulley.

- The tensioning element strip is being installed.

- The drive belt is tensioned. When performing this task, it is important that the deflection of the product is about 1-1.5 centimeters. When tightening the belt, it is necessary to tighten the nut on the tensioner bar. Then this element is clamped on the bracket until it stops.

After the installation is completed, you need to connect the terminal blocks to the generator device. When performing the task, you need to make sure that the clamps are disconnected from the battery. There should be a total of three wires connected to the unit. Paired cables are secured with nuts to a stud located on the back cover. A male connector must be installed in a female connector.

Then the terminal clamps are installed on the battery, and the power unit is started. The generator unit supplies the voltage required for full operation of all machine devices.

To be sure that the unit is working properly, you need to use a voltmeter to diagnose the voltage that the unit produces.

Generator set connection diagram

The practical part is removing the generator, disassembling it, repairing it and reinstalling it.

Due to the fact that the generator is located under the hood of the car, it is necessary to turn off the engine, turn the steering wheel to the right all the way and open the hood. The electric generator on VAZ 2108 - 15 cars is installed in front of the engine, in the lower left corner of the engine compartment, between the engine and the cooling radiator.

Before dismantling the generator, it is necessary to disconnect the ground from the battery, i.e. negative contact.

Replacing VAZ generator brushes

Before removing the generator itself, in order not to do unnecessary work, we remove the charging relay from the generator housing and check the production of the generator brushes. The charging relay is installed in the rear of the generator housing, and is attached to it with two bolts. To unscrew them you will need a Phillips screwdriver. When unscrewing the bolts, be careful not to drop them on the crankcase guard, otherwise getting them out of there will be one big problem.

To remove the relay, you need to disconnect the wire, the “female” contact. After removing the charging relay and visually inspecting the brushes, we decide to purchase a new generator voltage regulator relay or reinstall the dismantled one, depending on the wear of the brushes. For their normal operation, a brush length of at least 4 cm is required. Now we proceed directly to removing the electric generator from the engine.

- We disconnect the wires from the generator - as a rule, they are red and consist of two groups of wires, red. One group consists of two wires and is attached with a nut to a bolt on the rear wall of the generator. The other group consists of one wire and is connected to the generator terminal via a male-female contact, also on the rear wall of the generator.

- To remove the generator from the engine, you need to unscrew two nuts and one bolt in the following sequence: unscrew the nut attached to the generator belt tensioner bar (at the top of the generator), unscrew the bolt securing the tensioner bar to the engine block and remove it. The last step is to unscrew the nut from the bolt securing the generator bracket to the engine block.

- The generator mounting bracket is located at the bottom of the engine block, directly below the generator. After unscrewing this nut, you need to remove the generator belt from the generator pulley itself.

- The generator mounting bolt should be pushed to the left, out of the bracket, until it stops against the body shell or the generator’s mud protection.

- On the right wheel side, you need to unscrew the two screws that secure the dust protection of the generator to the car body.

- If the generator mounting bolt still rests against any body parts, you should press on the engine with one hand, and at the same time pull out the bolt with the other hand.

Now your generator is completely disconnected from the engine, and you can begin to disassemble and repair it.

Removing the generator pulley

To do this, we stop it from turning with a screwdriver and unscrew the nut securing it with a 19 mm spanner. The tightening torque is large, so it is better to use a wrench with a long handle.

Removing generator pulley 37.3701 for VAZ 2108, 2109, 21099 cars

Then we remove the following parts: nut, washer, pulley with impeller, segment key.

Separate the halves of the generator housing

First, we mark their relative positions (by placing marks on both parts). Using a 10 mm wrench (it’s more convenient to use a socket or socket wrench), unscrew the four nuts of the coupling bolts (there are engraving washers under the nuts).

Pull out the bolts. Remove the front part of the generator. Remove the rotor from the back of the generator. If it cannot be removed, you can tap it with a soft metal drift through the window under the voltage regulator, or by screwing a nut onto the thread of the shaft and holding it in a vice, with a sharp upward movement, pull the back cover into the shaft. The bearing remains on the rotor shaft. If necessary, we dismantle it with a puller and press on a new one (See “Replacing generator bearings”).

Disconnect the stator

Using an 8 mm wrench (it’s more convenient to use a socket or socket wrench), unscrew the three nuts securing the stator terminals to the diode bridge. We remove it from the back cover of the generator by prying it with a slotted screwdriver or hitting it with a hammer.

When is it time to repair a generator?

1. Any instrument cluster has a battery charge indicator (indicated by a red arrow, using the example of an instrument cluster from a high panel). When the generator stops supplying charge to the battery, this indicator lights up. When the ignition is turned on, it should light up, but when the car starts, it must go out. Otherwise, the generator does not produce current and needs to be inspected. It happens that the battery runs out quickly, and the indicator lamp does not light up at all. In fact, you can’t trust it 100%; sometimes the generator produces a very weak current, insufficient for a light bulb. This situation leads to the fact that literally in 1 week the battery is completely drained and you have to put it on charge. We recommend periodically checking a working battery.

2. You will need a multi-meter with the voltmeter function enabled. Measure the readings given by the generator to the battery (the procedure is demonstrated in detail in the video below). After you start the car, the voltage at the terminal will most likely be about 12-13 Volts and will gradually increase. Don't have a voltmeter? There is an alternative way to check, but it causes damage to the diode bridge (we do not recommend using this method on fuel-injected cars; it is better to stock up on a multi-meter):

- start the engine and let it run for approximately 2 minutes;

- apply gas and pull out the choke so that the engine reaches about 2 thousand revolutions;

- Disconnect the negative terminal from the battery.

If the car works, everything is fine with the generator, put the terminal back. The car stalled - the generator has become unusable and needs to be replaced or repaired. But! It happens that the generator gives a charge, but it is too weak (around 12 Volts), which is why the battery quickly runs out (the car will not stall after removing the terminal from the battery, so this method does not always work).

Safety precautions when working

Nuances that must be taken into account when repairing a VAZ 2109 generator:

- All control and adjustment work related to diagnosing the unit with the engine running must be carried out in a ventilated area or outdoors. If it is a garage, it is recommended to open the doors or provide good ventilation.

- Before carrying out the task, you need to button up your sleeves if the work is performed in a shirt. All hanging ends of clothing should be removed to prevent them from getting caught on the operating pulley.

- To carry out repairs, a specialized tool is used.

- The generator must not be allowed to fall after it has been removed during transportation to the machine. This can lead to complete failure of the unit.

- Repairs should only be carried out using serviceable, clean and oil-free tools.

- If the nuts are rusty and difficult to unscrew, it is recommended to treat the elements with kerosene or WD-40 before turning them out. Dismantling is carried out with preliminary tapping with light blows of a hammer.

- The vehicle is inspected using a 36-volt light bulb. If the diagnosis is performed in a ditch, a 12 V light source will be required. It is important that the light bulb is equipped with a safety net.

VAZ 2109: replacing alternator brushes on your own

In a VAZ 2109 car, replacing the alternator brushes is necessary if they are even slightly worn out. Otherwise, the generator may be damaged. And this will lead to the fact that it will be impossible to use the machine, since without a generator you can forget about normal functioning. Simply put, the car will not be able to start. And besides, the battery will discharge too quickly. If any defects are noticeable in the operation of the generator, they urgently need to be eliminated. Replacing the brushes of a VAZ 2109 generator is a simple process and anyone can handle it.

Reasons for replacement

Replacing generator brushes VAZ 2109

Generator brushes need to be changed in the following cases:

- They have worn out so much that they have ceased to perform their main function - to maintain battery charge.

- The battery drains quickly.

Note: there are many reasons why the battery discharges quickly. Therefore, this does not always signal bad brushes. But just in case, it is better to check them, since perhaps the reason is hidden precisely in them.

Checking brushes at home

Replacing generator brushes on a VAZ 2109

To check if the brushes are working correctly:

- Remove the battery so that the generator is de-energized. Otherwise, a small short circuit may occur in the system.

- Disconnect the voltage regulator.

- Visually inspect all brushes.

- If their length is less than 5 mm, they must be replaced urgently, as they no longer function as expected.

Quick brush replacement

Replacing brushes in a VAZ 2109 generator

To replace the brushes you will need the following tools:

- 8 key (or 8 socket).

- Flathead screwdriver (to remove the cover).

- Open-end wrench 13.

To replace brushes quickly and easily, do this:

- Loosen the nut and bolt that secure the generator.

- Remove the alternator belt.

- Start the engine.

Note: By the way, a bad belt can also cause alternator problems. It needs to be checked and replaced if necessary. To check, you need to bend it and see if there are any cracks on it.

- Disconnect the battery (to do this, disconnect its negative terminal). This must be done extremely carefully, since the battery contains acid that can damage the skin if it comes in contact with it. This must be done in order to avoid a possible short circuit.

- Disconnect the wires from the generator.

- Remove the front crankcase protection.

- Unscrew the lower mount of the generator.

- Use a flat-head screwdriver to block the rotor until it becomes completely stationary.

- Unscrew the pulley.

Repair costs

The approximate cost of spare parts is shown in the table.

| Name | Price, rub |

| Price of a set of bearing elements | Around 150 rubles. |

| Generator diode bridge | 200 rub. |

| Charging relay | About 150-200 rub. |

| Removal tool for bearing elements | Around 100-200 rubles. |

| Prices are relevant for three regions: Moscow, Chelyabinsk, Krasnodar. | |