01/26/2022 5,022 Sensors

Author: Ivan Baranov

Modern cars use many different types of controllers and sensors. Such devices can be control and executive. If for some reason the controller fails, it can cause inconvenience in terms of driving. What is a reverse sensor and what functions does it perform? The answers to these and other questions are presented below.

[Hide]

What is a reverse sensor

Any car has a reverse gear in the gearbox, or, more simply, reverse gear. You can’t do without this function; reverse direction of movement is required when making difficult turns in a limited space, leaving and entering a parking lot (garage), and when crossing off-road conditions. Since the natural position of the driver is directed towards the direction of travel, visibility when reversing is limited. There may be people, vehicles, or stationary obstacles around a vehicle moving backwards. It is necessary to ensure their safety, as well as help the driver navigate difficult driving conditions.

And what about the reverse gear sensor?

Among the safety measures and driver assistance when engaging reverse gear, the following technical means can be listed:

- Reversing lights. They not only illuminate the vehicle's path when reversing. For pedestrians and other road users, the inclusion of white lights on the rear of the car is a signal. Drivers located on the trajectory will be prepared for non-standard movement of the car in front.

- On large vehicles (buses, trucks, special equipment), turning on the reverse is accompanied by a sound signal.

- Activation of parking sensors.

- Turn on the rear view camera, which is the best means of monitoring traffic in blind spots.

How to activate these funds? Activating them manually is dangerous and unreliable; safety devices must be activated automatically. This is why you need a reverse sensor.

From a technical point of view, this is a switch (more precisely, a switch) activated mechanically.

Such limit switches are used not only in cars. When a certain object is moved into the action area of the push rod, the switch contacts close.

And then it’s a matter of technology. You can activate relays to turn on high-power devices, or supply power directly to them. For example, on the reversing lights. Actually, according to their purpose, these sensors are divided into universal (for connecting a number of systems via a relay) or working exclusively in the rear lighting circuit.

Functionality check

Before blaming the sensor for the malfunction of the reverse signals, make sure that the device has actually lost its functionality. To do this, run the diagnostics:

- Turn the wheels to the left all the way and look at the sensor from the driver’s side - there is a protection on the side of the gearbox, and contacts inside it;

- Remove this protection and inspect the device. There are also two contacts going to the sensor;

- Close the contacts on the frog limit switches (this is the same reverse sensor) and start the engine, engaging reverse gear;

- If everything is fine, the wires and contacts are working properly, then the white headlights will turn on;

- If the headlights do not light, use a tester to check the voltage on the wire (orange) and ground;

- If there is voltage, check the light bulb board and the quality of the contacts.

Causes of the problem and solutions

There are several most common reasons why the DZH fails. But there are countermeasures that can return the sensor to operation.

Causes of the problem

The contacts on the wiring have oxidized

They just need to be thoroughly cleaned and returned. In this case, the negative terminal of the battery must be disconnected

As the sensor is used, it may move out of its seat. Screw it in tighter

There is no contact with the wiring in the gearbox

Check the condition of contacts and wires. Clean or replace damaged parts

There is no contact between the plug and the fuse box

Also check the condition of the contacts, clean them, change the wiring

Here the situation can only be corrected by replacing the fuse

In some situations, the sensor is working properly, the contacts are intact and the wiring is undamaged. In this case, the light bulbs themselves burned out. They are easy enough to replace.

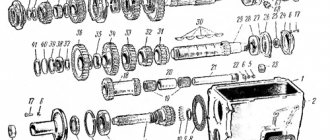

Location of the switch in the car

Where is the reverse sensor located? In principle, it can be placed next to any object that occupies a certain position when reverse gear is engaged. Is the gearshift lever suitable for this? In principle, yes, but moving the handle may not engage reverse gear. And vice versa: reverse gear may be engaged, but for some reason the handle will not take the desired position. It is most reliable to place the sensor itself in the switching mechanism. It is usually located in the gearbox housing.

The sensor rod is moved by the rocker, which is responsible for the position of the reverse drive gear.

Information! Sensors of this type are located only in manual transmissions. In cars with automatic transmission, the signal to turn on the reverse safety systems is provided by another device.

You should know that the mechanical part of the sensor and the threaded connection are actually a plug in the sealed gearbox housing. It contains transmission oil, which can spill out if the seal is broken.

Summing up

A reverse light that doesn't come on is just as potentially dangerous a problem as a reverse light that stays on all the time, even when the car is moving forward.

Therefore, such a problem cannot be ignored under any circumstances. Just like installing a flashing brake light for the sake of beauty. It may look impressive, but it confuses drivers significantly.

In some cases, you can find and eliminate the cause yourself. And without any problems. But there are also situations when the best solution is to visit an experienced auto electrician.

Types of sensors

By drive type:

- Rod or rod: a movable element in the form of a pin with a large range of movement.

Such an element does not require high mechanical precision, but takes up a lot of space in the gearbox. In addition, it is necessary to ensure tightness: for example, a seal around the rod. - Ball-type: a pressure mechanism in the form of a spring-loaded steel ball.

Small stroke (2–5 mm), high precision required. But the sensor takes up little space and is sealed in design.

By connector type:

- opening pin or knife type contacts;

- closed standard connector with casing for protection against oxidation;

- bayonet swivel connector;

- screw terminals for fastening wires without a connector.

The way the wires are connected is fundamentally unimportant. All types of connections, except open ones, are quite reliable and sealed.

Possible faults

Repairing the reverse sensor is perhaps exactly what no one is immune from. It happens that a unit needs to be replaced only because it simply does not work. How to act in such a situation? First of all, it is important to understand why the sensor is faulty or not working correctly.

Today it is customary to identify the following possible unit malfunctions:

- oxidation of contacts occurred at some point in the electronic circuit;

- the sensor has become “loose” or has failed;

- there was a “breakdown” in the electrical circuit of the identifier;

- contact between the sensor and the mounting block is broken;

- its fuse is blown;

- The rear headlight bulbs ("stopari") have burned out.

The symptoms of a malfunction of the reverse sensor are probably clear to everyone - the corresponding headlights are inoperative or function extremely incorrectly. It is simply unacceptable to operate a car in this condition, so the first thing you should think about when a problem with a unit arises is where the reverse sensor is located and how to repair it correctly. We'll talk about this in more detail below.

Sensor failure

The faulty element is identified immediately: the reversing lights and other related devices stop turning on. This problem can also occur due to a broken wiring. How to check the sensor for serviceability?

- Remove the connector, connect the multimeter in dial mode, and engage reverse gear.

- The next step is to unscrew the sensor, connect the device, and press the rod (ball) manually.

Important! When dismantling the sensor, it is necessary to prepare a screw plug to quickly block the hole. Otherwise, oil may leak from the gearbox housing.

- If the sensor itself is operational, you need to check the mechanisms inside the gearbox.

Repairing the reverse sensor is not practical. The case is sealed; after opening it and putting the contact group in order, it will be impossible to restore the structure to its factory condition. The unit is inexpensive, especially on domestically produced cars. Therefore, replacement will not be too expensive.

Important! There is no point in experimenting with selecting sensors from other car models. If the mechanical part is larger than standard, the gearbox may be damaged.

Replacement requires no special tools: just a wrench.

Replacement

Many people ask the question: where should you change the reverse sensor?

Of course, the easiest way is to take the car to a service station, where they will replace it at a price of 3-4 times its cost. But you can change it yourself, there’s nothing complicated about it. Let's look at the step-by-step instructions:

- It is necessary to remove the engine protection, if equipped.

- Turn off the electrical power and disconnect the wires connecting to the sensor.

- Prepare a container for oil, since all front-wheel drive cars leak oil when replacing reverse sensors.

- Using a 22mm wrench, preferably with a long ratchet type head, we try to remove the sensor. In this case, a problem may arise - the old thread does not allow it to be unscrewed. Then you need to arm yourself with a hammer and chisel.

- As soon as it is unscrewed, we substitute the oil container.

- We insert a new one very quickly.

- Using the same key, tighten it.

- We connect the wires and check the operation of the reversing lights.

- If everything works, add the leaked oil and install protection.

A malfunction of the reversing lights is not critical to the operation of the vehicle. But the key to safe driving is maintaining the entire vehicle in good condition.

Possible reasons

If the reverse lamps do not turn on when shifting into reverse gear, whether it is manual or automatic, you need to look for the reason.

The light must be on. This will not only result in a fine, but can also lead to a serious accident or accident.

- Sensor malfunction

. It is also a reverse switch, limit switch or frog. This controller is quite reliable and durable. But still, the possibility of its breakdown cannot be ruled out. Especially if the car was hit from behind, the headlight was broken and the lights were changed; - Burnt out light bulb

. Or maybe everything is outrageously banal. Over time, the light bulb has used up its resource, and therefore no longer works. It will have to be replaced; - Fuse

. Also, the signal may disappear if the sensor responsible for these lights burns out. This is a fuse link that burns out when the permissible voltage is exceeded. Since this fuse is responsible for several devices at once in most cars, in parallel with the reverse gear, other lamps, dashboard lights, etc. may not light; - Open circuit

. Here pins can break off, wires can fray, and more; - Oxides and corrosion

. Formed in places where the contacts of the circuit leading to the rear lights are connected; - Ground contact

. If the ground is bad, reverse gear may not function. This is also one of the reasons why the brake lights on a car do not light up.

Unlike the situation when the lamp is constantly on, there are many more potential causes.

But still, the most common problem is the failure of the reverse switch. It is also called a frog.

Repair methods

To repair the reverse signal, you can proceed in two ways. They differ in the way the sensor is accessed.

- Drive the car onto a lift or pit.

- Do the work by climbing under the car.

If you have already encountered a similar problem, then you will probably agree that replacing the DZH is best done using a pit or overpass. This makes access to the sensor as comfortable as possible, plus you minimize the risk of being splashed with oil from the gearbox.

Replacing the DZH is not the cleanest job

Self-replacement

It’s not difficult to get to and replace a failed DZH on your own. Follow the instructions, do not break the sequence of operations, and then the process will not take you much time and effort.

- Place the car on a pit or overpass. Be sure to apply the handbrake and place the transmission in first gear. This will help prevent your car from accidentally rolling away.

- Remove the protection from the contacts of your sensor, disconnect the contacts.

- Prepare a container into which the oil will be drained when unscrewing the DZH.

- When the container is ready, remove the sensor. In some cases, it may not be unscrewed by hand. In such a situation, use a 22 mm socket.

- Very rarely even the key cannot help, since the sensor becomes stuck to its location. Here you will have to arm yourself with a hammer and chisel and try to remove it as carefully as possible.

- Take out the failed device and insert a new one in its place.

- If oil gets on the gearbox housing, remove it with dry rags. There is no need for extra dirt. Plus, it can lead to a decrease in the efficiency of the device.

- Return all contacts to their places, put the protection back on.

- If a decent amount of lubricating fluid has spilled out of the box, be sure to top it up. Just use fresh ones. By the way, this is one of the reasons to completely change the oil in the gearbox if it has been there for more than the first season.

- The decision to change the oil will simplify the task when removing the sensor. If the liquid is drained in advance, it will not flow in different directions when the sensor is unscrewed. The work will be cleaner, plus you will kill two birds with one stone - replace the sensor and gearbox oil.

After completing the work, do not forget to check whether the reverse traffic warning system is now working. For this:

- Turn the ignition key, but do not start the engine;

- Engage reverse gear on your gearbox;

- See if the white lights turn on. If yes, everything went great.

Purpose

Obviously, the car's reverse mode is designed to accelerate the car in the opposite direction without resorting to a 180-degree turn. This allows you to park more comfortably, maneuver faster and, finally, save time for yourself and other drivers.

A reverse signal is needed to warn surrounding drivers of an upcoming maneuver, similar to the way turn signals or brake lights do, embedded in the taillights.

Thus, when reverse gear is activated, a white lamp lights up. All drivers and pedestrians behind are instantly informed that the driver plans to reverse and make decisions about their further maneuvers.

The reverse alarm is also intended for maneuvering in the dark and in fog. The lamp, which has a fairly powerful light beam, allows the driver to better see what is happening behind the car and avoid annoying accidents and incidents when maneuvering. In any case, it is worth paying attention to the condition and operation of the lights. This will eliminate most problems and protect the car from accidental damage.